Long gone are the days when you washed and rinsed clothes by hand. Reliable household appliances have become part of the everyday life of the modern housewife. It is not surprising that when the Indesit washing machine does not work, it causes confusion and sometimes panic. Do not get upset prematurely; randomly flashing indicators do not always indicate a serious breakdown. Whether you can deal with the problem yourself or whether you need the help of specialists, the error code will tell you.

Indesit washing machine error codes - all indicators flash

“Smart” machine technologies allow you not only to wash and dry everything, but also to report problems. True, they only find out about it when something happens. LED light bulbs are the main way of informing.

Why are all the lights on my washing machine blinking? Malfunctions are associated with incorrectly selected modes or, most often, breakdowns. Most likely, the malfunction is related to the electronic module (board). In fact, these are the “brains” of the Indesit washing machine, because it is this module that controls the operation of all the main components. Accordingly, if the signals do not pass through the board, the process immediately stops, and the lights on the main panel blink.

The most vulnerable places on an electronic board are capacitors. They burn out during operation of the washing machine. Sometimes the connecting contacts fail. As a result, automatic blocking occurs. To restore functionality, you will have to contact a specialist or arm yourself with the knowledge to repair it yourself.

If you know how to work with a soldering iron, you can replace the capacitors on the electronic module yourself.

See also -

How to choose a stabilizer for an automatic washing machine

How to determine an error without a display?

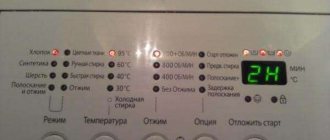

Sometimes the “home assistant” refuses to work, and the indicators on the control panel blink. Or the selected program started, but after some time it stopped working, and all or some of the LEDs began to blink. The operation of the device can stop at any stage: washing, rinsing, spinning. By flashing the indicators on the control panel, you can set the error code of the suspected malfunction. To understand what happened to the washing machine, you need to decipher the combination of buttons signaling problems.

Before you begin to determine the malfunction using the indicators, you should find out which model of the Indesit washing machine has broken down. The type is determined by the first letters of the model name. It is easy to set the error code indicated by the unit’s self-diagnosis system using the blinking light indication or lit buttons.

Next, we will consider each possible breakdown based on the indicator lights.

This is interesting: Water supply valve for a washing machine - how to replace the inlet (fill) valve

All the lights are flashing, what should I do?

Typically the indicators will display an error code according to the Indesit designation, but other symptoms may also appear.

For example, the washing modes are reset, and the program is reset, after which the lights begin to blink randomly. The most vulnerable components are:

- control module;

- capacitors on the electronic board;

- Heating element for drying and heating water;

- electric motor;

- command apparatus (KSMA), etc.

The causes of breakdowns are natural wear and tear, moisture on electronic circuits, and mechanical damage. You can save your washing machine if you diagnose the problem in time. Of course, it’s quite difficult to do this on your own and at home, so it’s worth calling a professional.

Multiple lights blinking can indicate several problems:

- the machine does not heat the water (the heating element does not turn on);

- The heating element does not send signals to the electronic unit;

- there is no voltage supplied to the drain pump, so water does not drain;

- temperature sensors do not give signals;

- control and power modules do not send signals, etc.

More information about the machine codes can be found in the instructions or on the manufacturer’s website “Indesit”.

See also -

How to repair or replace a washing machine cross

How to fix the problem?

You can fix simple defects in your Indesit washing machine yourself. Only individual breakdowns that affect the control module should be resolved with the assistance of a specialist. The cause of the problem is not always a mechanical problem. For example, the electronic control unit of a washing machine may freeze due to power surges. Repair of the unit should begin with the elimination of this error. To do this, just unplug the device from the network for 20 minutes and turn it on again. If this does not help, then the cause of the malfunction lies in something else.

- The electric motor is faulty. First you should check the voltage in the electrical network and the serviceability of the socket or cord. Due to frequent power surges in the network, electrical mechanisms deteriorate. If there are problems with the motor, then you need to open the back panel and inspect for wear of the brushes, windings and check the serviceability of the triac. If one or more elements are faulty, they should be replaced.

