Error codes for AEG washing machines. AEG is known for producing high-quality household appliances. All of it is equipped with an advanced diagnostic system, which helps to understand the cause of the breakdown and what to do. All information about faults is summarized in a table that is convenient to use.

- Malfunctions for AEG AMS with display

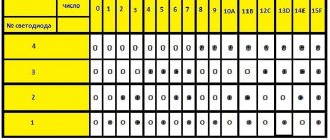

- Error codes for AEG washing machines without display

- Questions and answers

- E40 error video

- LG washing machine catalog with customer reviews

Malfunctions for AEG AMS with display

| Error code. | Description of the breakdown. | Causes of the malfunction. | Self-removal. |

| E00. | It's not a breakdown. | No water supply. | Check if there is water and if the tap is not closed. |

| E01. | The water doesn't go away. |

|

|

| E02. | Poor rinsing and spinning. | Problems with the drain hose. | Remove kinks and blockages from the hose. |

| E03. | The water drains slowly. More than 3 minutes. |

|

|

| E11. | There is no water filling during the wash cycle (the water level in the tank was not reached within the allotted time). |

|

|

| E12, E22. | The washing machine does not fill with water during the drying cycle. |

|

|

| E13. | A water leak into the pan was detected - the Aquastop system was activated. |

|

|

| E21. | The water was not drained from the tank within 10 minutes. |

|

|

| E23. | The machine freezes on any program cycle. | The control triac of the drain pump is faulty (located on the electronic controller). | Check and, if necessary, replace the specified triac or controller. |

| E24. | No water drainage. | Defect in the drain pump triac control circuit (its elements, like the triac, are located on the electronic controller). | Check the serviceability of the elements of the specified circuit. Repair or replacement of the board. |

| E31. | Lack or excess of water in the tank. |

|

|

| E32. | Excessive water heating. |

|

|

| E33. | The wash cycle does not occur. |

|

|

| E34. | The program is not running. | Inconsistency between the pressure switch and the anti-boil level 2.

|

|

| E35. | The water level in the tank is higher than permissible. | The water level sensor is faulty. | Replace the pressure switch. |

| E36. | Problems with water heating. | The heating element protection level sensor (AB S) is faulty. | Check the specified sensor and replace it. |

| E37. | Problems with water collection. | Malfunction of the first water level sensor (L1 S). | Replace the specified sensor. |

| E38. | Problems with water intake/drainage. |

|

|

| E39. | Too much water is being collected. | Malfunction of the overflow level sensor (HV1 S). | Replace the specified sensor. |

| E3A. | No water heating. | Heating element relay malfunction. | Change the relay or install a working electronic unit. |

| E41. | The program does not start. | The hatch is open or not closed tightly. | Close the hatch tightly until you hear a characteristic click. |

| E42. | The hatch is not blocked. | The hatch lock is faulty. | Replace the hatch lock (UBL). |

| E43. | The hatch is not blocked. | The control triac (located on the electronic controller) of the hatch lock is faulty. | Check the serviceability of the control triac of the hatch lock. Re-solder or new module. |

| E44. | The program does not start. | The sunroof closing sensor is faulty. | Check the specified sensor. |

| E45. | The program does not start. | The elements of the hatch lock triac control circuit are faulty (its elements, like the triac, are located on the electronic controller). | Check the elements of the hatch lock control circuit. Restore damaged ones. |

| E51, E53. | The drum does not rotate. | Short circuit in the control triac of the drive motor. | Check and, if necessary, replace the drive motor control triac. Or buying a new module. |

| E52. | The drum does not rotate. | The signal from the tachogenerator of the drive motor is not sent to the electronic controller. |

|

| E54. | The drum rotates in one direction. | “Sticking” of one of the contact groups of the reverse relay (there are two in total) of the drive motor. | Check and, if necessary, replace the reverse relay. |

| E55. | The machine suddenly stops working, stopping the drum rotation process. | Open circuit in the engine circuit. |

|

| E56. | The washing machine stops rotating the drum 15 minutes after it starts working. |

| Install a new tachometer generator. |

| E57. | The machine stops working (at any stage of the program). | The current exceeds the threshold value >15A. |

|

| E58. | The machine stops working (at any stage of the program). | The motor phase current exceeds the threshold value>4.5A. |

|

| E59. | After setting a new rotation speed other than zero, there is no tachometer signal for 3 seconds. | There is no tachogenerator signal when performing the drum acceleration task. |

|

| E5A. | Overheating of water. | The temperature of the cooling radiator on the module exceeds the threshold value (88°C). | Replace the electronic unit. |

| E5B. | Does not work. | The DC bus voltage drops below the threshold (<175V). |

