Typical faults of washing machines.

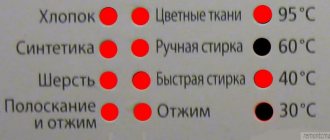

Washing machines of this model range are equipped with an on-board computer that helps the user care for the machine. The most common Samsung Diamond error codes:

5E – problem with draining water from the unit. Possible reasons: the drain hose or sewer is clogged, the hoses inside the washing machine are clogged, the pump filter is clogged, the water inside the machine is frozen, the drain hose is squeezed or severely bent.

H1, H2, NOT, HE1, HE2 – it is not possible to heat the water: the machine is not connected to the power supply correctly, the washing or drying heating elements of the machine are faulty.

NS, 4E – it is not possible to fill the unit with water: There is no water or the water supply valve to the machine is in the closed position, The inlet hose is compressed or bent, the “Aqua Stop” inlet hose protection system is likely to be triggered.

SUB – there is too much foam in the washing machine tank: the volume of washing powder is higher than necessary, the washing powder is not suitable for washing by automatic machines, the powder is expired or of poor quality.

UE – the machine automatically discharges water: the drain hose is connected incorrectly, the hose is too low, there is a hole in the machine’s tank.

LC, 3E – the washing machine motor is broken or overloaded: malfunction of the machine motor, overload due to a large volume of laundry.

What malfunctions are typical for SM Samsung

The design of the Samsung washing machine is distinguished by high-quality assembly, especially when it comes to electronics.

According to service centers, electronic parts - circuit boards, wiring - fail much less often than other elements.

Let's take a closer look:

- According to statistics, 54% of breakdowns occur in the heating element. It is the heating element that most often fails. Constant power surges and scale from poor-quality water contribute to element failure. This includes the connections of the heating element, as well as the temperature sensor. If there is a large amount of scale, the temperature sensor fails to work, and as a result of a short circuit, the contacts of the heating element burn out.

- The cause of MMA malfunction in 21% of cases is wear of the drive belt. The wash may stop mid-cycle and the drum will not rotate. Replace the belt only with an original part.

- 12% of breakdowns are caused by inlet valves. As a result of rubber wear or drying out, water spontaneously fills into the tank. Also, the valve may become clogged, and then water does not flow well into the machine.

- The remaining spaces are divided between parts: drain pump, worn seals and bearings. Poor drainage is caused by a clog in the drain system. Constant self-draining of water occurs due to incorrect connection. Depressurization of elements leads to leaks in a Samsung washing machine.

Prices for repairing Samsung washing machines

| Name of service | Price, rub.) |

| Visit of the master | 0 |

| Diagnostics in case of repair | 0 |

| Replacing the hatch opening handle | 400 |

| Replacing the sealing cuff of the hatch | 400 |

| Replacing the hatch lock | 400 |

| Replacing the drive belt | 300 |

| Replacing drum bearings | 2500 |

| Replacing shock absorbers | 800 |

| Control module repair | 1000 |

| Replacing a group of filling valves | 500 |

| Replacing the sump pump | 600 |

| Replacing the heating element | 600 |

| Replacing motor brushes | 500 |

| Electric motor repair | 500 |

| Installing a new | 1000 |

| Cleaning the fill system | 600 |

| Cleaning the drain system | 700 |

| Removing a Foreign Object | 600 |

| Replacing the inlet and drain hose | 400 |

| A technician will visit you for in-depth diagnostics without repairs. | 1500 |

| In case of refusal, departure is paid in the amount | 500 |

Call a specialist

8. Call!

* The minimum possible repair price is indicated, depending on the model and other factors. Please check the exact cost.

