How to check the operation of a washing machine?

What to check first in a washing machine

- outer casing of the washing machine;

- the inner surface of the drum, how easily it rotates by hand;

- documentation, coupon, instructions;

- complete set - all hoses for connection must be included;

- does the equipment work when plugged into the network?

Interesting materials:

Why does paint stick after drying? Why doesn't the paint come out of the spray gun? Why does oil paint take a long time to dry? Why doesn't enamel paint dry? Why can't putty be applied to paint? Why does car paint bubble? How long should the first layer of paint on wallpaper dry? How long should paint dry before varnishing? How long should paint dry? How many kg of paint per 1 m2?

Options for restarting equipment

If the Ariston washing machine freezes in the middle of washing and does not perform the specified functions, then resetting the parameters and starting the program again can help to restore it. To restore functionality, you must press the start button and hold it down for 10 seconds. The set program will be cancelled. After this, you need to re-set the parameters and start the required washing mode.

Perhaps an old-generation automatic machine, in this case it is enough to move the program selection knob to the neutral position. When the program is stopped, the indicator on the control panel should turn green and go out.

If light indexing does not occur, this may mean that the device is faulty or the equipment was stopped incorrectly.

If the program reset fails, a complete reboot may be required. In this case, you should do the following:

- the programmer knob must be moved to the neutral position;

- press and hold the “Start/Start” button for five seconds;

- disconnect the equipment from the network by unplugging the power cord from the outlet;

- After 15-20 minutes, connect the machine to the network and launch the desired program.

If the washing machine does not respond to pressing or turning the handle, you should immediately disconnect it from the network. It should be remembered that turning off the power while the modes are running can cause damage to the main control unit. If the actions do not help restore the functionality of the equipment, then you need to call a technician to repair the equipment.

If the power is cut off or there is a failure

If an unexpected power outage occurs, the equipment must be de-energized. To do this, you need to unplug the power cord from the outlet. Such actions will help to avoid breakdowns when voltage is suddenly applied.

After the power supply is restored, connect the machine to the network. If the program does not restart, the Ariston washing machine will continue to perform the set mode. On some models there is a special function that, after power is supplied, drains the water and goes into the neutral position. In this case, you need to select the mode again and start the washing process.

If problems occur, you need to find out the cause of the failure. There are two types - software or mechanical failure. In the event of a software failure, the control panel is locked and does not respond to presses. To correct the situation, you need to disconnect the washing machine from the power supply for 15-20 minutes. After that, connect to the network and start the required mode again.

If a mechanical breakdown occurs, you will have to use the services of specialists. They will find out the cause of the breakdown, make repairs or give recommendations for further action.

Interesting:

- Review of built-in dishwashers Ariston 45 cm

- How to reset a washing machine to factory settings?

- Rebooting a Bosch washing machine

- How to reset an error on a Bosch washing machine

- Child lock on a Bosch washing machine

- Resetting the washing machine program

1 reader comment

- 02/12/2022 at 20:17

Alexei:

Great article. Respect to the author.

Answer

How to determine the fault code - step-by-step instructions

In machines with a monitor, the cause of the malfunction is reflected on it in the form of an alphanumeric code. In older models, it is detected by the glow of indicators (washing modes, hatch blocking, etc.). For each error, a combination with an encrypted digital value is developed. To identify the cause of the malfunction, you need to perform the following steps:

Step 1. Determine the model of household appliances (look at the case or in the instructions for use).

Step 2. Remember which indicators were lit during the breakdown.

Step 3. Determine the digital fault code by checking the table in the instructions or on the manufacturer’s website.

Step 4. Check the table and eliminate the cause of the error, if possible.

Each washing mode on the front panel of the machine corresponds to numbers - 1, 2, 4, 8, 12, 16. If the indicators that correspond to the digital values 1 and 2 are lit, you need to look for error number F03 or F3. Do not forget that not all breakdowns can be repaired independently - sometimes it is better to contact a service center.

Attention! In different models, the indicators indicating errors are sometimes located in different places. Thus, in Aqualtis washing machines, failures are signaled not by washing modes, but by temperature indicators.

