Content

- Control module "FORA"

- Control module "JUMP"

- Control module "7S"

- Control module "N7S"

- Mini LCD control module

Explanation of the designations of VEKO washing machines.

| Position | Meaning | A comment |

| 1st block of letters | ||

| 1 | W (washing machine) - washing machine | |

| 2 | Place of production |

|

| 3 | Type of shell |

|

| Block of numbers | ||

| 1 | Series of models (differ by electronic control module) |

|

| 2 (or 2, 3)³ | Loading dry laundry (in kg) | 5 kg, 6 kg, 7 kg (or 3.5 kg, 4.5 kg) |

| 4 (or 3.4) | Maximum drum rotation speed during spinning (x 100 rpm) |

|

| 5 | Type of dynamic system (design of tank, drum, drive, shock absorbers) |

|

| 2nd block of letters | ||

| 1 | Firmware type for control module⁴ |

|

| 2 | Case color |

|

- “²” – washing machines of the “Fora” series designed for a load of 4.5 kg of laundry (WKE 14580D, WKL 14580D) – are equipped with the next generation control module: “Jump”.

- “³” - the third digit in the notation system, as can be seen from the table, has a variable purpose. In machines with a load of dry laundry indicated with tenths (3.5 kg, 4.5 kg) - this is the number after the decimal point. In other cases, this is the first digit in the designation of the maximum rotation speed of the drum during spinning.

- “⁴” — The control module firmware determines the washing and spin class. For the “Fora” series: K, KV – low indicators; D,DB – average; R, RV – high. For the “Jump” series: R – low (no spin speed control), T – medium and high.

Where are Blomberg washing machines made?

Most likely, you already understood from the name that the manufacturer has German roots. The brand's representative office is located in the German city of Ahlen. Production was moved to Turkey in 2002 due to a merger with the Turkish company Arçelik. This did not in any way affect the quality of parts, design and assembly of models, because production technologies remained German. In 2004, the company introduced an updated model range in our country, and although Turkey is in no way associated with the production of household appliances, the lion's share of reviews about washing machines are positive.

Control module "FORA"

- BEKO - mod. WK* 1**** (models starting with the number “1”, except for models with a load of 4.5 kg),

- ALTUS - mod. AKL135

TEST MODE:

Note: To prevent errors when entering a test program, it is necessary that the machine completes all programs and that previous errors are cleared.

- Move the regulator to the “Cotton 90”

. - While pressing and holding the “Start/Pause”

, turn on the machine using the

“On/Off”

. - "Start/Pause"

button until it starts flashing, at which time you can see the error code.

Each subsequent press of “Start/Pause”

will represent one of the functions:

- Closing the door lock.

- All LEDs on the panel flash.

- Water intake from the first compartment. (Max. time 10 sec.)

- Water intake from the second compartment. (Max. time 10 sec.)

- Water intake from the air conditioning compartment. (Max. time 10 sec.)

- Hot water intake into the second compartment. (models with hot water connection)

- Heat. (Note: if the water level in the tank is not sufficient to turn on the heating element, water will continue to flow to the required level)

- Rotate clockwise. (52 rpm)

- Rotate counterclockwise. (52 rpm)

- Drain.

- Spin. (50% of maximum speed)

- Water intake from all compartments.

- End of functional test.

You can exit the test program at any stage by turning off the machine. ( On off

)

Note: if the machine does not accelerate above 100 rpm during a spin cycle, this indicates a problem with the temperature sensor.

ENTERING ERROR IDENTIFICATION MODE:

Turn on the machine with the On/Off

.

From left to right (starting from the button next to On/Off

), press and hold for 3 seconds. button for the second additional function. An error code will appear for 3-5 seconds. It can be seen again by pressing the button.

WKL control panel

WKE control panel

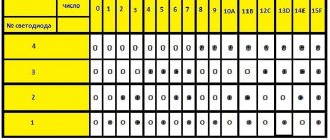

Legend:

☼ — LED is on;

◙ — LED flashes;

○ – LED is off

| Code | Description |

| ○ ○ ☼ | Temperature sensor shorted / not connected |

| ○ ☼ ○ | The heating element is not connected |

| ☼ ☼ ○ | The heating element is always on |

| ○ ○ ☼ | Valve triac is closed |

| ☼ ○ ☼ | Pump not connected |

| ☼ ☼ ◙ | Pump triac in diode mode |

| ☼ ☼ ☼ | Pump triac is closed |

| ☼ ◙ ◙ | Door lock error (no door lock signal) |

| ◙ ◙ ◙ | Door lock (triac short circuit) |

| ○ ☼ ☼ | Motor (triac short circuit) |

| ○ ○ ◙ | Engine or tachometer not connected |

| ○ ◙ ◙ | EEPROM error |

| ◙ ◙ ☼ | Short circuit or open circuit of the program / speed selection regulator |

Bloomberg washing machine instructions

Select your model from the list of instructions, or use the search form

| Model name | file size | Instruction language |

| Blomberg TAF 1230 | 5.3 MB | Russian |

| Blomberg TKF 1330 | 4.2 MB | Russian |

| Blomberg WAF 1200-WAF | 8.1 MB | Russian |

| Blomberg WAF 1300-WAF | 7 MB | Russian |

| Blomberg WAF 1540-WAF | 6.6 MB | Russian |

| Blomberg WAF 4XXX | 451.5 KB | Russian |

| Blomberg WAF 6XXX | 659.8 KB | Russian |

© 2006 - 2022 "Operating Instructions": free download of operating instructions.

