Modern automatic washing machines, regardless of the manufacturer (Samsung, LG, Indesit, Bosch, Ariston, Candy, etc.), are designed almost the same. Some models have a number of design features based on engine type, loading method and the presence of additional functionality. Having an understanding of the structure of the washing machine, the location of its main components and the operating principle of individual elements, you can not only carry out minor repairs yourself, but also prevent various breakdowns. In this article we will talk about how an automatic washing machine works, look at the diagrams and understand the technical features of different types of units.

A modern automatic washing machine has a complex technical device

Components of the “vertical”

To get acquainted with the washing machine, you need to know all its components. Only by studying the names and purposes of the main components can one grasp the relationship of structural elements and their location. So, each “vertical” necessarily has the following details:

- electric motor;

- washing tank;

- metal drum with doors;

- drainage pump;

- rubber pipes and hoses;

- drum pulley;

- drive belt (if the washer does not have direct drive);

- powder and gel tray (also called powder receiver and dispenser);

- shock absorption system (springs, vibration absorbers);

On vertical washing machines, things are loaded through the top lid!

- tubular electric heater (TEH);

- drain filter;

- control board (control module);

- dashboard;

- snail;

- thermistor;

- counterweights;

- electronic lock (UBL);

- inlet valve;

- cuff;

- pressure switch (water level sensor).

All components of the washing machine are “hidden” in a metal case. There is a “tidy” and a hatch cover on top, and blank panels on the sides. A tray is often attached to the bottom of the machine.

To check the machine and troubleshoot the problem, names alone are not enough - you need to know the device, the operating principle and the location of the parts. Let's look at the components in more detail.

Design

The main design feature of vertical washing machines, as is clear from the name, is the vertical location of the hatch for loading laundry. These devices do not have a transparent loading hatch in the front.

There are models where a special mechanism is used to regulate the drum to stop it after the end of the wash. These devices are called drum parking systems.

The second difference between vertical models is two symmetrically located drums and shafts on both sides, on which it rotates. Front-facing samples have one shaft rotating the drum on the rear side, since laundry is loaded into it from the front side.

Laboratory studies of companies producing both types of washing devices show some advantage in reliability and service life of vertical washing machines due to two shafts instead of one for front-facing models.

The control panel for vertical samples is standardly located at the rear of the top cover.

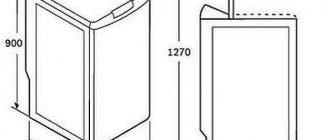

Standard dimensions of top-loading devices: height – 85–90 cm, depth – 60 cm, width – 40–45 cm.

The amount of laundry that can be loaded into a top-loading machine is determined by standard rules common to all types of devices from any manufacturer. There are minimum and maximum loads, measured in kilograms.

The minimum load of 1 kg is determined based on the need for uniform distribution of laundry throughout the drum at high spin speeds to level out unwanted excess vibrations. The maximum load – 10 kg and above is limited by the dimensions of the device.

Typical household washing machines have a load capacity of 5–7 kg.

Machine control center

Most modern washing machines have electronic controls. Unlike the “old” mechanics, everything here is performed and regulated by a module - a connecting unit consisting of sensors, conductors, tracks and microcircuits. The system works as follows:

- the user sets the cycle settings by pressing buttons or rotating the programmer on the dashboard;

- the control board records the selected parameters and issues a command to execute the program;

- the necessary system nodes are turned on;

- the wash starts.

It is the control module that starts the washing machine: it processes information from the dashboard and transmits commands “through the chain” to the destination. Turning on the equipment, drawing water, accelerating the engine, draining - all this is performed only after “permission” from the electronic unit using a variety of triacs, sensors and contacts. Afterwards, the board controls the progress of work, monitoring the signals and data coming from the nodes. In the event of a failure or deviation, the device detects the problem and urgently shuts down the cycle.

It is not recommended to test and solder the board at home - it should be checked and flashed by specialists!

If there is a failure in the electronics system, the machine stops working: it does not turn on, does not respond to user commands, or freezes. It is difficult to find the problem, since either a separate track or the entire control unit as a whole could fail. In any case, the board loses control over the washing machine and, for security reasons, does not allow startup.

