Whirlpool washing machines are reliable appliances that enjoy well-deserved consumer trust. But, as with any household appliance, breakdowns and malfunctions can occur with them.

In such cases, the self-diagnosis system displays an error code on the display. In some situations this may be F08.

We will tell you what error F08 means in a Whirlpool washing machine in this article.

Possible faults requiring repair

If “rebooting” the module did not help, and error F08 still appears on the display of your Whirlpool, then we are talking about a breakdown of the washing machine. According to the experience of RemBytTech specialists, the following components fail in Whirlpool with this code.

| Signs | Breaking | Repair or replacement | Cost* (work only) |

| The Whirlpool machine writes error F08 immediately after turning on the program or takes in water, spins the drum several times and goes into error. In some cases, the washing machine may knock out the machine or RCD. | heating element (heater). The heating element is burnt out or breaks through to the housing. Most often, heating elements fail due to scale (it is formed from impurities in tap water, powder residues and lint from things). Trying to heat the water to the required temperature, the “overgrown” heating element works “for wear and tear”. As a result, either the spiral burns out or its body burns out. In the second case, the machine knocks out the plugs. |

*Prices are given only for the work of the master. Spare parts are paid extra.

If your Whirlpool washing machine has issued an emergency code F08 and is no longer washing, it’s time to contact the professionals. Call RemBytTech:

We arrive promptly: within 24 hours from the date of request for repairs. We carry out all work at the client's home. We confirm the quality with a warranty card for up to 2 years. We will do everything to ensure that your life returns to normal, and that your equipment delights you with trouble-free operation for many years to come!

Why does the Whirlpool washing machine malfunction, how can I fix the situation?

F08 almost always indicates the need to repair the equipment of the Whirlpool washing machine. But in rare cases, the problem may be due to a random combination of circumstances and a failure of the control module.

This situation can be resolved by rebooting the equipment . To do this, the Whirlpool washing machine is disconnected from the power supply and turned on again after a quarter of an hour. If the problem does not go away, you need to proceed to sequential equipment diagnostics.

Problem with heating element

The heating element is a heating element that is responsible for heating water in a Whirlpool washing machine. With prolonged use, it becomes covered with plaque, which is formed from hard water, detergent residues and small debris.

covered with a thick coating cannot ensure heating of water to the required temperature and burns out .

In this case, the washing machine may display an error immediately after starting or after the water has been filled and the drum has made several uncertain revolutions.

A heating element that has become unusable cannot be repaired; it is replaced with a new part. To do this, it is necessary to partially disassemble the device.

During the diagnostic process, the heating element must be “ringed” with a multimeter and visually inspected. According to statistics, when F08 appears, a problem with the heating element is the most common situation. In addition to code F08, error F12 may indicate a problem with water heating.

How to check the heating element in a washing machine - on video:

temperature sensor

If the temperature sensor fails, the Whirlpool washing machine cannot correctly determine the degree of water heating. In this case, operation stops and F08 is issued. The solution to the problem is to replace the part.

If inspection of the heating element does not reveal any malfunctions, then you need to check the thermistor. It is located near the contacts of the water heater.

For diagnostics, the part must be removed using the following algorithm:

- Remove the chip from the heater contacts with the wires.

- Loosen the nut that secures the heating element.

- Take out the thermostat.

The thermostat has a cylindrical shape and is made of metal. After it has been removed, you can measure the resistance using a multimeter with probes.

If the thermostat is working, then it is returned to its seat, and the search for a fault in the Whirlpool washing machine continues.

Control block

The control module is a block with radio elements . When they burn out, the control unit is no longer able to control the water heating process, and the operation stops.

To carry out diagnostics, the module is removed from the housing and tested. Faulty Whirlpool elements are replaced, tracks are soldered if necessary. If the module is severely damaged, it may even require complete replacement.

How to perform Whirlpool diagnostics and repairs - on video:

Firmware crash

The Whirlpool control unit has firmware that contains sequences of actions for each built-in program. If the firmware is faulty, the washing machine displays various error codes, including F08.

Such a breakdown usually occurs due to a voltage drop. The solution to the problem is to restore the Whirlpool firmware using a programmer.

