*Prices are only for the work of the master. Spare parts needed for repairs are paid additionally.

If your Hansa washing machine displays emergency code E21, do not hesitate. Operating faulty equipment can be dangerous for you and your home! Contact the professionals at RemBytTech:

RemBytTech specialists arrive in the shortest possible time: our internal standard is 24 hours from the moment the application is submitted. We carry out work at the client's home. We confirm the quality with a warranty card for up to 2 years. We have repaired thousands of washing machines: we will return your Hansa to service. Contact us!

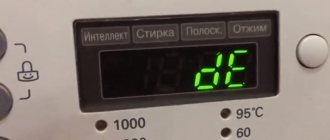

One of the advantages of most modern Hansa washing machines is the presence of a digital display that indicates the washing stage, the selected mode, time or other operational issues. Also, in the event of a problem, the screen signals the problem with an encrypted message, and one of the options reported by the “SOS” system is error E21. In order to correctly respond to the code that appears, you must first find out the nature of the failure. You will learn about the possible sources and extent of the problem with detailed instructions and instructions in this article.

The meaning of this code

It is not difficult to find out the meaning of the warning that pops up: just look at the instructions for the washing machine or the user manual for a specific model. If you don’t have technical papers at hand, it doesn’t matter, the list of fault codes is standard for most Hansa machines. So, with error E21, the machine reports that the drive belt has blocked due to the lack of a signal from the tachogenerator. By the way, the described problem occurs very often with this manufacturer due to engineering shortcomings. Sources of malfunction may be:

With a valid warranty, a car with E21 must be immediately sent for service. If the warranty period has expired, then in cases with the tachogenerator and thermal switch it is not necessary to contact professional repairmen. Diagnosing who is to blame and what to do is not difficult. The main thing is to act according to the instructions.

How to reset?

Usually, simply turning off and turning on the machine is enough to reset the problem. But if this method does not work, and it often does not work with errors E01 and E02, you need to remove the washing machine plug from the socket for 30-40 seconds, after which the door will automatically unlock.

If you have a fault with the main board, you can reset the error only after replacing the part.

Typically, many of these problems are found in older appliances. Worn parts are more susceptible to breakdowns and malfunctions. However, new models are not immune to any of these problems.

The main thing is to understand what malfunction the machine is signaling and change the corresponding parts in a timely manner.

For information on how to repair the electronic module of a Hansa washing machine, see below.

Checking the tachometer

To try to fix the problem yourself: you need to correctly determine the cause of the problem. In most cases, error E21 is caused by a faulty tachometer. It is located directly on the engine and is “responsible” for the intensity of the drum revolutions. To get to the sensor, you will have to perform a number of actions.

Important! Do not neglect markings or photographs so that during reassembly you do not mix up the contacts and perform correct installation.

When there are no doubts about the contacts and fastenings, we test the tachogenerator for performance. To do this, it is enough to measure the existing resistance or voltage. First of all, we check the resistance force by opening the connectors and applying the multimeter probes to the contacts. If the display shows numbers within 60-70 Ohms, then the sensor is working. Another option is to measure the current production. We switch the device to a new indicator and attach the connectors, turning the engine. The optimal value is about 0.2 Volts.

A negative result requires replacement of the tachometer. It is important not to make a mistake here, so we remove the removed part and take it to the store for clarity. The device is installed back in a similar way.

Testing the thermal switch

If the result is positive, we leave the tachogenerator alone and continue to search for a breakdown of the Hans washing machine in the thermal switch. We again disconnect the machine from all communications, open the back cover and pay attention to the heating element. Disconnect the wires going to the external thermostat and loosen the retaining fasteners. Then we remove the water heater and take out the thermistor located inside.

Now we check the sensor for sufficient resistance:

If the available numbers are far from normal, you will have to replace the thermistor. To repair the sensor, you cannot just purchase a new copy, focusing on the serial number and model of the washing machine. Subsequent installation of the device and assembly of the machine will not cause any trouble: we simply proceed in the reverse order.

Successfully passed tests with a thermostat and tachogenerator indicate one thing: the control board is to blame for the E21 error that appears on the display. Here it is better not to experiment with DIY repairs, since the control module is too sensitive to third-party manipulations. Any wrong movement will lead to large-scale consequences with an expensive call to the service center. It is recommended not to try to fix the breakdown yourself, but to immediately call a qualified specialist.

Error codes for Hans PA series washing machines

The error codes for Hans PA series washing machines partially coincide with the PC series codes, but there are also differences.

The hatch lock is faulty. The UBL or hatch lock may be broken. You also need to check the wiring.

Hans's washing machine does not fill with water. There is no pressure or low pressure, the pressure switch or liquid intake valve is broken.

The washing machine does not drain. The pump may be broken, the wiring may be broken, and the pressure switch may also fail.

The volume of water in the tank has been exceeded. Failure of the water level sensor or drain pump of the Hans washing machine, faulty board, contacts or wiring.