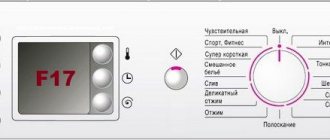

Samsung SMA error codes

By displaying fault codes on the display, the system informs the user about a problem that has arisen. You need to understand the meaning of Samsung washing machine error codes and start repairing it yourself.

| Fault codes | What do they mean |

| 1E | Failure of the pressure switch. |

| 3E, 3E1, 3E2, 3E3, 3E4 | Malfunction of the SM motor tachometer. |

| 4E, 4E1, 4E2 | There is no water in the tank. |

| 5E | Error draining water. |

| 8E | Failure of the SMA electric motor. |

| 9E1, 9E2, Uc | Electrical error. Voltage too high or low. |

| AE | There is no connection between the electronic board and the display panel. |

| bE1, bE2, bE3 | The washing machine does not turn on. |

| SE | The water in the tank has exceeded the heating rate. |

| bE1, bE2, bE3 | Problems with closing the hatch door. |

| F.E. | Ventilation is not working. |

| NOT, NOT1, NOT2, NOT3 | The heating element (heating element) is faulty. |

| LE (LE1) | There is a leak. |

| OE (OF) | There is too much water in the tank. |

| tE1, tE2, tE3 | Thermal sensor is faulty. |

| HER | Failure of the heating element or drying temperature sensor. |

| UE | An imbalance has arisen. |

| Sud | Foam concentration exceeded. |

Preparation

Disassembling a washing machine is not difficult if the owner of the device has minimal skills in electrical engineering and plumbing. In Samsung brand models, such as, for example, S821, WF-S861, S803J, WF6458N7W, it is easy to access the main mechanisms.

To disassemble and subsequently repair the washing machine, you need to choose a bright and spacious place where nothing will interfere with the work.

Whatever machine you are going to repair, first it is important to prepare a workplace and tools that will be useful during the disassembly process. Of course, you can get started with a few screwdrivers and wrenches. But if the machine requires a detailed inspection and subsequent repairs, it is better to prepare everything you need at once. So, you may need:

- hammer;

- wire cutters;

- screwdrivers (slotted and figured);

- open-end wrenches;

- heads (socket wrenches);

- pliers;

- hacksaw;

- pliers;

- mites;

- soldering iron

It is important to prepare auxiliary materials in advance - liquid for softening nut fasteners WD-40, silicone sealant and lubricant for hinge elements. It is convenient to have a clean rag on hand to wipe your hands or any remaining liquid from the machine. Experienced craftsmen advise beginners to photograph each stage of disassembling the unit to make it easier to reassemble the device after completion of the repair, therefore, you need to prepare a camera.

It is convenient to disassemble the unit when all the tools are at hand

The preparation stage may not seem so important, but the result largely depends on the quality of its implementation.

Troubleshooting

Let's look at how to repair a Samsung washing machine yourself.

Samsung machine does not pump out water

You need to check the drainage system: most often the cause is a clogged drain pipe or pump.

- Unplug the machine and turn off the water.

- Disconnect all communications.

- Remove the dispenser tray by pressing the lock in the center.

- Open the drain filter hatch on the front panel from the bottom.

- Drain off any remaining water and clean the filter.

- Lay the SM on its side, open access to the bottom.

- Having found the location of the pump and pipe, loosen the pipe clamps.

- Disconnect the pump wires.

- Unscrew the screws securing the pump.

- After removing the pump, check it for blockages.

- Remove the pipe and wash it to remove any dirt.

Carefully inspect the pipe for damage. Most often, it loses its tightness at the places where the clamp is attached. If the pipe or pump malfunctions, new elements must be installed.

No heating

To check and replace, you need to get to the heating element. Based on how the Samsung washing machine is structured, we can conclude: to get the heating element, you need to remove the front casing of the washing machine.

We repair the washing machine ourselves:

- After disconnecting the SM from the network, unscrew the screws securing the top panel from the back.

- Pull out the dispenser tray. Unscrew the bolts located behind it.

- Unscrew the remaining mounting bolts and remove the control panel of the Samsung washing machine.

- Remove the bottom panel.

- After bending the hatch cuff, pry up the metal clamp and remove it.

- Place the cuff inside the drum.

- After unscrewing the door lock screws and disconnecting the wires, remove the front panel.

- At the base of the drum there is a heating element.

- Disconnect the heater wires.

- Unscrew the central nut (not all the way).

- After pushing the central bolt inward, remove the heating element.

- Remove the thermostat from the heater.