Wiring

An open circuit in the water heating circuit in a Whirlpool washing machine or oxidation of the contacts can cause code F08 to appear on the display. The situation can be corrected by examining the wiring in the washing machine.

If a break is detected, the entire cable is twisted or replaced, and the oxidized contacts are cleaned.

Pressostat

A problem with the pressure switch is a rarer situation that leads to the appearance of code F08 on the Whirlpool display.

To analyze the condition, you need to gain access to the part. It is located in the upper part of the case, under the cover.

The pressure switch should be inspected externally and checked with a multimeter . If the resistance value does not change, the sensor has become unusable and will have to be replaced.

How to fix error F08 on a Whirlpool washing machine

Whirlpool automatic machines are distinguished by their build quality, reliability and high washing efficiency, and serve their owners faithfully for a long time. However, not a single household appliance is completely immune from breakdowns. For example, a situation may occur in which the user starts the washing process, the machine starts working normally, but after a while it stops and displays error code F08. We’ll talk further about what this designation means and what actions to take to fix the breakdown.

What would that mean?

A similar code may appear on the digital display at any washing step. It indicates that the temperature of the water in the tank does not correspond to the parameters specified by the program. This kind of malfunction on a Whirlpool washing machine can indicate either a minor problem or a serious defect that only a qualified technician can handle. It also happens that the error appears due to a short-term failure, and in fact there is no breakdown.

Before you undertake repairs yourself or invite a specialist, you need to make sure that this is not a normal malfunction of the washing machine. To do this, follow these steps:

If you have rebooted the unit and made sure that even with the standard parameters of the washing mode, this fault code appears on the display, you should start looking for a breakdown. Where to begin?

Prevention measures

Compliance with preventive measures helps prevent breakdowns and extend the life of Whirlpool equipment. These include:

- For washing, use only detergents that are designed for automatic processing.

- Do not send items for washing from which lint and pellets are separated.

- If power surges often occur in the house, then it is better to install a stabilizer in advance.

- Washing only at a high temperature or, conversely, only at a low temperature, contributes to a faster formation of plaque on the heating element.

- If the quality of tap water is low, it is recommended to install a filter at the entrance to the apartment to catch foreign impurities.

- It is necessary to clean the washing machine periodically.

Let's limit the range of breakdowns

The heating element, a tubular heater, is responsible for heating the water in the washing machine tank. In most cases, the F08 designation occurs precisely when the heater fails. If this is indeed the case, you need to replace the part with a new one. But a malfunction of the heating element is not the only reason for the appearance of such an error. The code can mean something else.

To begin with, you need to “weed out” the most minor and easily fixable faults. For example, diagnose a heating element, then a pressure switch or temperature sensor, and only after checking that this is not the reason, call a technician who can make a professional decision about the condition and performance of the control module of the Whirlpool automatic machine.

Calling a specialist: where to find and how much to pay a specialist?

Carrying out diagnostics and repairs of washing equipment cannot always be done on your own. If you lack skills or lack time, a specialist from a specialized company can help. Depending on the complexity of the breakdown and the company’s pricing policy, the cost for the work performed is determined.

In the capital, Whirlpool repair prices on average are as follows:

- wiring repair – from 2000 rubles;

- Firmware recovery – from 2500 rubles;

- repair of the control unit – from 2500 rubles;

- replacement of a temperature sensor – from 1600 rubles;

- replacement of heating elements - from 1800 rubles.

After the repair is completed, the operation of the washing machine is tested, and the technician issues a guarantee. In order not to make a mistake in choosing a specialist, you should seek help from a company that has been operating on the market for more than one year and has a good reputation.

Let's check the heating element

Often error F08 appears as a result of a heater malfunction. You can check the heating element very quickly. To do this, perform the following algorithm of actions (the sequence of steps described will help owners of machines with a front-loading type; for vertical machines, the manipulations will be slightly different):

Important! The heating element is located at the bottom of the machine, under a plastic casing; only by removing the protective cover can you gain access to the contacts of the heating element.

