The Bosh company has been pleasing its customers with high-quality household appliances for a long time. Regardless of which device the consumer uses from this manufacturer, be it a washing machine or a vacuum cleaner, you can be sure that it will truly serve the maximum service life and will be convenient to use. After all, advanced technology and high-quality components are used in production. The Bosch Maxx 5 line of multifunctional washing machines is no exception. However, in order not to cause harm yourself and to do everything possible to extend its service life, you must first read the manufacturer’s instructions.

Washing machine installation

Can be done independently, without calling a specialist. The following instructions must be followed:

- The previously prepared area must be clean and dry.

- Before putting the device in place and connecting the hoses, you will need to remove the shipping bolts that hold the drum.

- The washing machine is installed level by adjusting the height of the legs.

- The inlet hose is connected to the water supply, to cold water, the drain hose is discharged into the sewer.

- The electrical cord is connected to a 220 V socket with grounding.

Problems with water injection

Taking too long to add water can cause the cycle to slow down. First of all, inspect the inlet hose - the tube may be kinked or squashed. If everything is in order, you will have to check the incoming mesh filter. The algorithm of actions will be as follows:

- unplug the washing machine from the outlet;

- close the inlet valve;

- disconnect the inlet hose from the housing;

- rinse the tube under the pressure of warm water (if possible, you can clean the cavity with a special cable);

- pull out the filter mesh (you will need pliers for this);

- clean the filter element from debris and dirt;

- put the mesh in its original place;

- connect the inlet hose.

If the pressure in the system is normal, the filter mesh is not clogged, the inlet hose is not clogged, and water is not being collected, it makes sense to check the inlet valve.

To inspect the solenoid valve, remove the top cover of the MAS. You can check the element by applying a voltage of 220 Volts to its coils, or using a multimeter. If a malfunction is detected, the device will have to be replaced.

Where should I put the laundry detergent?

As a rule, washing machines in the Bosch Maxx 5 line are equipped with universal powder receptacles. The only thing you need to remember is what each of the three compartments is needed for:

- The first one is quite easy to find by the indicated Roman numeral “I” or the letter “A”. Visually you can see that it is the largest in size. Most of the powder or washing gel is poured into it. It is important to note that its use is for pre-soak or pre-soak purposes only. Therefore, most consumers use it extremely rarely.

- The second compartment is usually indicated in blue or with an icon in the shape of a flower or star. It is intended for liquid rinse aid. The product is only removed during the rinsing process. Not all washing modes of the Bosch Maxx 5 washing machine are programmed to take in air conditioner during the second washing stage. Therefore, if after executing the program the product remains in the compartment, this does not always indicate that the program was not executed correctly. For example, in the “Down Jackets” mode, rinse aid is not used.

- The third compartment is considered the main one. It contains powder or liquid gel for all washing modes. You can also add a stain remover here.

The machine “will not understand” how much water

The cycle can continue “indefinitely” due to a broken level sensor. The pressure switch sends incorrect data to the washer’s “brain” or does not work at all. As a result, the control module does not know that there is enough water in the tank and does not give a signal to start washing.

To replace an element with your own hands, you need to:

- remove the top cover of the Bosch SMA case;

- find the level sensor;

- disconnect the contacts leading to the pressure switch;

- remove the pressure hose, remove the mounting bolt;

- install a working element, connect the disconnected wires and tubes in the reverse order.

Simple diagnostics will help you understand whether the pressure switch needs to be changed. To check the part, you should find the water level sensor and remove the tube from it. Then you need to attach another tube of a suitable size to the fitting and blow into it. Clicks should be heard; if not, the element is faulty.

Basic care and safety rules

According to user reviews, the Bosch Maxx 5 washing machine can last more than 10 years, the main thing is to strictly follow the operating rules:

- The device must be connected via an RCD. A correctly selected automatic circuit breaker can protect the control apparatus of the device from power surges. And this is the most expensive part of the washing machine. Often, due to the failure of electronic components, you have to buy new household appliances.

- It is necessary to periodically, at least once every six months, clean the drain filter. It is accessed through the lower part of the front housing of washing machines from the Bosch Maxx 5 line.

- After completing the wash, it is recommended to empty the remaining water from the powder compartment. The manufacturer has provided the possibility of disconnecting the powder receiver. To do this, click on the blue part of the middle compartment.

- Do not overload the drum of the Bosch Maxx 5 washing machine. The operating instructions contain information on the maximum load of dry laundry to complete one wash cycle.

- There is always a certain amount of liquid left in the cuff, where the water is drained after washing; there you can also find small items that have fallen out of your pocket, buttons, locks and other small parts. All this must be eliminated, and the rubber gasket must be wiped dry with a dry soft cloth. Otherwise, over time, after washing, the clothes may have an unpleasant odor due to mold that has formed in this place.