If the thermostat is working properly, simply replace it with a new heating element. Installation is carried out in the reverse order, after which the housing is installed.

Doesn't take up water or fills up too much water

The reason for the lack of water may be a blockage. When repairing a washing machine with your own hands, first of all:

- Turn the shut-off valve.

- Check to see if the water pressure in the tap is sufficient.

- Inspect the inlet hose. Maybe he was bent, twisted.

- Disconnect the hose and rinse under pressure from the tap.

- Remove the inlet valve mesh filter.

- Clear it of any blockage.

If an excessive amount of water enters the machine, you need to check the fill valve.

- Having removed the top panel of the CM, you will see the inlet valve on top of the wall.

- Disconnect the valve wires.

- Unscrew the fixing bolts.

- Loosen the clamps and disconnect the hoses.

If the valve is generally in good condition, replace the rubber seals. If not, install a new part.

Drive belt wear

To replace the belt, you need to know how to remove the back wall of a Samsung washing machine:

- After unscrewing the bolts, remove the back panel.

- Remove the old belt from the pulley.

- If inspection confirms belt wear, install a new element.

- Begin to slide the belt onto the engine pulley by moving and turning the drum pulley.

Now you know how to repair a washing machine without calling a technician.

Samsung machine is noisy

When washing, did the SM begin to vibrate strongly, hum, or make noise? Check whether the installation is correct and how stable the equipment is on the floor.

A more serious cause of noise is bearing wear. To replace it, you need to know the device or have a diagram of a Samsung washing machine. Changing bearings is described in detail in the video:

Samsung washing machine repair

Samsung washing machines are produced by the South Korean concern Samsung Group. The history of Samsung begins in 1938. The first washing machine was released in 1974. Washing machines are assembled in China, South Korea, Thailand, and the USA. In Russia, the Samsung plant was opened in 2008 in the Kaluga region. Washing machines are assembled mainly from Chinese components.

The line of Samsung washing machine models includes compact, narrow, ultra narrow, vertical and frontal, budget and premium, and the latest innovative developments can satisfy any buyer. The average service life of Korean-assembled machines is up to 10 years, and the service life of Chinese-assembled machines is up to 7 years.

The concern has developed a number of technologies and special functions, for example, Diamond Drum technology is used in the drum design. The Digital Inverter motor is directly attached to the drum, which significantly reduces the wear of parts; the company guarantees a 10-year service life of the electric motor. Ceramic heaters are used that are not afraid of scale in water of any hardness. The Eco Bubble generator is a function where the powder becomes foam, which quickly penetrates the fabric structure and improves washing. AddWash has developed a small hatch on the door for additional loading of forgotten items. Smart Check technology wash can be controlled from a smartphone. The application monitors the process, eliminates errors, and resolves problems. Silver wash Silver Nano, where silver ions provide antibacterial properties to washed clothes. The QuickDrive quick wash allows you to perform a high-quality, complete wash in 40 minutes. VRT plus technology has also been developed to reduce vibration; the machine operates silently and does not bounce on the floor during spinning. Wide range of loading volumes from 4 kg. up to 12 kg. Aqua stop function is a two-stage protection system against water leaks.

Quick online diagnostics of washing machine faults (Just select a problem from the list and find out the approximate breakdown)

Most modern Samsung washing machines have the function of displaying an error code when certain malfunctions and malfunctions occur. Quite often, understanding what the error code means , you are able or breakdown yourself

For your convenience, a list of error codes for Samsung washing machines is provided with an explanation of each specific code . The table also includes a description of the error, the reasons for its occurrence and possible solutions.

The washing machine consists of units that are complex in design, and if they break down, it is better not to try to repair the devices yourself. Moreover, this is due to high voltage and the possibility of flooding neighbors living on the floor, or even two or three floors below.

When carrying out repairs yourself, remember your safety!

Disassemble without disconnecting the equipment from the mains!

It is best to use the services of an experienced technician who is familiar with any problems and can fix the problem. If your washing machine breaks down, entrust the repair to a professional: he will be able to perform all the steps quickly, efficiently and safely.