Next, disconnect the power contacts, take a multimeter and connect its probes to the terminals of the heating element, set the resistance on the device to 200 Ohms, analyze the results. If the value on the multimeter screen remains approximately the same as it was set, then the heater is fully operational. When the number 1 appears, this indicates a break inside the part and will have to be replaced. When the device displays the number 0 (or a number very close to zero), it means that a short circuit of the heater can be diagnosed, in which case you will also have to install a new heating element.

If the heater passes the first test with a multimeter, just in case, check it for breakdowns. To do this, switch the test device to buzzer mode. You will be notified that the mode has been selected correctly by a lit light and a characteristic signal that will appear when the wires are connected. Connect one multimeter probe to the heating element terminal, and attach the second to the element body. If the device does not make any sounds, everything is fine; if a characteristic squeak is heard, there are breakdowns in the body of the part, and the heater will have to be replaced.

Checking SM details

If you decide to start repairing it yourself, you should start inspecting the equipment. Code F23 is not the simplest. To understand how to deal with the problem, you should diagnose the internal parts of the SMA. To eliminate the error, you will have to dismantle several elements of the washing machine. If you doubt whether you can cope with the upcoming work, it is better to call an AMS repair specialist for help.

The first step is to check the pressure switch. The water level sensor is located under the top cover of the Whirlpool washing machine, on one of the walls. What to do after gaining access to the pressure switch?

- Carefully inspect the element, check that there are no defects on its body.

- Disconnect the pressure switch from the washing machine body and look for any blockages in the tube.

- Blow lightly into the tube - you should hear characteristic clicks.

- If you have a multimeter, test the contacts of the pressure switch with a tester.

If the pressure switch needs to be replaced, select its complete analogue in the store to avoid difficulties in the process of connecting the element.

If the water level sensor has completely passed the test and there is no need to repair it, you should inspect the heating element of the washing machine. The heater is located at the bottom of the tank body, behind the rear wall. It is not always possible to determine the breakdown of an element during a visual inspection. The heating element is tested with a multimeter, and the resistance of the heater is measured. The faulty element should be replaced with a new one.

The most difficult error to resolve is if it is caused by damage to the control module. To repair the main control unit, you must have a certain amount of knowledge and skills. To diagnose the control board you will need special tools.

Perhaps the problem is a failed resistor, an algorithm failure, etc. If you have little knowledge of connecting electronic circuits, it is better not to attempt repairs yourself, but to invite a specialist.

The principle of repairing a Whirlpool washing machine is practically no different from other brands. At the moment, SMs are produced, with vertical and horizontal loading, in the territory of the former Soviet Union, vertical ones are more common, but now more and more machines with horizontal loading are being repaired. Here it should be noted that both types have the same weak points, first of all we are talking about the control unit, which really does not like voltage drops.

As for the module, it is better not to repair this spare part yourself, but rather give it to a specialist. So, let’s put aside everything that has to do with brains and start talking about what you can do yourself. Next, I will list the error codes of Whirlpool washing machines and will immediately give a full explanation of how to repair this or that malfunction.

[custom_ads_shortcode1]

Let's check the thermistor

If the heating element has been fully tested and has proven that it copes with its functions perfectly, it’s time to check the thermistor. Just, it is located between the contacts of the heater. To remove the temperature sensor, perform the following manipulations:

The temperature sensor is a small metal cylinder. After the thermistor is removed from the washer body, you need to check the resistance in it using a tester.

When the temperature sensor fails, the old part should be replaced. The thermostat cannot be repaired. If the element is fully operational, we continue the diagnostics further.

We will inspect and test the pressure switch

It is easy to provide access to the water level sensor of the Whirlpool washing machine; it is located in the upper part of the unit, directly under the lid. Very rarely the pressure switch is located at the bottom. To get to the part, carefully unscrew the mounting screws and remove the upper wall of the SMA housing, after which the algorithm of actions will be as follows:

If after an external examination no defects were identified, you need to check the pressure switch with a multimeter. The device is switched to resistance measurement mode, the tester probes are connected to the sensor contacts. If the values on the screen change, it means that the contacts are actuated and the pressure switch is working. When the resistance value remains fixed, it means that the liquid level sensor has failed.