An electronic module is an extremely complex part. It is quite difficult to figure out on your own how it works and functions, especially for people far from electrical engineering. It’s better not to take risks and if you suspect a board malfunction, immediately contact a service center.

Washing spin and energy efficiency classes

The washing class is determined by assessing the remaining contaminants after the experimental washing process. Testing takes place under standard conditions for all tested samples, and then comparison is made with the results of reference samples. Then each model is assigned its own class from A to G in order of deterioration in consumer properties. Most modern machines have wash class A.

The spin class is determined by the speed and efficiency of the spin process. To designate classes, the same Latin letters from A to G are used in order of decreasing spin quality. Spin efficiency depends on the amount of residual moisture in the laundry. 40% is the best indicator, 90% is the worst.

The choice of sample with the best spin class indicator is ambiguous. Not all fabrics can be wrung dry without risk of damage. A high spin class increases the cost of the machine. Not every consumer needs such high standards.

The standard spin class for most washing machines is C.

Energy efficiency class is an important characteristic, given the rate of increase in electricity tariffs. All models are assigned classes from A to G in order of decreasing efficiency. There are models with classes A+, A++, A+++.

The difference between them is determined by the minimum amount of energy consumed, but the price is significantly different. When choosing a washing device based on its energy efficiency class, it is worth weighing several factors: electricity tariffs, frequency of use.

Parts responsible for clean water

The filling system in a vertical washer is represented by a pressure switch, hoses and an inlet valve. Water intake begins immediately after the user starts the program by pressing the “Start” button on the dashboard. The drum is filled according to the following scheme:

- the board receives a signal about the need for filling;

- pressure switch – water level sensor, measures the pressure in the tank and signals the level of filling;

- the module makes sure that there is no water in the tank and sends a dialing command to the valve;

- voltage is applied to the intake valve, its membrane is activated, the flap rises;

- water from the water pipe flows into the machine through the inlet hose;

The pressure switch has a long tube that goes down into the tank and measures the pressure in it.

- the pressure switch controls the volume of water;

- when the required volume is reached, the pressure switch signals the unit;

- the module cuts off the current supply;

- the valve membrane closes;

- recruitment stops.

All elements of the filling system constantly interact, and the main “controller” is the water level sensor. Thanks to it, the tank is filled to a certain level, which prevents underfilling or overfilling.

Technical device of the washing machine

Let's start with the most important thing - the “brain” of the washing machine.

Control module and electronics elements

The electronic module controls all parts in the machine. It sends a signal to start or shut down through the wiring that connects the board and the CM assembly.

All programs, modes and functions are controlled and executed by the module. Therefore, if one of its elements fails, any part of the machine may stop working. In order to perform certain tasks: correctly pour water into the tank, control engine speed during washing and spinning, the control unit has “assistants”.

Pressostat

A pressure switch or level sensor controls the amount of water in the tank. It does the job by measuring the pressure in the tank. Then it sends a signal to the electronic module. The control unit, in turn, sends a command to the inlet valve to stop water intake.

Water intake valve

Depending on the type, the valve can have from one to three coils. These coils are energized, causing the valve diaphragm to open and fire. As soon as the unit gives the command, the membrane opens and water is drawn into the tank. After the electricity supply to the coils is stopped, the membrane closes.

Tachogenerator

It is the tachometer that helps the electronic unit regulate engine speed. After all, each washing or spinning program requires a different drum rotation speed.

temperature sensor

The structure of the heating element in modern models "Ariston", "Zanussi", "Ardo", "Electrolux" provides for the presence of a thermistor. The device is a metal tube that is installed in the heater body.

The thermistor determines the degree of water heating by sending a signal to the module. The main unit turns off the heater when the water temperature rises to the desired level.

Other elements

These are wiring, control panel, command apparatus, indicators. Everything that allows you to control, set modes and programs in the washing machine.

Performing parts

The design of a semi-automatic and automatic washing machine requires the presence of operating units. The electronic unit gives a command to the parts, after which they begin to work.

Electric motor

The motor in the washing machine rotates the drum at different speeds.

Modern cars have direct drive motors. These are inverter motors that are attached to the drum. They are more efficient, powerful and silent. Their design is reliable, so such motors rarely break down.