You have entered the directory of manufacturer's instructions. To search for instructions, enter the model name of your washing machine in the search bar or go to the appropriate section.

- TAF 1230 (pdf – 5.34 MB)

- TAF 1230A (pdf – 5.34 MB)

- TKF 1330 (pdf – 4.21 MB)

- TKF 1330A (pdf – 4.21 MB)

- WAF 1200 (pdf – 5.57 MB)

- WAF 1220 (pdf – 5.57 MB)

- WAF 1240 (pdf – 5.57 MB)

- WAF 1300 (pdf – 4.03 MB)

- WAF 1320 (pdf – 4.03 MB)

- WAF 1340 (pdf – 4.03 MB)

- WAF 1540 (pdf – 6.57 MB)

- WAF 1560 (pdf – 6.57 MB)

- WAF 1560S (pdf – 6.57 MB)

- WAF 4080A (pdf – 451.52 kB)

- WAF 4100A (pdf – 451.52 kB)

- WAF 6080A (pdf – 659.79 kB)

- WAF 6100A (pdf – 659.79 kB)

- WAF 6120A (pdf – 659.79 kB)

- WAF 6140A (pdf – 659.79 kB)

- WAF 6150A (pdf – 659.79 kB)

- WAF4XXX (pdf – 451.52 kB)

- WAF6XXX (pdf – 659.79 kB)

It’s very easy to get the necessary advice or order repairs - dial the phone number

Text describing the characteristics of the device.

| General characteristics | |

| Installation | free-standing |

| Load Type | vertical |

| Maximum load of laundry | 5 kg |

| Drying | yes (up to 2.5 kg) |

| Control | Electronic (intelligent) |

| Display | there is a digital |

| Dimensions (WxDxH) | 45x60x85 cm |

| Color | white |

| Efficiency and energy classes | |

| Electricity consumption class | B |

| Washing efficiency class | A |

| Spin efficiency class | B |

| Spin | |

| Spin speed | up to 1300 rpm |

| Spin speed selection | There is |

| Safety | |

| Protection against water leaks | partial (body) |

| Child lock | No |

| Imbalance control | There is |

| Foam level control | There is |

| Programs | |

| Wool washing program | There is |

| Special programs | economical wash, anti-crease, super rinse, express wash, prewash, stain removal program |

| Other functions and features | |

| Wash delay timer | yes (until 19:00) |

| Tank material | plastic |

| Additional features | selection of washing temperature |

| Additional Information | POSISTOP |

Control module "JUMP"

BEKO models:

- WK* 2**** (models starting with the number “2”),

- WK* 145** (models starting with the number “1” and designed for 4.5 kg load)

BLOMBERG models:

- WAF 4080A,

- WAF 4100A

TEST MODE:

- Turn off the machine using the “On/Off” button.

- Move the regulator to the “Cotton 90°” position.

- Press and hold the “Start/Pause/Cancel” button to turn on the machine. The start LED will flash for 3 seconds. At this time, you can see the error code.

- After identifying the error, delete it by pressing “Start/Pause/Cancel” for 3 seconds.

- After removing the error, you enter the functional test. Each subsequent press of “Start/Pause/Cancel” will represent one function.

Functional test:

- All LEDs flash.

- Checking the speed controller. (The LEDs of the first and second additional functions show four different combinations, depending on the position of the control knob).

- Water intake from the first compartment.

- Water intake from the second compartment.

- Water intake from the “air conditioning” compartment.

- Heat. If the water level is not sufficient to turn on the heating element, water will flow to the specified level.

- Clockwise rotation (52 rpm).

- Counterclockwise rotation (52 rpm).

- Drain. After draining - rotation with max. speed.

- Water intake from all compartments to a given level.

Note: You can exit the test program at any step by simply turning off the machine with the On/Off button.

ENTERING ERROR IDENTIFICATION MODE:

Press and hold for 6 seconds. the first additional function button on the left. “Start/Pause/Cancel” will start flashing and the program LEDs will flash for 3 seconds to indicate an error. After 3 sec. The machine will return to program selection mode.

Resetting the error code: In error code mode, press and hold “Start/Pause/Cancel” and the error will be erased from memory. If, after repair, you are not sure that you have fixed the problem and you are going to replace the main board, do not clear the error code. In other cases, it can be deleted.