- Problems with the heating element. Owners of Indesit brand devices quite often encounter this situation. A typical breakdown is the failure of the electric heating element due to excessive accumulation of scale on it. The element should be replaced with a new one.

Manufacturers have thought through the placement of the heating element, and getting to it is quite easy.

There are other problems too. It is worth knowing what to do in an unpleasant situation.

- Sometimes the unit stops draining water. You should check whether there is a blockage in the filter or hose, whether the impeller blades are jammed, and whether the pump is working properly. To eliminate the breakdown, you need to thoroughly clean the filters, blades and hoses of debris.

- The control board is faulty . It is often impossible to fix this breakdown on your own: you need quite serious knowledge in the field of radio engineering. After all, in fact, the unit is the “brain” of the washing machine. If it breaks, it usually requires a complete replacement with a new one.

- The loading tank lock refuses to work. Most often, the problem lies in trapped dirt, from which the element must be cleaned. The locking device has contacts, and if they are dirty, the door does not close completely, the signal does not reach the other components of the device, and the machine does not start washing.

- The SMA begins to fill in water for washing and immediately drains it. The triacs that control the valves fail. They require replacement. With this problem, it is best to contact a household appliance repair specialist.

We determine the error code using the indicators in the video below.

Troubleshooting and troubleshooting

If you are well versed in technology, then you can figure out all the problems yourself. You can check the condition of the electronic board and fix breakdowns at home, but first you will have to disassemble the unit.

To do this you need to do the following:

- de-energize equipment;

- remove the housing cover;

- unscrew the hex screws holding the control board;

- disconnect all wires from the connectors;

- change the capacitors (or the board itself).

In front-loading Indesit models, the electronic board is located at the bottom of the rear. Getting to it won’t be difficult if you have the most common tools. For diagnostics, it is better to use a multimeter, which can be used to “ring” capacitors and contacts.

Unwinding the case usually does not cause problems, but each model has its own design features. The control panel is mounted with two bolts at the back, and the electronic board is held in place with small screws.

Top-loading models have the electronic control panel at the top, while front-loading models have it at the lower rear.

When externally examining the electronic board, look for capacitors that have a round shape. Particular attention is paid to capacitors C16, C17 (capacitance from 680 mF to 1000 mF), C20. If they fail, they usually start to swell at the top. To accurately diagnose a breakdown, you can “ring” them with a multimeter. When replacing capacitors, you must carefully check the markings to select the exact model for your washing machine.

Tips for troubleshooting problems yourself

Having established the error code and found out the reason for the blinking of the indicators, you can independently check and replace the board on the Indesit washing machine at home. To do this, you need to have a soldering iron, screwdrivers, a multimeter and a little experience in working with such tools.

First of all, you need to carefully disassemble the body of the machine. This work consists of the following stages:

- the device is disconnected from the network;

- remove the upper part of the body;

- unscrew the screws holding the electronic board;

- disconnect the wires;

- change capacitors or install a new board.

Indesit washing machines are produced in two types: with vertical or horizontal loading. In the first case, the electronic board is located at the top of the device, in the second - at the bottom rear. Getting to it is not difficult, but you should always take into account the design features of a particular model.

The electronic board must be carefully examined from all sides. Most often, capacitors C16, C17, C20 fail. If the top of these elements is swollen, then the capacitor is clearly faulty and should be replaced.

In addition to external inspection, the board elements can be tested with a multimeter. Some capacitors dry out as a result of long-term use; upon visual inspection they cannot be distinguished from serviceable ones. Using a multimeter, you can more accurately determine where the circuit is broken and which of the elements requires replacement.

Now all that remains is to install the new capacitor and connect the wires correctly. The main thing is not to confuse the markings and choose the electrical element that matches the model of the machine. After the installation of the board is completed, the unit body is assembled and a trial run is carried out.

