All washing machines produced in recent years are equipped with a special module. It notifies the user when problems occur. Depending on the design features, information is reported in the form of a code on an electronic display or transmitted by flashing indicators. Ariston washing machines also provide this function. Therefore, knowing how the error codes of Ariston washing machines are deciphered, it is not difficult to independently determine the breakdown.

Trouble Code Determination

Hotpoint Ariston washing machines have self-diagnosis that detects problems and notifies the user of the situation with a special code. If the owner understands the meaning of the code and is able to decipher it, he can independently determine and try to fix the problem. In this case, you do not need to use the services of specialists.

Important! For devices that do not have an electronic display, information is provided by flashing indicator lights.

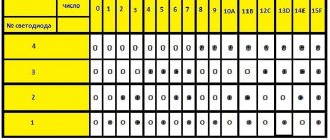

The number of short flashes of the light corresponds to the code number. After a cycle of such signals, a longer break occurs. Then the cycle of short signals is repeated. For SMA with a display, the code is displayed on it in the form of numbers. It's much more convenient.

Once you receive information about the code, the device user is able to determine where the failure occurred. After assessing the severity of the problem, the car owner can try to fix the problem themselves or call a specialist for more serious repairs. It is important to understand that troubleshooting the problem yourself requires special knowledge. Therefore, people who do not have experience in handling complex equipment are better off contacting a service center for repairs.

Without display

Error codes for an Ariston Hotpoint washing machine without a display can be determined by the light indicators:

- “Additional rinse” and “Key” flashes - F1;

- “Power” blinks and “Key” or “Lock” lights up - F2;

- flashing “40°C” - F04;

- “Key” and “Drain” or “Wash in cold water” and “40°C” flashes - F05;

- “No heating”, “30°С” and “40°С” are flashing - F07;

- flashing “50°C” - F08;

- “Wash in cold water” and “50°C” lights up - F09;

- “End”, “Spin” and “Key” flash simultaneously - F11;

- “Rinse” and “End” flash simultaneously - F18.

Malfunction of the motor or control board

Such problems are usually detected at the start of the cycle. If after loading dirty laundry into the drum, selecting the desired washing mode and pressing the start button, nothing happens, then the motor has broken down. Also, the source of the problem is often the control controller. The Ariston machine will signal that a breakdown has occurred with codes F1, F2 or F18. Such problems sometimes occur in the middle of a wash cycle.

An option suitable for solving all problems is to turn off the machine from the network for a quarter of an hour, and then turn it on again. In this case, the system reboots and, in the event of a simple failure, stops generating an error.

Problem with f1 code

This signal is displayed on the screen in the event of a malfunction with the motor, which starts the rotation of the washing drum. The device does not turn on when there is no response to the signal sent by the control module. Then, when switching to other programs, the code for this problem is still displayed.

To get rid of the problem yourself, perform the following steps:

- The cause of error code f1 is sometimes a power surge or a broken plug or cord. Then you need to refrain from simultaneously connecting the AVR to the network at the same time as other energy-intensive devices.

- You should check the plug, power cord or socket for defects. Perhaps the problem is due to their breakdown.

- Also, the explanation for the malfunction in the engine control circuit lies in the significant humidity in the bathroom. The contacts on the board should be dried and the humidity maintained at no more than 70%.

- The error is also caused by loose contacts on the motor control circuit. If you have experience working with electronics, you can fix this problem yourself by checking all suspicious areas with a multimeter.

Important! If independent attempts to fix the problem did not lead to success, it means that the control controller, electric motor, or cable with wires has broken down. The workshop will help you fix these problems.

Problem under code f2

Typically, this code is displayed at the very beginning of the wash or when trying to spin out wet laundry when the device increases speed. Then the drum twitches or an intermittent whistle is heard. Then the symbols f2 are shown on the display, and the soap solution is drained at the same time. This code appears when the engine circuit or tachogenerator breaks down. This part has a small ring and regulates the speed of the SMA motor.

To troubleshoot the problem, follow these steps:

- Check the option with drum blocking. In normal condition it turns easily. When, during the execution of a program, a foreign object enters the tank space behind the drum, it interferes with rotation. The interference is removed and the device is restarted.

- Damage also occurs due to faulty contacts. Then check the wires from the motor to the board and tachogenerator.

