The impeller of the SMA drain pump often fails. In such a situation, experts recommend completely replacing the pump. But a real Russian person, undoubtedly, would be sorry to throw away a functioning pump because of a faulty plastic part. You can try to replace the impeller, and if the process goes smoothly, the pump will return to normal operation and continue to pump out water without any problems. Let's figure out how to remove the impeller from the washing machine pump and how to restore the functionality of the drain element.

How to remove the impeller from a washing machine pump

The impeller of the SMA drain pump often fails. In such a situation, experts recommend completely replacing the pump. But a real Russian person, undoubtedly, would be sorry to throw away a functioning pump because of a faulty plastic part. You can try to replace the impeller, and if the process goes smoothly, the pump will return to normal operation and continue to pump out water without any problems. Let's figure out how to remove the impeller from the washing machine pump and how to restore the functionality of the drain element.

Why is the drain pump most often beyond repair?

For two reasons. Firstly, most washing machine manufacturers install non-separable drain pumps. And secondly, for models with a dismountable pump, separate repair kits are still not available. Therefore, it is possible to repair the pump only if all its parts are intact, and the pump is simply clogged: small objects (thread, toothpick, sock, handkerchief, etc.) have gotten into it, which prevents the normal rotation of the impeller.

Note! If the blockage is not cleared in time, this can lead to overload of the pump motor and its failure or damage to the impeller. Therefore, if the first signs of a malfunction appear, it is recommended to call a specialist as soon as possible, because in this case, there is still a chance to get by with repairs, which are cheaper than replacing the part.

Impeller dismantling process

If you decide to remove the impeller from the pump with your own hands, we will help you with this. Let us present a detailed algorithm for dismantling a plastic part. So, after the drain pump is removed from the washer body, perform the following manipulations:

- cut off the plastic part located at the end of the impeller with a hacksaw;

- forcefully pull out the prefabricated base together with the impeller from the water pump;

- insert the removed structure into a vice and securely fix it in it;

- Take 2 flathead screwdrivers and, placing them on the bottom of the plastic screw, gently press upward on the impeller with upward movements.

At this stage, the main thing is not to overdo it and not to break the fastening of the drain pump impeller.

After lifting and pulling the impeller up, it should fly off the mount. When the plastic impeller is removed, you will see the shaft that powers it.

Now you need to remove the metal shaft from the overall structure. To do this, unscrew the vice from the tabletop, turn it over and reinstall it so that the compression bars are on the bottom. After this, the element to be disassembled is clamped in a vice in the area of the metal shaft.

Then you need to take a screwdriver, install its end into the upper hole of the shaft (it is important to choose a screwdriver of a size that matches the diameter of the hole) and carefully tap it from above with a hammer. The shaft should remain in the vice, and the structure remaining in the hands should be free to understand.

It is possible that the problem with the impeller was caused by abrasion of the rubber in the shaft area. Therefore, carefully inspect it and, if necessary, replace the rubber ring with a new one. The process of dismantling the impeller with your own hands is completed; you need to proceed to reassembling the element.

Restoring the impeller base

Half of the work is completed, now the logical question arises: how to restore the impeller base? If you managed to disassemble the structure correctly, then putting it back together will not be difficult. So, you need to do the following:

- insert the metal shaft into the plastic impeller; to ensure a tight connection, you can press it into the seat with a screwdriver;

- lubricate the rubber gaskets of the structure with lithol;

- attach the shaft with the impeller on it to the rubber part;

- clean the internal cavity of the pump (where the impeller base will be inserted);

- install the structure inside the pump (it will be attracted by a magnet).

- Apply sealant to the cavity in the area of the upper plastic part cut off from the impeller.

This way you can replace the pump impeller. The process happens quite quickly, it will take about one hour to complete the work. The main thing is to prepare all the tools necessary for repairs and imagine what the essence of the upcoming manipulations is.

Perhaps the pump is intact?