Flashing LEDs on the Indesit washing machine may be caused by user inattention or a malfunction. In any case, smart technology will tell you where to look for a breakdown. You just need to decipher the error code that corresponds to the combination of blinking indicators, and use the table to find out the reason for the malfunction of the unit.

The automatic washing machine in our house often literally wears out. Thanks to the abundance of modes and additional features, it makes our life easier. You can refresh your clothes after a working day, or you can load 6-7 kilograms of things at once. But this cannot go on forever, if all the indicators on the Indesit brand washing machine are blinking, this is a clear sign of problems.

Rare reasons for all lights to blink

The visual information system sometimes works for other reasons. Sometimes confusion arises, so first you need to accurately determine the malfunction:

- involuntary drainage of water;

- burnout of the heating element for water and drying;

- motor failure;

- breakdown of the drain pump, etc.

If the washing machine is not working, the indicators will flash accordingly.

The heating element becomes coated with scale over time, causing increased wear. The motor can break down due to worn brushes or entangled hair and fur. The control device fails much less often; usually the cause is burnt contacts.

Check error codes according to Indesit instructions. Accurate diagnostics make it easy to repair the washing machine without major financial investments.

Indicators do not light up, machine does not work

If the washing machine does not turn on, the indicators do not light up or blink, check to see if the electricity supply in the room has been cut off. Also, if the functions do not work and the lights do not light up when turned on, check:

- Power cord. It may have been damaged or choked.

- Fork. Its body could have melted, or the contacts could have come loose.

- Connect another device to the outlet to check its functionality.

Regardless of the brand of washing machine, if you have electrical problems, call a specialist. You should not fix such problems yourself.

If you notice flashing lights when you turn on your washing machine, the first thing to do is find out what the fault code means. Then you will understand whether you can fix the problem yourself or whether you will have to contact a service center.

Possible causes of error F01

When it comes to engine malfunction, various reasons can lead to this:

- Sometimes when you turn on the Indesit washing machine, the drum does not spin. This situation indicates that the fault must be looked for in the motor.

- In some cases, error F01 occurs due to power problems. Sometimes this is caused by a faulty cord or plug.

- If it turns on, the drum rotates, but a strange crackling noise is heard, then the Indesit machine must be turned off immediately. The likely cause in this case is wear on the motor carbon brushes.

- It is possible that the reason that error F01 appeared on the screen of the Indesit machine is damage to the winding. This is often caused by a break in the wire used there.

- Since the operation of the Indesit washing machine creates an environment highly saturated with moisture, the presence of corrosion is quite likely. If the contacts of the engine pads are exposed to it, the contact is broken, which leads to disruption of the engine.

- Sometimes problems arise due to a malfunction in the triac.

Typical faults

By studying various information on SM Indesit, you can identify certain typical problems. Thus, one of the reasons for breakdowns of WISN series machines is the heating element. Due to the lack of coating, the heater quickly corrodes, and carbon deposits quickly accumulate on it. This series is also distinguished by a voltage surge sensitive surge protector. A breakdown occurs when the machine refuses to turn on. It is not difficult to repair it. Most often you just need to replace the capacitor.

The situation is more complicated with repairs related to processor failure. It is unlikely that you will be able to repair the board yourself. You will have to change the entire electronics board. The engine sensor is the weak point of the WISE series, but its repair is simple. Typically, the operation of the SM is restored after replacing the capacitor located in the data transmission circuit from the meter to the electronics board.

Drum bearings can only be removed for models up to 2014. The stabilization system, which includes two springs and a shock absorber, is quite good on all models, with a significant margin of safety. However, as a result of improper installation and increased vibration, it may break. In this case, characteristic sounds will appear during the spin mode. Restoration consists of replacing the stretched spring.

Mechanical problems also include leaks in the cuffs. Like in the WIN series. The reason is a violation of their integrity. Can only be repaired by replacement. If it is determined that the rotation of the tank is difficult, then the cuff can be carefully trimmed from the outside.

Thus, in some cases you can repair the SM yourself, especially if purchasing a failed part does not cause problems. But if you doubt your abilities, then it is better to contact a service center.

