Modern washing machines impress with their speeds and power, but high values on the label logically increase the cost of the unit. Especially when it comes to spinning. Along with the usual machines with push-ups of 1000-1200 rpm, there are also models that can accelerate to 1800 and even 2000 rotations. But is this race really necessary, isn’t the wear of parts increasing and can all fabrics withstand such loads? We invite you to figure out together how many revolutions to set in the washing machine program for a safe and efficient cycle.

What does the choice of speed depend on?

Most washing machines offer the user to independently adjust the spin speed until the function is completely cancelled. This is due to the need to “adjust” the washing machine to the laundry in the drum. Since cotton products and items made from mixed fabrics can easily withstand a load of 1000 rpm, and delicate materials, silk, wool, polyester, are deformed if the push-up occurs at levels above 400.

The user can independently adjust the number of spin speeds depending on the type of fabric of the clothes being washed.

But the main boundaries are set by the manufacturer. The optimal maximum and minimum speed depends on the capabilities and power of the machine. We’ll tell you further how to determine what a washing machine is capable of.

What is the power of the SM engine

The performance of the motor depends on its type. Three types of washing machines are used:

Asynchronous motor

It was installed in cars manufactured before 2000. The motor of a semi-automatic washing machine has 2800 rotations per minute and a power of 180–360 W. To adapt such an engine for garage “homemade” products, you need a three-phase network, a frequency converter, and a set of capacitors. This is expensive, which is why asynchronous systems are not popular among do-it-yourselfers.

Brushed motor

A favorite of the masters. Powered by direct and alternating electric current, power 300–800 W, number of armature turns 11,500–15,000 rpm. On the plus side, the cycle can be easily adjusted without loss of power. The downside is that the brushes wear out often.

Inverter motor

The most modern and economical look. Converts alternating current to direct current. It operates without a belt drive and brushes with a power of 400–800 W, making a number of turns from 16,000 to 20,000 per minute.

Currently, a commutator electric motor is the best option for home workshops in terms of availability and price. It is versatile and easy to operate. Let's look at its structure, connection and adjustment methods.

Speed capabilities of cars

The spin class indicated on the factory label will help the consumer find out how well the machine spins. There are only seven of them - A, B, C, D, E, F and G, where "A" is considered better and "G" is considered worse. Levels are assigned to the unit depending on two parameters: the residual moisture of the laundry and the optimal number of revolutions per minute.

First of all, attention is paid to residual moisture. In other words, experts measure how dry the laundry is after the spin cycle. The calculation is simple: first, items are weighed before washing, then after the drum finally stops. Next, the smaller is subtracted from the larger, and the result is divided by the “dry” weight and multiplied by 100%. The resulting percentage will show the degree of dryness of the fabric and reveal the spin class:

- up to 45% – A;

- up to 54% – B;

- up to 63% – C;

- up to 72% – D.

Residual moisture in models of classes E, F and G is squeezed out by approximately 15-20%. Due to the low spin force, these washing machines are almost completely out of production and are no longer available for sale.

But there is no point in chasing cars with o or “B”. In fact, the gap between the percentages only seems large, but in reality they are equally wet things. The difference is only a few extra hours of drying, while the quality of washing remains at the same level. Why do you buy a washing machine?

In addition to residual moisture, the maximum permissible number of revolutions per minute also affects the efficiency of push-ups. That is, how quickly the engine spins the drum to release moisture. The higher the indicator, the greater the speed and the closer the coveted spin class of level “A”. And if previously the mark of 1000-1200 rotations was considered amazing, now some machines can accelerate to 2000. A striking example is the Gorenje WA 65205 model, which offers the most powerful operation of the engine and drum.

It has been proven that the higher the spin speed, the less hardness salts remain in the fabric fibers and the softer the laundry becomes.

