Atlant brand machines usually issue code F9 at the beginning of the wash after drawing water. Wherein:

- the drum does not spin at all;

- the drum twitches slightly;

- the drum rotates for a short time, but only in one direction;

- At the beginning of the wash, the drum immediately accelerates to high speeds, as if spinning.

Occasionally, an error appears during the spin phase.

Based on the experience of RemBytTech specialists, it is worth noting that for the first time error F9 can occur at any stage of washing. As a rule, after the first appearance, it repeats precisely when trying to start a new cycle.

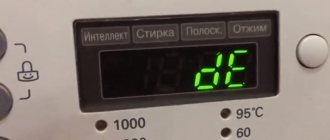

Decoding the F9 code

The F9 coding indicates a malfunction in the operation of the device, which concerns the functionality of the tachogenerator . The washing machine fails to accelerate the drum to the required speed, and the control module, which coordinates the operation of the entire washing machine, interrupts these attempts by displaying an error message.

The violation can also be determined by the fact that after filling the tank with water, the wash does not start, and the drum itself does not move as usual. If the tachogenerator fails, the rotation of the drum will be disrupted.

This could be one of the options:

- complete lack of movement;

- sluggish twitching;

- a short rotation in one direction, after which it stops;

- too active rotation, more characteristic of a spin.

In automatic Atlant washing machines that do not have a display, information about a failure is conveyed to the user by the glow of a certain combination of indicators.

An analogue of F9 for them are the following signals:

- For machines in the OptimaControl line, these are “Prewash” and the “Water Stop” light.

- For devices of the SoftControl line, this is “Wash” plus the “Spin” glow.

A failure with F9 in Atlant can occur at any stage of processing items in an automatic washing machine.

Tachometer

It is an important structural element. The main task is to accurately count the revolutions made by the drum. Its functions also include measuring the amount of generated voltage. Control over such parameters is necessary so that the machine runs the set washing program smoothly.

It is worth noting that the design of washing machines of this brand is very typical and does not have any complex elements or mechanical features. Therefore, getting to this or that node is quite easy. This also applies to the tachometer. You just need to unscrew a few fasteners from the back panel and remove it. Next you will see:

- rear wall of the tank;

- pulley with drive belt;

- A heating element with suitable electrical wiring and contacts;

- several pipes;

- engine with chip, electrical wires, tachometer.

Next, you should disconnect all the wires from the tachometer and check the value of its resistance using a multimeter. It would be a good idea to remove the part and inspect the ring for the presence of accumulated oxide. If there is one, it is recommended to carefully but gently remove it. If the sensor malfunctions, it is accordingly replaced.

Causes and remedies

In most cases, F9 indicates a problem with the equipment that requires repair. But sometimes the reason may lie in a random coincidence or in a user error.

Overload

Sometimes the user tries to tamp the drum as much as possible . This can not only significantly deteriorate the quality of washing, but also creates an increased load on the machine components.

If the Atlanta drum is filled to capacity, and the weight of the loaded items is clearly greater than that recommended by the equipment manufacturer, the operation may stop and F9 will be issued.

The solution to the problem is to remove some of the laundry from the drum and start the wash again.

Imbalance

Uneven distribution of things in the drum may be one of the reasons for F9. This situation can arise when things are knocked into a tight lump, which the machine itself cannot distribute evenly throughout the drum. The solution to the problem is to manually distribute the laundry evenly.

One-time random failure

A sudden power surge or other unexpected reason can cause the washing machine to freeze and display an error code on the display. If this situation was not caused by a breakdown, but by a random combination of circumstances, then a reboot will help.

To do this, you need to turn off the device from the network for 15 or 20 minutes by unplugging the plug from the socket. After such a reboot, you need to turn on the washing machine again. If error F9 does not go away, you will have to move on to more serious diagnostics.

Control unit failure

If the elements on the board that are involved in the operation of the motor fail, the washing machine may stop after drawing water and freeze without rotating the drum. Its movement will not occur at all or will become insignificant, and only in one direction.

If the control module breaks down, it is dismantled . Burnt out elements are replaced. If this unit is severely damaged, it is completely replaced.

The firmware of the electronic unit has gone wrong

If the board's firmware is faulty, it needs to be reflashed. To do this, remove the unit from the washing machine and work with it separately.

The tachometer is broken

If the element that controls the rotation speed of the drum fails, the Atlant washing machine does not wash. The drum does not move.

The tachometer is dismantled for diagnostics . To do this, disconnect the wires and unscrew the screws that hold it in place. The new sensor is installed in place of the removed one, and all wires are connected.

Engine brush wear

When the motor brushes wear out, the washing machine does not perform a full spin cycle according to the set parameters. Over time, the situation worsens and the drum does not rotate even during the washing phase.

This situation is due to the fact that during prolonged use the brushes lose their original size , and the electromagnetic field necessary for the operation of the device is not created in the motor. When the brushes are completely worn out, the rotation of the drum stops completely.

Since brushes are considered consumables, they should be replaced with new ones. To do this, the motor is removed from the mounting socket.

Wiring problems

In automatic washing machines, there are a lot of wires running inside the body that connect the working units. Damage to any part of the electrical circuit leads to malfunctions of the washing machine.

If the damage concerns the motor chain, then the drum may not rotate , or it will occur jerkily. As a result, the control module generates an error code F9, which is displayed on the display.

