We continue the theme of homemade products and this time we will breathe new life into an old washing machine, make a grain crusher out of the washing machine for grinding corn, wheat, barley and other cereals.

To make a grain crusher, we will need a washing machine in the form of a barrel of the “Riga” type and its analogues; the design of such a machine consists of a barrel body, a stainless steel tank, an electric motor of 180 W and 1350 rpm and a starting device.

The structure of the Riga washing machine.

Of course, for a grain crusher such an engine will be rather weak, it is not designed for high loads and will quickly overheat, so to increase productivity you need to replace the engine with a more powerful one of about 1 kW, 3000 rpm.

Grinder grinder

Grain crusher from a grinder

You can assemble a grain crusher using an angle grinder (grinder) with a disc size (diameter) of 115 or 125 mm as an engine.

The assembly process of such a device consists of the following steps:

- A rectangular or round base is cut out of waterproof plywood 8-10 mm thick with a jigsaw.

- A round hole is made in the center of the base for the grinder gearbox.

- Diagonally from the central hole on the base, another hole is made for the grain bin.

- The chopper knife is made from hard high-carbon steel 1.5-2.0 millimeters thick.

- If necessary, the knife is released over the fire and a hole is drilled in the center for mounting on the gearbox shaft of the grinder.

- Using sandpaper, the knife is sharpened.

- The grinder is placed on the base, its round protrusion is placed in a pre-cut hole.

- Using a homemade clamp made of metal tape and two screws, the angle grinder is secured to the base.

- A sharpened chopper knife is attached and fixed to the grinder shaft.

- The old pan is cut in half, holes are made in its bottom with a 4 or 5 mm drill;

- The resulting sieve is secured to the base on the knife side using 4 corners, rivets or screws.

- The assembled grain crusher is placed on a capacious container - a bucket or large metal pan. A plastic 5-liter bottle with a cut bottom is inserted into the hole for the grain bin.

During operation, the grinder is connected to the network, and the constant speed of the knife is set with a locking button on the handle. To obtain flour, grain is poured into a homemade receiving hopper - a plastic bottle.

Be sure to read:

How to make a vegetable cutter for livestock with your own hands from scrap materials.

In this case, to regulate the flow of grain, a movable tin valve is inserted into the neck.

Grain crusher from a washing machine

Grain crusher from a washing machine

You can make a simple and productive grain crusher from an old vertical type activator machine (Oka, Volga, Fairy) as follows:

- The squeezing device is removed from the machine.

- With the washing machine on its side, unscrew the fixing (locking) screw or bolt on the activator pulley.

- Having installed the machine in the working position, the activator is removed along with the shaft.

- A plate of galvanized sheet metal of the appropriate size and shape is attached to the activator niche.

- The shaft is unscrewed from the activator.

- A trapezoidal knife is cut out of an old circular saw and rapid blade, the diameter of which is slightly smaller or the same as that of the removed activator.

- The knife is sharpened using sandpaper and secured to the shaft using two nuts.

- The shaft with the attached knife is inserted into the hole in the tank and secured in the pulley with a locking screw.

- To collect the final grinding product - flour - the drain hole at the lowest point of the tank is widened using a hammer and chisel, a piece of steel pipe is inserted into it and brought out at an angle.

- To prevent large particles from getting into the final product, a fine-mesh steel mesh or a sheet of galvanized sheet with holes 4-5 mm in diameter is installed in front of the hole for collecting flour at an angle of 60-700.

- To load grain into the removable lid of the machine, widen the existing hole and insert a 5-liter plastic bottle with a cut bottom into it.

The advantage of such a homemade grain crusher is that its assembly does not require drawing up a drawing or making a base for the engine.

In addition, it has good stability, has a spacious tank (up to 30-40 l) and low electricity consumption.

Crusher balancing process

Most equipment that uses rotating components as a working tool undergoes a balancing procedure. This work can be done either independently or with the help of invited specialists.