Why doesn't the equipment finish the job?

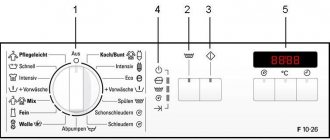

The “intelligence” of washing machines is quite developed. Several special programs are programmed in the memory, differing in water heating temperature and spin speed. Also, depending on the selected mode, the cycle duration changes. If the washing machine does not stop after the time set by the “brain”, then you need to look for a breakdown.

After waiting an extra hour after the moment when, according to plan, the washing should have ended, you can drain the water from the tank with your own hands (through the drain filter), open the door, and take out the laundry. It is important to test your Bosch washing machine to understand exactly at what stage of the cycle it slows down.

So, you will have to turn on the machine again and run the shortest program. After this, you need to observe, you will probably find out that:

- The machine takes too long to draw water. Perhaps the problem is low pressure or there is a blockage, kink, or defect in the inlet hose. The reason may lie in a “clogged” inlet filter or a faulty inlet valve. If there is a problem with the solenoid valve, the MCA will not begin to collect fluid and will emit a characteristic hum;

- The tank fills, but the water immediately goes down the drain. This can lead to endless washing. There are high chances that the washing machine is not connected to the communications correctly. The cause could also be a broken level sensor, which sends chaotic signals to the control module;

- Draining of waste fluid is delayed. Long drainage of water is often explained by clogged elements of the drain system or pump failure;

- The machine cannot heat the water to the required temperature for a long time. Heat transfer is disrupted by a layer of limescale on the heating element. It is also likely that the heater has simply failed;

- The washing machine freezes several times while running the program. Most likely, the electronics are malfunctioning;

- the drum does not reach the required rotation speed within the allotted time. Perhaps the matter is that the machine is “overloaded” with things or an imbalance. The problem may also lie in the engine or tachometer.

Careful observation of the operation of the equipment will help determine the cause of the freeze.

If you analyze the “symptoms of illness” of a Bosch washing machine, then it is quite easy to narrow down the range of possible breakdowns of the machine. Once the malfunction has been determined, equipment repair should begin.

Bosch Maxx 5 washing machine errors

First of all, it is worth saying that repairing a washing machine yourself is a risky undertaking, which may result in the replacement of many parts or the need to buy a new device. One of the most common errors is F17. Typically, it indicates that the inlet water is no longer flowing in the required quantity and most likely the main cause is contamination. To avoid errors, it is necessary to clean the hose and monitor its functioning.

Another malfunction occurs if the machine stops heating the water during the washing process. As a rule, the cause is fabric lint that remains in the tank after washing. Therefore, in order to rid the device of such unwanted problems, it is recommended to blow out the pressure switch from time to time.

Poorly organized drainage

First you need to check if there is water pressure in the tap. If it barely flows, this would be a logical explanation for the delay in washing. We'll have to wait until the supply is restored. In some cases, this will be the solution to the problem.

Another reason for “eternal” washing may be an incorrectly connected drainage hose. If it is simply stretched across the floor, water can be drawn into the tank and immediately go down the drain. The level sensor will send a signal about the shortage, the liquid will begin to fill again and instantly go down the drain.

What to do in this situation? The solution is obvious - connect the drain hose correctly. It should be located at a level of half a meter from the floor. If you do not fix it at such a distance, the water will flow away by gravity.

In addition to uncontrollably rapid drainage, the cycle may be delayed due to the reverse. If the garbage filter, pump or drain pipe is clogged, water, on the contrary, cannot leave the system and the washing stops. In this case, the procedure will be as follows:

- Turn off the power to the machine, turn off the shut-off valve;

- Cover the floor under the washing machine with dry rags, prepare a container to collect water;

- Unscrew the garbage filter (water will flow out of the hole);

- wash the filter element;

- remove any debris that has accumulated there from the hole;

- screw the filter back on.

If cleaning the drain filter does not produce results, you will have to inspect the pump and pipe. To do this, you need to lay the machine on its side, loosen the clamp securing the tube, remove the pipe from the pump, wash it and put it in place. The drain pump is disassembled, cleaned and reinstalled.

Setting up other popular models of washing units

Owners of a Siemens washing machine often experience that the machine freezes or an error appears on the display after a repair has been carried out. Removing Siemens errors is carried out as follows:

- The machine is first turned off (the program selector should be in the “Off” position).

- The program dial turns to o.

- The spin speed button is pressed and the regulator is set to position 9 until the code appears on the screen. The rev button cannot be released.