Sometimes, when fault f2 occurs, you have to completely change the engine, control board or tachogenerator. This can only be done in a specialized workshop.

Ariston f9 or f18 error codes

Code f18 appears when the electronic controller breaks down on models with an asynchronous motor. Devices with a commutator motor cannot generate this error. The failure manifests itself as follows:

- the engine operates with fluctuations, at very high or low speeds;

- when the program is turned on, the drum is motionless;

- the machine does not spin;

- water is drawn in and immediately drained, displaying a fault signal on the screen.

Error f09 appears due to power surges, but also indicates a controller malfunction. If the standard option of disconnecting from the network does not help eliminate the failure, check the microcircuits of the board.

Causes

Various reasons can lead to error E9 or L9. Some problems can be fixed with your own hands, in other cases you will need the help of experienced specialists. First of all, you need to check the following:

the tightness of the connection of the water drain hose to the sewer and the hose itself for ruptures; in the case of draining water into a bathtub or toilet, see if the hose is torn off or if water is flowing past;

correct connection of the drain hose to the sewer pipe; if the level of the hose is not correct, then water will spontaneously pour out of the tank; the tightness of the installation of the drain filter, if you pulled it out for cleaning the day before; pay attention to whether water is flowing from the powder tray; if the holes for pouring water into the tray are clogged, then water will not flow into the tank, it will flow out; after the external inspection, proceed to inspect the “insides” of the washing machine, check the pipe from the tank to the pump and from the powder receiver to the tank, maybe there is a need to replace the clamps that hold the pipes; check the contacts of the electrical wires going to the water level sensor and to the Aqua stop.

If error E9 appears in a Samsung or any other washing machine, you can try to restart the washing machine, so to speak, reset the program. There may have been some kind of glitch that caused the error to appear. You can reset everything by unplugging the machine from the outlet for a few minutes.

More serious reasons are caused by the breakdown and malfunction of the part, in this case it is:

- Aquastop sensor;

- rubber cuff;

- hose and pipes;

- pressure switch;

- electrical wiring and electronic module.

Changing sensors

First, we will describe the replacement of the Aquastop sensor; this part is also called a microswitch with a float. It is located, as we have already noted, in the tray of the washing machine. Therefore, to replace it, you need to disconnect the equipment from communications, pull it out to a convenient place and put it on its side. Next we do this:

- unscrew the pan;

- carefully remove the pan from the car, do not shade it sharply, so as not to tear off the wires coming from the sensor;

- disconnect the chips with wires;

- disconnect the latches and pull out the sensor;

- We replace the faulty part with a new one.

The water level sensor, which is called a pressure switch, on the contrary, is located at the top of the washing machine. You can also replace it yourself, spending about 20 minutes on the work. To do this, disconnect the machine from the network, close the water supply tap, and then follow the instructions:

- unscrew the rear bolts and remove the top housing cover;

- in the upper corner of the car they find a part as in the photo below;

- disconnect the chip with wires;

- Unclench the clamp and remove the air supply tube;

- an original new part is installed in place of the faulty pressure switch.

Replacing the cuff and pipes

Replacing a cuff in a washing machine of any brand is more labor-intensive than replacing sensors. After all, in order to remove and put on the elastic band, you need to disassemble the body of the machine. Some specialists, having the skills, can replace the cuff on a Samsung washing machine by removing only the top cover, but those who do this for the first time may not be able to do this “trick”.

We described in detail how to disassemble the washing machine and replace the rubber band in the article How to change the cuff in a washing machine, so we decided not to repeat ourselves.

As for the pipe, most often the pipe connecting the pump and the tank breaks. This part is replaced through the bottom. It is either missing or easily removed. The pipe is held in place with clamps, which will also need to be replaced.

What to do with the electronic module

The electronic module is not only the most expensive part in a washing machine, but also requires special knowledge during installation and especially during repairs. If the processor on the control board is not burned out, it can be repaired. Otherwise, the board will need to be completely replaced.

When replacing an electronic module, there is such a nuance as firmware; some boards do not have software installed. To install it, you must first find it, and then carry out the process correctly. It is for this reason that we recommend turning to specialists and not taking responsibility. Perhaps, after finding out the cost of parts and repairs, you will think about buying a new machine, because everything will cost a lot.

Thus, there are many reasons for the appearance of error E9. Most of them require skills in repairing and disassembling the washing machine. We hope our article will help you determine the trajectory of action in this situation. Good luck!