Conclusions and useful video on the topic

Demonstration of code signals of indicators with malfunctions using the example of Indesit series WIDL, WIL, WISL—WIUL, WITP, suitable for most analogues:

Video instructions on how you can change the heating element yourself:

When planning to repair complex household appliances yourself, you need to take into account the warranty period of the washing machine. When the breakdown is not limited to an incorrectly closed door or an accidentally pressed hose, it may be wiser to submit the malfunctioning equipment for official warranty repair. There they will do everything for free and at a professional level, or even give you a new machine.

If you had to deal with problems with your Indesit washing machine yourself, please tell us what kind of problem you encountered and how you managed to fix it. Write your comments, share your experience, ask questions - the contact block is located under the article.

Troubleshooting and possible repairs

First of all, you should know that a failure situation is not always fatal. In most cases, the problem is only a slight slowdown of the electronics - just disconnect the machine from the current for 15-20 minutes, and then start it again for everything to work.

This action should always be the first in the process of troubleshooting.

If there is no result, it’s time to take on specific instructions. Each problem has a serial number after the letter marker F and a required repair. For convenience, various faults are divided into categories.

#1 - electric motor problems (F01, F02)

Outwardly, both positions look the same - the machine is inactive from the very beginning, washing does not start after pressing the start button.

On electronic models the indicator F01 or F02 , on electromechanical ones (without a monitor):

- “Additional rinse” is on or “Spin” is flickering, at the same time “Lock” is active;

- The “Quick Wash” button is active or the “Extra Rinse” button is blinking.

Or no indicator lights up except the lock icon.

If the value F01 appears on the display and after a reboot, you need to check:

- voltage strength in the network (normally more than 200 V);

- serviceability and integrity of the socket and cord.

If there is no result, you need to open the back panel of the equipment and inspect the engine - it is located under the tank - for wear on the windings, motor brushes, and the serviceability of the triac. If any of this is damaged, the engine will most likely have to be replaced, and how to do this is written in detail here.

This is what the electric motor of Indesit automatic machines looks like - its average cost is 4700-6000 rubles or $40-100, and the design of the element is compatible with Ariston analogues

Problem F02 relates, among other things, to the tachometer that counts revolutions. To solve this, you should carefully examine all the contacts involved in the motor-tachometer and board-tachometer connections. There should be no broken wiring or loose terminals.

Along the way, it is necessary to check the resistance of the tachogenerator - the operating indicator is 100 Ohms and higher. Otherwise, the unit is also subject to more qualified inspection and replacement.

#2 - sensor failure (F03, F04, F07, F13)

For all these breakdowns, the problem lies in special sensors. You need to act according to the error code that appears and the model of the washing machine.

On F03 is indicated by “Revolutions” and “Quick Wash” lighting together, or “Revolutions” and “Additional rinse” blinking. This means that the machine does not heat the water, so the system will not start from the very beginning.

To eliminate the violation, the following are checked:

- rinsing function - turn on, turn off, start washing;

- contact elements of the temperature sensor - a device 20-30 mm inside the system tank;

- thermostat resistance, which should be 20 kOhm or higher.

If everything is intact or turned out to be broken, but was corrected, and the washing still does not start, the thermostat must be replaced after checking it and the entire control board by the master.

Code F04 without a display is manifested by the frozen burning of “Super Wash” or the dynamic flashing of “Soaking”.

The system tells the user that water is not filling or not filling enough, even if filling occurs. The source of the breakdown is the water level meter (pressure switch).

You can recognize the pressure switch by its characteristic plastic case and volumetric size; you need to look for it in the upper part of the system. It cannot be repaired due to the monolithic shell - only replacement will save it

What needs to be done to correct the inconsistency:

- check the presence of water in the water supply;

- measure the pressure - for the machine to work correctly you need at least 1 atm;

- inspect the supply tubes, hoses, filters (if there are any blockages there) and clean them of debris;

- check the water supply valve for mobility;

- Replace a failed pressure switch based on the results of an inspection by a specialist.