So, when you have checked the functionality of the main elements that can trigger the F08 error code, no faults have been identified, you should invite a professional to determine the root cause of the code. After all, the problem may come from the main control board, and it is not recommended to deal with it yourself.

Necessary actions

If you find error E01 on the display, you should diagnose the control board. Before starting work, turn off the power to your Whirlpool washing machine. Then you can begin to remove the board from the case and inspect it. Usually, a damaged element on the board can be seen with the naked eye.

First of all, inspect the Z0103 triac; it can literally “explode” on the board due to small voltage surges.

Then you should inspect a pair of resistors in the circuit, namely R9 - 1 kOhm and R36 - 470 Ohm. If the problem is a failed triac, you will have to dismantle it and replace it, along with the resistors described above. While working, it is advisable not to rush, but at the same time clean and solder the tracks on the control board. This will improve the contact of the elements.

Replacing the sunroof locking device can help fix the problem. It is the UBL ZV-446 that often breaks down. If, when carrying out repairs yourself, you decide to simply clean the part from carbon deposits and reinstall it, a recurrence of error E01 is inevitable.

How to fix error F08 on a Whirlpool washing machine

Whirlpool automatic machines are distinguished by their build quality, reliability and high washing efficiency, and serve their owners faithfully for a long time. However, not a single household appliance is completely immune from breakdowns. For example, a situation may occur in which the user starts the washing process, the machine starts working normally, but after a while it stops and displays error code F08. We’ll talk further about what this designation means and what actions to take to fix the breakdown.

What would that mean?

A similar code may appear on the digital display at any washing step. It indicates that the temperature of the water in the tank does not correspond to the parameters specified by the program. This kind of malfunction on a Whirlpool washing machine can indicate either a minor problem or a serious defect that only a qualified technician can handle. It also happens that the error appears due to a short-term failure, and in fact there is no breakdown.

Before you undertake repairs yourself or invite a specialist, you need to make sure that this is not a normal malfunction of the washing machine. To do this, follow these steps:

If you have rebooted the unit and made sure that even with the standard parameters of the washing mode, this fault code appears on the display, you should start looking for a breakdown. Where to begin?

Decoding the code

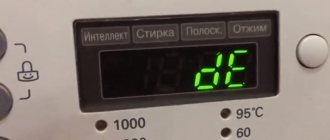

Code F08 indicates that there is a malfunction in the water heating circuit of the Whirlpool washing machine. In washing machines with a display, this problem appears as F08 or F8.

In devices without a display, the problem with water heating is manifested by the glow of the corresponding indicator lights:

- "Service";

- "Wash".

An error code may appear on the display immediately after pressing the cycle start button or after filling the Whirlpool tank with water. In the latter case, the washer may make several rotations and stop working with an error message.

Let's deal with light bulbs

The LEDs on the control panel of older Whirlpool models are located above the program switch knob. You need to count the light bulbs from left to right. So, the first indicator will be “No water supply”, the second will be “Pre-wash”, the third will be “Wash”, the fourth will be “Rinse”, the fifth will be “Water Hold”, the sixth will be “Drain/Spin”, the seventh will be “Door Open”. As for the lower ones, the eighth is considered the “Clean filter” diode, the ninth is “Service”.

It is through the blinking of some of these nine lights that the technology indicates a failure that has occurred in the system. It is necessary to count which LEDs are lit and figure out what kind of malfunction is indicated by a Whirlpool washing machine without a display.

Basic codes

If your Whirlpool washing machine suddenly stops working, be sure to pay attention to the dashboard. Using LEDs, the machine will indicate the error code and significantly narrow the range of possible problems. To restore the unit, you will have to figure out what failure occurred in the system and carry out the repair yourself or with the help of a technician.

You need to count the light bulbs from left to right, and very carefully so as not to confuse the serial number of the LED.

Let's look at the main fault codes for Whirlpool washing machines and the LEDs corresponding to each error.

If repairs to the main control unit are required, it is better to contact specialists so as not to damage the equipment even more.

To clean the powder tray, remove it by pressing on the plastic tab located in the rinse aid compartment.