Do not immediately panic and disassemble the structure at the first doubt. First, figure out what kind of breakdown occurred, where it is located, and whether repair of the drain pump is necessary. It may not even be a faulty pump. The verification algorithm will be as follows:

- listen to how the drain pump works;

- examine the garbage filter, check it if necessary;

- inspect the drain hose; if there is a blockage, clean it;

- check whether the impeller rotates freely; perhaps its movement is being inhibited by something;

- examine the wires and sensors leading to the pump.

You can determine a malfunction by ear; you don’t have to be a master to do this. Listen to your washing machine, especially when draining the water from the tank. If the washer operates without making any extraneous noise, you will have to disassemble the body a little to be able to check the drain hose, filter, and wiring.

Source of the article: https://mashmaster.ru/snyat-krylchatku-s-nasosa-sm/

Repair of machines that require vertical loading of laundry

The path to the pump in machines of this type lies through the side panels, so installing the pump here is somewhat more hassle than in the previous ones. You can remove the side panels as follows:

- Remove the screws located on the back of the panel;

- Remove the screw that secures the panel and is located in the lower side corner of the panel;

- Remove the back panel;

Next, you need to carry out all the actions as in previous cases. Checking the correct installation of the pump is carried out in a similar manner before installing the side panel.

It should be noted that replacing pumps in Hansa brand machines is carried out according to the first option, but taking into account certain features. The fact is that the front panel does not need to be removed. To work, you can remove the base wall, which is secured with a couple of screws.

Please rate the article:

Join on Telegram

Removing the pump

Repairing the impeller is not easy - it will take at least an hour of painstaking work. But there are no risks, since the pump will have to be changed in any case. To get to the screw, you must first remove the pump from the washing machine. It is located at the bottom of the machine - attached to the volute, drain hose and pipes. The dismantling sequence is as follows:

Before dismantling the pump, it is necessary to turn off the power to the machine and disconnect it from the water supply!

- disconnect the washing machine from communications;

- drain the water by unscrewing the garbage filter;

- remove the powder receptacle (pull it all the way and, holding the central latch, remove it from the recess);

- lower the machine gun to the left side;

- find the pump;

- disconnect the wires and hoses connected to the pump;

- turn the pump clockwise;

- remove the device from the grooves.

If your LG washing machine model has a tray, you will need to first disable the Aquastop system. To do this, disconnect the power supply from the float and unscrew the holding bolts. The removed pump is placed on a flat surface with the impeller facing up.

Nuances of repair

One of the parts that can break is the washing machine drain pump. Although this is an inexpensive part, it is very important.

This pump is responsible for the final stage of washing, and can also recirculate water if the model does not have an additional pump for the washing machine.

Now let's look directly at the problems that can occur with this mechanism:

- This may occur as a result of small objects falling into the drum and clogging the filter

. The washing machine pump filter is not always able to cope with the load, and the pump may deteriorate. If a blockage has formed, the following symptoms are possible:

- Often the washing machine program freezes at the stage of draining water and spinning clothes;

- A grinding or cracking sound is heard when draining and spinning occurs;

- The washing machine starts working several times longer. It may be possible to clean the filter and repair the washing machine pump will not be necessary.

- If everything is normal with the filter, then check the impeller

. To do this, you need to scroll it manually. The impeller works jerkily, and if small objects get into it, it can jam. - If no problems are found in the first two stages, then check the operation of the drain hose along with the pipe that connects the tank and the drain pump volute

. Water may stagnate in the hose or small objects may become stuck. You can also check the pipe for blockages. - Once you have checked all the places where clogs can get in to interfere with the draining of water and the operation of the pump, you need to make sure that there is sufficient voltage at the terminals of the drain pump

. To do this, “ring” the wires for breaks.

The cost of repairing a washing machine drain pump will depend on the breakdown and model of the washing machine. Usually, calling a technician to the site and diagnostics are done free of charge (unless, of course, repairs are required).

The price of restoration varies depending on the complexity of the work from 1000 to 3000 rubles.

Cleaning the pump will cost about 800 rubles. Replacing a washing machine drain pump will cost about 1,000 rubles.

