Engine malfunction is a problem that requires immediate attention. After all, the motor is the “power” of a household appliance, the “rod” without which it is impossible to start the washing process.

Having basic knowledge of the internal structure of a washing machine and strictly following the prescribed algorithm of actions, you can independently eliminate the problem of a non-working motor.

Otherwise, you will have to use the services of professional craftsmen. We will tell you further how to repair the motor of a Bosch washing machine.

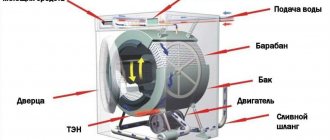

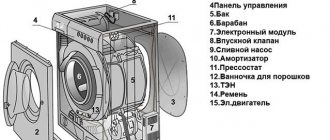

Bosch washing machine motor design

Most models of Bosch washing machines are equipped with compact but quite powerful commutator-type motors .

The commutator motor consists of several parts: a housing (the rotor, stator and winding are placed inside), electric brushes (attached to the motor body) and a tachogenerator (rotation speed sensor).

The commutator motor operates on both alternating and direct current. The brushes transmit current to the rotor, a magnetic field is formed in the winding ring, which triggers the rotation of the shaft (depending on the voltage in the network, the rotation speed may vary). Through a drive belt stretched over a pulley wheel, the shaft causes the drum to rotate.

Since the 2000s, the range of Bosch washing machines has been replenished with household appliances equipped with an innovative inverter motor. This is a compact design consisting of a magnetic rotor and a cage with coils (stator).

Unlike a commutator-type motor, an inverter motor is mounted directly on the drum of a washing machine; instead of graphite brushes, the inverter supplies current to the winding.

It is the absence of graphite brushes and a drive belt that ensures the longest period of operation of the inverter motor without repair.

You can determine the type of motor without disassembling the washing machine by the parameters of rotation speed and power (the data is indicated in the passport of the household appliance). A power of 300-800 W, a maximum speed of 15,000 rpm indicate that the washing machine is equipped with a commutator-type motor. A speed of 16000-20000 rpm, a power of 400-800 W indicate that the washing machine has an inverter-type motor.

Trouble-shooting

Most often, the commutator motor in a washing machine stops working because the brushes wear out. Less often, this occurs due to faulty windings or wear of the lamellas.

To identify the malfunction, you need to start the engine. To do this, you need to make a series connection of the stator and rotor windings, and then supply alternating current with a power of 220 Volts through the free connectors. The motor will begin to rotate.

If the washing machine is many years old, the brushes will be almost worn out, and strong sparking will be noticeable when the motor is running. The whole brushes are long and have no external defects. Otherwise, the brushes must be removed from the motor and replaced. New parts should be purchased only original ones, this will significantly increase the life of the washing machine.

Strong noises, heating of the motor, and insufficient operating power indicate a faulty winding. To verify this, you need to take a multimeter, select the ohmmeter mode and measure the resistance on adjacent lamellas. The difference should be no more than 0.5 Ohm. Otherwise, the user will see a short circuit between the turns. In the same way, you need to check the operation of the stator. Next, you need to diagnose the short circuit of the windings to the stator or rotor housing. If the motor parts are in good condition, the resistance values will be very high.

To make sure that the lamellas are worn, you need to remove the rotor from the motor and inspect the collector. A malfunction will be indicated by peeling of the lamellas, burrs appearing, or a break in the supply contact. All this leads to sparking of the brushes. Usually the lamellas overheat and peel off if the rotor becomes jammed or an inter-turn short circuit occurs.

Another popular car malfunction is a broken or slipped belt. In cases where this problem occurs frequently, this may indicate a faulty pulley. It will need to be replaced. You need to disassemble the washing machine, remove the belt, unscrew the fasteners, remove the pulley from the engine and replace it with a new one.

How to replace?

The process of replacing (repairing) a faulty Bosch washing machine motor consists of several stages:

- Preparation,

- dismantling,

- diagnostics of a faulty unit, based on the results of which repairs are carried out or a new engine is connected.

Preparation

Before starting repair work, the washing machine must be disconnected from the electricity network (safety first) and the house’s communication systems (plumbing and sewerage). The de-energized household appliance is moved away from the walls, providing free access to any side of the washing machine body.

To ensure that nothing distracts you from the engine repair process, you must take care of the necessary set of tools in advance: screwdrivers (Phillips and flat-head), keys (including an asterisk wrench), pliers, a hammer and wire cutters.