- As soon as the screen goes dark, the Siemens machine can be turned off and then proceed to normal washing.

LG washing machine CL error

The LG washing machine is quite easy to operate. The attached instructions explain in detail the cause of the errors and how to reset them:

- If the LG device indicates that the hatch door is closed, it is often possible to reset the error by closing the hatch again.

- If the drum is unbalanced, laundry is added or evenly distributed to reset the code.

- When the letters CL appear on the LG display, press 2 buttons and release after 5-8 seconds.

To resolve errors in a Samsung washing machine, it is often enough to restart the device, that is, you need to press “Start/Pause”.

If you carefully study the instructions for the washing machine you are using, you can cope with resetting errors yourself, without resorting to the services of specialists.

Decoding fault indicators

Error code E21 stands for the inability to rotate the drum. The washing machine may try to start spinning several times; if the result is negative, code F21 appears on the control panel. Failures when trying to start the reel rotation can occur for several reasons:

- Malfunction of the Hall sensor - information about the motor speed is not transmitted to the control module and it stops the operation of the washing machine.

- Motor failure - a faulty motor cannot rotate the drum; the module displays an error after several startup attempts. The malfunction may occur due to wear on the carbon brushes.

- Problem with the belt driving the drum - wear, stretching, weakening, misalignment or breakage of the drive belt will cause the drum to malfunction or stop rotating.

- A foreign object that gets into the tub during washing can jam the drum.

- Voltage drop in the network.

To identify the cause of the malfunction, it is recommended to check all points in a certain order until the problem is detected.

https://youtube.com/watch?v=TbivsrpUW6c

How to reset error F00?

Removing F00 from the display is easy if you follow a certain algorithm:

- plug in the washing machine;

- press the “Start” button with your finger and hold it;

- Simultaneously with pressing the key, turn the program switching knob one click counterclockwise.

Interesting materials:

How much RAM does a smartphone need? How much experience do you need for 1 Perk? How long do you need to work to be approved for installment plans? How long do you need to work to get a bank loan? How long do you need to work on the first list? How long do you need to work after your vacation to quit? How many assessments are needed for a half-year assessment? How much should you step back from the road when building a house? How much should you retreat from the boundaries of the site when building a house? How much do you need to retreat from the boundary when building a residential building?

Coding system

A washing machine from the famous Bosch brand is capable of independently diagnosing the condition of its components and identifying a breakdown, if any. How is an error detected? The error coding system for Bosch models is similar to the failure encryption systems for units of other brands. All relevant information about the identified problem with the washing machine is displayed as a combination of numbers and Latin characters.

In other words, having received such a designation in the idea of numbers and letters, you can decipher it. This will enable the user to understand exactly where the collapse occurred, and which component of the household laundry washing machine needs to be replaced in order to return the washing machine to its former productivity and uninterrupted operation.

Error codes

Below is a unified classification of various error codes for Bosch washing machines. It logically divides all error codes into specific groups.

Errors in the main control system.

- D09 – failure of the running program;

- D20 – water filling errors;

- D24, D28 – damage to the motherboard;

- D29, D30, D31, D32 - various types of interference, usually eliminated by restarting the washing machine;

- F10 - The electric motor cannot communicate with the control module;

- F11 – stop or failure of the selected program;

- F21 – drum stop, inability to start;

- F24 – lack of communication between Aqua-Stop and the control module;

- F32 – lack of communication between the control module and the UBL;

- F42 – excess engine speed;

- F44 – reverse relay errors;

- F63 – software crashed;

- F67, E67 – incorrect coding of the control card.

The reasons for these errors to appear on the washing machine screen may be damage to various parts of the control system: motherboard, processor, tachogenerator, control card (module) and others.

It is important that errors associated with incorrect control card encoding indicators may be a factory defect, therefore, if the washing machine displays such indicators, you need to call a specialist

Parts responsible for heating water

Heaters installed in Bosch washing machines are sensitive to hard water. Over time, without proper care, a layer of scale forms on their surface. This disrupts heat transfer from the heating element. It takes a long time for the water to heat up to the desired temperature, so the wash takes tens of minutes.

To check the health of the heating element, you will need a multimeter.

The first step is to remove the heating element. For this:

- remove the top cover, remove the back panel of the case;

- disconnect the wiring from the heater;

- loosen the fixing nut;

- push the screw inward;

- remove the heating element from the washing machine.

The heating element is tested with a multimeter. If everything is fine, you can descale it yourself. In the fight against limescale, both “folk” remedies and special household chemicals are equally good. It would be a good idea to check the temperature sensor. If a thermostat malfunction is detected, it will have to be replaced.