As you can see, the same error can indicate different failures. Therefore, it is necessary to carefully understand the problem and conduct additional diagnostics of the equipment. The explanation of the fault codes is presented in the instructions for the Whirlpool washing machine.

Let's limit the range of breakdowns

The heating element, a tubular heater, is responsible for heating the water in the washing machine tank. In most cases, the F08 designation occurs precisely when the heater fails. If this is indeed the case, you need to replace the part with a new one. But a malfunction of the heating element is not the only reason for the appearance of such an error. The code can mean something else.

To begin with, you need to “weed out” the most minor and easily fixable faults. For example, diagnose a heating element, then a pressure switch or temperature sensor, and only after checking that this is not the reason, call a technician who can make a professional decision about the condition and performance of the control module of the Whirlpool automatic machine.

Whirlpool Error Codes

The list of malfunctions that you can deal with yourself is not limited to those described above. Knowledge of the machine's structure and the ability to understand its messages will allow you to solve most of the possible problems.

In any case, before you start repairing Whirlpool washing machines, you need to identify the malfunction and find its cause. The manufacturer has taken care of ease of repair; for this purpose, the firmware includes an automatic testing system, the result of which, in the form of an error message, is displayed on the indicator.

Problem with water getting into the machine. Errors: F01 (FH), F09, F13, F23

The first thing you should check when such errors occur is the presence of water in the water supply and its pressure. If the pressure in the system does not correspond to the nominal value, washing will have to be postponed until the water supply normalizes.

It is worth paying attention to the condition of the inlet valve. It contains a mesh that acts as a filter; if necessary, it should be washed or replaced.

If water flows into the machine normally, but an error still occurs, the reason may lie in the sensor that monitors the water level. It is worth checking the sensor itself, its connection, and possibly the control module.

The water supply is emergency shut off. Error F02 (FA)

This error may occur if the inlet valve is blocked. It must be checked and, if necessary, replaced. The same error may appear in the event of a water leak. It is worth carefully inspecting the installation site of the machine. If a puddle appears, the wash will have to be rescheduled until the problem is eliminated.

Problems with drainage. Error F03 (FP)

If the machine refuses to drain water, you need to check the entire drainage path. The reason may be a clogged filter, drain hose, or excessive bending. Such errors can be caused by a broken or clogged drain pump. In rare cases, the cause may be a controller malfunction.

Problems with water heating. Errors: F04, F05, F12

The machine does not heat water or its temperature parameters do not correspond to the values set in the program. The causes of this problem may lie in the heating element or temperature sensor. In any case, for repairs you will have to disassemble the device, test the heating element with an ohmmeter, and replace it if necessary. The same goes for the sensor.

There is no signal from the tachogenerator. Error F06

A tachogenerator is a small device that is installed on the engine to control its speed. Most often, the cause of this error is a spring washer that has flown off or a break in the conductors going to the device.

Motor controller problem. Error F07

The source of the fault is the controller board. To repair it, you need to remove it and replace parts that have failed.

Heating system problems. Error F08

The heater of a washing machine is one of its most vulnerable components. When in contact with water of poor quality, it becomes covered with scale, which significantly reduces its characteristics. This error may mean:

To troubleshoot, it is necessary to disassemble the machine, check and, if necessary, replace the heating element or faulty sensor.

Problems with the electric motor. Errors: F10, F15, F26, F27, F28

The appearance of any of these errors indicates a failure of the electric motor or connection circuit. To eliminate them, you need to check the temperature relay and control triacs on the board. Burnt parts will have to be replaced.

Errors F27 and F28 indicate the impossibility of rotating the motor in the opposite direction and its rotation is too slow, respectively. To correct the situation, it is necessary to check and, if necessary, replace the reverse and winding switching relay.

Problems with motor windings are more difficult to diagnose. It is possible that one or more windings may burn out, break in them, lack of contact, or damage to the insulation. In most cases, the engine will have to be replaced, with the exception of worn commutator brushes.

Various communication problems. Errors: F11, F19

Most often, the source of these errors is the inconsistency of the electrical network parameters with the required values. It is necessary to check the voltage in the outlet and take measures to normalize it. It would be a good idea to use a stabilizer to connect the machine.