The machine does not heat the water

Problems in the heating circuit are indicated by constant freezing of the device during washing, lack of heating of water, or constant filling and draining. Then the signals f4, f7 or f8 are displayed on the display of the washing machine.

Problems with the heating element or pressure switch, indicated by codes f4, f7

Such errors, indicating a malfunction of the heating element, appear in those modes where washing is carried out with hot water. This happens immediately at start or after filling the water. Those programs where water heating is not needed operate as usual.

In addition to the standard method of solving the problem, there are several more effective methods to cope with this problem. If the problem manifests itself immediately and even water does not fill, then the heater is broken. It burns out or breaks through to the housing due to loose contacts. To troubleshoot the problem, check all connections of the heating element and measure its resistance.

Important! If the liquid is drained immediately after filling, then the pressure switch has broken down. Then the controller receives information that the heater is not in the water. Because of this, the water does not heat up.

To eliminate the malfunction, check the hose with the pressure switch. It sometimes gets clogged, bends or jumps off. It would be a good idea to inspect the sensor contacts. They may need replacing. If code f4 appears, then the pressure switch itself needs to be changed.

Sometimes problems are more serious. Therefore, to be sure, check all the parts in the area from the controller to the heater and the sensor responsible for the liquid level. If necessary, burnt parts are replaced.

Malfunction of the heating circuit under the designation f8

Fault symbols f8 appear when the heater circuit is not operating correctly. Usually the cause is a broken pressure switch. The failure occurs due to high humidity. Therefore, the board is thoroughly wiped and blown with a hairdryer.

It is also recommended to check the contacts, they may have come loose or need cleaning. This happens especially often when the device is started for the first time after transportation. In other cases, it is not possible to solve the problem on your own.

Faults indicated by f8:

- If the program is interrupted immediately after start or the water does not heat up, you need to replace the heating element.

- If the machine stops after starting or when going to rinse, some chips on the board have failed and need to be replaced. There is also a chance that flashing the board will help.

- The machine “freezing” in different modes indicates a faulty wiring or contacts. The reason may also be a broken pressure switch.

Important! If, when checking all the elements, the fault could not be identified, then the control module of the machine itself will have to be replaced with a new one.

How is the electronic module checked?

This part of the Ariston washing machine is very difficult to repair.

To begin with, you should have the necessary tools, and the skills of such work will not be superfluous. In addition, you will need spare parts that will have to be soldered if necessary. To begin with, the board is called to identify failed areas. It is best to entrust such work to an experienced specialist. By the way, the module is located at the bottom left, near the rear panel of the Ariston machine.

There are cases in which the board was not repaired, but was simply broken. This happened due to ignorance of the repair features. Even replacing an entire part has some nuances. And the point of repair is not at all to remove the failed Ariston washing machine board and install a new one. The point is that it must be programmed - “stitched”, as experts say.

Malfunctions during draining or filling of water

When the device does not fill with water or stops operation with a full tank, codes f5, f11 or f20 are visible on the screen. The first of these errors appears when the tank is full. But attempts to empty the tank lead to nothing, and a signal remains on the screen. This is often accompanied by a crackling or buzzing sound. A similar breakdown occurs frequently in Ariston Artf 1047 machines; you can get rid of the problem yourself.

The reason here lies in a clogged drain filter or hose. To correct the situation, drain the liquid and clean the blockage. This can be done through a hose. If it is clogged, you will have to bail out the water through the tank.

After this, open a small hatch at the bottom of the device and disconnect the drain filter. Check its condition and rinse the pipe under pressure of water. Additionally, the condition of the sewer system is inspected. Perhaps the blockage is there.

Causes of failure, troubleshooting procedure

You can try to resolve error F06 on your own. To do this you should:

- Reboot the Ariston washing machine so that the error is cleared at this moment. To do this, you need to disconnect the machine from the electrical network for about twenty minutes. If the attempt was unsuccessful, we begin to check further;

- If the panel malfunctions, the buttons stop responding to pressing. In this case, the panel of the Ariston washing machine simply changes;

- if the management board breaks down, it is necessary to check the module and replace it if such a need arises;

- The wiring from the display system and control unit of the Ariston device could be broken, or the contact terminals may simply have come loose. You should check the connections and replace damaged wiring.