|

| E5C. | The washing machine does not turn on or stops working unexpectedly. | The DC bus voltage rises above the threshold value (>430V). | Replace the electronic unit. |

| E5D,E5E. | The washing machine has stopped working. | FCV is unable to receive and/or send a message within 2 seconds. | Change the electronic unit. |

| E5F. | The machine refuses to start (or continue to operate). | The FCV control board continuously requests configuration parameters due to repeated resets. |

|

| E61. | When heating water, its temperature does not reach the set value within a certain time. | ! This code is not available for reading in the normal operating mode of the SMA - it is displayed only in the diagnostic mode. | If necessary, you can check the heating element - its resistance should be about 30 Ohms (at room temperature). If there is a discrepancy, replace it. |

| E62. | While heating the water, its temperature reached more than 88°C in 5 minutes. |

|

|

| E66. | Heating does not correspond to the selected mode. | The heating element relay is faulty. | Check and, if necessary, replace both the heating element relay itself and its control circuits. |

| E68. | Doesn't respond to commands. | The leakage current in the washing machine is too high. | Replace the heating element or replace other components. |

| E71. | No water heating. | The resistance of the temperature sensor is outside the specified limits.

|

|

| E72, E73. | The dryer heats up laundry excessively or does not dry it. |

|

|

| E74. | Incorrect temperature values. | NTC (temperature sensor) is in the wrong position in the tank. | Check the position of the temperature sensor. |

| E82. | The wrong program is running. | Selector position selection error. | The electronic unit is faulty (incorrect configuration data), selector, electrical wiring. |

| E83. | The program is not running. | Error reading data from the selector (this code can only be read in diagnostic mode). | Incorrect machine configuration, replace the electronic unit. |

| E84, E85. | The washing machine does not carry out the operating program. |

|

|

| E91, E92. | The washing machine does not carry out the operating program. | Communication error between the user interface and the main unit. | Install a new module. |

| E93. | The machine does not turn on. | Washer configuration error. | Such a defect can be eliminated by entering the correct configuration code. |

| E94. | The machine does not turn on. | Errors in SMA and cycle (program) configuration. | It is necessary to rewrite the non-volatile memory of the controller or replace the control module. |

| E95. | The program is not running. | Communication error between the processor and non-volatile memory located on the electronic controller. |

|

| E96. | Does not enter the wash mode or performs the program incorrectly. | Mismatch between the configuration of the electronic controller and the external elements that are connected to it (or not). | Check the conformity of the configuration of the electronic controller and its external elements. |

| E97. | Does not enter the wash mode or performs the program incorrectly. | Inconsistency in the operation of the program selector and the software of the electronic controller. |

|

| E98. | The drum does not rotate. | Mismatch between the engine control unit and the main electronics. |

|

| E99. | Incomprehensible signals are heard. | Abnormal connection between the sound unit and the input/output electronics. |

|

| E9A. | Incomprehensible signals are heard. | The hardware/software between the speaker and the input/output electronics is faulty. | New electronic unit or repair. |

| E9B, E9C. | The program does not start. | There is no data exchange between the microprocessor and the board's flash memory. |

|

| E9D. | The washing machine performs the operating program more slowly or faster than the set period, and may also not include a delayed washing program. | Problems with the machine's internal clock. |

|

| E9F. | The program is not running. | Lack of communication between the inverter board and the main control board. |

|

| EA1. | The washing machine rotates the drum with uncharacteristic sounds different from normal, or does not rotate at all. | Positioning system malfunction. |

|

| EA2. | The drum does not rotate. | Drum position recognition error. | Replace the main unit or repair. |

| EA3. | The drum does not rotate or only rotates in one direction. | Positioning cannot fix the motor pulley. |

|

| EA4. | The drum does not rotate well. | Rotation sensor malfunction. |

|

| EA5. | The drum does not rotate. | Malfunction of the thyristor of the drum rotation sensor. | Resolder the thyristor or replace the main unit. |

| EA6. | There is no signal about drum rotation. The work process stops |

|

|

| EB1. | The washing process does not start, there is no response to commands. | The frequency of the supply network does not correspond to the permissible frequency. | Check the power supply parameters. |

| EB2. | The washing process does not start, there is no response to commands. | The supply voltage is above the permissible limit. | Check the power supply parameters. |

| EB3. | The washing process does not start, there is no response to commands. | The supply voltage is below the permissible limit. | Check the power supply parameters. |

| EBE. | The washing machine does not turn on. | The safety circuit relay is faulty. | Replace or repair the electronic module. |

| EBF. | The washing machine does not turn on. | Protection circuit recognition error. | Replace or repair the electronic module. |