To eliminate a break or rotted/lost terminals, partial disassembly of the washing machine is necessary. If a defect is detected, it is eliminated by repair (twisting) or replacing the entire group. Most often, the contacts rot in the motor terminal block, so you need to remember to check their condition.

The motor broke down

Motor failure is a serious breakdown, followed by expensive repairs or complete replacement of the engine. Damage may include winding breakage, electrical leakage to the housing, etc.

It is the motor that is responsible for rotating the drum . When the motor is damaged, the washing machine can only draw water, but the wash itself does not start. If the motor is seriously damaged, it is usually simply replaced.

Video review of the Atlant washing machine engine:

Error F9 - when you can fix it yourself

In rare cases, an error occurs in Atlanta without any breakdown. Its appearance is caused by:

- Overloading or uneven distribution of laundry in the machine . It is necessary to reduce the number of items in the drum (and henceforth not exceed the weight recommended by the manufacturer), or manually distribute the “crumpled” items throughout the drum.

- One-time control module failure . It is required to disconnect the SMA from the power supply for 10-15 minutes. This will overload the control module and the error will probably go away on its own.

Call the master

It is not always possible to cope with a breakdown of the Atlant washing machine on your own. If simple reasons are not confirmed, and diagnostics of the condition of the motor and other components is required, it is better to entrust the work to a professional.

There are a large number of companies operating in the services market. Their prices and conditions can be found on the Internet. Those companies that have positive reviews from clients and have been working on the market for more than a month should inspire trust. Such companies strive to maintain their reputation and recruit only good specialists.

The cost of the technician’s work depends on the complexity of the repair and the company’s price list. The average prices for repairs in the capital are as follows:

- motor repair/replacement – from RUB 2,100;

- wiring repair - from 1600 rubles;

- replacement of brushes - from 1500 rubles;

- replacement of tachometer – from 2100 rubles;

- repair/reflashing of the control unit – from 2100 rubles.

The cost of new parts is paid separately by the customer. If repairs to other components of the device are required along the way, the cost of the technician’s work increases.

Prevention measures

In order not to encounter the problem of failures with the issuance of F9, you need to remember the following preventive measures:

Do not overload the machine drum when storing things.- If power surges are a common occurrence in your home, it is advisable to think about buying a voltage stabilizer.

- You should not run wash after wash without allowing the machine to rest.

- If any water leakage into the housing is detected, the device must be repaired, since ignoring this circumstance provokes corrosion and can lead to very serious damage and current flow to the housing.

How to fix

To troubleshoot F 5 yourself, you should disconnect the refrigerator from the household network and check the voltage with a test device. If the value is normal (in the range of 220-240 V), you need to inspect the plug. Traces of carbon deposits on the surface and overheating of the contacts indicate poor contact; it is recommended to replace the internal mechanism of the socket; the plug is replaced along with the power cable. If the network voltage is high, you must contact your local power supply company. Error F 4 is eliminated in the same way.

To remove error H, you need to inspect the rubber sealing edge mounted around the freezer or refrigerator lid. When an element leaves the guide groove or when foreign objects get under the seal, air flows in from the warm room. A malfunction occurs when the thermostat breaks down, which incorrectly sets the temperature in the chamber, as well as when refrigerant leaks from the compressor and lines (detected by oiling of the tubes or when checked with a test pressure gauge in the service).

On some models, the malfunction disappears after forced defrosting of the equipment for 24-36 hours. It is also recommended to check the operation of the limit switch installed on the door. When using incandescent lamps for illumination, the generated heat warms the air in the chamber, triggering the emergency sensor. The sensor may turn on briefly after loading the chamber with a large amount of high-temperature products.

If errors occur in the operation of the compressors (F6 or F7), you can try to dismantle the control relay and check the resistance of the windings and the absence of short circuits to the housing. A serviceable start winding has a resistance of 20-30 Ohms, a working winding has a resistance of up to 60 Ohms. If the value increases, the electric motor is considered unsuitable for further operation. It is possible to test the operation of the compressor without using a start relay by connecting the power cord directly to the terminals. If the error disappears, then the control relay is faulty or the power circuits are damaged.

The indication of the letter L is an error only when turned on continuously for more than 24 hours; the symbol turns on automatically when the accelerated freezing mode is activated. If the icon does not turn off, then the thermal regulator or power supply is faulty. The technician will determine the cause of the breakdown after diagnosing the components of the refrigeration unit. Error F2, which occurs due to incorrect operation of the sensors in the evaporator, cannot be eliminated on its own. It is necessary to replace the elements and replenish the refrigerant supply.

Codes E 2 and E 1 occur when there is no signal in the power supply circuits of the heating threads of the freezer (for automatic removal of frost). Repairing the parts yourself is not possible; it is recommended to check the condition of the fuses and contacts in the connectors. When water gets on metal surfaces, oxides are formed that do not allow electric current to pass through. Corroded areas are cleaned with sandpaper and coated with a special compound that repels water-based liquids.

Recommendations

In cases where you have encountered error F9 on your washing machine, the following recommendations can help:

- In some cases, repairing parts may not be practical and replacement will be better. This applies, for example, to engine repairs.

- The minimum length of brushes when they can still maintain their functionality is 1 cm.

- You can only open the case when the electricity is turned off and the water supply tap to the washing machine is closed.

- Machines that are under warranty can only be repaired by service center technicians.