Bosch washing machines are household appliances of high quality and reliability. Many housewives, when choosing a home assistant, opt for the Bosch Maxx (Maxx 4, Maxx 5, Maxx 6, Maxx 7) or Bosch Logixx 8 Varioperfect models. However, even the most reliable washing machine sooner or later develops malfunctions. The advantage of modern models is the self-diagnosis system, which allows you to determine the nature of the problem without calling a technician.

Fault codes are displayed on the display of the Bosch washing machine in case of various problems.

The information code helps owners not only independently determine the reason why the washing machine stopped working, but also quickly eliminate a number of malfunctions. This significantly saves time and the family budget. It is most convenient to diagnose faults in models equipped with an information display. In washing machines without a display, the error code must be determined by the blinking indicator lights.

Before you begin inspecting and repairing your washing machine, you must read the operating instructions.

In this article we will look at error codes for Bosch washing machines, possible causes of malfunctions and ways to eliminate them. For different series of Bosch washing machines, the list of codes will vary.

Bosch WFP washing machine codes

Bosch washing machines of the WFP series were especially popular in the 90s. Currently, there are fewer and fewer of them, but many domestic helpers still work diligently for the benefit of their owners. The machine has an indicator field for starting a program - a kind of predecessor of a full-fledged display. It is in this small window that a number appears indicating the equipment malfunction code (for example, number 1 corresponds to code F01). Below is a table with a breakdown of the information codes.

| Code | Causes | Remedies |

| F01 | Problems in the water supply system (lack of water in the water supply network or low pressure, clogged water supply hose or filter, broken water supply valve), Aquastop system error | Checking the water pressure in the water supply, removing blockages in the filter and hose, repairing or replacing the valve, checking the Aquastop sensor, replacing if necessary |

| F02 | Malfunction in the water heating system (water temperature does not reach the required value for a certain period) | Checking the circuit in the area of the temperature sensor or heating element, eliminating the break if necessary, checking the condition of the heating element and its contacts |

| F03 | Problems with draining water (breakage of the drain pump, clogged drain filter or drain hose, malfunction of the pressure switch - water level sensor) | Removing blockages in the filter and hose, restoring the operation of the drain pump and pressure switch, replacing parts |

| F04 | Error in motor operation | Checking the tachogenerator and engine, repairing or replacing if necessary |

| F05 | The electric motor is faulty (starts without a command) | Checking the motor control circuit, eliminating the defect, restarting the program |

| F06, F07 | The water heating sensor is faulty, its connection with the control module is broken | Repair of sensor, control module, replacement of parts |

| F08 | The washing machine door is not closed (foreign objects may get in or the lock may break) | Closing the door, removing foreign objects, performing lock repairs |

| F10 | Lost communication between engine and control module | Control module repair |

| F11 | Motor overheating | Turning off the washing machine, restarting after 5-10 minutes |

| F13 | Increased network voltage | Turning off the washing machine, stabilizing the voltage |

| F14 | Reduced voltage in the network | Turning off the washing machine, stabilizing the voltage |

| F15 | Incorrect temperature in the water heating system | Troubleshooting the water temperature sensor, replacing the sensor |

Why else does imbalance occur?

Most often, overweight or underweight laundry leads to imbalance. In the first case, the drum becomes too heavy and goes astray from the intended “orbit”, and in the second, things become crumpled and upset the balance. Fixing the failure is simple: just open the hatch, take out excess clothes or add more.

It’s more difficult if the problem with E32 is caused by improper installation of the washing machine or damage to the machine’s design. So, five breakdowns and failures lead to imbalance at once.

Unremoved shipping bolts. Such fasteners are necessary for the safe transportation of the washing machine, as they fix the drum in a stationary position. Before the first wash, all 4 latches must be removed, and plastic plugs are inserted in their place. If you start a tank clamped with screws, the engine will try to spin it, which will lead to shaking, “jumping” and internal mechanical damage. Moreover, such breakdowns are not covered by a free warranty, as this is a serious violation of Bosch operating rules.

Incorrect installation of the washing machine. According to the instructions, the machine must be placed on a flat and hard surface - concrete or tiles. The more stable the equipment is, the more vibration is suppressed and the less likely it is to become unbalanced, which is why wood, linoleum and carpet are considered poor surfaces.

