Error codes for SMA "Hansa". Hansa washing machines are excellent value for money, which is largely undervalued in our market. A special feature of these washing machines is the presence of two series, which differ technologically. And the display of faults in them is implemented differently. Therefore, the information is presented in two sections and summarized in tables for convenience.

- PA series SMA errors

- Fault codes for HANSA PC series washing machines

- Catalog of washing machines "HANSA"

PA series SMA errors

E01, 1 E02, 2 E03, 3 E04, 4 E05, 5 E07, 7 E08, 8 E10, 10 E11, 11 E12, 12 E14, 14 E15, 15

| Codes. | Description of the breakdown. | Causes of occurrence. | How to fix. |

| E01, 1 | The door lock limit switch does not work. | After 10 seconds, error code 1 is displayed and the washing program is interrupted.

|

|

| E02, 2 | There is no door lock. | After 2 s, error code 1 is displayed and the washing program is interrupted.

|

|

| E03, 3 | Problem with water flow into the washing machine. | After 3 minutes from the start of filling the tank with water, error code 2 is displayed, the water continues to fill. After 7 minutes from the start of filling (in the absence of a signal from the level switch), the washing program is interrupted.

|

|

| E04, 4 | The water does not drain. | Error code 3 is displayed. The door lock remains activated until the machine is turned off (the program selection knob is turned to position 0).

|

|

| E05.5 | During operation, the level relay sends a “tank overflow” signal to the controller. | The washing program is interrupted, the drain pump P1 is turned on, error code 4 is displayed. After 2 minutes after receiving the “empty tank” signal from the PS1 level turnip, the drain pump is turned off. The door lock remains engaged until the machine is switched off.

|

|

| Short circuit or break in the temperature sensor. | After 2 seconds, error code 5 is displayed. The washing program continues to run without heating the water.

|

| |

| The increase in water temperature in the tank is less than 4″C after 10 minutes of heating. | Error code 5 is displayed. The washing program continues to run.

|

| |

| The temperature in the tank did not reach the value specified by the program at the specified time. | Error code 5 is displayed. The washing program continues to run.

|

| |

| E07, 7 | There is no signal from the tachogenerator about the rotation of the drive motor in washing mode. | 3 attempts are made to start the engine at 120 rpm. If this does not happen (the engine rotation signal is not received by the electronic controller), the washing program is interrupted and error code 7 is displayed.

|

|

| E08, 8 | In spin mode, there is no (disappears) signal to the electronic controller from the tachogenerator. | After 1 s, while the drive motor is rotating at a constant speed (or after 4 s during acceleration), it stops. 3 attempts are made to start the engine. If this does not happen (the engine rotation signal is not received by the electronic controller), error code 8 is displayed.

|

|

| E10, 10 | The power supply parameters are outside the recommended limits. | Error 10 can appear either immediately after turning on the power, or during operation of the SMA. If an error is detected, the washing program is not executed. | Check the parameters of the supply network (voltage 180...260 V, frequency 50/60 Hz). If there is a significant deviation, contact an electrician. |

| E11, 11 | The control module is faulty. | 3 attempts are made to start the engine. During pauses between starts, relays RL2 and RL3 are used to briefly remove the supply voltage from triac TR8. If the attempts are unsuccessful, the washing program is interrupted and error code 11 is displayed.

|

|

| E12, 12 | A water leak into the pan was detected - the Aquastop system was activated. | The washing program is interrupted, error code 12 is displayed. Drain pump P1 is turned on and the door is locked. After the level relay PS1 gives the “empty tank” signal, the door lock is removed after 10 minutes, and after 2 minutes the pump is turned off.

|

|

| E14, 14 | Error (failure) of the electronic controller. | The washing program is interrupted and error code 14 is displayed. May occur due to a short-term loss of voltage in the supply network. | Check the power supply. Restart the specified washing program. If the error recurs, replace the electronic controller. |

| E15, 15 | Fatal failure of the electronic controller. | The error may appear immediately after turning on the power to the washing machine or after selecting a washing program, three seconds after pressing the START button. The electronic controller is faulty. | Replacement or repair of the control module. |

Do you wash by hand?

Oh yes! No

Checking the tachometer

To try to fix the problem yourself: you need to correctly determine the cause of the problem. In most cases, error E21 is caused by a faulty tachometer. It is located directly on the engine and is “responsible” for the intensity of the drum revolutions. To get to the sensor, you will have to perform a number of actions.

- Disconnect the machine from the power supply, sewerage and turn off the water supply tap.

- Provide free access to the unit by moving it away from the wall or pulling it out of the cabinet.

- Remove the back wall by unscrewing the corresponding screws with a Phillips screwdriver.

- Remove the drive belt by pulling the rubber towards you while rotating the pulley.

- Mark the conductors connected to the motor and disconnect them.

Important! Do not neglect markings or photographs so that during reassembly you do not mix up the contacts and perform correct installation.

- Unscrew the bolts holding the engine and, loosening the engine, remove it from the housing.

- Inspect the Hall sensor attached to the motor, checking the fixing force and the existing contacts. If any of the above are loose, you need to tighten the terminals, restore connections and return to their original position.

When there are no doubts about the contacts and fastenings, we test the tachogenerator for performance. To do this, it is enough to measure the existing resistance or voltage. First of all, we check the resistance force by opening the connectors and applying the multimeter probes to the contacts. If the display shows numbers within 60-70 Ohms, then the sensor is working. Another option is to measure the current production. We switch the device to a new indicator and attach the connectors, turning the engine. The optimal value is about 0.2 Volts.

A negative result requires replacement of the tachometer. It is important not to make a mistake here, so we remove the removed part and take it to the store for clarity. The device is installed back in a similar way.