Control system malfunctions. Errors: F14, F16

Errors appear in the event of various malfunctions in the controller. To correct the situation, you may need to re-flash the module, or possibly replace it completely.

Also, the cause of errors may be hidden in faulty wiring, a break in one or more wires running from the control module to actuators and sensors. In this case, it is necessary to “ring” each conductor and, if necessary, replace the damaged one.

Wrong detergent. Errors: F18, Fod

The sensor detects an excessive amount of foam, which can cause machine failure. It is necessary to replace the detergent and repeat the wash.

Problems with the controller. Errors: F20, F21

The first of these errors appears if normal program execution is impossible due to a malfunction of the control unit, the second due to the inability to transmit commands from the module to the actuators. To eliminate them, you need to disassemble the machine, check the integrity of the wiring and components of the controller board.

Violations in the water level control system in the tank. Error F24

The reason is that the pressure switch, the sensor that controls the water level, is not working. Replacement required.

Water level sensor

Firmware update problem. Error F31

This error indicates that an attempt to update via the Internet failed. You may need to check your router settings or contact your provider.

Problems with the hatch. Errors: F31, FDU

The appearance of these errors indicates that the hatch is not tightly closed or the corresponding sensor is not working. It is worth trying to open the hatch and close it again; if the error does not disappear, replace the sensor.

You can deal with most Whirlpool washing machine breakdowns at home. For this, a small set of standard tools, the ability to use them and, of course, desire are enough. Of course, you should not try to repair a machine whose warranty period has not yet expired, and you should not undertake repairs without having experience working with electrical equipment. It is important to soberly assess your strengths and, in case of the slightest doubt, contact a repair shop.

Whirlpool washing machine errors

There are error codes that can be easily reset by pressing the Start/Pause button twice. Of course, not every error can be reset, for example, if a breakdown related to the heating element is highlighted, then in order to clear this code, you will need to either replace the heating element or change the relay.

How to read the error code on a Whirlpool washing machine without a display

Now I’ll tell you a little about Whirlpool washing machines without a display, or rather I’ll explain how to read the code from these washing machines. Below you will see 2 photos of the control panel. The first photo shows the numbering of the LEDs, and the second photo shows an example of an error code and a table by which codes are determined in the SM. The whole point is to detect which indicators are lit and then look at the table to see what kind of failure has been displayed on your SMA, I think everything is so simple that even an ordinary person can count the failure. Photo 1. Numbering of indicators on the control panel of the Virpul washing machine Photo 2. Table of error codes for the Whirlpool washing machine

Error code F01 or FH

Over a certain period of time, water did not fill the tank , that is, the water level sensor did not give a signal to the brain that there was the required water level in the tank. Despite the fact that the module directly points to the pressure switch, you need to look at the root of this problem, that is, check everything related to water filling

Error code F02 or FA

The AquaStop system has activated . This error appears in cases when, after the main supply of water, the washing machine begins to draw again, that is, initially the pressure switch worked and stopped drawing, and then again and again gives a signal to fill with water. As a result, the control module blocks the fill valve. It happens that there is a leak in the tank, that is, something has broken through it. You also need to check the self-draining. In short, we check everything related to unauthorized leakage of water from the tank

Error code F03 or FP

For a certain period of time, the SM did not drain the water . It is very important that before this error code is displayed, the “Sud” code and only then you will see f02. There is no need to immediately change the pump, first you need to thoroughly clean the drain pump filter, the pipe that goes from the tank to the pump body and blow out the drain hose. If this does not help, you can think about replacing the pump and be sure to watch the video, although the procedure is simple, many make the same mistake related to the filter

Error code F04

The water did not have time to heat up in the allotted time . First of all, you need to check the temperature sensor, wires and contacts on it. In my practice, sometimes it happens that the terminal is simply not pressed tightly, and the tongue on the sensor that secures this terminal is completely broken off. At room temperature, the resistance of the water temperature sensor on the Whirlpool washing machine should be about 36 kOhm

