#lg-washing-machine-errors

Published: 10 Feb 2021

You turned on the wash as usual, but LG SMA:

- does not draw water at all and displays IE on the display;

- fills the tank long and slowly, then shows an error and stops without filling the water to the required level.

Sometimes, with this error, washing proceeds normally, but water is not added to the rinse, and code 1E lights up on the screen.

From the experience of the masters! Although the code is correctly designated as IE, many people read the capital English I as the number 1. Therefore, in the description of the error you can find both names: IE and 1E.

Reasons for the error

The actual algorithm for the appearance of the IE error is as follows - after selecting a program, the washing machine opens the inlet valves and water enters the tank. If within a certain time it has not reached the required level, then the electronic module issues a code that some read as 1E.

Error ie LG.

Let's look at the factors that lead to this:

- The water supply tap is closed.

- The inlet hose is kinked.

- The inlet filter is clogged.

- The fill valve is damaged.

- The pressure switch is faulty.

- Control module failure.

- "Self-draining."

In LG washing machines, as a rule, it takes 8 minutes to reach the desired water level in the tank. We will consider each reason in detail, and what to do in these cases.

What does error 1E mean in an LG washing machine?

The IE error usually occurs a few minutes after turning on the washing machine. Sometimes the unit does not draw water at all to start the work program, in other cases it takes too long to fill it.

IE failure in an LG washing machine is often called “error 1E”, since the first icon looks like both a letter and a number

The code means that for some reason the machine was unable to receive the required amount of washing liquid. In this case, processing of things does not begin - the unit issues an IE fault and turns off.

How to fix

No water supply

A rather banal situation, but nevertheless it constantly arises. First of all, you need to check whether the tap is turned off. And also make sure that there is water in the pipes. Let us note another non-trivial situation. In some residential building layouts, there are so-called technical transit pipes. They pass through the riser through the apartment, but do not participate in its water supply.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Household appliance repair technicians are faced with the situation that the washing machine is connected to just such a pipe. But sooner or later, the management organization may turn off this pipe. Therefore, if you have this particular position, then you need to check for the presence of water in it, and if not, switch.

Fill hose is clogged

Inlet hose

Here, too, everything is simple and easy to identify the problem by visual inspection. This situation occurs when the washing machine is moved close to the wall. As a result, the inlet hose becomes bent and water will not flow.

A blockage may also occur. This happens especially often in the summer, when water is turned off to prevent pipeline maintenance. After it is fed into the hose, rust and debris may become clogged.

For cleaning, it is completely removed and washed under high pressure.

The mesh filter on the valves is clogged

This problem is similar to the one discussed above, but it occurs at any time. There is a mesh on the inlet valves, where the hose is connected, which ensures safe operation of the washing machine, without leakage.

This filter periodically becomes clogged. Depends, of course, on the quality of the water and the presence of devices in the apartment’s pipe system that prevent the passage of debris and sand.

Valve filter see

In order to clean it, you need to perform the following steps:

- Turn off the water supply.

- Disconnect the inlet hose from the machine.

- Using pliers, pull out the filter.

- While tapping, rinse the mesh under pressure.

- Put it back.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Important! This can be done as a preventive measure if it is noticeable that water is entering the washing machine for a long time.

Problems with fill valves

These devices operate on the following principle. The fill valves are constantly closed by default, and when you need to add water, the control module supplies voltage to the valves. And the coil located inside opens the shutter.

Sometimes they burn out and cannot perform their functions. In this case, replacement with new ones is necessary. This work can be done with your own hands, without the involvement of third-party specialists. The main thing is to buy a valve that matches the mounting and shape of your washing machine model.

Triple fill valves

You will need the following tools:

- screwdriver;

- pliers.

Pressostat

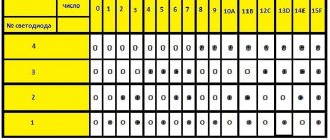

This device detects the water level in the tank, and if it is faulty, the LG washing machine displays an error code IE (1E). Note that there are two types of sensors: analog and electronic. LG uses mainly electronic ones. They generate a current of a certain frequency. And the filled tank should correspond to - 24.6 kHz. If within 8 minutes this frequency is not reached, an error appears.