| EC1. | Water does not fill up. | The fill valve is blocked. |

|

| EC2. | The rinsing does not stop or takes a long time. | Malfunction of the water transparency sensor (if equipped). | Replace the turbidity sensor. |

| EC3. | The program has stopped. | Incorrect operation of the weight sensor. |

|

| Ed1. | The washing machine does not run the set programme. | Lack of interaction and exchange of data from two boards: the SMM control board and the main board of the electronic unit. |

|

| Ed2. | The machine does not dry washed laundry. | The drying resistor relay is broken. |

|

| Ed3. | The machine does not dry the laundry well enough. | Failure of the second drying resistor relay. |

|

| Ed4. | The washing machine does not dry items after washing. | The relay that provides power between the washing and drying resistors has failed. |

|

| EF1. | Doesn't drain water or takes a very long time. |

|

|

| EF2. | Too much foam. |

|

|

| EF3. | Sudden stop. |

|

|

| EF4. | Water does not fill up. | There is no signal from the flow sensor when the fill valves are turned on. The water tap is closed or there is insufficient pressure in the water supply. |

|

| EF5. | Doesn't wring out. | Spin cycle interrupted, imbalance too large >1200g. |

|

| EH1. | Doesn't turn on. | The supply voltage frequency is outside the permissible limits. |

|

| EH2. | Doesn't turn on. | Supply voltage too high. Inappropriate power source. |

|

| EH3. | Doesn't turn on. | Supply voltage too low. Unsuitable power supply or network interference. |

|

| EHE. | Stop work. | The safety circuit relay is faulty. | Change the electronic unit or resolder the relay. |

| EHF. | Stop work. | Protection circuit recognition error. | Replace the electronic unit. |

| C0. | Water does not flow or flows slowly. | The water level sensor is faulty. | Change the pressure switch. |

| C1. | Water is not flowing. |

|

|

| C2. | The program does not start |

|

|

| C3. | Doesn't drain water. |

|

|

| C4. | The water drains slowly. | The drain pump is faulty. | Replace with a working one. |

| C5 | Stops during washing. | Electric motor sensor overheating. | Replace sensor or motor. |

| C6. | Not enough water is being added. | The pressure switch is broken. | Install a working pressure switch. |

| C7. | Weak water heating. | The heating element is damaged. | Install a new heating element. |

| C8. | Weak water heating. | The thermistor is faulty. | Replace temperature sensor. |

| C9. | The drum rotates slowly. | Tachometer failure. | Install a new tachometer generator. |

| CF. | The program does not start. | Memory failure. | Replacement or repair of the control module. |

| CD. | The program does not start. | The hatch is not closed. | Close the door until you hear a characteristic click. |

| F2. | No water heating. |

|

|

| F4. | Water does not drain. |

|

|

| F5. | The machine cannot fill the tank with water to the required operating level: it collects and drains water at the same time. |

|

|

| F8. | The water level in the washing tank of the machine exceeds the permissible level. |

|

|

| F9, F12. | No drum rotation. |

|

|

| F13, F14. | The machine may stop or will not run the program. | Control module failure. | With proper diagnostics, it is possible to repair the electronic controller. |

Aeg washing machine programs

The devices have a convenient display on which the progress of programs is displayed using icons and numbers. The marking corresponds to the main characteristics of the model.

Different models are equipped with different types of displays; more information about the symbols can be found in the operating instructions. Look at the main indicator values.

Electrical and electronics breakdown

If there are failures in the electronics, you can see a certain group of codes on the display. Problems can be caused either by problems with the main electrical network or by damage to the machine’s wiring. Let's look at the designations of this category.

- E91 - informs about a communication failure between the control board and the washing machine interface. The way out of this situation is to replace the main control unit.

- E92 - indicates inconsistent operation of the user interface and the main control module.

- E93 - indicates that the washing machine is configured incorrectly. Specifying the correct configuration code will help eliminate the inaccuracy.

- E95 - indicates a violation in the “processor - non-volatile memory of the washing machine” circuit.

- E96 - signals an incorrect configuration of external parts (in particular the controller).

- E97 - indicates that the washing mode switch knob cannot function in harmony with the control module. This may be due to a configuration error or a malfunction of the main unit.

- E98 – informs about inconsistent operation of the unit motor and the control unit. It is necessary to either replace the circuit wiring or replace the control board with a working part.

- E9A - indicates a software violation between the electronics of the washing machine and the speaker. You can get rid of this code only by changing the main control module.

- EH1 (EB1) – indicates that the network voltage exceeds the permissible limit. Perhaps there is interference in the electrical network, or the power supply of the washing machine is not entirely reliable. If everything is normal, you should check the control unit.