It is also important to level the unit to the building level by adjusting the height of the legs. It is recommended to use special anti-vibration attachments and mats. Destroyed bearing assembly. If you don’t know what to do with damaged bearings, then it is better to entrust their repair to professionals

The work is long, difficult and costly. Damaged shock absorption system. The drum in the washing machine is suspended, and the springs and shock absorbers holding it are designed to smooth out the pressure of the centrifugal force and suppress outgoing vibrations. However, if the racks are worn out or fasteners are loose, the dampers do not fully perform their functions, which leads to imbalance. It’s easy to check the integrity and elasticity of the shock absorption: just remove the top cover, press on the tank and evaluate its behavior. If the tank jumped up and fell into place, then everything is in order; if chaotic rolling begins, replacement is required. Damaged counterweights. Designed to suppress vibrations of the accelerating drum and counterweights are concrete blocks located on the top, bottom and sides of the body. They add weight to the washer, increasing its stability. But if the concrete is destroyed or deformed, then the balance is upset. We remove the cover, check the integrity of the stones and try to repair it: tighten the bolts and cover the cracks with PVA glue.

If you don’t know what to do with damaged bearings, then it’s better to entrust them to professionals. The work is long, difficult and costly. Damaged shock absorption system. The drum in the washing machine is suspended, and the springs and shock absorbers holding it are designed to smooth out the pressure of the centrifugal force and suppress outgoing vibrations. However, if the racks are worn out or fasteners are loose, the dampers do not fully perform their functions, which leads to imbalance. It’s easy to check the integrity and elasticity of the shock absorption: just remove the top cover, press on the tank and evaluate its behavior. If the tank jumped up and fell into place, then everything is in order; if chaotic rolling begins, replacement is required. Damaged counterweights. Designed to suppress vibrations of the accelerating drum and counterweights are concrete blocks located on the top, bottom and sides of the body. They add weight to the washer, increasing its stability. But if the concrete is destroyed or deformed, then the balance is upset. We remove the cover, check the integrity of the stones and try to repair it: tighten the bolts and cover the cracks with PVA glue.

The imbalance protection function is often called the “self-preservation instinct” of the washing machine. Here, as in nature: the machine senses the approach of danger, anticipates the consequences and leaves the distance, reducing the risk of breakdowns. The owner needs to react to the Bosch signal in a timely manner and restore the balance of the drum.

Bosch Maxx washing machine codes 5-6-7

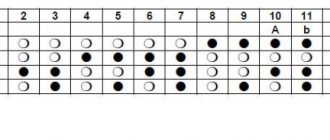

Models of Bosch Maxx 5 series washing machines can be with or without a display. For units equipped only with light indicators, codes are deciphered by their blinking. Bosch Maxx washing machines 6 and 7 series, as a rule, have a display on the front panel that displays an information error code. Below is a table with a breakdown of the codes and the corresponding combination of light indicators.

| Code | Combination of light indicators | Causes | Remedies |

| F16 | The washing machine door is not closed, low voltage | Checking the washing machine lock, removing foreign objects, closing the door | |

| F17 E17 | Problems in the water supply system (lack of water in the water supply network or low pressure, clogged water supply hose, filter, broken water supply valve) | Checking water pressure, removing blockages in the filter and hose, repairing or replacing the valve | |

| F18 E18 | Problems with draining water (breakage of the drain pump, clogged drain filter, drain hose, malfunction of the pressure switch) | Removing blockages in the filter and hose, restoring the operation of the drain pump and pressure switch, replacing parts | |

| F19 | The water heating sensor is faulty, its connection with the control module is broken, there is a problem with the heating element. | Repair of sensor, control module, heating element, replacement of parts | |

| F20 | |||

| F22 | |||

| F21 | Engine problems | Diagnostics, repair or replacement of the engine | |

| F23 E23 | Water leak | Restoring the tightness of connections |

Locking device

According to statistics, every third case of E3 is associated with UBL. An electronic lock is provided for additional protection of the door, preventing it from accidentally opening during washing. The device fails for several reasons:

- The UBL mechanism is broken (it is not recommended to repair the device, it is better to replace it with a new one);

- the electrical part is faulty (to check, run the device with a multimeter);

- The line connected to the UBL has come loose or is damaged.