When balancing, the following sets of work must be performed:

- identifying the causes of vibrations and eliminating them;

- monitoring the condition of equipment in terms of vibration;

- balancing shafts in existing bearings;

Why is balancing necessary? The answer lies on the surface. The thing is that the presence of excessive vibration leads to failure of the bearing units, and as a result, everything can end very sadly.

Grain crusher from a vacuum cleaner

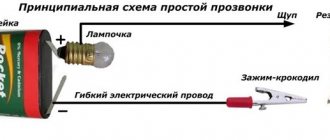

Grain crusher with an engine from a “Raketa” vacuum cleaner

To make a simple and reliable grain crusher, working but unused Soviet vacuum cleaners such as “Raketa” and “Saturn” are used.

Be sure to read:

How to check eggs for embryos at home: collecting an ovoscope with your own hands

The production of such a grain crusher is carried out as follows:

- The motor in the housing is removed from the vacuum cleaner.

- The chamber with the suction impeller is removed from the motor shaft.

- A round base is cut out of thick sheet steel.

- A hole is cut out in the center of the base for the motor shaft, and a hole is made on the side for the grain bin.

- The motor housing is secured to the base using screws and brackets.

- A trapezoidal pre-sharpened knife is attached to the motor shaft.

- A sieve made from an old saucepan with 4- or 5-mm holes in the bottom is attached under the knife.

For convenient operation of such a unit, it is attached to the container with special clamps and short self-tapping screws.

Important! The hole into which the grain bin is inserted and through which raw materials are supplied for grinding must be located in the rotation zone of the chopper knife. If the rotation zone of the knife does not completely cover the feed hole, not covering 1 centimeter or more, most of the grain will spill out and not be crushed, thereby clogging the sieve.

Design features

It’s not just the financial component that forces you to start making grain crushers yourself. Yes, for factory models they sometimes ask for 10-20 thousand rubles or more. Someone is willing to pay that kind of money. Others have them, but they don’t see the point in overpaying when you can assemble everything yourself.

In fact, a grain crusher can be thought of as a coffee grinder enlarged several times. Grains are also loaded there, after which the device starts up and the process of crushing into small fractions begins.

But still there is a difference. And it consists in the following points:

- The coffee grinder turns the beans into powder. The crusher creates fractions of coarser grinding, and their size can be adjusted with a replaceable sieve.

- Devices for crushing grain are capable of processing several tens or hundreds of kilograms of product per hour. A coffee grinder has limited capabilities.

- The equipment has the ability to work for a long time without stopping. Some are capable of crushing for several hours. Others recommend turning it on for a maximum of 1 hour followed by a break.

Structurally, grain crushers have certain components.

The device consists of:

- Protective housing. Assembled from metal, plastic or composite materials.

- Supports. It is installed permanently and in a specific place, or can be removable for carrying equipment.

- Bracket. Its adjustment is carried out using a bolt and nut.

- Second basics. It has a special softener. Looks like a rubber shoe.

- Pairs of motors and pulleys.

- Seals. Necessary to soften vibration during equipment operation.

- Knives. With their help, grain and other products are crushed.

- Funnels. Through it, raw materials are poured into a bunker for subsequent processing.

- Locking mechanism.

- Removable grilles. They are needed to regulate the size of the fractions passed into the container for ready-made raw materials.

- Rubberized wheels.

All these components can be installed at home on a washing machine that is no longer suitable for performing its direct duties.

Grain crushers assembled on the basis of an automatic machine have the highest productivity and capacity.

When selecting or manufacturing components, it is necessary to start from the overall dimensions of the base from which the grain crusher is made. Without balancing, homemade units will not be able to work properly.

Types of grain grinding machines

Types of machines for grinding grain

Depending on the grinding method, design and location of the working parts, there are 4 types of grain crushers:

- Rotary – crushing of grain in such devices occurs due to a rotor located horizontally and moving at high speed.