Another question is, are escape speeds necessary or is an average value of 1000 revolutions sufficient? Let us illustrate with a diagram of the spinning process. It starts immediately after draining the water after rinsing. After stopping, the engine begins to increase power, gradually picking up speed. At the same time, the drum spins, and the laundry in it is pressed against the walls thanks to centrifugal force. Moisture is pushed out of things and goes out through the holes into the tank. The laundry is dried, and the separated liquid, gradually accumulating, is pumped out into the sewer. Towards the end of the program, the speed reaches a maximum and is held for 2-3 minutes, after which the system slows down. Thus, the indicated 2000 is reached in a couple of minutes.

The device of the commutator electric motor of an automatic washing machine

The appearance of motors of different models may differ, but the design and operating principle are almost identical. The device consists of:

- housings;

- starter;

- starter coils (shoes) with two or three terminals;

- anchors;

- pulley;

- two brushes;

- collector;

- tachometer (with two or three wires);

- terminal block.

To connect the motor, you need to know the outputs of the armature, starter and tachometer windings. A tester will help you avoid getting tangled in wires.

Easy motor connection

Set the tester to the mode of least resistance and call the windings of the tachometer, coils and armature. Make connections through terminals that communicate with each other. A correctly connected device picks up speed smoothly, does not crackle or spark. You can check how many revolutions the motor makes using a speed sensor.

A visual step-by-step implementation can be seen in this video:

Is high spin speed really necessary?

It is a common belief that excessive revolutions affect the life of the washing machine. More specifically, it is believed that if a machine can withstand strong acceleration, then its design and parts are stronger and more reliable. But now experts say that this is a myth.

At the moment, no direct relationship has been established between the maximum withstand speed and the reliability of household appliances. Even keeping in mind that strong acceleration requires strong parts, we must not forget that at the same time the overall loads and wear of spare parts increase. Therefore, the less stable components of low-speed machines, which are not subject to rotation at 2000 revolutions, do not deviate from more advanced competitors. Thus, units with a maximum of 600 revolutions work properly for 7-10 years.

Much depends on the manufacturer and the quality of the materials used. It is the brand that establishes the period of trouble-free operation and assumes warranty obligations . However, previously announced figures are revised over time. A striking example will be, which reduced the life of manufactured equipment from 10 to 7 years. There were no official statements, and it was believed that the decision was influenced by complaints from consumers and desire. Most likely, the matter is in the use of low-quality spare parts in order to reduce the cost of products and increase demand.

High-speed washing machines are prestigious and expensive, but their usefulness in everyday life is questionable. As a rule, if a consumer wants to quickly dry laundry, he or she will use a dryer or an iron, but with standard hanging of clothes, 20-30% humidity does not matter.

Interesting:

- Rating of Samsung washing machines

- Which Bosch washing machine is better to buy?

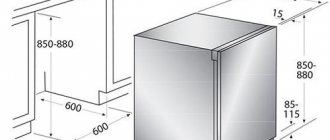

- Dimensions of the Indesit washing machine

- What is the best spin speed in a washing machine?

- How much does a washing machine cost?

- List of washing machines with collapsible tank

2 reader comments

- 03/14/2021 at 06:39

Alexander:

And if it jumps on a wooden floor and there is nothing that can be done about it, then I recommend reducing the speed for the safe operation of the machine.

Answer

- 02/20/2022 at 17:34

Bean:

I don’t agree at all, I had a machine with 1200+ rpm, the laundry is not as damp as after 1000.

Answer

What experts say

Until now, no dependence has been identified on the speed of the machine, its service life and reliability. All models have different service lives, which are set by the manufacturer, who provides warranties and produces spare parts. Even those models that can spin no more than 600 rpm can still work for a whole decade. However, some manufacturers are reviewing the service life of their devices. Sometimes without even giving official statements about it.

For example, Ariston has reduced the service life of its machines from ten to seven years. Most experts attributed this to the fact that many complaints began to be received about the operation of equipment from this manufacturer. And thus, he decided to protect himself. Today, more and more companies have gradually begun to accept such a reduction in quality. Perhaps this is due to attempts to make their products cheaper for the buyer.