Error code F05

The wires of the water temperature sensor are broken, or it is in a closed state . Almost exactly the same as f04, only here the module accurately points to the broken part. First of all, you need to check the wiring and the sensor itself. I indicated the resistance of the temperature sensor for Whirlpool washing machines in paragraph 4. You also need to check this thermistor for current leakage to the housing, in this case you need to check only with a megger, and the scale on it should be at least 20 mOhm

Error code F06

The breakdown is related to the engine tachogenerator . We take a multimeter, put it in the ringing position, connect it to the terminals of the tachometer on the motor and turn the motor shaft, if you hear intermittent sound signals, then most likely the tachometer is intact. On Whirlpools, such a breakdown is rare, but it does happen. Pay attention to the rotation of the engine; usually with such a breakdown it rotates at low speeds or does not rotate at all. You also need to check the wiring that goes to the engine from the module, this malfunction happens much more often. If all this does not help, then look at the control unit

Error code F07

Violation of the engine control circuit . Here you can’t do without a specialist; here you need to check everything related to the main triac of the motor. Many people immediately try to change it, but often the result is negative, since it is necessary to check the entire circuit, including those spare parts that control this triac. I repeat once again, the control module is a complex spare part and I do not recommend trying to repair it yourself, without certain knowledge and skills. Also, this malfunction may be related to the engine, or rather to the fact that the control module simply does not see it. First of all, we check the wires and terminals, both on the brains and on the motor itself. You also need to check the brushes; often they simply wear out. In practice, it happened that the contacts oxidized, as a result of oxidation, the track on the board itself rotted

Error code F08

The water heating element, that is, the heating element, has failed . Don’t rush to rejoice, it’s 50/50, maybe the heating element barked, or maybe the heating element’s relay turned on. In addition, it is imperative to check the heating element for current leakage to the housing. In my practice, it happened that this error popped up when the washing machine motor failed. Be sure to watch the video located at this point, in it I show how to properly check the heating element and the engine. And there is no need to shout that this cannot be, theory and practice are different things. On my YouTube channel, half of the wise guys say that such a check does not give anything, I assure you that this is how it should be checked.

Error code F09

Water is poured above the required level . What nonsense they write about this error, and the fact that there is a lot of foam, and the fact that the pressure switch needs to be changed, and in general all sorts of crap that has nothing to do with this. As for the water level sensor, it is this that gives the signal that there is a lot of water in the tank, so it is somehow wrong to talk about replacing it. First of all, you need to check the valve; it is quite possible that it does not close completely. Also pay attention to self-draining. As for the pressure switch, it rarely fails in Virpuli

Error code F10

The module's thermal protection device has tripped . Simply put, my brain is on fire! First of all, you need to check the motor; it is quite possible that the triac is overheating because of it. It has happened that you come to an application, and the washing machine is standing next to the stove and still leaning against the radiator, this can also cause such an error. Sometimes protection works when the owners do laundry frequently. That is, you need to let the machine rest for at least one hour between washes. If all this doesn’t help, then you need to look at the module, you won’t be able to figure it out without a specialist

Error code F11

Incorrect mains voltage . At the beginning of the article, I said that the Whirlpool CMA control module is very picky about voltage, so if the network is less than 210 volts, your machine may not wash. Call an electrician and restore the network

Error code F12

The washing machine washes in cold water . Here the control unit clearly points to the heating element. This error code is identical to code f08, so I won’t rant too much, just watch the video in the above code

Error code F13

Exactly repeats the code F01 or FH , go up the article and look at the description of this error

Error code F14

All “Kin will be no more” means incorrect EEPROM values , that is, a scribe to the processor

Error code F15

The washing machine motor has failed . I described this breakdown in code f06 and f07, so go up and look at these errors

Error code F16

The control module has failed . In short, call a specialist

Error code F18 or Fod

Increased foam production . We stop the wash at SM, drain the water, remove the laundry from the tank, rinse it in plain water and start washing again. In general, you don’t need to throw a lot of powder

Error code F19

Low voltage in the network . I think everything is clear here, you need to check the socket, plug, measure the voltage, if there is no required voltage, wait for normalization and only then start washing

Error code F20

The control module is malfunctioning . Sometimes simply restarting the washing mode helps; if that doesn’t help, then repairing the control unit will help.