Pulling off the broken impeller

The second step is to remove the plastic impeller. In order to install a new one instead of a broken plastic one, you must act strictly according to the instructions. The algorithm is like this:

- cut off part of the plastic from the tip of the impeller (use a hacksaw);

- pull out the base along with the blades from the pump;

- fix the dismantled base in a vice;

- take two slotted screwdrivers;

- Place the screwdrivers on the bottom of the screw and press the impeller several times, moving from bottom to top.

You cannot put excessive pressure on the plastic - you need to gradually move the impeller up. As a result, its base will “fly off” from the fasteners and expose the shaft, which spins the entire system. The main thing is not to overdo it, otherwise you can break the threads on the axle and make further repairs useless.

Use WD-40 cleaner to remove stuck and rusted parts.

The next step is to remove the rod shaft from the pump. The vice is unscrewed from the tabletop, turned over and installed with the clamps down. The pump is fixed in them, or rather, its dismantled axis. Further instructions look like this:

- take a screwdriver commensurate with the diameter of the shaft seat;

- insert a screwdriver into the hole mentioned;

- tap the rod with a hammer (with light but increasing blows).

Building a Solid Foundation

Before you can put the impeller back in place, you need to restore its solid foundation. Afterwards you can put the structure back together. The general sequence is:

- insert the shaft into the new plastic impeller (to make the part “seat” more tightly, press it with a screwdriver);

- treat all rubber seals with lithol;

- insert the shaft with blades into the rubber ring;

- clean the “socket” for installing the impeller;

- install the shaft with the blades in the “socket” (they should be magnetized to the pump);

- Lubricate the top of the impeller with sealant (where it was previously cut off).

When replacing the impeller, be sure to use sealant - otherwise water will penetrate into the pump and the pump will break.

It will take about 60-90 minutes to dismantle and reinstall the drainage device. The work will go faster if you prepare the components and tools in advance, and also first study the structure of the pump and its rotating element.

Replacing a faulty part

Remove the pump in the step-by-step sequence described above. Examine the pump in detail and determine whether a complete replacement of the washing machine pump is required or whether the snail can be left.

Before installing the pump, it is necessary to clean the volute and the pump mounting area from dirt. Then the pump is screwed on and the pipes are connected.

A new pump is selected based on the following indicators:

- Mounting method: bolts or snaps.

- The location of the contacts is front or rear.

- Connection to the network - with terminals or chips.

- Power – from 19 to 20 W.

Is the impeller really damaged?

If there are problems with drainage, it is irrational to immediately begin dismantling the impeller. Damage to the propeller is a rare breakdown; more often the blades are blocked by debris, or the entire drainage unit fails. It is better not to rush into repairs, but first diagnose the drain system. Then it will become clear where the failure occurred and whether the pump requires inspection.

If the LG washing machine does not pump out water, then you need to pay attention to the following points:

- listen to how the drain works (whether it makes an intermittent noise or hums evenly);

- check the garbage filter for blockages (perhaps it is clogged and does not allow water to flow into the sewer);

- feel the drain hose (if it is squashed or clogged, it will require cleaning);

- turn the impeller by hand (it is important to make sure that it is not slowed down by hair or debris);

- assess the condition of the sensors and wires connected to the pump (are there any burnt out or loose contacts).

A broken impeller is not a reason to replace the entire pump. If desired, you can replace the plastic separately. The main thing is to make sure that the part is broken and follow safety precautions.

Source of the article: https://mashmaster.ru/snyat-krylchatku-s-nasosa-sm-lg/

Diagnostics

The first stage of diagnosis is to check for signs of incorrect pump operation. Before disassembling the structure, you need to make sure that the malfunction is related to the pump. A breakdown can be identified by the following symptoms:

- the water drainage mode has been activated, but the pumping system is not functioning;

- during the draining process, loud noise and buzzing are heard;

- the pump pumps out water, but more slowly than initially;

- During washing, the machine turns off spontaneously;

- You can hear the hum of the pump motor, but the water does not drain.