Table 1. Typical fault codes for Ariston brand cars.

| Error code | The problem it signals |

| F01 | Malfunction (short circuit) of the circuit that controls the drive motor |

| F02 | Tacho sensor or motor circuit malfunction |

| F03 | Temperature sensor error |

| F04 | Failure of pressure switch functions |

| F05 | Water supply/drain fault |

| F06 | Damage to UBL or control buttons |

| F07 | Failure of the heating element or pressure switch |

| F08 | Water heating relay malfunction |

| F09 | Machine memory (firmware) failure |

| F10 | Lost water level sensor signal |

| F11 | Failure of the pump responsible for draining water |

| F12 | Lost connection between the electronic controller and the display module |

| F13 | Malfunction of the drying temperature sensor |

| F14 | Drying fault (does not turn on) |

| F15 | Drying fault (does not turn off) |

| F16 | For vertical machines - an error in the operation of the drum. Models with horizontal loading do not have a code. |

| F17 (sometimes referred to as DOOR) | The door is open or does not seal against the rubber rim |

| F18 | Microprocessor failure |

| H20 | Incorrect water supply |

Video – All error codes + error indication without display

Hotpoint Ariston and its weaknesses

We continue the series of articles on repairing washing machines with your own hands! The Hotpoint Ariston range is very diverse and includes two dozen washing machines.

As an example: family 105 - arsl, arusl, arsf, armxxl, aqsf, then ariston 5050, 109 and 129. Let's decipher ARSL 105 (A - ariston, R - Russian assembly, S - depth 40 cm, L - no display, 10 speed spin 1000 rpm, 5 - noise level).

To be honest, everything is confusing and hard to make out. And troubleshooting during repairs is similar in all copies.

There are machines that have a liquid crystal screen, then if it breaks down there is an error code on it. And if it’s not there, then look at the flashing indicators of the front control panel!

- To determine the error code, you need to sum up the blinking LEDs according to the figure.

Ariston models HotPoint (1 pic) and AVL, AVSL (2 pics)

- Well, now the most interesting thing - error codes for Hotpoint Ariston washing machines with DIY fixes!

F01 - the signal between the control board and the engine is lost.

Make sure the network voltage is stable. It must be at least 210 Volts.

The motor control circuit is a rather capricious component of the washing machine mechanism. It would be a good idea to check the contacts yourself for corrosion and moisture. It is advisable to check every connection from the control board to the motor. It is possible that the problem may even arise from a loose motor block.

Using a tester, we measure the control voltages on the motor block.

The thyristor may have become unusable. Check the motor terminals.

Control board with brushed motor:

Control board with asynchronous 3-phase motor:

1 NTC thermistor. 2 Capacitor. 3 Throttle. 4 Diode bridge. 5 Power supply. 6 engine control processor. (Q1-Q6) - IGBT transistors.

F02 - lack of signal from the engine tachogenerator and electronic module.

We also check the engine block and module connector.

We make sure that the tachogenerator is working properly:

The resistance of the contact group in a quiet state should be about 70 Ohms. Without removing the probes from the coil terminals, rotate the motor shaft. The resistance must change. If this happens, then the tachogenerator is working.

F03 - break in the temperature sensor (thermistor), closing of the washing heating element relay.

The sensor itself rarely fails. Usually there is no signal from the board (temperature sensor connector contacts)

F05 - the drain pump or pressure switch (level sensor) does not work.

About 80 percent of the time, a clog (filter, drain hose) or pump is to blame.

We clean the filter by removing the front panel with a flat screwdriver and twisting it:

The pump impeller must be clean and free of debris:

Place the washing machine on its side and separate the pipe from the tank and pump:

If error F05 pops up again, the reason is electrical, namely, why doesn’t the sump pump work?

We take a multimeter in our hands and start the draining program and measure the voltage at the pump terminals. It should be equal to 220 volts.

Its presence tells us that the pump needs to be replaced.

F06 - in Diagnostic models, indicates non-working buttons.

A rare mistake and here everything is clear.

F07, F08 - the heating element is not in the water, does not work (burnt out or broken).

