"First aid" and decoding

What to do if the washing machine stops working and displays an error on the screen? You need to try to correct the situation and figure out what kind of breakdown the machine is “hinting” at. Code E2 ( E02) indicates problems with the commutator motor.

Error E2 is considered critical; if the fault is not corrected, the electrical wiring may be damaged or the engine may burn out.

Equipment repair is not always necessary; you can try to reset the error code without interfering with the machine mechanism. Be sure to check the voltage in the electrical network, in case it is simply not enough for the machine to operate. If the power supply is weak, call an electrician.

The cause of error E2 may be a short-term failure of the control module due to a power surge. Try unplugging the washing machine for 20 minutes, then turning the machine back on. On some Bosch models, you will have to force reset the code by following these steps:

- press and hold the “Power” key;

- Turn the programmer from the standard position (“off”) two clicks to the left. During this, the “On” button must be held;

- wait a couple of seconds and release the Power key.

After this procedure, the Bosch washing machine will display on the display the cycle time of the washing program indicated by the selector handle. On machines without a screen, the indication on the control panel should “blink”.

If such actions do not help reset the error code, then a real breakdown has occurred. It is necessary to diagnose the washing equipment motor and repair the unit.

Error codes for Hans washing machines (HANSA)

The following table shows the main errors and how to eliminate them in HANSA PA series washing machines

| Error code | Decryption, solution |

| E01 | Door lock malfunction (no lock). The washing program is interrupted (if there is no blocking - after 2 seconds, if the limit switch does not operate - after 10 seconds). |

| E02 | Malfunction of the water level sensor (there is no signal about reaching 1 water level, washing stops). |

| E03 | Malfunction of the drainage system (there is no signal from the sensor about the lack of water). The washing machine blocks the hatch until it turns off completely. |

| E04 | Working tank overfilled. In this case, the washing machine automatically stops washing and turns on the drain pump. The hatch remains locked until the machine is completely turned off. |

| E05 | Malfunction of the temperature sensor. The water heats up by less than 40ºC after 10 minutes of operation of the heating element (due to a short circuit or break) or does not meet program standards. Washing continues without heating the water. |

| E07 | In the washing mode, there is no contact between the control element (electronic controller) and the tachogenerator. The wash stops. |

| E08 | In spin mode, there is no contact between the control element and the tachogenerator. Stop the cycle. |

| E10 | The system detects a discrepancy between the parameters of the supply network (voltage, frequency). The wash stops. |

| E11 | There is a malfunction (short circuit) of the control element (triac) of the drive motor. The wash stops. |

| E12 | Water leaking into the washing machine tray. The drain pump is activated and the hatch lock is blocked. The door opens after receiving the “Empty Tank” signal. |

| E14 | Error in the operation of the electronic controller. The wash stops. |

| E15 | When turning on the power or after selecting a washing mode, a malfunction of the electronic controller is detected. |

The following table shows the main errors and how to eliminate them in HANSA PC series washing machines

| Error code | Decryption, solution |

| E01 | There is no control signal to turn on the door lock. |

| E02 | The time it took to fill the working tank with water to the nominal level exceeded 2 minutes. |

| E03 | The time for draining water from the working tank exceeded 1.5 minutes. |

| E04 | The pressure switch signals when the working tank is overfilled. |

| E05 | The time it took to fill the working tank to the nominal level exceeded 10 minutes. |

| E06 | The “Empty tank” signal has not been received from the pressure switch for 10 minutes. |

| E07 | Water leaking into the washing machine tray. |

| E08 | Mismatch of power supply parameters (voltage, frequency). |

| E09 | Excessive foaming during the spin cycle that the washing machine could not cope with. |

| E11 | Malfunction of the triac (control element) of the power supply circuit of the hatch locking mechanism. |

| E21 | Error in the operation of the drive motor (no connection with the tachogenerator, blocking the operation of the motor). |

| E22 | Error in the operation of the drive motor (unauthorized rotation). |

| E31 | Defect in the operation of the temperature sensor (short circuit). |

| E32 | Defect in the operation of the temperature sensor (open circuit). |

| E42 | Error in the locking mechanism. |

| E52 | Washing machine offline memory error. |

Let's take it out and check the motor.

What to do if you find code E2 on the machine display? As already mentioned, the error indicates problems with the washing motor. How does this machine unit work?

Bosch machines are equipped with a commutator motor. The engine is small in size but has high power. The rotation is started by a drive belt that connects the drum pulley and the motor.

The collector of Bosch washing machines consists of a rotor, a stator and a pair of electric brushes.

A Hall sensor is also installed on top of the engine. This device regulates the engine speed. The machine may not start washing also due to problems with the tachometer.

Masters diagnose the “heart” of the machine in several ways. However, in any case, you will have to remove the motor from the housing. The algorithm of actions will be as follows:

- Unscrew the bolts securing the back wall of the machine, move the panel to the side;

- by rotating the drum “wheel”, loosen and remove the drive belt;

- disconnect the wires going to the motor;

- unscrew the screws fixing the engine in the housing;

- carefully remove the element by rocking it in different directions.

It is recommended to take a photograph of the wiring connection diagram to the engine so that you can then accurately install the part in place.

Now that the engine has been removed, you can begin to diagnose it. First of all, you should connect the wires of the stator and rotor windings. After this, they are supplied with a voltage of 220 Volts. If rotation is observed, then the reason is not in the electric motor, because it is functioning properly.