JUMP Error Codes

WKD control panel

WKL control panel

Legend:

- ☼ - LED is on;

- ○– LED does not light up

| Code | Description |

| ☼ ○ ○ | Temperature sensor shorted / not connected |

| ○ ☼ ○ | The heating element is not connected |

| ☼ ☼ ○ | The heating element is always on |

| ○ ○ ☼ | Valve triac is closed |

| ☼ ○ ☼ | Pump not connected/short-circuited |

| ○ ☼ ☼ | Motor (triac short circuit) |

| ☼ ☼ ☼ | Water level sensor error |

What are the features of Blomberg washing machines?

The manufacturer presents a wide range of machines: “frontal”, “vertical”, free-standing, built-in, with drying - for every taste. It’s hard not to pay attention to how the SMA is constructed: a traditional design, but an interesting design that Frog Design helped develop - a unique style, thoughtful details. Plus world-famous German build quality, practicality and efficiency. Features that simplify operation and make the device economical:

- Logitronic display. The black display clearly highlights red time indicators, mode parameters, error codes and other information useful to the user.

- Hygiene+ function. The ability to maintain a temperature of 95 degrees throughout the washing process. A useful option for caring for cotton items (for example, baby diapers, linen).

- The special Active 40 °C option reduces energy consumption during any cycle. How to use: first select the optimal program for your laundry, then press Active 40 °C.

- Mini 30 mode. Allows you to refresh your clothes in just half an hour. Suitable for small quantities of lightly soiled items.

Control module "7S"

BEKO - mod. WK* 5**** (models starting with the number “5”)

TEST MODE AND ERROR IDENTIFICATION.

- Turn off the machine using the On/Off button.

- Move the regulator to the Cotton 90° position.

- Press and hold the “Start/Pause/Cancel” button to turn on the machine. The start LED will flash for 3 seconds. At this time, you can see the error code in the form of a binary code on the LED bar or on the seven-segment indicator.

- After identifying the error, delete it by pressing “Start/Pause/Cancel” for 3 seconds.

- After removing the error, you enter the functional test. Each subsequent press of “Start/Pause/Cancel” will represent one function.

Functional test:

- All LEDs light up after the hatch door is closed.

- Water intake from the first compartment (pre-wash).

- Water intake from the second compartment (main wash).

- Water intake from the “air conditioning” compartment.

- Water intake into the second compartment through the hot water valve (if installed, if not, skip a step)

- Heat. If the water level is not sufficient to turn on the heating element, water will flow to the specified level.

- Clockwise rotation (52 rpm).

- Counterclockwise rotation (52 rpm).

- Drain.

- Drum rotation with max. speed.

- Water intake from all compartments to a predetermined level to detect water leakage from the tank.

- End.

Note: You can exit the test program at any step by simply turning off the machine with the “ On/Off”

»

.Error codes 7S

| Code | Description |

| F01 | Temperature sensor shorted / not connected |

| F02 | The heating element is not connected |

| F03 | The heating element is always on |

| F04 | Valve triac is closed |

| F05 | Pump not connected/short-circuited |

| F06 | Motor (triac short circuit) |

| F07 | Water level sensor error |

| F10 | Engine/tachometer not connected |

| F11 | The engine runs without stopping (signals from the tachogenerator continue to arrive for 3 minutes after stopping). |

Control module "N7S"

BEKO - mod. WK* 6**** (models starting with the number “6”)

TEST MODE:

- Turn off the machine using the On/Off button.

- Move the regulator to the Cotton 90° position.

- Press and hold the Start/Pause/Cancel button to turn on the machine. The start LED will flash for 3 seconds. At this time, you can see the error code.

- After identifying the error, clear it by pressing Start/Pause/Cancel for 3 seconds.

- After removing the error, you enter the functional test. Each subsequent press of Start/Pause/Cancel will represent one function.

Functional test:

- Door lock.

- All segments flash.

- Checking the regulator (Cotton 90 – P 10, etc.)

- Clockwise rotation (52 rpm).

- Counterclockwise rotation (52 rpm).

- Spin (rotation at half the maximum speed), drain.

- Water intake from the first compartment (max. time 10 seconds).

- Water intake from the second compartment (max. time 10 seconds).

- Water intake from the “air conditioning” compartment (max. time 10 seconds).

- Heating and clockwise rotation (52 rpm) (The machine will enter this mode automatically)

- Drain.

ENTERING ERROR IDENTIFICATION MODE:

The error code is displayed on the screen after pressing the buttons of the first and third additional functions for 3 seconds. The error code will not be displayed when selecting a new program. The error code will not be displayed again when you press the first and third additional buttons. functions.

Removing an error code:

see TEST MODE “N7S”.

N7S Error Codes

| Code | Description |

| F01 | Temperature sensor shorted / not connected |

| F02 | The heating element is not connected |

| F03 | The heating element is always on |

| F04 | Valve triac is closed |

| F05 | Pump not connected/short-circuited |

| F06 | Motor (triac short circuit) |

| F07 | Water level sensor error |

| F08 | Pump triac is closed |

| F11 | Engine/tachometer not connected/short circuit |

| F13 | Short circuit (or partial breakdown) of the Jetsystem pump triac. |

| «—:—» | Program selection switch malfunction |