Make sure there is water in the tank by looking into the drum. Next, remove the back wall and check the heating element with a tester:

F04, F08 - pressure switch (water level switch).

Presence of signal from connector J3.

Check the condition of the level sensor:

- contacts 2-4 are closed - level "EMPTY TANK" - contacts 2-3 are closed - level "FULL TANK" - contacts 2-1 are closed - level "OVERFLOW" (not less than half the level of the glass of the loading hatch.

Remove the top cover by unscrewing the two screws at the back. This sensor is located on top:

Why is it needed?

To adjust the water level in the tank: low, medium and high. Protection against overflow of the tank is also provided.

How to check? We just blow into it. You should hear clicks. There can be three of them. It depends on the water levels provided by the program: economical, delicate, half load.

F09 The memory card of the electronic board is faulty.

F10 - water intake time exceeded.

The filler pipe from the detergent cuvette to the tank may be clogged, or the water fill valve may not be working properly.

Also check the level sensor (see above).

F11 problem with the drain pump.

The pump winding resistance should be about 170 Ohms - measure with a tester. Follow the instructions for error F05

F12 - there is no signal between the control board and the program selector.

Carry out an external inspection of the board for damage to the elements.

If no burnt components have been identified, diagnostics of the control module and its flashing are required.

F13, F14, F15 the drying element is faulty (washers with a drying function).

F16 - the breakdown is due to the blocking of the drum (vertical loading machine).

F17 - problem with the hatch lock.

There is no power to the door lock - ring the contacts.

F18 - board processor.

Module diagnostics required.

H20 - error no water flow.

It often happens that the inlet filter is clogged and there is no water passage due to dirt.

Unscrew the inlet hose and clean the filter mesh at the inlet

In addition, check the water pressure at the inlet of the solenoid inlet valve and its serviceability.

More common Hotpoint Ariston malfunctions:

- The washing program does not start, the door lock light blinks frequently:

It gives an error and drains the water.

We change the motor brushes. We place the washing machine on its side so that there is free access from below. Attention! The detergent dispenser must be located at the bottom to prevent water from getting on the control board!

Disconnect the power connectors and unscrew the engine from the tank.

Don't forget to clean the collector and between the motor lamellas. They are covered with a copious layer of graphite dust. It needs to be removed. The most convenient way to do this is with a vacuum cleaner. The engine manifold should be cleaned with the abrasive part of a dishwashing sponge, and the degree of wear should be visually checked.

We install the engine in place, plug in the connectors, but do not put on the drive belt. It is necessary to perform the brush grinding procedure without load. To do this, we start the spin mode at the minimum available speed, visually and auditorily monitoring the operation of the engine. It should be smooth and without excessive sparking. Then we put on the belt and once again start the spin cycle at minimum speed with an empty drum.

- Water does not flow, the drum does not spin (the motor does not work):

The door is locked, code F-01 appears on the display, error H20

It is necessary to properly organize the drainage system. The tip of the hose should be at a height of 60 to 100 cm.

In addition, a break in the stream must be ensured when draining to avoid water being sucked back into the SM.

Detailed diagram of the tank with bearings and drum:

001 - screw m8x23 002 - bearing 25 x52 x 15 003 - screw m8x22 004 - bearing 20x47x14 6204 skf 004 - bearing 6206-2z 005 - o-ring 008 - fastening screw + washer 009 - cross member of a 46-liter tank, 01 0 - upper counterweight 11 kg 011 — suspension spring bracket 012 — tank spring l = 181 mm 013 — inspection window gasket 016 — front counterweight 017 — side hose clamp 019 — pressure switch tube clamp 021 — 46 l tank holder with hole. n1040325 024 - shock absorber 80n hole 8.15 025 - drum flange 46 l. 029 — cross with seal. 030 — pulley d=210 mm h=20 mm 031 — elastic belt l=1046-1051

Useful tips

Most automatic washing machines have a diagnostic system that detects failures during operation and directly issues an error code for the washing machine. In addition, this system allows you to run auto-test programs, with which you can check the performance of the washing machine in various modes.

