"A-Iceberg" - 27 years with you. 5,700,000 repairs completed.

We repair Atlant washing machines quickly, efficiently and at an affordable price. We will fix any problem of any complexity.

If your washing machine breaks down, in order not to have to deal with issues with the delivery of large equipment to the workshop, use the services of a service center that repairs Atlant washing machines at home. To call a master who arrives with the necessary tools, you need to submit an application in any convenient way: online or by phone: 8(495) 213-33-33

.

Symptoms of a problem

How to determine bearing failure at home? The first and main sign is increased noise during operation of the washing machine. Also, if you shake the drum by hand, you will notice play - the drum moves upward from the tank. And if you twist it by hand, it rotates unevenly.

At the first sign of a malfunction, you should immediately begin replacing the bearing in the Atlant washing machine. This is a breakdown that requires immediate repair.

Why is it dangerous to delay bearing repairs? When they are washed, the drum cross suffers, and uneven vibrations of the latter can damage the tank. As a result, repairs will cost many times more.

Washing machine repair Atlant

Washing machines under the Atlant are produced by the Belarusian JSC Atlant. Production was launched in 2003 and is located in Minsk. Atlant washing machines meet all the requirements for modern washing machines. The warranty period is 3 years and the service life is 10 years.

It should be noted that the indicated periods are the longest in this market segment. Warranty period - 3 years

Atlant washing machines have no analogues at all. These terms characterize high fault tolerance relative to the entire washing machine market. Atlant washing machines become the uncontested leader. Washing machines Atlant belongs to the middle price category.

A huge variety of models from super-narrow machines with a depth of 32.8 cm for a small room to full-size 56 cm with a load of up to 6 kg. Quick online diagnostics of washing machine faults (Just select a problem from the list and find out the approximate breakdown)

Atlant washing machines have the function of displaying an error code when certain malfunctions and malfunctions occur. Quite often, understanding what the error code means , you are able or breakdown yourself

For your convenience, a list of error codes for Atlant washing machines is provided with an explanation of each specific code . The table also includes a description of the error, the reasons for its occurrence and possible solutions.

The washing machine consists of units that are complex in design, and if they break down, it is better not to try to repair the devices yourself. Moreover, this is due to high voltage and the possibility of flooding neighbors living on the floor, or even two or three floors below.

When carrying out repairs yourself, remember your safety!

Disassemble without disconnecting the equipment from the mains!

It is best to use the services of an experienced technician who is familiar with any problems and can fix the problem. If your washing machine breaks down, entrust the repair to a professional: he will be able to perform all the steps quickly, efficiently and safely.

Decoding Atlant error codes

| Error code | Description of the error | Causes and elimination |

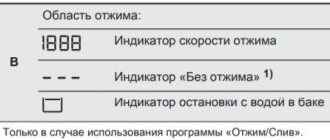

| The error code on machines without a display is displayed by alternate blinking of the LEDs located on the front panel. 1 indicator is on; 0 indicator is off | ||

| Sel 0000 | Problems with the program selector. | 1. The functionality of the selector itself is checked; 2. The controller is checked. |

| None 1111 | There is too much foam in the drum. | 1. The program was selected incorrectly; you should select a more correct program for a particular type of fabric. 2. It is necessary to adjust the dose of washing powder or select a different brand of detergent. |

| F2 0010 | Temperature sensor malfunction. | 1. The functionality of the sensor is checked and the integrity of electrical circuits is monitored. 2. The sensor is replaced and the control module is checked. 3. Replacing the heating element. |

| F3 0011 | Heating element malfunction. | 1. The heating element must be replaced. 2. Make sure the module is working properly and replace it. 3. Make sure that all wires and contacts are in working order. |

| F4 0100 | Drain pump malfunction. | 1. Check the permeability of the drain system. 2. Foreign objects are removed from the pump. 3. The filter is checked and cleaned. 4. The control module and electrical circuits are checked. |

| F5 0101 | Filler solenoid valve malfunction. | 1. The water supply hose is clogged with foreign objects or pinched. 2. The filter in the hose is clogged. 3. The water supply is cut off, cold water in the house is turned off. 4. Fill valve is faulty. 5. The wiring connecting them between the module and the valve is damaged. 6. The contacts in the valve are damaged. 7. Malfunction in the operation of the control module. |