The temperature sensor is broken, the water is not heated or it is heated very slowly. Possible damage to the temperature sensor or its wires, low voltage in the network or malfunction of the heating element

The tachometer is damaged. The engine tries to start three times and then turns off. There may be a breakdown of the engine, tachogenerator, broken wiring or failure of the board. To reset the error, you need to check the motor and tachometer and replace broken components. You will also need to diagnose the board, ring contacts and wiring.

The tachogenerator does not produce a signal during a spin cycle. The engine tries to start three times, after which the washing machine displays an error and ends the cycle.

Diagnostics of the motor, tachogenerator and control board is necessary.

Error E10 indicates that the network voltage is too high or too low. It is necessary to install a voltage stabilizer or wait until the situation changes.

The engine is broken. There may be a short circuit or the control triac has failed. The washing machine motor will need to be replaced or the central board repaired.

The Aquastop system activated, notifying about a leak. To know what to do in such a situation, you need to make sure that the leakage protection is working properly, and then start checking all the elements of the washing machine to detect the location of the water leak.

The control board is broken. The program did not complete its work due to problems with the voltage supply or due to failure of the control module. You need to restart the washing machine; if the problem persists, you need to contact a professional to diagnose and replace the board.

Appears after turning on the washing machine and notifies that the control unit needs to be repaired.

Possible causes and their elimination in different parts of the machine

Water supply and drainage

E03 – (PA series) the cause of this error is the lack of water in the pipe, insufficient water pressure, damage to the electrovalves CV1 and CV2, a broken level switch, incorrect operation of the ASJ distribution valve of the Aqua Spray system.

Solution: updating the fill valve, replacing the pressure switch, repairing the control board; if there are distribution valves, they need to be replaced.

E03 – (RS series) the drain pump filter is clogged, the drain hose is clogged. The machine cannot start draining water.

Solution: The washing machine user should remove the cover from the pump and remove the clogged filter, clean it thoroughly and close the cover. Complete flushing of the drain hose.

E06 - incorrect operation of the drain pump, debris in the drain hose, faulty operation of the level sensor or wire connections.

Solution: replacement of the drain pump, temporary repair to get out of an emergency situation, complete cleaning of the drain hose, if possible, visually inspect and touch with your hands from start to finish, updating the pressure switch.

E12 - a quickly rectified error occurs due to water leakage into the pan, damaged contacts and wires, or incorrect operation of the float sensor (AS1).

Solution: this error can and should be fixed as quickly as possible. To do this, the user needs to do basic things; there is no need to call a wizard. First, visually inspect the washing machine and prevent water leakage, then restore the wiring and their contacts.

If after these steps the error is not resolved, then the user needs to change the float sensor.

Heat

E05 – incorrect operation of solenoid valves, oxidation of wire contacts, unstable supply of water pressure, incorrect operation of the electronic controller.

Solution: if the valves malfunction, you need to update the fill valve, mount/install a new pressure switch, remove the board and take it to a technician to repair the control board.

Visually check the wires or replace the faulty sensor with a new one or a working used one (temporarily as a way out); in the event of a malfunction, after applying the two previous steps, the user should try to replace the electrical unit.

Checking the wire contacts; if the user detects a fault on the wires, immediately replace the wires, replace the heating element, or you need to contact the power supply to correct the electricity reception.

Drum

E07 - incorrect operation of the M1 drive motor, the tachogenerator is inoperative, the problem is in the wire connections, the electronic controller is damaged.

Solution: for reliable and long-term operation of the motor, it is best to replace the drive motor with a new one, or for temporary work, take it to a specialist to repair the motor, update the tachogenerator, check and correct the wiring, repair or completely replace the control module.

E21 – the motor is not working, the wires are bad, which is why there is no connection between the controller board and the board.

Solution: initially check the motor, you need to carry out the appropriate diagnostics, and if possible, repair the motor. If the motor cannot be repaired, then install a new one instead of the old one. As well as checking the wires and their contacts. If oxide is detected, complete cleaning or replacement of the wires is required.

E08 – There may be several reasons. Incorrect operation of the drive motor, wire contacts may be damaged, the tachogenerator may be inoperative or the electronic controller may be inoperative.

Solution: repair or replace the drive motor, replace the tachogenerator with a working one, the user of the equipment needs to completely visually check the wires and their contacts. If possible, clean the contacts or replace the wires; if these solutions do not help in eliminating the identified error, then you need to repair or replace the control module of the washing machine.

Electronics

E02 - occurs in the following cases: if the electronic controller fails, if the electronic door lock device is not working, if the voltage is low, or if the wire is damaged.

Solution: replacement or repair of the controlled unit. This approach includes a thorough visual inspection, installation of a new UBL, restoration/cleaning/replacement of wiring.

E10 – when the washing machine is turned on or during operation, the power supply decreases or increases.