If one of the listed breakdowns is present, the pump will most likely need to be repaired. Before proceeding with dismantling and repair, you need to carry out diagnostic steps. To check, remove and clean the drain hose to get rid of the blockage, and then wash the filter. Next, include a test wash in the rinse and drain mode, and if the steps performed did not help eliminate the problem, you should proceed to repair work.

How to remove the impeller from a washing machine pump

Hi all. The LG machine is 7 years old, I changed the heater a couple of years ago, now it’s time for the pump. When draining, a specific roar began to appear, but she was still pumping out water. In order not to wait for a leak and emergency drainage of water through the door, it was decided to disassemble and look. The most important thing here is not to rush to call a repairman and try to fix everything yourself. The pump (pump) consists of a housing and, strictly speaking, the motor itself with an impeller. Initially, we remove the front panel and drain the water, the process is the same when we collect coins, pins, etc. from the pump. Next, remove the front panel and unscrew the front screws. On the reverse side, remove the wires going to the motor, loosen the self-clamping clamps and remove the inlet and outlet pipes. Now we dismantle the pump itself, unscrewing the three screws, install a new drive and mount everything in the reverse order. You can first connect the pump to the network, making sure that the impeller does not touch or snag the housing. In my case, the cause of the breakdown was wear on the front bushing of the impeller shaft, after which dirty water and sand began to get into the middle. Actually, the process itself:

Full size The impeller itself is made of green plastic

Full size After removing the front panel, unscrew the three front screws

Full sizePump still assembled

Full size Cause of failure: dirt, sand penetrated into the middle

Full size Pump with new motor

Full sizeAfter installation

Failure of a washing machine pump is not uncommon; That’s why we decided to understand the principles of repairing a drain pump, simultaneously highlighting the main breakdowns and signs of malfunctions. Frequent breakdowns We will highlight the most common breakdowns that specialists whose specialty is repairing household appliances have to deal with, simultaneously indicating the main reasons:

- Pump motor. The engine can fail - burn out - for various reasons. Among the most common: liquid ingress, excessive loads, natural wear and tear. Water can penetrate into the engine location as a result of a leak caused by a leak in any element: drain hose, pipe, hopper.

- Impeller. Rotation of the impeller may be difficult due to foreign bodies entering the structure or natural wear of the part. Mechanical damage (for example, cracks) means that the damaged element must be replaced.

- Making a rod with an impeller or an impeller on a shaft. The main reason is extremely long operation: these elements are usually not durable. The average service life of a drain pump is five years from the date of operation.

- Foreign bodies. If a foreign body gets inside the structure - even a coin lying in your pocket - it can block the operation of the washing machine pump.

Main featuresOnly a specialist can clearly determine whether the washing machine pump needs repairs: a layman will not be able to do this by eye. However, users can focus on the main signs that indirectly indicate pump failure (however, the problem may lie in a completely different component of the washing machine - this is worth remembering). Almost all of them are related to drainage problems; Let's list them:

- No drain. The most characteristic “symptom” that makes it highly likely that the washing machine pump has failed. If the motor is in order, then you should hear it working, and the sound should not be in any way strange. If the problem is in this particular device, repair of the washing machine drain pump will not be required - measuring the motor will be sufficient.

- Cracking sound when draining. The appearance of strange noises—primarily cod—indicates that a foreign body (coin, bra wire) has entered the structure, making rotation of the impeller difficult. Also, the root cause may be the deterioration of the rod (shaft) on which the impeller is fixed: when draining, the shaft dangles, and the impeller touches the pump housing.

- The machine fills with water and immediately drains. Another “symptom” of impeller rod wear. The motor drive does not engage the shaft well, as a result of which the impeller either rotates chaotically or does not rotate at all.

- Control module. Occasionally, a control module may fail, which literally “does not understand” the failure that has occurred in the system. However, usually a breakdown of the impeller does not affect its correct functioning. Keep in mind that any gaps may be due to a broken control module.