Commutator motors are often found. They transmit speed to the drum through a drive belt.

The collectors are simple: their design contains a stator, a rotor and brushes. Electric brushes are made of soft material, so they often need to be replaced due to wear and tear.

Electric heater (TEH)

Serves to heat water in the tank. Each wash program requires a different water temperature. The electronic unit sends a specified signal to the heating element, after which heating is performed. The thermostat controls the temperature and, after reaching the specified values, sends a signal to the module.

How to replace the heating element in case of a problem, read in previous articles.

Hatch locking device

This is an electronic door lock. You manually close only the mechanical door lock. When the program starts, a click is heard, which indicates that the hatch is locked. Only after this the water intake begins.

Find out how to replace the UBL in a washing machine.

Drain pump

The pump allows you to pump water out of the tank after washing and rinsing. There are synchronous and asynchronous pumps.

What does the pump consist of? From the inside, its design is the same: motor, impeller. There is a snail on top, to which a drain pipe and hose are connected.

Most often, the pump breaks due to foreign objects. If coins fall out of your pocket during washing, they may then end up in the drain. The filter, hose, pipe and the pump itself become clogged. Read how to clean it.

Tank design

The tank can be made of steel or plastic. The latest development is a polyplex tank. Depending on, “Kandy”, “Whirlpool” and others) it can be:

- Collapsible. The two halves are held together with screws.

- Non-separable. The two parts are hermetically sealed.

Various elements and terminals are connected to the tank. Let's take a closer look at them.

Shock absorbers

Dampers or shock absorbers are parts that dampen vibrations during the operation of the SMA. The damper is attached to the bottom of the tank and to the body of the washer. With a strong spin, the tank will not bounce and hit the wall.

Springs

Springs hold the tank on top and perform the same function as shock absorbers. The upper hook of the spring is attached to the body, the lower hook to part of the tank.

Pulley

If the washing machine has a belt-driven motor, then a pulley is attached to the tub. A belt is put on it, transmitting engine speed. The pulley rotates along with the drum. Secured with a powerful bolt in the center.

Counterweights

Heavy blocks are made of concrete or plastic. They are bolted to the outside of the tank to restore balance.

Over time, the counterweight can become damaged due to strong vibration. But most often their fastenings become loose, which can be tightened more tightly.

Drum

Located inside the tank, made of stainless steel. It has a cylindrical shape and has a hole in the front for loading laundry. The rear part serves to connect to the cross and the tank. Inside, the entire surface of the drum is perforated, which allows water to drain.

Other details

It remains to deal with the small elements that serve for the convenience of washing and automation of the process.

Dispenser tray

The tray is divided into several parts (usually three). The powder for the main wash is poured into one of them, and the powder for the preliminary wash into the second. The third compartment is used for liquid products and rinses.

The tray is placed in a hopper to which hoses from the inlet valve are connected. Through them, water flows into the compartments to collect the powder.

Rubber cuff

The rubber seal is located on the hatch and serves to seal the door. One part of the rubber is attached to the body, the other is attached to the tank with clamps.

"Heart" of the machine

The “heart” of a washing machine is its engine. It is the electric motor that accelerates the drum shaft, ensuring rotation of the cylinder at the desired speed. The number of revolutions is controlled by a tachogenerator, which clings to the engine and constantly monitors the pace, eliminating chaotic rotation and sudden changes in direction.

The driving force is an electric motor. Modern vertical machines are equipped with inverter motors, which are connected directly to the drum shaft, without the use of a drive belt. This system eliminates “middlemen”, which makes unwinding the cylinder more efficient, reliable and safe.

Some top-loading washing machines have commutator motors. Here the impulse from the motor is transmitted to the drum through a drive belt wrapped around the pulleys. This option is cheaper, but more unreliable: the elastic often falls off, breaking or stretching. The second disadvantage is the electric brushes, which during operation of the machine wear off on the engine body and periodically need to be replaced.

Where does the hot water come from?

As with front-mounted automatic machines, on vertical units a tubular electric heater – heating element – is responsible for heating. Once the user selects a mode and adjusts the temperature, the electronic board accepts the parameters and starts the heater. The part receives the signal, and upon completion of filling, its “spiral”, brought into the tank, begins to heat up.