| F6 0110 | Motor reverse relay malfunction. | 1. The stator winding is overheated, the thermal protection contacts of the electric motor are open. 2. The relay is checked and replaced. 3. A check of engine performance is required. |

| F7 0111 | Electrical fault. | 1. The power supply voltage is above (below) the range of nominal values. 2. Replace the radio interference filter. 3. The control module is faulty. |

| F8 1000 | Overflow of water in the washing machine tank. | 1. Inspect the pressure switch and clean its tube. 2. Replace the control module. 3. If the valve is stuck open, it must be replaced. |

| F9 1001 | Electric motor tachogenerator malfunction. | 1. Assess the operating ability of the tachogenerator and electric motor. 2. Make sure that the wiring connecting the parts to the control module is not broken. 3. If necessary, replace the control module. |

| F10 1010 | UBL malfunction. | 1. It is necessary to check the position of the loading hatch and the tightness of its closure. 2. The operation of the electronic lock and its electrical circuits is checked. 3. The electronic module is checked. |

| door 1011 | Malfunction of the hatch lock. | 1. It is necessary to check the position of the loading hatch and the tightness of its closure. 2. The operation of the electronic lock and its electrical circuits is checked. 3. The electronic module is checked. |

| F12 1100 | Motor malfunction. | 1. Ring the motor windings and contacts. 2. The control triac on the board burned out. 3. Check the control module. |

| F13 1101 | 1. Defect in wiring or contacts. 2. The control module has failed | 1. Check the contact in the harness connectors. 2. Repair of the control module. |

| F14 1100 | Software error. | The module is programmed incorrectly, the entered program is incorrect. |

| F15 | Water leaking from the tank. | 1. The rubber cuff is torn or worn. 2. The tightness of the hose connection is broken. 3. The car tank is leaking. |

How to call a specialist?

Requests for repairs are accepted daily, from 8 am to 10 pm by phone or using an online application.

8 (985) 181 – 02 – 88

8 (985) 181 – 02 – 88 (Whatsapp)

Leave a request for repairs

Important! When contacting, please provide the following information: Your contact information: name, phone number and address, make of the machine, if possible, send a tag with the serial number and product code of the machine and the day and time of arrival of the technician that suits you.

To carry out repairs and select spare parts for your washing machine, you need to know its model and serial number.

The exact model of the machine is indicated on the tag on the body of the washing machine or stickers, as well as in the operating instructions. If you have already purchased replacement parts yourself, please indicate only the make of the machine. For example, ATLANT 50 C 82.

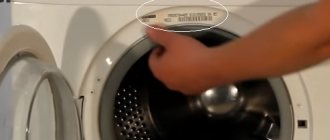

places where washing machines may contain a sticker with all the necessary service information.

1. Under the hatch door on the body. Most often, on front-type washing machines, the serial number is located on a sticker under the hatch door. Either on the door itself or on the body. In most cases, the number consists of numbers, less often of numbers and letters .

2. On the back side of the pump filter hatch. On vertical models, a sticker with a service number is most often located on the inside of the small hatch that covers the pump filter.

3. On the back wall. The back wall of the washing machine is a traditional place for all kinds of service information. If you couldn’t find a sticker with a number on the front, then it was probably preserved on the back wall.

4. In the passport or instruction manual. Finally, the serial number can sometimes be found in the documents that come with the purchase of the washing machine. As a rule, the number is located in the passport or warranty card.

The arrows show the location of the tags.

washing machine manufacturers encode on a tag (sticker) what they produced, when, where and from what parts. This information is encoded in two sequences of numbers (letters) product and serial numbers. Their combination is unique and applies only to one specific instance of the washing machine.

Please take a photo of these tags

To maximize the life of your washing machine, you need to carefully read the operating instructions. If you have lost it, here you can select your model and download it in pdf format.