Benefits of professional services

It’s not difficult to call a technician to repair household appliances at home – just find an ad on the Internet or in a newspaper. However, the question often arises about the competence of such specialists, because replacing the pump of an Ariston washing machine requires experience and knowledge of the design features of various models. In addition, to ensure high-quality work results, you should always use original and new spare parts, and private owners often use used and refurbished components for replacement. Such a pump will not last too long, and your Ariston washing machine will soon end up back in the household appliance repair shop. Are the savings worth the hassle? We believe that it’s not worth it, so we offer residents of Dnipro and the region a completely different level of service.

Replacing the drain pump

If the impeller falls off the pump, it is recommended to install a new unit for pumping and draining water. We will try to explain clearly how to dismantle the old pump and install a new analogue. Note that the operation algorithm is quite simple and is suitable for washing units from various manufacturers - LG, Samsung, Beko, Atlant, Candy, Ardo:

- the washing machine is carefully laid on its side, soft material is first spread under it so as not to scratch the body part;

- if the machine has a bottom, you should unscrew the fastening bolts and move the pan to the side;

- after this the back panel is removed;

- you will have to feel the drain hose with your hands to make sure there are no blockages inside;

- the ring holding the pipe is loosened, after which the hose is removed from the drain pump;

- the screws securing the pump are unscrewed, the electrical wiring is disconnected, the pump is removed out;

- a new analogue is being installed. All actions are carried out in reverse order.

If you have washing equipment from Bosch, Siemens or AEG, you will have to act a little differently:

- First of all, the top panel is removed;

- the tray intended for filling in detergents is removed;

- the control panel fasteners are unscrewed, using a flat screwdriver, the latches made of plastic material are unfastened along the entire perimeter of the panel;

- Without disconnecting the electrical wires, carefully lay the panel on top;

- At the bottom of the washing machine there is a false panel (under the loading hatch door), which must be removed;

- loosen the clamp securing the cuff, remove it, tuck the rubber seal into the drum;

- disconnect the wiring going to the door lock;

- Unscrew the screws holding the front case panel and remove it;

- we find the drain pump and dismantle it;

- install the working element in the vacant space, connect the drain hose and electrical wiring;

- We assemble the washing machine in reverse order.

Cleaning the drain filter and checking the pump impeller

The drain filter needs to be cleaned approximately every three months. Manufacturers of washing machines always describe how to do this in the instruction manual, but equipment owners, unfortunately, rarely look there.

The drain filter catches debris contained in the soap solution that flows down the drain after washing.

If the owners of the washing machine neglect the operating rules, dirty water contains not only small particles of lint and thread, but also large ones:

- coins,

- paper clips,

- candy wrappers,

- bra wires,

- buttons and so on.

All this debris clogs the drain filter. This way the filter “saves” the pump itself from damage. However, it does not always manage to trap debris.

When the drain filter allows large debris into the pump, the pump fails.

To clean the filter you need:

- Disconnect the washing machine from the power supply.

- Shut off the water supply to the unit by tightening the special valve.

- Tilt the machine body back and lean it against the wall. Be careful and careful! Make sure that the heavy machine does not slip. Otherwise, a domestic injury cannot be avoided!

- After the machine door is unlocked, open it and empty the water from the drum. If the machine still manages to drain the water, skip this step and move on to the next one.

- Remove the lower decorative panel or open the small hatch at the bottom of the front panel (different models “hide” the filter differently).

- At the bottom (usually on the right) find a round drain filter, place a low bowl under it and place a rag.

- Turn the filter by hand and remove it from the snail in which it is located. At this moment water will flow.

- Clean the filter and rinse.

- Look into the snail (it’s better to illuminate it with a flashlight). The drain pump, or rather its impeller, will be visible.

- Clean the snail and impeller from debris.

- Rotate the impeller to make sure it is not blocked. The impeller should rotate but not be loose.

- Carefully inspect the impeller blades. They must be intact and undamaged.

If the pump impeller is not damaged and the blockage is cleared , wash in test mode.

If after cleaning the filter the problem of missing or slow drainage of water remains, check the drain hose . To do this, you need to partially disassemble the washing machine.