- EH2, EH3 (EB2, EB3) – errors inform the user about too high and low voltage in the power supply network, respectively. In both cases, a change in electronics will be required.

- EHE (EBE) - indicates damage to the protective circuit relay.

- EHF (EBF) – signals that the protective circuit could not be recognized.

It is better to entrust repair work related to SMA electronics to a professional. The electronic module is the most expensive element of an automatic machine, so it is better not to repair it without special knowledge and skills.

Failure of individual elements and modules

And finally, we will analyze the error codes that appear on the digital display due to the failure of individual parts and elements of AEG brand washing machines. These include:

- E41 - indicates that the hatch door is not tightly closed; it does not lock in the desired position. Try pressing the door with force, if this does not help, you will need to repair the hatch locking device, the guide, or change the handle.

- E42 – detects a violation in the operation of the UBL. Inspect the hatch lock; if a defect is detected, install a new device.

- E43 – informs about damage to the main triac of the hatch door lock. The part will need to be replaced with a working one.

- E44 - says that the sunroof closing sensor is broken. By replacing the old sensor with a new one, you can eliminate this error.

- E45 – allows you to identify damage to the connection elements between the control triac and the UBL. All sections of the chain need to be checked.

- E82 - indicates a failure when trying to select a washing mode using the selector knob. Such an error may appear due to failure of the control board, broken wiring, or damage to the selector.

- E83 - indicates that the data from the washing program switching knob is not read by intelligence. The main module will have to be replaced.

- EF5 - appears when the washing mode is interrupted due to an imbalance in the drum. Solving this problem is very simple - you need to distribute things over the surface of the drum or reduce the volume of loaded laundry.

Depending on the model of the AEG brand washing machine , error codes may be displayed using different alphanumeric combinations. So, for example, for some washing machines, if the failures already described above occur, slightly different designations will be relevant:

- C0 – indicates failure of the pressure switch;

- C1 – says that water does not flow into the SMA tank;

- C2 – states that the hatch locking device is defective;

- C3 – informs about damage to the main control module;

- C4 – indicates a malfunction of the drain pump;

- C5 – signals overheating of the electric motor sensor;

- C6 – warns of failure of the pressure switch;

- C7 - indicates improper operation of the tubular heater;

- C8 – tells about a malfunction of the thermistor;

- C9 – indicates that the TAKH sensor is faulty;

- CF – signals a failure in the memory of the intellect.

What to do if a particular error is detected? First, study as much information as possible on this issue. Secondly, adequately assess your strength in resolving the issue that has arisen. If the repair is quite complex, which requires special equipment, as well as in-depth knowledge and skills, it is better to seek the help of specialists.

Interesting:

- Washing machines AEG

- Which is better: Bosch or AEG washing machine?

- AEG washing machine malfunctions

- Reviews of Aeg dishwashers

- Gorenje washing machine error codes

- Error codes for different dishwashers

Reader comments

- Share your opinion - leave a comment

Codes dedicated to water heating

Very often, the display of the AEG washing machine displays fault codes indicating damage to the heating element or thermistor. Let's look at the main designations of errors in this group.

- E61 - informs the user that the heating element cannot heat the water to the set temperature in the allotted time. It is important to diagnose the heater using a multimeter. A working heating element will give a resistance of 20-40 Ohms at room temperature.

This code will never appear during normal operation of the SMA; an error of this kind can only be determined during a service test.

- E62 – signals that within a specified period of time (5 minutes) the water temperature has exceeded 88 °C. In other words, the machine is overheating. First, examine the thermistor - you can check it with a tester. When measuring the resistance of the sensor at room temperature, the multimeter screen should display a value in the range from 5.7 to 6.3 kOhm. If the thermistor is working properly, diagnose the heating element and replace the part if necessary.

- E66 - warns that the heating element relay has failed. It is necessary to double-check the functionality of the relay, as well as its main circuit.

- E68 - indicates a very large current leak in the washing machine. To eliminate the failure, you should replace the tubular heater, and also check the elements directly associated with it: the temperature measurement sensor and wiring.

- E71 - indicates that the thermostat resistance is outside the permissible range. To find a way out of this situation, it is necessary to examine the thermistor for an open circuit or a short circuit of the thermostat. You should also inspect the heating element; perhaps it is the one that has failed.

- E74 – detects the displacement of the NTC temperature sensor in the system. To reset the error code, just check its location in the tank and, if it is displaced, install it in the right place.

- E3A - the designation indicates a breakdown of the heating element relay. In such a situation, the relay will need to be replaced.

Having seen one of the described codes on the screen, it is necessary to eliminate the problem as soon as possible. After all, problems with water heating can lead to even more serious consequences.