- Hammer crushers - the design of such grain crushers includes a rotating vertical drum and stationary hammers located in a circle, against which the grain is crushed. When grinding in this way, the finished flour is poured down and, passing through a sieve, ends up in a container placed under the deck of the housing.

- Roller crushers crush grain due to 2 rollers located in one chamber, rotating towards each other. At the same time, the gap between them is so small that the incoming raw material is not simply crushed, but, due to high speed, is crushed into dust. The advantage of such devices over others is the ability to crush grain with high humidity.

- Millstones are grain crushers in which grain is crushed when it gets between two discs (millstones) located with a small gap. In this case, one disk rotates at high speed, and the second is stationary.

Be sure to read:

How to make a feather removal machine with your own hands: an economical option from a washing machine

Among these varieties, the most common are rotary and hammer ones - they are more productive, reliable, and easier to repair and maintain.

How to make a crusher mill with your own hands

Making a grain crusher with your own hands is not that difficult. To do this, you need to have on hand a motor from an old household appliance, for example, a vacuum cleaner or washing machine.

In addition, you must have some locksmith skills. By the way, when assembling such equipment with your own hands, you need to remember the safety rules. Since all engines operate on electricity, it is necessary to take all measures to reduce the traumatic risk of the assembled product.

We must not forget that fast-rotating parts are used as a working body, which can cause injury to the person working on it.

Structure of a grain crusher, design features of the machine

Manufacturers put a variety of crushers on the market, with different characteristics, productivity, etc. Most of this equipment is easy to maintain and does not take up much space. As noted above, in practice crushers are used that use rotary or hammer principles in their operation.

Rotary machines have a drum with knives. In hammer mills, hammers are used as a working tool, which are loaded inside the drum.

By the way, there is equipment that uses compressed air as an energy source. The processed raw material moves inside the drum along with air. As a result of this, the quality of the resulting product increases dramatically. In addition, in this, and in many other designs, magnets are used that select metal particles that get into the mixture.

Crushers for home use

“Vikhr ZD-350K”

Among factory-made grain crushers, the following models are most suitable for private farms:

- "Whirlwind ZD-350K";

- "Zubr-2";

- "Three Little Pigs 350";

- "Farmer ISE-05";

- "Cyclone-350";

- "Bison 400";

- "NIVA IZ-250".

"Zubr-2"

Important! The average cost of a factory installation, depending on power, performance and brand, ranges from 2000-2300 to 6200 rubles. Assembling a homemade device if you have an unnecessary working washing machine, an old vacuum cleaner, or an angle grinder will cost only 500-1000 rubles.

"NIVA IZ-250"

Grain crusher performance

Productivity is the most important characteristic of grain crushers, which indicates the amount of grain they grind per hour (kg/h).

For homemade and factory models, the average is:

- Homemade units - up to 150-200 kg / h;

- Factory models - from 180 to 400-500 kg / h.

Moreover, in most cases, the productivity of factory crushers cannot be increased, while for any home-made unit this characteristic can be significantly improved by changing the power unit (engine) to a more powerful one.

Recommendations

To ensure that the shredder's performance is high enough, follow the advice of experts.

- Insulate the motor using an additional casing made from, for example, a large tin can. The fact is that the motor gets into a dusty environment - this dust is formed when grinding dry grain. The engine may become clogged with deposits, and its operation will slow down - a noticeable part of its useful power will be lost.

- Do not use the grain crusher at maximum speed, trying to grind tons of grain in one go. A large farm with large numbers of farm animals will require two or more grain crushers. It is better not to skimp on equipment so that it does not break down after a few days, but works for a number of years.

- Use grain collection containers with as large a capacity as possible.

- Clean and lubricate the mechanics every three months or six months. Regular maintenance - and scheduled replacement - require bearings, without which no electric motor would work.

- The listed measures will allow the user to process large volumes of grain without investing extra in repairs and without stopping urgent work.