It may happen that the culprit is a short circuit in the control module, which can also be determined by a visiting technician.

You can read even more about why the washing machine does not fill with water in this article.

When the equipment reports a failure under the sign F07 , you need to act in exactly the same way as in the case of F04 . The code is simply one of the types of pressure switch failures.

The only difference is how the machine reports this: “Super Wash”, “Quick Wash” and “Revolution” are lit at once, or “Soaking” with “Revolution” and “Re-Rinse” continuously flickers.

Coding F13 is expressed by the “Delay start” and “Super wash” indicators (they freeze and light up together) or the turn indicator and the rinsing function. The basis of the breakdown is that drying is not carried out.

The drying heating sensor does not look like a general temperature sensor: the first resembles a tablet when viewed, the second - a long capsule. The standard motor thermostat is oblong and can be easily replaced

In most cases, a simple reboot will save you, since the temperature sensor is frozen. But if no changes have occurred, the drying thermometer can only be checked for insulation; in other cases, it must be replaced.

#3 - incorrect drain and fill (F05, F10, F11, H2O)

The group of problems associated with the operation of the drain pump has similar symptoms to the manifestations of the previous series of errors.

The most striking symptoms:

- the washing machine pumped water and stopped despite being filled;

- the system notifies about an empty tank;

- The rinse and spin function does not work;

- no water is pumped out.

The failure of the drain pump design is to blame.

The first step is to check the drain filter and the permeability of the sewer. The cleaning unit is located on all models on the side where the water supply hose inlet is located. A clogged drain filter, especially in the case of F11 , almost always means the pump is burnt out; the latter will have to be replaced.

A clogged drain needs to be cleaned, making sure at the same time that the tap of the water supply system is not accidentally turned off or the water is not turned off at all.

Other causes of failure are malfunction of the water supply valve, damage to the pressure switch, damage to the wiring of the pump-control board assembly, and failure of the board itself.

You can correct the wiring, make adjustments, or reinstall the pump or valve manually, but repairs to the control module and level sensor must be carried out by a specialist.

You can only get to the SMA Indesit drain pump through the bottom of the equipment from the front, this is what distinguishes it from analogues from other manufacturers

To find out without a monitor that it is the drainage system that has broken down, you need to check the indicators:

- F05 - “Super wash”, “Rinse again” are turned on at the same time, or “Spin”, “Soak” are blinking;

- F10 - “Quick Wash” and “Delayed Start” remain lit, or “Revolutions” and “Additional Rinse” blink, while “Door Block” blinks at high speed;

- F11 - continuous lighting of “Delay”, “Quick wash”, “Re-rinse”, the second type - “Spin”, “Revolution”, “Additional rinse” flash simultaneously.

H2O that is different from others . From the outside it seems that this is the letter H and the number 20. In fact, the usual formula of water is used here as an indication that the breakdown is connected specifically with the “water” sphere.

The hint can appear simultaneously with another code, as an addition, and the same methods as described for F05, 10 and 11 are suitable for eliminating its consequences.

#4 - electronics failure (F06, F09, F12, F18)

If the display shows F06, F09, F12 or F18, the “brain” of the machine – the motherboard – has broken down. The washing machine does not react in any way to the given commands, and no matter how much you press the buttons, it only issues a certain code (when there is a screen).

Talking LEDs allow you to understand if the control module is damaged:

- F06 – “Super wash” - “Quick wash” are active or “Additional rinse” - “Soak” are blinking, plus “Increased contamination” - “Iron” are on, “Lock” is blinking quickly;

- F09 – “Delayed wash” - “Re-rinse” are active or “Revolutions” - “Spin” are blinking;

- F12 – “Delayed wash” - “Super wash” are active or the speed indicator is flashing;

- F18 – “Spin” - “Quick wash” are active or “Delay” - “Extra rinse” are blinking.

The only way to correct this situation on your own is to reboot the system. You should unplug everything from the network and leave it for half an hour, then plug it back in.

Checking the integrity of the electrical wiring will also help. All other methods require disassembly, repair and reinstallation of the control center.