To determine the exact problem of the F06 error, it is recommended to perform a self-test. Self-diagnosis will allow you to figure out the causes of the keyboard malfunction even in a situation where the F06 code is not displayed.

Decoding other errors

In total, there are 19 errors found in Ariston automatic machines. After a detailed look at the most common ones, let’s briefly look at the rest. These problems are signaled by the following codes:

- F3 indicates a breakdown of the temperature sensor. To solve the problem, check the condition of the circuit up to the controller and measure the resistance on the sensor itself. For normal operation, its value should be 20 ohms. Broken parts found during inspection are replaced.

- Error f6 appears only in models made on the Arcadia platform. It indicates a problem with the drum door locking system. This code also appears in Dialogic models when the control buttons are broken. If there is a problem with the drum, check the door for foreign objects and close it tightly until it clicks. Button failure occurs due to stuck or damaged contacts.

- Code f10 appears when there is no response from the water level sensor. The problem occurs due to improper connection to the sewer, lack of water in the water supply, or a break in the circuit going from the control board to the sensor.

- The f12 symbols appear on the display when communication between the display module and the control unit is lost. In this case, these parts and their connections are checked for defects.

- Error f13 occurs due to a broken sensor responsible for the drying temperature. Eliminate the malfunction by replacing the part or worn contacts.

- Codes f14, f15 indicate a breakdown of the heating element or contacts on it.

- Error f16 appears on SMA with vertical linen laying. She says that the sensor responsible for blocking the drum has broken down. This usually occurs due to the valves not being tightly closed. But the sensor or the contacts on it may fail.

- Code f17, also known as door, appears when the door is not closed tightly enough. The device is checked for interference. If there is none, then the fault is in the part that blocks the hatch during the cycle. It is replaced with a new one.

Methods for eliminating identified breakdowns

If a fault is detected in the washing machine, an error code will appear on its interface. For example, f 05. After studying the manufacturer's instructions, you can understand how to proceed further.

If f 01 is detected, you should check the contact of connector J9 of the controller. Water may get on it. It would be useful to check for corrosion processes on the contacts of the drive motor connector. To fix the problem, you need to replace the controller and drive motor.

Using a tester, we measure the control voltages on the J09 block

If the value f 02 appears on the display, then you need to check the drive motor rotor for blocking. This can happen due to problems with the drum bearings. It is also worth analyzing the quality of contact between connector J9 of the controller and the drive motor, and determining whether the electrical resistance of the tachogenerator winding is sufficient. The norm for this indicator ranges from 115 to 170 Ohms. You need to inspect the wiring and the tachogenerator. If the motor in the model is three-phase, then you will need:

- evaluate the external circuits of contacts 6,7 of connector J9 for open circuits;

- Replace the drive motor and electronic controller.

Problem f 03 is solved by checking contacts 11, 12, as well as connector J8 of the electronic controller and NTC temperature analyzer. It is also worth analyzing the level of electrical resistance of the NTC alarm. If these parts fail, they are replaced.

Error f 04: you need to fill the washing machine tank with water to about and evaluate whether the contacts of the connector JЗ of the electronic controller are securely connected, the water level indicator. The situation is resolved by replacing the level switch and controller.

With f 05, it is worth examining the quality of the connection of the contacts of connector J9 of the electrical controller, drain pump, because f05 indicates problems in this area. If f 06 - is there any contact between the connectors, inspect the wiring from the board to the control panel.

f 07: for AVD and AVL models, it is necessary to determine the quality of the contacts of the J3 connector of the electrical controller, the level detector, the quality of the latter, and the performance of the heating element.

Checking the operation of the heating element

F 08 indicates the need to check the water level alarm. If it malfunctions, f 08 can only be eliminated by replacing this part.

F 09 indicates the need to replace the controller.

At f 10, you will need to evaluate the contacts of connector 33 of the controller and the level switch. At f 11, they analyze how reliable the connection is from pins 8, 9 of connector J9 of the controller to the drain pump.

F 12 indicates the need to check the contacts of connector J11 of the electronic controller. With f 13, it is worth inspecting the contact of the CAN controller connector, the drying temperature indicator; with f14, the contact between the electrical controller and the drying heating element; with f 15, the contact of connector CN1.

Inspect the board for damage to elements

F 16 requires eliminating drum overload.