Fault codes for HANSA PC series washing machines

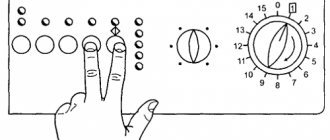

In this series, the company produces two lines of washing machines: Comfort and Optimum. They differ in their set of functions and technical characteristics. The Optimum SMA does not have a display, and therefore information about the presence of errors occurs by illuminating the indicator light. In the figure below, the buttons with which fault codes are generated are marked with letters.

Control Panel

And here is a summary table for the entire line of PC washing machines.

E01 E02 E03 E04 E05 E06 E07 E08 E09 E11 E21 E22 E31 E32 E42 E52

| Error code in the Comfort series SMA. | The glow of LEDs in the Optimum series SMA. | Description of the problem. | Causes of occurrence. | What to do. |

| E01 | D | Problem with hatch locking. | After 15 s, an error code is displayed and the washing program is interrupted.

|

|

| E02 | B | Water does not flow or very slowly. | The time it took to fill the tank with water to the nominal level exceeded 2 minutes. After the wash is completed, an error code is displayed. Options:

|

|

| E03 | B, C | Water does not drain or drains very slowly | The duration of draining water from the tank exceeds 1.5 minutes. The maximum spin speed is limited to 400 rpm. An error code is displayed at the end of the program.

|

|

| E04 | C, D | The level sensor generates the “TANK OVERFLOW” signal. | The washing program is interrupted, the drain pump is turned on, and an error code is displayed. After 1.5 minutes have passed from the moment the level sensor generates the “EMPTY TANK” signal, the drain pump turns off.

|

|

| E05 | A, C | The time to fill the tank with water exceeded 10 minutes. |

|

|

| E06 | B, C, D | After 10 minutes have passed after the water starts draining, the level sensor does not generate the “EMPTY TANK” signal. |

|

|

| E07 | A | A water leak into the pan was detected - the AquaStop system was activated. | The drain pump turns on and then turns off after 1.5 minutes have passed after the level sensor generates the “EMPTY TANK” signal.

|

|

| E08 | A, B, C, D | Problems with the electrical network. | The power supply parameters are outside the recommended limits. | Check the power supply parameters. It should be: voltage 160...253V, 50/60Hz. |

| E09 | A, C, D | Excess foam. |

|

|

| E11 | D | The hatch lock does not lock. | The control triac is faulty. | Replacement or repair of the SMA control board. |

| E21 | C | Engine problem. There is no connection with the tachometer. |

|

|

| E22 | C | The drive motor rotates when there is no command to do so. | Short circuit of the drive motor triac. | Repair or replacement of the electronic module. |

| E31 | A, D | Temperature sensor short circuit. | Short circuit of the temperature sensor or its wire connections . |

|

| E32 | A, D | Open circuit in the temperature sensor circuit. |

|

|

| E42 | D | The door is locked after the wash has finished (after 2 minutes). | Failure of the door lock, electronic controller (lock triac) or mechanical locking of the door itself. |

|

| E52 | A, B | Non-volatile memory failure. | The control module is faulty. | Repair or replacement of the control module. |

Testing the thermal switch

If the result is positive, we leave the tachogenerator alone and continue to search for a breakdown of the Hans washing machine in the thermal switch. We again disconnect the machine from all communications, open the back cover and pay attention to the heating element. Disconnect the wires going to the external thermostat and loosen the retaining fasteners. Then we remove the water heater and take out the thermistor located inside.

Now we check the sensor for sufficient resistance:

If the available numbers are far from normal, you will have to replace the thermistor. To repair the sensor, you cannot just purchase a new copy, focusing on the serial number and model of the washing machine. Subsequent installation of the device and assembly of the machine will not cause any trouble: we simply proceed in the reverse order.

Successfully passed tests with a thermostat and tachogenerator indicate one thing: the control board is to blame for the E21 error that appears on the display. Here it is better not to experiment with DIY repairs, since the control module is too sensitive to third-party manipulations. Any wrong movement will lead to large-scale consequences with an expensive call to the service center. It is recommended not to try to fix the breakdown yourself, but to immediately call a qualified specialist.

How to get rid of the problem?

Don't immediately think about the worst. The control board breaks down extremely rarely; more often it is much easier to fix the “E10” error. In most cases, problems that can be resolved without repairs and lengthy diagnostics lead to failure. To make a “diagnosis” of Hansa and begin “treatment”, you will have to consistently check all possible breakdowns, starting from the simplest.

First of all, we check whether the error will repeat a second time. It is possible that there was a short-term technical glitch. To diagnose, just restart the machine and assess the condition of the equipment. We proceed like this:

If, after rebooting, Hansa did not generate an error at the same point in the cycle, then the failure was short-lived and does not require further diagnostics. Otherwise, you will have to immediately determine the cause of E10. You cannot continue trying to reset the code - you can aggravate the situation, even to the point of death.

The second step is to check the electrical network. Ideally, you should call a qualified electrician, but if you have experience, you can do it yourself. The main thing is to follow safety precautions and be extremely careful. If the power supply to the house is unstable and voltage surges occur constantly, then it is better to include a stabilizer in the circuit.

The third stage is checking the outlet and extension cord. Here, signs of a breakdown will be obvious: burnt out wiring, melted insulation, a burning smell, dark spots. If there are no suspicious “symptoms”, we move on to practice: we connect a working device to the electrical network or remove the “adapter” from the circuit. Works? Then the problem is found. If checking the electrical network does not reveal any problems, then the problem is an internal failure - the control board has failed. Here, amateurish work is dangerous: you need to contact a service center for professional diagnostics and repairs.