Source

How to correctly determine the number of revolutions per minute for washing?

In modern models, the choice of washing conditions is entrusted to the consumer himself, which is due to the different composition of things. The indicator is increased or decreased manually by the user using the appropriate controls on the unit panel. The materials used for clothing have a maximum permissible number of revolutions, exceeding which adversely affects the quality of the items. Cotton or mixed materials can easily tolerate up to 1000, and delicate fabrics tend to lose their original qualities at around 400.

To maintain quality, the following recommendations for the optimal number of revolutions must be taken into account:

● 400-600. Comparable to manual, slightly superior in strength and quality, “gentle”. Fine wool, polyester, silk, cotton fabric.

● 800-900. Intensive, efficiently removes dirt from delicate materials, most often used. Synthetics.

● 1000. A highly intensive mechanism that does an excellent job of cleaning dense fabrics and heavy dirt. Jeans, mixed fabrics.

● Above 1000. Very intensive process, removes the heaviest stains. Not required by every user, rarely used in everyday life. Towels, products made from terry materials, linen, cotton or colored linen that does not require special care.

The number of spin revolutions is also indicated in the model name.

Magnet

There is a magnet inside the tachometer generator. It is used to generate electrical signals. Since this unit is subject to strong vibration, for example, when doing push-ups at high speeds, sometimes the magnet jumps out of its place. As a result, the operation of the generator is disrupted.

To fix it, you need to open the Tahoe assembly and put the magnet back. Before installing the motor, check the proper operation of the motor with a tester.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Important! This is a fairly common reason!

How to adjust rotation

There are many ways to control speed:

The adjustment scheme is simple, you can do it yourself.

This is a satisfactory option for a pump or fan. For more powerful mechanisms (for example, machine tools), a different regulator circuit will be needed.

The essence of the question is how to reduce speed without losing performance? The connection is made through a tachogenerator, which transmits the number of turns to the speed controller microcircuit, which coordinates the cycle using a thyristor.

Such a board allows you to either increase or decrease the speed, but requires constant, intensive cooling due to overheating. A detailed video about how the speed and power of the stroke are regulated by connecting to the microcircuit can be viewed here:

Now you know what speed different types of engines make and how to set up this process in your home workshop. Good luck!

Source

Frequency regulation

Just recently (10 years ago), there were a limited number of frequency controllers for motor speeds on the market, and they were quite expensive. The reason was that there were no cheap high-voltage power transistors and modules.

But developments in the field of solid-state electronics have made it possible to bring power IGBT modules to the market. As a result, there is a massive appearance on the market of inverter air conditioners, welding inverters, and frequency converters.

At the moment, frequency conversion is the main way to regulate the power, performance, speed of all devices and mechanisms driven by an electric motor.

However, frequency converters are designed to control three-phase electric motors.

Single-phase motors can be controlled by:

- specialized single-phase inverters

- three-phase inverters with the exception of the capacitor

Converters for single-phase motors

Currently, only one manufacturer announces serial production of a specialized inverter for capacitor motors - INVERTEK DRIVES.

Optidrive E2 model

For stable engine starting and operation, special algorithms are used.

In this case, frequency adjustment is possible upward, but in a limited frequency range, this is prevented by a capacitor installed in the phase-shifting winding circuit, since its resistance directly depends on the frequency of the current:

f – current frequency

C – capacitance of the capacitor

The output stage uses a bridge circuit with four output IGBT transistors:

Optidrive E2 allows you to control the motor without removing the capacitor from the circuit, that is, without changing the motor design - in some models this is quite difficult to do.

Advantages of a specialized frequency converter:

- intelligent motor control

- Stably stable engine operation

- Huge capabilities of modern inverters:

- the ability to control the operation of the engine to maintain certain characteristics (water pressure, air flow, speed under changing load)

- numerous protections (motor and device itself)

- sensor inputs (digital and analogue)

- various outputs

- communication interface (for control, monitoring)

- preset speeds

- PID controller

Disadvantages of using a single-phase inverter: