Theory of operation of a 220 V electric motor

Asynchronous motors for single-phase networks are mainly motors with two-phase windings and an auxiliary phase taken from a capacitor. Such motors are used in household appliances. A similar motor is used, in particular, to drive a washing machine. In addition to two-phase winding motors, three-phase winding motors are sometimes used in some other household appliances.

During direct starting, the motor can receive a current from the network that significantly exceeds its rated value. This current is called the motor starting current, and its value varies in the region Ir = 5-7In .

One way to reduce the inrush current is to use a star-delta switch. A motor designed to operate the stator in a triangular connection at a given mains voltage is connected to the star system at the time of start-up:

Due to the reduced voltage supplied to the stator winding phase and the change in connections from delta to star, the current taken from the network will be reduced by three times compared to the starting current in a delta circuit. However, when connected to a star, the motor has three times less starting torque, which makes it impossible to use this method during heavy starting (with a heavy load).

Call the master

If you are unable to repair and replace the Indesit washing machine motor on your own, you need to seek help from a specialist. There are several ways to find a master:

According to the advertisement . Repairers place information about their services in newspapers, post them on poles, and deliver business cards to mailboxes.- Contact the service center . The main thing is that this organization establishes itself well in the locality.

- By word of mouth . It is possible that relatives or friends have used a similar service in the recent past. If they recommend a professional, you can trust them.

- Internet message boards . There are a lot of them on the Internet, so you can find a master in every city.

Most craftsmen do not charge money for a visit if the person agrees to pay for the repairs. This information needs to be clarified at the stage of calling a specialist. Before choosing a repairman, you need to study reviews of his work. Moreover, it is better to do this on a site other than the one on which he placed an advertisement about his services.

Approximate prices:

- replacement of brushes – from 1400 rubles;

- engine replacement or repair – from 2000 rubles.

As a rule, the brushes are guaranteed for 6 months, and the motor is 1 year. Prices do not include the cost of parts (if they need to be replaced).

Before agreeing to repair the engine, you need to clarify its final cost with a specialist. An honest master will immediately name the price. If there is a need for repairs, he can announce the estimated cost, but there will be no significant deviations from it.

A lot of important and useful information about repairing Indesit washing machines is presented in this section.

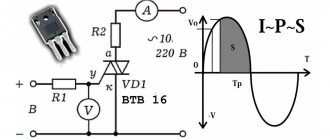

Capacitor for electric motor

For small motors (<1 kW), the value of the starting capacitor can be determined from the relationship:

C [uF] = (1800 x Pn) / U2

where Pn [W] – rated motor power, U [V] – supply voltage.

This formula is also suitable for calculating the starting capacitor value for single-phase start-phase motors.

For larger motors (>1kW) a capacitance of around 70uF/1kW is suggested. It is necessary to use starting capacitors with operating voltages of 400..630 V AC.

You can omit the calculations and simply connect a standard motor from the washing machine to 1 phase 220 V through a 7 microfarad capacitor connected between the required terminals. Connect the first power wire to the middle, and the second, depending on the direction of rotation, to one of the capacitor wires. The power drop will be 30% - this is in theory.

The issue of choosing a capacitor is easily resolved. Here are examples of capacitance values for different engine powers.

Pn [W] 90 120 180 250 370 550 750 1100 S [µF] 4 5 6 8 12 16 20 30

Useful: Connecting an external microphone to a laptop

The rotation power in the washing machine is the same in both directions. These are motors with a typical connection for a single-phase motor. The main winding is connected directly to 220 V and a phase winding is connected in parallel with it along with a series-connected capacitor. If you reverse the phase winding wires, the motor will rotate in the other direction, but the power will be slightly less. This circuit works during the spin cycle. The same for slow and fast rotations - the capacitance switches inside the washer from 7 µF to 16 µF. Read more about the capacitor here

Possible breakdowns

Now you know how to connect an electric motor to give it a whole new life, but a small incident may occur: the motor will not start.

It is necessary to understand the reasons and find a way to solve the problem. Check engine heating after running for 1 minute. In such a short period, the heat does not have time to transfer to all components and the place of active heating can be clearly fixed: the stator, bearing assembly, or something else.

The main factors for rapid heating are:

Then we examine every 5 minutes of work; it is enough to do this 3 times. If the reason is the bearing, then it needs to be disassembled, lubricated or replaced. During further operation, we regularly monitor the heating of the motor. Avoid excessive overheating, as repairs can cause huge damage to your home budget.