Removing the unit

To dismantle the engine of a Bosch washing machine, you need to carry out a series of sequential actions:

Unscrew the fasteners holding the back wall and remove the panel from the case.- While rotating the pulley wheel, carefully remove the drive belt.

- Find the engine under the tank.

- Disconnect the wiring terminals from the motor.

- Using a spanner, remove the two bolts holding the motor.

- Gently rocking the motor with your hands, remove it from the washing machine body.

To avoid reconnection and reassembly errors, all dismantling actions must be recorded in photos or videos.

Diagnostics

The engine is placed on a flat, well-lit surface, after which you can begin the diagnostic procedure.

The first thing to do is to transfer the winding wire from the rotor to the stator, and then apply voltage . If there is no movement of the shaft, the motor requires replacement; if there is movement, the motor can be repaired.

The second stage is checking the carbon brushes. It is these small elements located on the sides of the housing that ensure the transfer of electrical energy to the rotor winding of the power unit. Over time, the brushes wear out and, as a result, not receiving enough energy, the motor stops rotating.

You can determine the length of the brush as follows:

- disconnect the wire from the brush case;

- move the contact;

- stretch the spring;

- pull out the brush.

The minimum permissible length of a carbon brush is 1.5-2 cm. Greater wear is a reason to replace the worn element.

The third stage is the diagnosis of lamellas (metal plates that transmit electricity to the rotor). The lamellas are fixed on the motor shaft. During operation of the washing machine, the lamellas begin to peel off, thereby blocking the very process of transmitting electricity. The slightest peeling of the lamellas is a signal to replace the motor.

The fourth stage is winding testing. To do this, switch the multimeter to the “Resistance” mode and, applying probes to the motor shaft, analyze the result. Resistance less than 20 Ohm - signal of a short circuit, more than 200 Ohm - a winding break has occurred. A break or short circuit is a direct indication for replacing the washing machine motor.

Repair and rewinding of the electric motor of a Bosch washing machine - in the video:

How to remove and replace the motor on an activator-type washing machine

In activator-type devices (Malyutka washing machine, some compact top-loading washing machines), an activator is located on the motor shaft to create water movement.

To remove the engine in such devices, you need:

- Remove the plug from the housing behind which the motor is hidden.

- Align the hole in the impeller and the notch in the rotor by manually turning the activator.

- Use a screwdriver to lock the rotor by inserting it into the hole.

- Disconnect and remove the activator (if the washing machine was manufactured before 1985, turn the part clockwise, otherwise counterclockwise).

- Pull out the drive mechanism, then remove the motor.

How to repair?

You can repair the engine yourself, provided that the problem is not caused by a short circuit, broken winding or peeling of the lamellas. Most often, restoring the performance of the motor occurs by replacing the carbon brushes.

Algorithm of actions:

- Unscrew the fasteners holding the brushes.

- Clean the seat from dust and dirt.

- Install new elements in the prepared place.

Brushes on a washing machine are replaced only in pairs. New elements are selected according to the engine serial number.

Grooving the lamellas yourself

Has the lamellas become detached? Then you need to assess the scale of the disaster. If the lamella has peeled off by literally 0.5 mm, an ordinary groove on a lathe will help - clamp the rotor and carefully equalize the thickness of the lamellas.

After this, carefully clean the gaps between the lamellas; there should be no traces of metal shavings left in them. As a result, we get a flat surface from many lamellas, with well-cleaned gaps - to make sure of this, we check the resistance between the lamellas with an ohmmeter. If the ohmmeter shows a short circuit, then the spaces between the lamellas need to be cleaned more thoroughly.

By the way, cutting lamellas does not always give positive results, since most often we eliminate the effect, not the cause. It should also be remembered that it is almost impossible to return the slats to their factory appearance, so grooving is not a panacea . If the lamella has completely peeled off or torn off, you should throw the engine in the trash bin - nothing can be done here at home.

Don’t despair if the engine cannot be repaired, because you can use it to make various homemade items from a washing machine, for example, a sharpening machine.

Connecting a new part

Installing a new motor with your own hands will not be difficult if you strictly follow a certain sequence of actions:

We insert the engine precisely selected in terms of power, mounting shape and other technical parameters with bushings into the seats, and fix the housing with fasteners.- We connect the wiring of the power unit (photos or video notes taken earlier will come to the rescue).

- While turning the pulley wheel, carefully tighten the drive belt.

- We install the back panel in its original place and secure it with the mounting bolts.

After the washing machine body is assembled, the device is connected to communications, the power cord is inserted into the socket, and a test wash is started.