To avoid overheating of the heating element, do not run three high-temperature cycles in a row!

The degree of heating is monitored by a thermistor - a temperature sensor. It looks like a metal tube and is located in the heating element itself. When the set degrees are reached, the device signals the module, which turns off the heater.

Weights and shock-absorbing system

When the drum unwinds, centrifugal force inevitably appears, which is absorbed by shock absorbers. They compensate for outgoing vibration, preventing the equipment from “jumping” around the room and hitting the wall. The stability of the washing machine is ensured by the following details:

- dampers - vibration dampers with a built-in spring, connecting the washing tank to the machine body;

- springs - the tank is suspended from the top and sides;

- counterweights are concrete blocks that are attached to the bottom or sides of the vertical, weighing down the entire structure.

The shock absorption system takes on the entire “shock”. Due to constant vibration, dampers wear out, springs stretch, and counterweights become loose. Especially if the washing machine is not installed correctly or has been used for too long. In this case, it is necessary to tighten the fixing bolts and replace worn components.

Facts about technology and work

- for such washing machines, the top cover must always remain free, since it must be constantly opened to load laundry;

- vertical machines do not differ in variety of sizes. In addition, they do not need additional space to open the hatch, so such a device can be installed anywhere: in the corner of a small bathroom or kitchen. At the same time, devices with somewhat modest sizes allow you to load up to 7 kilograms of laundry;

- the drum of such machines is fixed on both sides, the devices vibrate less during operation, for this reason their internal mechanisms do not wear out longer;

- There are no additional rubber seals on the lid of such washing machines, since there is no need to seal it.

Lock and seal

Each vertical is equipped with both mechanical and electronic. The mechanics are activated when the door is closed normally, when the locking “tongue” falls into the corresponding groove. The electronics turn on automatically when the washing program starts due to the UBL - blocking device. Thanks to the latter, the user will not be able to open the drum after the cycle has started.

The seal of the hatch is also responsible for the tightness of the drum - a rubber seal stretched over the edges of the cylinder. It closes the gap between the tank and the body, preventing leaks and clogging of the structure. If the rubber band is damaged, do not start the wash, as water will begin to leak out.

Principle of operation

How the washing machine works:

- After loading dirty laundry into the machine and turning on the washing program, the pump starts working, which supplies water and detergent into the drum through many round holes.

- Once the required liquid level is reached, the supply stops.

- During the washing process, the drum rotates in both directions at low speed. There is a strong mechanical impact on the laundry, which allows you to efficiently remove dirt and stains.

- The speed increases sharply to the maximum level when spinning clothes.

- Then the water leaves the tank due to centrifugal force and is removed through a pump to drain the liquid.

- The drum stops and the hatch opens.

So the principle of operation of the machine is very simple.

Electric pump

A mandatory stage of any program is draining. To empty the tank, the machine is equipped with pipes, hoses, a pump and a drain filter. The key element of the drainage system is the pump, which pumps waste liquid from the drum into the sewer.

Vertical pumps are equipped with two types of pumps:

- synchronous;

- asynchronous.

Each pump is designed the same. The device is started by a motor, which accelerates and spins the impeller - a screw that gives the water the desired trajectory. The pump is fixed to the cochlea, and a drainage hose and pipes are connected to it to drain the fluid.

The garbage filter protects the washing machine from clogging - most of the debris and dirt settle on its spiral!

Problems with pumping water rarely occur, and are not the fault of the pumps. The main reason for difficult drainage is that the hoses are clogged with debris that has gotten into the washer. The drainage filter suffers the most, where dirt settles and foreign objects get stuck. For prevention, you need to check the pockets and periodically clean the nozzle and all elements of the drain system.

The emergence and development of the Ardo brand

The history of the company is inextricably linked with the name of Aristide Merloni, who laid the foundation for the industrial development of a provincial town called Fabriano. This happened in 1930. At that time, young people were leaving the agricultural region, and Senator Merloni took a step towards progress by opening a factory for the production of scales. The product quickly gained popularity, and the company expanded.