Source

Connecting the motor from the SMA

This motor contains two independent windings:

for synchronous speed 3000 rpm - two-phase winding.

for synchronous speed 500 rpm - symmetrical three-phase winding . The three-phase connection system allows you to change the rotation speed by switching the power supply to the winding.

An older type motor usually has 5 wires, black, blue, white, red and green. A series of measurements were carried out to determine the windings and the resistance between them:

- Blue-black 85 Ohm

- Blue-green 85 Ohm

- Black-green 80 Ohm

- White-blue 15 Ohm

- White-red 30 Ohm

Connecting an old electric motor requires finding the starting winding using a multimeter.

- ON - initial winding . It is designed to start the engine only and starts at the very beginning until the engine begins to rotate.

- OB – field winding . This is the work winding that runs constantly and constantly turns the motor.

- SB – button from which voltage is supplied to the starting coil and turned off when the engine starts.

How to make a simple feather removal machine for home use from a washing machine with your own hands

The time of slaughtering a bird is a troublesome stage. This is usually done in the fall, when the ducks and broilers have reached the desired weight, and it is no longer profitable to keep them in the winter. You need to pluck several dozen or even hundreds of carcasses very quickly. You can get rid of hard labor with the help of a feather removal machine, and it’s easy to do everything from the same parts of the washing machine.

The only thing that can cause difficulties is the search for rubber fingers with threads - beaters. You will have to order them, so keep in mind that you need to think about making the machine long before slaughter

The device does not require disassembling the washing machine. It is especially convenient to use machines with vertical loading. You just need to fix the beats in the drum so that they point inward. Before plucking, the chicken carcass must be scalded with boiling water and then simply thrown into a rotating drum. Here's what happens:

Important! To prevent water from getting on the engine of the feather removal machine, you need to protect it with a plastic casing.

And the last point - the feather removal device must be firmly fixed, since the vibration when loading the carcass will be very strong.

Connecting the electric motor from a new washing machine

If you look at the terminal block with the wires on the front, usually the first two wires on the left are the tach wires, which measure and regulate the rotation speed of the washing machine motor. We don’t need them - they are crossed out with a cross.

In different models of washing machines, the wires differ in color, but the connection principle remains the same. You just need to find the necessary wires by testing them with a multimeter.

A working tachogenerator in a quiet state usually has a resistance of 50-100 Ohms. You will immediately find these wires and disconnect them.

If you need to change the engine speed in the opposite direction, simply drag the jumper to the other pins. Look at the diagrams to see what it looks like.

Two contacts go through the brushes to the rotor windings, and the other two contacts go to the stator winding. The remaining contacts are a sensor for measuring the motor rotation speed. The rotor and stator windings are connected in series and by changing the ends of one of the windings, you change the direction of rotation. Without an electronic regulator, the engine will accelerate to several thousand revolutions per minute (as at maximum spin).

- Read how to regulate the motor rotation speed from the SMA here.

How to use the engine

The electric motors that modern units, such as those from Indesit, are equipped with are quite reliable and durable. And even a part from an old washing machine of a brand like Vyatka can last long after the equipment itself has become hopelessly outdated.

Based on the engine from a washing machine, you can make a grinding machine

In a washing machine, an electric motor rotates the shaft, which drives the drum. If the part is removed from the unit, a wide variety of attachments can be attached to the shaft, resulting in new tools and accessories. The most common ways to use an electric motor are:

- Sharpening apparatus (sharpening machine). It is considered the simplest option for using a motor. The engine is mounted on a flat surface, and a round sharpening stone is attached to the shaft. The machine can be used for sharpening knives, scissors or tools.

- Concrete mixer. To make it, we use a motor and a tank from an old washing machine.

- Special vibrator or vibrating table for the production of concrete products. The vibrations created by the motor can contribute to the shrinkage of concrete, and it is this property that is used in the manufacture of these tools.

- Device for grinding pet food. To do this, it is enough to secure the knives on the shaft. This device can also be used to chop large volumes of feed, such as grass for cattle.

We have listed only a small part of the devices that can be obtained from a washing machine motor. In order to make one of them, or come up with your own application, you need to know how to connect the motor so that the winding does not burn out.

What else can be made from a washing machine drum: original decor ideas

The drum with its correct perforation is a material for the manufacture of decorative objects. Here are some interesting ideas.

Ottoman with drum base. It’s easy to do – you just need to attach the wheeled legs and make a soft seat

Such a drum can also be turned into an original lamp. If you place a lamp inside, the perforated surface of the drum will cast glare on the walls. Such lamps will look good on the ceiling of the veranda or even on the floor

Bedside tables and tables. Drums with doors from top-loading machines can be used to hide small items.

This is how the drum turns into a cabinet or nightstand