Solution: Carefully check the voltage at the outlet. At low voltage, it is recommended that the user of the equipment install a stabilizer to obtain a continuously stable voltage in the outlets. With the help of a stabilizer, the owner of the equipment will protect his other devices related to electricity.

E22 – malfunction of the drive motor triac.

Solution: visually inspect the electronic module. Check the module with technical equipment and, if possible, correct/repair this module. After checking the module by the user or specialist, if necessary, be sure to replace this module.

E11 – in this case there can be only two errors. The first is the poor or completely non-working condition of the TR8 triac. The second is the M1 motor inoperative.

Solution: To resolve the first problem above, you need to repair the control board if possible. If the board cannot be repaired, then you need to completely replace it. To eliminate the second reason, there is only one option - replacing the motor.

Without repairing the faulty motor, the user will not change anything. The M1 motor will continue to break down and cause damage to other parts. Because of this, it is recommended to install a new motor immediately.

E14 - this error can be detected when the process is interrupted during washing.

Solution: you need to check the voltage in the outlet, if the voltage is normal, you need to turn it on again and set the washing mode. If after these steps there are no changes, then the user of the washing machine must replace the old electronic controller with a new one.

E15 - the error is detected when the washing equipment is turned on or after selecting the washing mode settings, after 3 seconds after the “Start” command is given. Or with a faulty electronic controller.

Solution: this error, unfortunately for the user, cannot be resolved at home. There are two ways out of the situation: take the electronic controller to a household appliance repair specialist for repair; if the controller cannot be repaired, you need to buy a new control module and install it.

E32 - the failure may be caused by two factors. This is a burnt out sensor or a wiring problem.

Solution: the user must check the electronics for serviceability; if there is damage in the wiring, then replace the wire. If the wire is normal, you need to replace the NTC sensor.

Possible faults requiring repair

As a rule, emergency code E21 signals a serious breakdown. According to the experience of our service, the following malfunctions most often lead to errors in machines of this brand.

*Prices are only for the work of the master. Spare parts needed for repairs are paid additionally.

If your Hansa washing machine displays emergency code E21, do not hesitate. Operating faulty equipment can be dangerous for you and your home! Contact the professionals at RemBytTech:

Or submit an online application.

RemBytTech specialists arrive in the shortest possible time: our internal standard is 24 hours from the moment the application is submitted. We carry out work at the client's home. We confirm the quality with a warranty card for up to 2 years. We have repaired thousands of washing machines: we will return your Hansa to service. Contact us!

Rate this article: 4.9 1 5 15 votes (average 4.9 based on 15 votes)

Rare ciphers

There are error codes that appear on the display of Midea washing machines very rarely. Finding their decoding is quite difficult. But users who encounter these designations will definitely be helped by a brief interpretation of them.

If the machine produces an error, do not rush to panic and call a team of technicians to your home. First of all, try rebooting the equipment (turn off the power and let it sit for about 15 minutes). Often a simple reboot helps eliminate the code.

Source

Hansa washing machine: basic error codes

The Hans series produces 2 lines - Optimum and Comfort. They differ in their functionality and a number of characteristics. There are also external differences - the Optimum machine does not have indicator 21, as well as a difference in the purpose of some buttons; the controls on the SMA Comfort and Optimum are located identically.

You can find the main error codes for your Hansa washing machine on the Internet or in the instructions.

Errors:

The latter means that there are problems in the operation of non-volatile memory. This error indicates a failure in the electrical control module. The problem can be solved by replacing the board with a new one, or by trying to change the ROM and resoldering all the contacts on the board. Any of the errors requires immediate correction. It's better to contact a professional.

Description

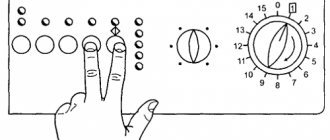

When using Bosch equipment, error F21 may appear not only in the form of a code of letters and numbers. On Bosch models that do not contain a display, the fault is indicated by a combination of flashing indicators located on the control panel.

Flashing indicators allow you to recognize a number of errors. Technicians who have extensive experience working with similar washing machines determine error code F21 offhand. But an ordinary user can also identify an error using indicators. To do this you will need a table of error codes.

On Bosch washing machines without a display, error F21 is displayed as follows. The washing machine freezes and does not respond to button presses. Also, the machine does not respond to turns of the program selector. At this moment, 3 lights on the control panel flash or light up at once: rinse, 800 revolutions and 1000 revolutions.

You can see how the F21 code is displayed on Bosch machines without a display in the picture below.

Older models spin at a maximum of 800 rpm. In this case, the rinse, 600 and 800 rpm indicators will light up.

Code F21 has a fairly simple interpretation. However, this does not mean that determining the causes of its occurrence will be easy.

This error may appear if the following malfunctions occur:

Also, code F21 may appear when the voltage in the supply network drops.

Source