The main disadvantage of this diagnosis is that it will be incomplete. The washing machine, in fact, works on different programs that differ in spin speed and smooth rotation of the drum. And during such actions, only one mode is checked. The second drawback is that the motor may overheat due to direct connection to the network, which will lead to a short circuit. Therefore, before applying voltage to the stator and rotor, it is better to connect a “ballast” - a heating element - to the circuit, this will help protect the engine.

Heating element malfunction

Heating elements fail, as a rule, due to scale: impurities contained in water, particles of detergents, lint from clothes - all this sticks to the heating element, which reduces its thermal conductivity. Trying to compensate for the decrease with more intensive work, the heating element heats up “to wear out”, overheats and either burns out the coil or burns out its body. In the latter case, water gets on the heater coil and a short circuit occurs.

| Signs | How to fix | Cost* (work only) |

| The washing machine does not heat the water or knocks out plugs immediately when the program is turned on. Codes F19, F22 may appear. | A faulty heating element must be replaced. | from 1800 rub. |

*The price is only for the work of the master, a new heating element is not included.

Brushes worn out

In most cases, replacing the commutator brushes helps eliminate the E2 error code. The carbon rods are located on the sides of the engine. The brushes have a wire through which electricity passes, and a spring that presses them against the lamellas. Finding the details is easy - they cannot be confused with anything.

To reinstall the elements, you must remove them from the engine. Even if only one brush is worn out, it is necessary to change the pair. Let's figure out how to remove erased parts from the engine. The algorithm of actions will be as follows:

- using a slotted screwdriver, lightly pry up the wire terminal and remove the cable;

- move the electric brush contact away from the wiring;

- very carefully pull the terminal up. The spring-loaded carbon rod will pop out and can be removed.

When pulling out the electric brush, be sure to remember which edge it was on, so that later you can “stick” the part in the same way.

Once both brushes are removed, inspect them. If the elements are severely worn, replacement will be required. You can buy new spare parts at any specialized store, specifying the model and serial number of the Bosch washing machine.

Installation proceeds as follows:

- insert the brushes into the motor traverses as they were before;

- push the spring there;

- Insert the terminals into the clamps of the upper area of the traverses, move them towards the wire. Thus, the electric brushes will be fixed in the motor.

After this, all that remains is to connect the power supply connector to the terminals. When both brushes are installed in the engine, you should check that all contacts are connected securely. The repair is complete, you can reassemble the Bosch washing machine in reverse order.

If these steps do not help in eliminating error E2, then it is better to seek help from a technician. It is likely that more complex repairs or even replacement of the electric motor will be required. Perhaps the problem lies in the “brain” of the washing machine, and diagnostics of the control module is necessary.

Interesting:

- Bosch dishwasher errors

- Whirlpool washing machine errors without display

- Error codes for AEG washing machines

- Which Bosch washing machine is better to buy?

- Bosch dryer error codes

- Miele dishwasher errors

Reader comments

- Share your opinion - leave a comment

Bosch WFP washing machine codes

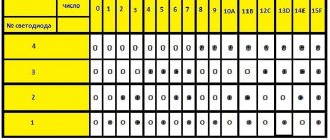

Bosch washing machines of the WFP series were especially popular in the 90s. Currently, there are fewer and fewer of them, but many domestic helpers still work diligently for the benefit of their owners. The machine has an indicator field for starting a program - a kind of predecessor of a full-fledged display. It is in this small window that a number appears indicating the equipment malfunction code (for example, number 1 corresponds to code F01). Below is a table with a breakdown of the information codes.

| Code | Causes | Remedies |

| F01 | Problems in the water supply system (lack of water in the water supply network or low pressure, clogged water supply hose or filter, broken water supply valve), Aquastop system error | Checking the water pressure in the water supply, removing blockages in the filter and hose, repairing or replacing the valve, checking the Aquastop sensor, replacing if necessary |

| F02 | Malfunction in the water heating system (water temperature does not reach the required value for a certain period) | Checking the circuit in the area of the temperature sensor or heating element, eliminating the break if necessary, checking the condition of the heating element and its contacts |

| F03 | Problems with draining water (breakage of the drain pump, clogged drain filter or drain hose, malfunction of the pressure switch - water level sensor) | Removing blockages in the filter and hose, restoring the operation of the drain pump and pressure switch, replacing parts |

| F04 | Error in motor operation | Checking the tachogenerator and engine, repairing or replacing if necessary |

| F05 | The electric motor is faulty (starts without a command) | Checking the motor control circuit, eliminating the defect, restarting the program |

| F06, F07 | The water heating sensor is faulty, its connection with the control module is broken | Repair of sensor, control module, replacement of parts |

| F08 | The washing machine door is not closed (foreign objects may get in or the lock may break) | Closing the door, removing foreign objects, performing lock repairs |

| F10 | Lost communication between engine and control module | Control module repair |

| F11 | Motor overheating | Turning off the washing machine, restarting after 5-10 minutes |

| F13 | Increased network voltage | Turning off the washing machine, stabilizing the voltage |

| F14 | Reduced voltage in the network | Turning off the washing machine, stabilizing the voltage |

| F15 | Incorrect temperature in the water heating system | Troubleshooting the water temperature sensor, replacing the sensor |