Step-by-step instructions for replacing a brushed motor

- The motor can be mounted either at the rear or at the front wall, depending on the manufacturer. For models Indesit, Ariston, Candy, Zanussi, Electrolux you need to unscrew the back panel. Bosch, Siemens, Samsung, LG, Beko have the front one, along with the cover and control module.

- The motor is easy to find under the laundry bin. Then you need to remove the belt, disconnect all the wires and terminals, unscrew the fastening screws with a 13mm wrench. You will have to tinker here - during operation, the screws stick, and you need to pry them out with a screwdriver. Before disconnecting the wires, it is better to photograph them, so as not to be confused later when connecting. Mounting may vary slightly between models.

- So, you need to pull out the motor, repair it or replace it with a new one, and then return everything to its place in the reverse order: first tighten the screws, then the wires, grounding, belt. Close the lid, walls and control panel. The installation must be carried out carefully and carefully. An error will cause even a new motor and drum pulley to fail ahead of schedule.

Where to buy and at what price?

The quality of operation of the washing machine after repair directly depends on which motor will be installed. In order not to make a mistake with your choice, before going to the store you need to find out the following information:

- motor serial number,

- Name,

- model,

- number and year of manufacture of the washing machine.

The necessary information can be found on a special plate (located on the back wall of the washing machine) or in the passport of the household appliance.

It is better to buy a motor for a washing machine in stores that specialize in spare parts for Bosch household appliances. It would also be a good idea to study reviews about the selected seller (store) in advance.

This approach minimizes the risks of buying counterfeits and low-quality engines. The price for a Bosch washing machine motor varies between 2000-4500 rubles .

Opening the engine

Let's look at how to open and disassemble a washing machine motor using a Samsung electric motor as an example. Almost all modern models from popular manufacturers have a similar device, so engines from other machines will be disassembled in a similar way. To dismantle, you need to turn the engine with the pulley towards you.

- First of all, it is necessary to disconnect the rotor commutator, that is, in fact, the front filling of the motor from the aluminum housing and stator, which are fastened together with special rivets. The engine in question has 8 of them: 4 on each side, 2 on the bottom and 2 on top, but the number may vary. To drill out the rivets, you can use a regular drill and an 8 mm drill bit.

- After removing the rivets, take a screwdriver, knife, scissors or any other sharp object, pry up the gap between the housing and the contents of the motor from the pulley side and separate one from the other.

- Next, simply pull the anchor (from the side opposite the pulley) and disconnect it from the rest of the housing.

- Now you need to separate the motor stator from the rear wall of the housing by prying it with a chisel or screwdriver.

- After removing the stator, let's inspect its winding. Most often, it consists of 4 wires, two of which are the same color and go to protect the stator. They lead to a block breaker, which can also be removed. To do this, you need to cut two wires, and then carefully remove the block from the grooves. If you plan to subsequently restore the engine’s functionality, there is no need to touch the wires and remove the block either; the inspection, if necessary, is carried out purely visually.

Attention! The wire from the stator, if it is intact and not burnt, in addition to being used for copper, can be used for winding transformers, since it is easily removed, and the varnish is not damaged.

Now let's return to the rotor part of the engine. It consists of bearings, magnetic rings, commutator, armature, wear ring and pulley wheel. Some of this can also be useful in the household if the electric motor has served its purpose.

For example, bearings can be used to insert into the wheels of a country cart. As a rule, a person does not develop high speed on foot, so bearing rings can withstand such pressure without any problems. To do this, it is enough to remove the bearings from the engine device with a special puller, lubricate them and insert them into the wheels of the trolley.

The collector-armature connection is more difficult to use somewhere outside the washing machine, but it contains a huge amount of copper wire, which is much more difficult to unwind, so it can be safely sold for scrap. As a rule, electric motor repair does not include such a detailed analysis. It is enough just to disassemble the case, and then act based on the detected problem.

Source

Call the master

Lack of desire, time, experience or knowledge associated with repairing or replacing the engine of Bosch washing machines is a reason to use the services of service center specialists.

The necessary contacts can be found in the passport of the household appliance (often listed on the last page), found out from acquaintances, friends, or found through search engines on the Internet.

When submitting an application, the manager must be informed of the essence of the problem, the model name, serial number and year of manufacture of the washing machine.

On average, replacing a motor will cost a client 3,500 rubles . Diagnostics are free, a new power unit is paid separately. Full payment for the repairs carried out is possible only after running a test wash!