The washing machine's motherboard is a sensitive electronic mechanism responsible for all work. That’s why the place where it is located (the area of the “Start” button) should never be filled with water.

Position F06 is characterized by failure of the “Start” button, failure of the triac, or break in the wiring.

The infrequent error code F09 signals the need to replace the control contacts of the washing machine, reset the board settings, or reflash the entire module.

F12 marking indicates a breakdown in communication between the board and the indicator contacts.

Worst of all, when error F18 , the only way to correct it is to completely replace the entire system unit.

#5 - faulty heating element (F08, F14, F15)

The operation of a heating element - a tubular electric heater - allows an automatic washing machine to heat water and dry clothes. In Indesit models it is located in the rear.

Error F08 is one of the most common during the washing process. This means that the heating element is not functioning.

Among other signs of a malfunction: the laundry after the procedure turns out to be as dirty as before (for old prototypes), the laundry takes too long to wash, the process does not stop on its own, the laundry is still wet after drying ( F14 ), drying does not start at all after washing ( F15) .

If there is no monitor for different codes, the following lights up and freezes at the same time:

- F08 – “Quick wash” or “Power”;

- F14 – “Delayed start”, “Super mode”, “High speed mode”;

- F15 – “Delayed start”, “Super mode”, “High speed mode”, “Additional rinse”.

What you need to do to fix it:

- inspect the water level meter for damage;

- find out if there are any blockages in the drainage system;

- check the wiring and contacts between the heating element and the module for insulation and integrity, do the same for the heating element-thermostat connection;

- test the control module.

Based on the inspection results, you will have to either replace the heating element, or reinstall one of the sensors (level, temperature), or install a completely new control unit.

The most famous reason for the breakdown of washing equipment is the same heating element. It is about its safety that so much is said in advertising when offering water softeners.

The need to replace electric heating tubes arises for owners most often, but this is quite easy to do without spending money on a technician. You will need a flat and shaped screwdriver and a socket wrench.

Work order:

- Step 1 - completely separate the washing machine from all communications.

- Step 2 : Carefully turn the back wall towards you and remove the outer panel.

- Step 3 – under the tank you can see the contacts of the heater, which goes inside, disconnect their terminals.

Next, we use a wrench with a head - with its help, the central bolt on the contact panel is unscrewed. After this, the heating element should be alternately picked up from several sides with a flat screwdriver and pulled towards you; the faulty element will be in your hands.

By easily reinstalling a tubular electric heater yourself, you can save a lot of money, since replacing this element by specialists costs from 1000 rubles

All that remains is to remove the thermometer from it and attach it in the same place to the new electric heater. Next, the heating element is installed to replace the old one in the reverse order, but first it is better to clean the seat from accumulated dirt.

#6 - incorrect drum position (F16)

This type of error appears only on washing machines with a vertical loading method. In this case, the washing procedure does not begin after pressing “Start” or suddenly stops in the middle of the cycle. The drum has fallen silent, the “Lock” light is blinking intensely.

The vertical loading drum should be secured with a special button before you start washing, otherwise the hatch will open when twisted and break the machine.

Necessary:

- turn off the system, open the lid, move the drum with your hand - often it is jammed by a foreign object, for example, a torn button or hard parts of underwear - remove the obstacle, start the unit back;

- inspect the drum hatch to see if it has accidentally swung open (due to damage) and is blocking movement;

- the locking function - UBL is responsible for it - the hatch block device, replace if damaged;

- the control module for serviceability and replace the faulty one.

A reverse failure may occur when the drum does not stop. The situation will be solved by disconnecting the washing machine from the network for 20 minutes.

#7 - hatch sealing does not work (F17)

A problem identical to the previous number in terms of symptoms is caused by the fact that the door could not be locked before starting.

On models without information screens, it appears simultaneously by the indication of the “Spin” and “Re-rinse” (“Power”) buttons or a combination of “Push-ups” and “Delayed start”.