Call the master

A technician will come out for diagnostics and repairs upon prior request. You can make a call by phone or through the feedback form on the website. Provide the service manager with the following information:

- Make and model of the washing machine (see the instructions on the body).

- What happened, when, after what, the main symptoms of the breakdown (needed to select tools and components before leaving).

- Optimal time for repairs.

- Contact details.

The technician will tell you why the malfunction occurred and what to do only after visiting and inspecting the washing machine. Most breakdowns are fixed within 1-2 hours; removal of equipment to our service is not required. Immediately after the repair is completed, the washing machine will be ready for use. In rare cases, repairs may require more time and a return visit from the technician. We are ready to order any components and perform complex software repairs, but this often increases the work time.

The exact cost of repairing a washing machine is determined taking into account its model, type, and cause of the malfunction. In the “Price” section you will find approximate financial terms of cooperation, the specialist will name the exact ones after checking. Diagnostics does not oblige you to order services from us, but in this case it will be paid.

You also need to drain the water

There may be an emergency need to access things (forgot your keys, money, phone in your pockets). In this case, it is not necessary to completely overload the Ariston washing machine. It is enough to stop the washing process, drain the water and open the door.

The algorithm of actions is as follows:

- the program is stopped by pressing the “Start/Start” button;

- the washing mode selection knob is set to the neutral position;

- select the “Drain” mode without the spin function;

- you need to wait until the water is removed and the door is unlocked.

If the functions of the automatic machine do not work, then you can drain the water using a compartment with a garbage filter. It is located at the bottom of the device on the right side on the front of the machine behind a special door. Before draining the water through the garbage filter, we recommend preparing rags and a bucket for water.

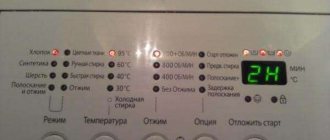

Bc a, Display

Page 17

- Image

- Text

17

KZ

Display

Display kurylgyny bagdarlamalagan kezde paydal zhane ote kop akparat beredi.

Bar zhuu cycldaryny nazmіmіmen i ske kosylgan cycldun ayaktaluyna deyin kalgan kakyt

A

bolіminde corsetіlady

(Display and cycle the maximum speed of the corset, remove the battery pack

zhuktemesi men tandalgan parametrlerge baylanysty bolgandyktan, ol birneshe mintan kein azayuy mumkin);

KESHIKTIRP BASTAU options ornatylgan bolsa, tandalgan zhuu cyclyn bastaluyna deyingi keri sanak

korsetіledi.

Tisti tuymeni bass arkyly ornatylgan zhuu cycles vysynda kurylgyda koldanylatyn yogary sygu

zhyldamdygy men temperature manderin nemese, ornatylgan zhuu tsiklymen syyysymdy bolsa, en songy

tandalgan manderdi koruge bolada.

Tandalgan zhuu tsiklyna saykes keletin "zhuu tsiklynyn kezenderi" zhane iske kosylgan zhuu tsiklynyn "zhuu

cycles of kezen"

B

More information about the corset:

Negіzgі zhuu

Shayu

Sygu

Agyzu

“Temperature”, “sygu” and “keptiru” (soldan ona karai) parameterlerine saikes keletin belgisheler

C

more than a corset.

"Temperature" zholaktary

Ornatylgan cycle ůšĭn tandaźga bolatyn œngary temperature dengein

korsetedi.

“Sygu” zholaktary

Ornatylgan cycle ushіn tandaug bolatyn yoghary sygu dengeyin korsetedi.

"Keshiktiru" tanbasy

, zhanyp turgan kezde, ornatylgan “keshiktirip bastau” mani displayde korsetilgen

bіldіredі.

ESIK KULYPTAULY

Shama indicator:

Janyp turgan tanba esik kulyptauly ekenin bildiredi. Kez kelgen zakymnyn aldyn alu ushin esikti ashpas buryn

Tanbanyn songenin kutiniz.

The ordinal cycle is reaped wherever you use your BASTAU/TOKATA TURU tymesin bass; ESIK KULYPTAULY

tanbasy oshse, esіkti ashuga boladas.

B

C

A