For f 17, you should check the following points:

- mains voltage of contacts 3,4 of connector J4 of the electronic controller.

- whether the door lock microswitch operates;

- Is the hatch door lock securely latched?

F 18 indicates the relevance of replacing the electrical controller.

Service area

Service is constantly expanding the geography of its activities. The company offers on-site repair services for washing machines, dryers, dishwashers, refrigerators, ovens and electric stoves in Moscow, the Moscow region, New Moscow, Odintsovo, Elektrostal, Troitsk, Domodedovo, Dmitrov.

- After our technicians, your household appliances will delight their owners with impeccable performance for a long time to come.

- Contact us and we will do our best to restore your unit as quickly as possible.

- The client is satisfied - “Stir-Repair” is calm.

If the heating element breaks down

If the heating element (heating element) breaks down, the water stops heating to the set temperature, and an alphanumeric code may appear on the display, notifying you of the problem.

E6, E5

Errors occur when difficulties arise with heating water. The malfunction occurs due to a breakdown of the heating element or due to disturbances in its power supply circuit.

HC2, HC1, HC

The main reason is a breakdown of the heating element, incorrect connection to the electrical network or a power outage. Initially, check the connection of the equipment to the electrical network. If you are using an extension cord, it is better to plug it directly into an outlet.

H2, H1

The appearance of the H1 sign signals a too rapid increase in water temperature. If within a couple of minutes of operation the water heats up above 45 degrees, a warning about the problem will appear.

HE3, HE2, HE1, HE

The display of the code HE3, HE2, HEi, HE indicates the following defects:

- damage to any part of the internal electrical wiring;

- breakdown of the heating element;

- damage to the temperature sensor;

- Incorrect electrical connection.

Recommendations on how to conduct a test on a Hotpoint Ariston washing machine: error F 05 and more

Errors in washing machines Indesit, Ariston and other models can be: F 01, F 05, F 06, F 03, N 20, F 18, F 11, F 12.

When running a test to identify an error, a number of actions are performed

:

- The solenoid valve turns on, due to which water is filled to the main level, and then to the pre-wash. Each period is allotted only 10 seconds. time.

- The solenoid valve for hot water inlet is activated for a period of 10 seconds.

- The solenoid valve is turned on, controlling the water during the main and preliminary washing modes. After this, water begins to flow up to the mark until it is filled to its maximum.

- The drum of the device begins to rotate clockwise, and then back.

- The heating element, which is responsible for heating the water to 30°C, is put into operation.

- The drain pump is turned on and operation continues until the signal that the tank cavity is empty is triggered. At this time, the drum begins to rotate in spin mode.

- The test is completed.

If during testing such errors as F 05 and F 08 were identified, then the testing indicator will begin to blink. The flashes will be slow with gradual pauses. Depending on the error code, it will be possible to detect the cause of the failure and subsequently begin troubleshooting. After repair, regardless of whether it is done independently or in a service center, additional testing is needed to ensure that the device does not turn on if there is a problem.

How is error F06 indicated on an Ariston washing machine?

As always, you have laid out a batch of laundry, defined the program, and activated the process. But your Ariston machine does not start washing, it may not even take in water, displaying the F06 signal on the display screen.

It is worth noting that error F06 can be identified at the very end of the washing process, when the program is completed, but the drum door does not open. And in this case, wait for the corresponding signal on the screen.

Quite rarely, but error F06 can occur in the following cases:

- at the time of washing, rinsing or spinning;

- can appear at any time during operation, then disappears, and the Ariston machine operates as normal.

If your Ariston machine does not have a display, then error code F06 is manifested by certain indicator signals, and here everything depends on the model itself.

| model name | signal order |

| Older Ariston models with two indicator lamps (power and interlock) | When error F06 occurs, the power lamp will blink six times at an interval of ten seconds. At the same time, the knob selecting the program will turn in the direction of the clock hand, making characteristic clicks. |

| Low-End model range (ARSL, ARXL, AVM, etc.) | Error F06 is accompanied by the blinking of the “Program End” and “Drain” lamps. They are placed vertically in the second and third places from the bottom, indicating the current stages of washing. In addition, all the additional function button lights may light up. |

| Line of models AQSL, AQ9L, AQS0L, etc. | When error F06 occurs, the temperature indicator of the Ariston machine starts blinking at 30 and 40 degrees. |