Perhaps the lid just needs to be closed more tightly. If this does not work, check for foreign objects or breaks between the inlet hole and the hatch valve or between the hatch and the rubber lip. The door also does not close when the drum is overloaded.

Another option is that the UBL has deteriorated or the control center has shorted out. Replacing them will solve the problem. The third option is low voltage. This is often observed in individual houses, but it is not uncommon in apartments.

If the power supply does not reach 220 V, an electrical appliance of this size will not work.

The rubber seal between the body and the tub door can accumulate laundry waste or foreign objects that have fallen into the drum. This may cause the lock to fail to lock, so it is better to periodically clean the cuff cavities

The manufacturer Indesit received 19 signals about defects in the operation of its equipment.

If a situation arises that does not fit any of the described errors, you will have to contact a reliable service center or official representative office of the company individually.

We also recommend reading our other material, where we described in detail the popular malfunctions of Indesit washing machines and how to eliminate them. For more details, follow the link.

How to start repairs

When error F01 appears, first of all you need to check whether the electrical outlets are working. Once you are sure that everything is in order with the network, you can proceed to further steps.

It should be noted that a failure and the occurrence of error F01 does not necessarily indicate a malfunction. In some cases, there may be a coincidence. In order to check this, you need to turn off the washing machine, unplug the cord from the outlet, wait about twenty minutes and turn on the Indesit machine again. There is a chance that everything will work fine.

Let's assume that the breakdown that caused error F01 could not be corrected by simple means.

We'll tell you how to fix error F01 in this case:

- You need to carefully inspect the socket and cord of the Indesit washing machine.

- Next, proceed to a direct inspection of the washing equipment engine.

- First, open the service hatch. The electric motor of the Indesit washing equipment is disconnected using an 8 mm wrench.

- Next, to correct error F01, you need to remove the engine and inspect its brushes. To do this, unscrew it using a screwdriver. Then you need to inspect for possible damage or wear. If problems are found, it is recommended to replace these parts.

- After replacement, everything is installed back.

The Indesit machine is then turned on to check how it works. Sometimes a clearly audible cracking sound is heard, which means there is no cause for concern. This noise is due to the grinding of the brushes.

If the problem that caused error F01 to appear is not related to the operation of the brushes, the inspection of the Indesit machine engine must be continued:

Now you need to pay attention to the control module. When examining the board, you need to determine whether there are traces of corrosion.

If they are found, they will need to be carefully cleaned. Now the motor winding is inspected. If it burns out, then the motor cannot be repaired - it will have to be replaced. This is a fairly expensive operation. If it is not financially feasible to do this, it is more profitable to buy a new, more modern car model. One of the possible causes of error F01 is a malfunction of the control module. If all other reasons are excluded, you will need to pay attention to this node. You cannot repair it yourself. This should be done by specialists who use the appropriate equipment.

One of the possible failures is when the drum suddenly stops during operation. In this case, the washer indicates error code F01.

In this case, it is recommended to take the following actions:

- When error F01 appears, the first thing you need to do is turn off the Indesit machine.

- Now you need to carefully drain the water from the tank of the Indesit washing machine.

- After there is no water left, you must try to rotate it by hand.

- If it moves normally, the reason for the F01 error may be too much laundry to wash. Now you need to divide the amount in half and try to wash half the original amount.

- If these attempts are unsuccessful, you need to inspect the engine of the Indesit machine.

- Perhaps error F01 appeared because the motor pulley was torn. Over time it can become worn and weakened. In addition, it may not have been damaged, but simply slipped. In the latter case, it is enough to simply install it carefully in place.

- In the event of a malfunction of the electronic control board, the motor of the Indesit device may simply not receive a start signal. In some cases, you can do the fix yourself. To do this, it makes sense to try resetting the programs. If this does not help, then you will have to contact a workshop with such a malfunction.

- If the brushes are worn or damaged, they will need to be replaced.

- Voltage surges can lead to damage to the Indesit machine's electric motor and the appearance of error F01. What to do in this case? You will not be able to carry out repairs yourself. Only a specialist can fix this problem.