The serviceability of the electronic pressure switch can only be diagnosed using an oscilloscope. These devices cannot be repaired.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Important! Sometimes there is a problem with contact oxidation. To eliminate it, treat it with a special product or sand it.

Pressostat in the car

Control module is faulty

Control module.

In modern washing machines, an important element is the electronic module. It is he who determines the program execution parameters, what needs to be turned on and when. But when there are overloads in the network or machine circuits, it becomes damaged and processes information incorrectly or gives the wrong commands.

In this position, correct operation of the SMA is impossible. Then you need to install a new module that matches the model with the firmware or restore the faulty one. You won’t be able to do this yourself - you need to contact a specialized service for repairing household appliances.

Water constantly leaves the car

If the washing machine is incorrectly connected to the sewer, a “siphon effect” occurs, which is popularly called “self-draining”. That is, water flows out of the tank by gravity. The pressure switch sends a signal to the control module that it is not enough. As a result, the program execution stops, and a fault code is displayed on the display - IE (1E).

Simply install the machine correctly and the problem will go away.

As you can see, most of the reasons that lead to this error are quite easy to fix yourself.

In what cases can you fix it yourself?

Error IE, 1E may not always be associated with a breakdown of the equipment itself. This often indicates that the pressure in the water supply is not strong enough.

- Shutting off water by utilities . First of all, before searching for the problem, you need to make sure that no plumbing or repair work is being carried out on the property at your address. Usually, the population is warned about this in advance, or in the event of an accident, the relevant housing office workers or heads of households report as far as possible.

Important:

Lack of pressure or its insufficiency is the main reason for the appearance of the “1E” or “IE” error.

- The tap in front of the hose leading to the machine is closed . In addition, you should check all the taps that are located along the water supply path to the machine. Some of them may be blocked. After opening them, the pressure that appears will eliminate the error.

- The valve in front of the machine hose is slightly open . Opening the valve not “all the way” may produce insufficient pressure. Therefore, you should check how open this locking mechanism is and unscrew it fully.

- The water supply hose is damaged or kinked . Kinked or crushed hoses supplying water from the water supply to the washing machine can also cause an error to appear on the display. It is necessary to check their integrity and, if a defective element is found, replace it.

- The filter mesh is clogged . A dirty mesh may not allow water to pass through in the required volume, so it should be checked if there is pressure in the water supply, open taps, and serviceable supply hoses. This part is cleaned with water with 1-2 teaspoons of citric acid diluted in a liter or other detergents.

Important:

Rebooting the machine, which is done by disconnecting it from the power supply for a quarter of an hour, often helps eliminate the “1E” or “IE” error.

UE error code

A very common mistake. The appearance of such an inscription on the display indicates that the device cannot spin washed clothes due to an imbalance in the drum. To put it simply, things are clumped together (not distributed evenly throughout the drum).

There are two options for writing code in which the cipher is:

- uE (lowercase u) means that the device is trying to independently redistribute the load and complete the operation normally;

- UE - The washing machine requires third-party intervention.

What to do

If the check shows that the pressure in the pipes is sufficient, all valves are open, and the washing machine hose is not kinked or bent, the filter should be cleaned. It is a mesh that covers the junction of the pipe through which the filling is made with the device. If it becomes clogged, the water will not be able to flow at the required speed and will not have time to fill the drum in the allotted time. To remove the blockage, you need to place this filter in a citric acid solution for 1-2 hours, then rinse under a strong stream.

You can check the condition of the fill valve using the following instructions:

- remove the top cover of the washing machine;

- inspect the valve for rust;

- check its resistance with a multimeter, normal value is 2-4 kOhm.

A malfunction of the fill valve may result in water being partially drawn or not flowing into the drum at all. This depends on whether it has completely stopped responding to the control signal or whether it opens slightly when it arrives. The cost of replacing this spare part by a service engineer reaches 4.5 thousand rubles.

The pressure switch can also be checked with a multimeter and checked visually for blockages in the tube. If it malfunctions, the machine will not fill with water and the drum will remain dry. If the cause of problems with the set is this part, repairs will cost from 2 thousand rubles.

If the error is caused by a malfunction of the control unit, you will notice burnt tracks on it.

If the engineer manages to restore it, the cost of the work will be 3-4 thousand rubles. In cases where replacement is required, the price increases to 6.5 thousand rubles.