If the pump impeller is damaged , does not rotate well, has become loose or has fallen off, the machine will also have to be disassembled, but for the purpose of dismantling the broken pump.

Impeller installation

When it is not possible to buy a new drain element, you can use a simple, but not so reliable repair option - install the impeller on the sealant. An impeller fixed in this way will function normally for some time, but soon it will fall off again and the drain system will fail.

However, if the impeller is broken and there is no time for normal repairs, do this:

- provide access to the impeller installation site;

- carefully “dry” the shaft on which the plastic element is installed;

- degrease the seat with a special compound, apply sealant or waterproof glue;

- install the impeller.

How to call a specialist

You can call a RemBytTech specialist from 8 a.m. to 10 p.m. every day, including weekends and holidays, by calling:

7 (495) 215 – 14 – 41

7 (903) 722 – 17 – 03

or using the online form on the website (24/7).

When contacting the RemBytTech workshop, please inform:

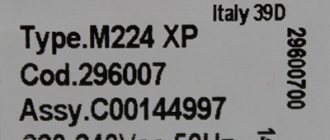

- The brand and, preferably, model of the washing machine on which the pump needs to be replaced. For example, Bosch Maxx 5 or Samsung S1005J. The exact model name can be found on the sticker on the body of the washing machine. This is required so that the technician takes with him a part suitable for your washing machine. If you have already bought a new drain pump, it is enough to indicate only the brand of the machine.

- Convenient day and time for the specialist to arrive.

- Your name, address where repairs need to be carried out, and telephone number.

On the day you set, the specialist will call you back to confirm the time of arrival.

The impeller turns - what to do?

In such a situation, the washing machine drains the waste water from the tank, after which the pressure decreases, and ultimately the dirty water is drained either for a long time or partially remains inside the machine. At first glance, the drain pump looks quite functional, the impeller is tightly placed in the place intended for it. Then what could be the problem?

Most likely, the impeller is turning. In normal operation, if you rotate the impeller manually, it will move in jerks, confirming that the magnet in the pump is coping with resistance normally. If the impeller begins to rotate freely without stopping, this means that a malfunction has occurred in the operation of the device. The cause of such spinning may be a foreign object that accidentally got into the drain system, or a normal defect made during assembly of the washing device.

Mechanical check

For a mechanical check, remove the snail. In this case, the movement of the impeller and the wear of the bushings are checked. Let's turn the impeller manually. In a normal state, its rotation occurs intermittently, as if in jerks. This is due to the rotor made of a permanent magnet. Next: shake the impeller from side to side across the axis. If there is significant play, it is time to replace the drain pump. If all the signs are normal, the last check is to connect the motor directly to the network using a pre-prepared wire with two terminals and a plug. The motor should start without any extraneous noise.

Article on the topic: Where to return a washing machine in Chelyabinsk

Useful tips

Do not rush to disassemble the washing machine and change the drain pump - first determine exactly what the cause of the breakdown is. To do this you will have to follow simple steps:

- “listen” to the pump;

- open the drain filter and clean it;

- clean the drain hose;

- determine how the pump impeller rotates;

- check the contact group and all sensors going to the pump.

A number of malfunctions can be easily determined by ear - just walk up to a running washing machine and listen. You should wait until the liquid is drained or withdrawn. When the pump starts to hum and tries to work intensively, but there is no water in the tank, or no sounds are heard from the pump, you have localized the breakdown.

Diagnostics

Most modern models of Bosch washing machines, for example the Maxx 5-6-7 series, are equipped with a self-diagnosis system, which greatly simplifies the identification of faults. In order to establish the nature of the breakdown, it is not necessary to contact the service center; it is enough to perform a few manipulations, and your machine itself will “tell” what the problem is. So, let's start performing the service test:

- Close the sunroof, move the program selector to the “Off” position.

- Pause for 2-3 seconds, move the switch to “Spin” (clockwise).

- When the Start LED flashes, press and hold the Mode Speed button. Watch "Start" - it should start flashing again.

- Turn the switch to "Drain" (clockwise).