In 1968, the concern Antonio Merloni S. p. A. the Ardo brand was registered. The first washing machines were released after a thorough study of market needs. This determined the further direction of development. Already in the 70s, the factory turned into a large industrial center for the production of washing equipment.

In the 2000s, the company encountered a number of difficulties; it sold off some of its capacity. The Ardo brand business was acquired by the Italian company JP Industries S.p. A. This fact did not affect either the pricing policy or the quality of the products.

Today, Ardo is a large manufacturer of household appliances, which produces 3 million units of products per year. Thousands of workers work in several factories to produce household appliances. The brand’s washing machines have become the standard of reliability and quality.

The use of innovation and careful testing at all stages of production has made it possible to create elegant and durable devices that operate quietly and demonstrate high washing performance. The machines are designed for the middle price segment and are not inferior to products from the world's leading brands. The quality of products is confirmed by international certificates.

Main tanks

The key element of the washing machine is the tank - a sealed plastic reservoir. It is tap water that is mixed with the powder. On vertical machines, the tank is positioned with the hole facing up, and on front ones – forward.

The drum is made of stainless steel. Clothes are placed in the cylinder, then the motor spins it to a predetermined speed. It is smaller, has perforated walls and rib punches - plastic blades that “mix” things and foam the powder.

The drum volume varies from 3.5 to 15 kg and depends on the capacity of the machine.

Useful tips

Before purchasing a washing machine, you should decide where it will be installed. Maybe you want to build it into furniture or under the sink - you should take accurate measurements of the space available for this.

In addition, consider a number of nuances:

- will you use the top panel as a shelf for small items,

- is there a need to add new portions of things during washing,

- Is there a need for a hatch to monitor the washing process?

Quite often, small apartments do not allow for a front-facing washing machine because there is not enough space to open the door. In this case, you should pay attention to the vertical model.

When it comes to safety, the vertical washing machine takes the lead. But all this is explained by the fact that water will not pour out of the machine, as can happen with a machine that has a hatch on the front panel. If a front-loading washing machine breaks down, you will have to call a specialist, but with a vertical washing machine you can simply open it and take out all the things.

Hoses and powder box

A mandatory element of the washing machine is a powder receptacle. This is the plastic tray needed to add detergent . Powder or gel is taken from the bins in doses - at specified intervals and at certain stages of the program. The main thing is to fill the concentrate correctly, choosing the appropriate dispenser compartment.

Each powder receptacle has 3-4 compartments - for the main and pre-wash, bleach and conditioner.

We must not forget about the system of pipes through which water flows from the water supply into the drum, and then goes into the sewer. They “connect” the nodes of the machine, resembling human blood vessels. Separately, we note the hoses: inlet and drain. According to the first, water is poured into the equipment, and according to the latter, it is pumped out of the tank.

Automatic washing machines are multifunctional equipment that includes dozens of components, sensors and pipes. But if you want to understand the structure and mechanics, you can do it without any special preparation.

Interesting:

- Top-loading or front-loading washing machine…

- How does an Electrolux washing machine work?

- How to put a belt on a washing machine

- How does a Zanussi washing machine work?

- The drum does not spin in a Siemens washing machine

- Best top loading washing machine

Reader comments

- Share your opinion - leave a comment

A few convenience issues

This point also needs to be given attention. Which machine is still more convenient to use? To answer such a question, subjective factors must be taken into account. Often a person simply likes vertical loading, since he is more accustomed to it, and there is no explanation for this. The same can be said about cars with a front hatch. You should not focus on subjective aspects; it is better to immediately consider the objective reasons that make this or that group of washing machines convenient:

- For vertical group cars, the hatch is located on top. When loading laundry you will not have to bend over, and this is very convenient for users suffering from radiculitis,

- For washing machines with a front hatch, the top panel is free. Many people place cans, bottles, bags of powders and other things on its surface, finding a certain convenience in this. But the buttons and elements of the touch group are located on the front panel. On the left there is a tray with three compartments, where you can pour washing powder, liquid soap and fabric softener,

- the front model can be installed under the countertop, but the vertical model will require free space on top,

- In a front group machine, the tray for detergent compositions can be easily removed, and it is much more convenient to use. Owners of a vertical unit claim that their model is very convenient in this sense, but their opinion remains in the overwhelming minority.