Operating instructions for Atlant washing machines

| ATLANT 45 U 102 | ATLANT 5 FB 1040T | ATLANT 5 FB 520 |

| ATLANT 35 M 102 | ATLANT 45 U 101 | ATLANT 45 U 121 |

| ATLANT 45 U 144-A | ATLANT 45 U 84 | ATLANT 50 C 121 |

| ATLANT 50 C 126-A | ATLANT 50 C 81 | ATLANT 50 C 82 |

| ATLANT 5 FB 1040T | ATLANT 5 FB 820E | ATLANT 35 M 8 |

| ATLANT 45 U 124 | ATLANT 45 U 146-A | ATLANT 50 C 101 |

| ATLANT 50 C 124 | ATLANT 50 C 144 | ATLANT 50 C 82 |

| ATLANT 5 FB 1020E | ATLANT 5 FB 1220E | ATLANT 5 FB 840 |

| ATLANT 35 M 81 | ATLANT 45 U 104 | ATLANT 50 C 102 |

| ATLANT 50 C 124-A | ATLANT 50 C 144-A | ATLANT 50 C 84 |

| ATLANT 5 FB 1020E1 | ATLANT 5 FB 1220E1 | ATLANT 35 M 101 |

| ATLANT 35 M 82 | ATLANT 45 U 106 | ATLANT 45 U 144 |

| ATLANT 45 U 82 | ATLANT 50 C 104 | ATLANT 50 C 126 |

| ATLANT 50 C 146-A |

Washing machines from manufacturers that we repair

Preparatory work before repairing the Atlant machine

What tool will you need:

- screwdrivers: straight, slotted;

- keys: socket, wrench 12-19 mm;

- chisel, hammer;

- WD-40 product;

- replaceable bearings, as well as oil seals - buy taking into account the brand and model of SM;

- lubricant;

- sealant.

Unplug the washing machine. Turn off the water and prepare a container for draining. By unscrewing the inlet hose from the SM body, drain the remaining water, and do the same with the drain filter. It is located behind the hatch, at the bottom of the front panel. Open the hatch and unscrew the filter.

Having moved the washing machine away from the wall so that it is convenient to move, get to work.

Popular breakdowns and malfunctions

Remember that any malfunction of the washing machine indicates a serious problem that needs to be solved. Usually, the longer the owner delays with repairs, the harder it is to restore full functionality later. If the user encounters the following problems, then he should immediately contact the service.

- Does not turn on or off;

- Sparks are observed during operation;

- Does not collect or drain water;

- Doesn't squeeze enough;

- Damage to the door;

- Strong noise level during operation;

- Does not pick up powder or conditioner;

- Buttons do not function;

- Programs do not work correctly.

All malfunctions can have completely different reasons, ranging from software failures to problems with electronics. The technician will be able to accurately identify and eliminate the cause only after a complete diagnosis.

How to call a specialist

A technician will come out for diagnostics and repairs upon prior request. You can make a call by phone or through the form on the website. Provide the service manager with the following information:

- Make and model of the washing machine (see the instructions on the body).

- What happened, when, after what, the main symptoms of the breakdown (needed to select tools and components before leaving).

- Optimal time for repairs.

- Contact details.

SHOW MORE

Household appliances, including the washing machine, sometimes break down. Wear-out of spare parts, sudden failure and other reasons force you to search for a service that will repair the equipment at an affordable price and with a guarantee of quality.

Fault codes for Atlant washing machines

There are problems that are most common in Belarusian washing machines. The breakdown can be expressed as an error code (door, none, sel, F2, F3, F4, F5, F6, F7, F8, F9, F10, F12, F13, F14). Judging by user reviews, the most common ones are:

- Door - the washing machine door (SM) is not blocked. The cause may be a broken lock or locking device.

- F2 - no water heating. The point is incorrect readings of the temperature sensor or combustion of the heating element.

- F4 - water drains from the tank very slowly or does not drain at all. It is worth checking the pump and the hoses supplying it.

- F5 - water does not enter the system. Diagnostics of the filler path is required.

All fault codes are listed in the operating instructions. Why does equipment break down? Here are the main reasons:

- Poor water quality.

- Items left in pockets that fall into the drain and damage parts.

- Poor quality powder or excess of it.

- Natural wear and tear.

As you can see, violation of operating rules is not the last place on the list. If you often overload the drum with laundry or wash items with small decor without a bag, this may lead to breakage of one of the units.

How to clean?

The latest models of Atlant washing machines are equipped with a drum self-cleaning function. To start the process you need to do the following:

- empty the drum - there should be no things in it during cleaning;

- close the hatch and turn on the device;

- press the button labeled “Self-cleaning”;

- wait for the cycle to complete.