- Release “Revolution Mode” (you didn’t forget to hold this position, did you?).

- Next, put the switch in the position corresponding to testing any component of the washing machine (3 – motor, 4 – drain pump, 5 – tubular electric heater (TEH), 8 – main wash water inlet valve, 14, 15 – quick automatic test). Below is a diagram of the switch and the location of the numbers that correspond to the position of its handle.

Here is a schematic image of the switch and an explanation of the positions of its handle.

Some models differ in the numbering of commands: for example, in the Bosch Logixx 8 washing machine, the motor is checked in the 4th position (by the way, in this washing machine you can carry out quick diagnostics by setting the switch to number 3). When the test is completed, an error code will appear on the display, which the instructions will help you decipher. In older models without a display, the error can be recognized by the glow of the LEDs, after which you can begin to repair the Bosch washing machine.

The photo shows the control panel of the Bosch Logixx 8 washing machine; Diagnostics of breakdowns in it is carried out according to the Bosch Maxx principle, only the numbering of commands is slightly different

It is somewhat more difficult for owners of older generation models - they will have to determine the breakdown based on its symptoms.

Signs of malfunctions and their causes

Devices from earlier years, for example Bosch WFT 2830 or Bosch WFF 1201, cannot independently diagnose problems, so the user will have to do this based on their characteristic symptoms:

- Water is collected slowly or not at all. This occurs due to the accumulation of debris in the inlet filter or a malfunction of the fill valve. The culprit of the breakdown may also be the water level sensor - pressure switch;

- water does not drain well. The problem most often lies in a clogged drain filter, failure of the drain pump or pressure switch;

- the water does not heat up. The heating element is almost always to blame for this. The heating element burns out for two reasons - natural wear or scale formation. Sometimes there is no heating due to problems with the control board or a malfunction of the temperature sensor;

- The drum does not spin. A belt drive transmits torque from the engine to the drum. If the belt falls off or breaks, the drum will not move. A more serious option is engine failure;

- loud noise during spin cycle. The reason usually lies in the destruction of the bearings.

In the photo Bosch Maxx 4 WFC 2060 is a model equipped with a self-diagnosis function

Any of the listed problems can be caused by a failure of the control module (electronic controller). Unfortunately, it is very difficult to repair this unit yourself; it is better not to try. Contact a service that provides repair services for Bosch washing machines at home. Specialists will resolder the board or replace it with a new one.

Changing the pump

If the impeller of the washing machine drain pump has come off, it would be best to install a new pump. We will try to explain in detail how to dismantle the old part and mount a new pump with your own hands. The algorithm of actions is quite simple and can be applied to washing machines of LG, Whirlpool, Ariston, Candy, Samsung, Beko, Ardo models.

- Carefully lay the automatic machine on its side; it is better to place a soft blanket under it to avoid damaging the body wall.

- If the washer has a bottom, unscrew the bolts holding it in place and move the tray to the side.

- Remove the back wall of the washing machine.

- Use your hands to inspect the drain hose for foreign objects and blockages.

- Loosen the ring securing the pipe and disconnect the hose from the drain pump.

- Unscrew the screws holding the pump, disconnect the power wires connected to it, and remove the element from the housing.

- Install a new pump; to do this, secure the part in the housing, connect the wiring and drain pipe.

If you are the owner of Bosh, AEG or Siemens washing machines, the algorithm of actions will be slightly different.

- Unscrew the bolts holding the top cover of the unit and remove it.

- Remove the detergent tray from the housing.

- Unscrew the bolts securing the control panel of the washing machine, then, using a flat-head screwdriver, unfasten the special plastic latches around its perimeter.

- Carefully place the control panel on the top of the case without disconnecting the power wires.

- Remove the false panel located at the bottom of the washing machine, under the hatch door.

- Loosen the clamp holding the hatch cuff, remove it and tuck the rubber seal inside the drum.

- Disconnect the wires leading to the sunroof locking device.

- Unscrew the screws holding the front wall of the case and move the panel to the side.