Error code F21

The same crap as f20 only from the side, there is no difference. Why the manufacturer introduces the same errors under different numbers, I don’t know.

Error code F22

No one knows the exact designation of this error, but the manufacturer indicates two reasons: either the heating element has failed, or for some reason there is no water flow through the powder container. In short, we check the heating element or look for the reason why water is not poured into the washing machine tank.

Error code F23

Again an exact copy of error f01 or FH . We go up to the top of the article and read everything related to it

Error code F24

It takes a long time to fill the tank with water. Although again, this error exactly repeats the F02 or FA code, I still have to mention this code in this material.

Error code F26

No engine rotation . First of all, you need to look at the tachometer, it happens that it flies out of its socket and as a result, the brain does not see the rotation of the shaft. You also need to remove the belt from the drum pulley and try to turn the motor shaft by hand. In short, we check everything related to the rotation of the shaft on the motor. It is advisable to check the brushes as well.

Error code F27

The motor only rotates in one direction . First of all, you need to check the reverse relay on the control module

Error code F28

Slow motor rotation . We check everything connected with this, first of all the tachometer, then the relay on the control unit and of course the motor control triac

Error code F31

The software was not updated via the Internet. Complete nonsense, I have never seen such machines, although I think the time is not far off when they will appear in the vastness of the former mighty USSR.

FDL error code

The hatch lock is broken . To begin, take a screwdriver and imitate the door hook, that is, you need to push the locking mechanism, as the hook on the hatch pushes it. If the washing machine starts to fill with water, then the lock is working and you need to do something with the mechanism itself; if everything remains the same, change the lock

Let's check the heating element

Often error F08 appears as a result of a heater malfunction. You can check the heating element very quickly. To do this, perform the following algorithm of actions (the sequence of steps described will help owners of machines with a front-loading type; for vertical machines, the manipulations will be slightly different):

Important! The heating element is located at the bottom of the machine, under a plastic casing; only by removing the protective cover can you gain access to the contacts of the heating element.

Next, disconnect the power contacts, take a multimeter and connect its probes to the terminals of the heating element, set the resistance on the device to 200 Ohms, analyze the results. If the value on the multimeter screen remains approximately the same as it was set, then the heater is fully operational. When the number 1 appears, this indicates a break inside the part and will have to be replaced. When the device displays the number 0 (or a number very close to zero), it means that a short circuit of the heater can be diagnosed, in which case you will also have to install a new heating element.

If the heater passes the first test with a multimeter, just in case, check it for breakdowns. To do this, switch the test device to buzzer mode. You will be notified that the mode has been selected correctly by a lit light and a characteristic signal that will appear when the wires are connected. Connect one multimeter probe to the heating element terminal, and attach the second to the element body. If the device does not make any sounds, everything is fine; if a characteristic squeak is heard, there are breakdowns in the body of the part, and the heater will have to be replaced.

Let's check the thermistor

If the heating element has been fully tested and has proven that it copes with its functions perfectly, it’s time to check the thermistor. Just, it is located between the contacts of the heater. To remove the temperature sensor, perform the following manipulations:

The temperature sensor is a small metal cylinder. After the thermistor is removed from the washer body, you need to check the resistance in it using a tester.

When the temperature sensor fails, the old part should be replaced. The thermostat cannot be repaired. If the element is fully operational, we continue the diagnostics further.

We will inspect and test the pressure switch

It is easy to provide access to the water level sensor of the Whirlpool washing machine; it is located in the upper part of the unit, directly under the lid. Very rarely the pressure switch is located at the bottom. To get to the part, carefully unscrew the mounting screws and remove the upper wall of the SMA housing, after which the algorithm of actions will be as follows:

If after an external examination no defects were identified, you need to check the pressure switch with a multimeter. The device is switched to resistance measurement mode, the tester probes are connected to the sensor contacts. If the values on the screen change, it means that the contacts are actuated and the pressure switch is working. When the resistance value remains fixed, it means that the liquid level sensor has failed.

So, when you have checked the functionality of the main elements that can trigger the F08 error code, no faults have been identified, you should invite a professional to determine the root cause of the code. After all, the problem may come from the main control board, and it is not recommended to deal with it yourself.