It is practically useless to repair a faulty UBL. It is better not to waste time and effort, but to purchase a new device. Ideally, we are looking for an analogue only from original Bosch spare parts. Then we dismantle the old blocker and replace it with a whole one according to the following scheme:

- disconnect the washing machine from communications;

- open the hatch door;

- find the locking hole on the right and unscrew the two bolts holding the UBL;

- we tuck the cuff as deep as possible into the drum, and try to pull the blocker out into the vacated slot;

- disconnect the “trick” with the wires;

- inspect the blocker for integrity, and then “ring” with a multimeter.

Having eliminated the malfunction, we return the UBL and the cuff to their place, paying special attention to the wiring. Then run a test wash

If the door closed and the diagnostic system remained silent, then everything was done correctly.

Bosch Maxx Logixx 8 Sensitive washing machine codes

The Bosch Maxx Logixx 8 Sensitive washing machine is a modern model equipped with a display. It is subject to the error codes listed for the Maxx series, as well as additional codes listed in the table below.

| Code | Causes | Remedies |

| F25 | Aqua sensor is faulty | Checking the functionality of the sensor and pressure switch, replacing them if necessary, checking the patency of the drain |

| F26 F27 | Malfunctions in the operation of the pressure switch | Checking and adjusting the sensor, replacing if necessary |

| F31 | The permissible water level in the washing machine tank has been exceeded | Checking valves, pressure switch, water drain pump, filter and drain hose, electrical circuits of the specified equipment |

| F34 F36 | Washing machine hatch lock is faulty | Checking the lock, then resetting the program by turning the washing machine on and off |

| F37 F38 | Temperature sensor faulty | Checking, repairing or replacing the sensor |

| F42 | The motor is faulty (rotating too fast due to a malfunction of the control module or triac) | Checking the motor and triac |

| F43 | The engine is faulty (the engine does not rotate as a result of a breakdown of the tachogenerator, a malfunction of the control module, or a foreign object) | Checking the engine, tachogenerator and control module, removing foreign objects |

| F59 | 3D sensor is faulty | Checking the sensor, control module, replacing faulty parts |

The listed information error codes for Bosch washing machines appear on the display when there is a problem with the installation and the washing stops. But there is another category of codes that can only be seen by a specialist when performing a service test, during which the machine analyzes the operation of all its systems. Thus, if self-diagnosis of faults does not bring results, you need to call a technician who can fully test the washing machine and fix the identified problems.

Checking and replacing parts

First of all, you need to check the part with a tester or multimeter. You can't do without an electronic lock circuit. You must clearly understand how to act. Follow these steps:

- set the tester to resistance measurement mode;

- connect the probes of the device to the phase and neutral contacts;

- now look at the multimeter display, if you see a three-digit number there, then everything is in order;

- move the probes to the common and neutral phases and look at the display again;

- if you see a number from 0 to 1 there, it means the device is working properly.

Putting a new element in place of the old one is very simple. It is enough to perform all operations in reverse order. Namely, insert the lock into the niche and connect it to the wires (a photo was taken earlier for this), then screw in the bolts holding the lock. Now you can bend the cuff and secure it with the removed clamp. After the operations performed, you can be sure: the Bosch machine will no longer show fault code d07.

Share your opinion - leave a comment

Sensor malfunctions

These types of breakdowns are less common than the ones listed above, but you still have to deal with them.

| Code | Cause |

| E4 | The sensor for switching the flow of liquid to the sprayers and adjusting its pressure is faulty. Therefore, water does not wash the dishes from the spray nozzles. The spray nozzles may be clogged with food debris. |

| E6 | The water quality sensor located next to the heating element is faulty |

| E14 | The sensor, whose task is to control the amount of water entering the dishwasher tank, does not function |

| E15 | The dishwasher has leaked, meaning there is liquid in the pan. This malfunction is possible due to a violation of the seal of the chamber, as well as depressurization at the joints of hoses or pipes. The code appears in PMM models equipped with the Aquastop protective system |

Indication of code combination E04

It is better to entrust diagnostics and replacement of sensors to specialists. If the Aquastop system is activated, you can only check the tightness of the joints in the hoses. It is better to look for other damages to specialists.

The Aquastop system sensor has tripped

Now you know the codes for the most common dishwasher breakdowns. You can fix many of them yourself without calling a specialist. This will save time and money.