- Find the drain pump and dismantle it.

- Install a properly functioning element by connecting the drain hose and power wires to it.

- Reassemble the machine in reverse order.

This repair method will be the most correct. After completely replacing the drainage pump, the part will last for several years, while if you replace an impeller that has fallen off, you risk encountering the same problem after several wash cycles.

Preparation for work and disassembly

To repair or replace the water pump, prepare everything you need.

Accessories:

- New pump that fits your washing machine model. Before going to the store, you can remove the old part and show it to the seller. He will suggest a suitable replacement. If you decide to buy components on the Internet, an individual number is indicated on the pump, which you should use to navigate.

- Rubber gaskets.

- Impeller (in case of malfunction).

- Pulley and axle.

- Sensors and contacts for the pump.

Tools:

- Crosshead screwdriver.

- Multimeter.

After you have removed the pump for disassembly and inspected the impeller, check the condition of the rubber gaskets. If there is wear on their surface, replace them immediately.

To disassemble, you need to remove the pressure booster pump cover. Do this:

- Let's immediately look at how to remove and install the impeller if it breaks.

- First, the pump volute is removed - you need to unscrew the screws.

- Mark the location of the motor in relation to the volute and remove it along with the impeller.

- Now use a sharp knife to cut off the impeller blades and install everything in the reverse order.

During assembly, you can use a special lubricant for the pump.

To check the pump winding for serviceability, use a multimeter. How to ring the winding? Apply multimeter probes to the winding, measuring the resistance. If the winding is faulty, the part cannot be repaired. Needs a complete replacement.

For a modern person, a washing machine is an indispensable “assistant” in solving everyday problems. And you begin to appreciate all its convenience when it breaks.

And there can be many reasons why a washing machine breaks down. And some of them you can figure out on your own.

Installing the impeller in place

If you cannot quickly purchase a new drain pump, you can use a simpler, but at the same time not very reliable option - try to put the impeller in place using waterproof glue or sealant. If you fasten a plastic part in this way, you can correct the situation, but just for a few wash cycles. It will not be possible to operate the machine for a long time, since the impeller will soon fall off and the waste liquid drainage system will fail again.

So, if the impeller is broken, and there is no time to fully replace the pump, you can do the following:

- gain access to the impeller mounting point;

- thoroughly dry the shaft on which the plastic part “stands”;

- degrease the shaft with a special product;

- apply anaerobic sealant or moisture-resistant glue to the seat;

- “plant” the pump impeller on the shaft.

Please note that this method will not eliminate the problem, but will only help to temporarily cope with it. Try to replace the faulty drain pump with a new one as soon as possible. This way you can forget about the problem of draining water for many years.

If the impeller turns?

In such a situation, the automatic washing machine begins to drain the waste liquid from the tank, then the pressure becomes very small, and as a result, the water either takes a very long time to drain or does not drain completely and remains in the tank. At first glance, the drain pump may seem to be fully operational, the pump impeller “sits” tightly in place, so what’s the problem?

Most likely the impeller is turning. During normal operation, if you rotate it with your fingers, the impeller should rotate in jerks, this indicates that the pump magnet is overcoming resistance. When the impeller rotates freely and spins on the axis without stopping, it means that the device is not working properly. Such scrolling can be caused by foreign objects that periodically enter the drain system or by a banal factory defect.

There is only one solution to the problem - completely replacing the drain pump of the washing machine. You can purchase it at specialized retail outlets or online stores using the machine model number.

Source of the article: https://stiralmashinyinfo.ru/drugoe/kak-snyat-krylchatku-s-nasosa-stiralnoj-mashiny/

High level of service combined with excellent prices - “Repair at home”

To find out the exact cost of replacing your washing machine drain pump, check out our price list, which shows prices for the most popular household appliance maintenance work. And then submit a request to call a specialist, and within a maximum of 24 hours from the moment of his arrival at the specified address, you will receive a fully operational device at your disposal. In addition, when it is necessary to replace individual elements of equipment, we use only original new spare parts, which is the key to its long service life.