The average duration of cleaning is 1 hour 30 minutes. If the device is not equipped with such an option, then the drum is cleaned using folk remedies.

You can get rid of salt deposits using citric acid. To do this, 3 bags of lemon are poured into the powder compartment, select the “Cotton” program with a water temperature of 90 degrees. Start the wash cycle.

Cleaning should be carried out at least once every 6 months . This will avoid the appearance of unpleasant odors and prevent premature wear of parts.

Possible faults

If a destruction process has started inside the drum or its components, this will not go unnoticed. Problems manifest themselves in different ways: the drum may stop spinning, start knocking or humming when rotating, and more. Knowing these signs, you can accurately determine the breakdown.

Doesn't spin

If the drum does not rotate when the streaking mode is turned on, you need to look for the reasons and eliminate them:

There was a power surge that caused the control board to malfunction. This can be corrected by rebooting the device.- The drum is overloaded. You can cope with the problem if you lose excess weight.

- Drum axis imbalance. This happens when washing large items that clump together. To cope with the problem, you need to straighten the clothes and then continue washing.

- The belt is broken or slipping. It is necessary to remove the back wall of the cover and assess the situation.

- The motor brushes are worn out, or the motor itself is broken. Inspection, diagnostics and repair of faulty components are required.

- The drum is jammed due to a foreign object getting inside. Most often these are bra underwires or debris from pockets. In such a situation, you will have to disassemble the washing machine to remove the drum.

- The bearing assembly is worn out. It needs to be replaced.

- The crosspiece is broken or bent. The part cannot be repaired and must be replaced.

- The tachometer that controls the rotation speed of the drum has failed.

- The contacts leading to the control board have broken.

If the machine stops suddenly and does not respond to any command, most likely the reason lies in the failure of the control module. To repair it, you will need skill with a blowtorch, and sometimes programming skills.

Makes noise and knocking noise when spinning

Knocks and extraneous noises during spin cycles appear when the drum is overloaded. There is no need to wait until the wash is completed. It is necessary to forcefully turn off the device, remove the laundry and put it back into operation.

If the knocking stops, the reason really comes down to overweight. Such situations cannot be allowed in the future, as they lead to rapid wear of parts.

Other reasons why the drum knocks and makes noise during the spin cycle:

- bearings and oil seal are worn out;

- a foreign object has entered the drum;

- the counterweight fastenings have become loose;

- the shock absorbers fixing the tank inside the body have weakened;

- the drum is unbalanced, which often occurs due to weak shaft fastening.

Normally, the machine works quietly. If, in addition to knocking and noise, the quality of spinning things has deteriorated, then you should look for the cause in a faulty engine.

Creaks

If the squeak resembles metal friction, then the most likely cause is deteriorating bearings. It will not be possible to find out without disassembling the washing machine.

An indirect sign of bearing wear is rusty smudges on the tank . A creaking noise during rotation occurs when the crosspiece is broken or deformed.

This problem is encountered by users who regularly overload the drum. The most common cause of squeaking is small parts getting into the space between the tank and the drum: coins, pins, buttons and more. You can fix the problem by disassembling the washing machine. You can't do it without removing the tank.

Sometimes foreign objects or small things get caught in the rubber seal, causing a squeaking noise to be heard when the drum rotates. Correcting the situation is not difficult; no repairs are required. It is enough to drain the water, open the hatch and remove the foreign object.

Water stagnates

Stagnation of water in the drum can be caused by the following reasons:

- The drain hose is kinked. It’s not difficult to detect, just inspect it and straighten it out.

- The drainage system is clogged. To clean the pump, you need to remove the bottom trim panel, remove the filter and clean it.

- The pump is broken. Pump repair involves disassembling the washing machine. The easiest way to access it is to turn the machine over on its left side. If the motor has burned out or the impeller blades are jammed, you can solve the problem by replacing the part. In other cases, the pump is changed.

- The pressure switch (water level sensor) has failed or its tube is clogged. The blockage is removed or the pressure switch is changed.

Dangles

Normally, minimal drum play is acceptable. If it moves from side to side, when rotating it touches the glass of the hatch or the body, rubs against the cuff and makes strange sounds, diagnostics is required.

As practice shows, excess play is associated with stretching of shock absorbers. When the drum is overloaded, they experience significant loads, which is why they lose their original shape. The problem is solved by replacing them.