Deciphering Samsung error codes

| Error code | Description of the error | Causes and elimination |

| 1E | Water level sensor error. | 1. Part of the level sensor tube is damaged (punctured). 2. The tube is clogged with foreign material or pinched. 3. The handset is not connected. 4. Sensor malfunction (sticking). 5. Malfunction of contacts and connections of the level sensor. 6. Control module malfunction. |

| 3E | Electric motor tachogenerator error. | 1. Malfunction of contacts and connections of the electric motor. 2. The motor windings are damaged (short circuit or open circuit). 3. Malfunction of contacts and connections of the tachogenerator. 4. The electric motor is blocked by foreign objects (for example, a bolt). |

| 3E1 (30) | 1. The motor is overloaded due to too much laundry. 2. Malfunction of contacts and connections of the electric motor. 3. Tachogenerator malfunction. | |

| 3E2 (300) | Weak signal from the tachogenerator, poor contact in the relay, etc. | |

| 3E3 (3000) | 1. It appears due to erroneous operating signals coming from the tachometer. 2. Malfunction of contacts and connections on the control module. 3. Large gaps on the direct drive motor, misalignment of parts. | |

| 3E4 (30000) | 1. Malfunction of contacts and connections. 2. Tachogenerator malfunction. 3. Electric motor malfunction. | |

| 4E | Water supply error. | 1. A foreign object has entered the water inlet valve. 2. Faulty contacts and connections of the fill valve (valve winding is not connected). 3. Incorrect connection of hot and cold water (vice versa). 4. This happens if there is no connection from the drain hose to the detergent container. Check if the transparent hose is kinked or torn. |

| 4E1 (40) | 1. The cold and warm water supply hoses are mixed up. 2. The temperature of the water supplied through the valve during the drying cycle is higher than 70°C. | |

| 4E2 (400) | On the “wool” and “delicate wash” programs, the supply water temperature is more than 50°C. | |

| 5E | Drain error | 1. The pump impeller is damaged. 2. Incorrect voltage of installed components. 3. Component failure 4. This occurs due to freezing during the winter season 5. The drain hose is clogged (pinched). 6. Clogged drain path (coins, rubber bands, etc.). 7. Malfunction of contacts and connections. |

| 8E | Motor error. | 1. Occurs when the rotation of the electric motor is inconsistent because the tachometer of the electric motor is not working. 2. Malfunction of control circuits. 3. Malfunction of contacts and connections of the electric motor. |

| 9E1 9E2 (90) | Power error. | 1. Check the power supply parameters: 1.1) Make sure that the current voltage is normal. Connect the tester to the internal power contacts during heating or drying and observe the operation of the washing machine. 1.1) Check the voltage. The error occurs when the network voltage drops more than permissible. Check if an extension cord is being used. When the length of the extension cord is 1 m, the instantaneous voltage drop can be up to 10 V. 2. Control module malfunction (rare). |

| Uc | 1. If the supply voltage is equal to or less than 176 V, or equal to or greater than 287 V, the washing machine will pause to protect its electrical components. 2. When the voltage is restored to the standard (187 V - 276 V), the cycle will resume automatically. | |

| A.E. | Communication error. | 1. There are no signals between the control and display module. 2. Check the connection between the control and display module, check that the connectors are connected correctly. 3. Replace the control and display module, check for soldering defects. |

| bE1 | Switch error (relay error) | 1. The network button is stuck (pressed for more than 12 seconds) 2. The button is constantly pressed due to deformation of the control panel. 3. This error can occur when the screws that hold the control panel in place are tightened too tightly. |

| bE2 | 1. Buttons (except for the “power” button) are pressed continuously (more than 30 seconds) 2. Deformation of the internal plastic parts. 3. The screws that hold the control panel in place are too tight. | |

| bE3 | 1. The relay on the control module is short-circuited. 2. Incorrect connection of the relay (contact is bent in the connector, no connection) | |

| C.E. | Cooling error. | 1. This happens when the temperature of the washing machine is more than 55°C and draining cannot be performed. (Reason: If hot water comes into contact with your skin, it may cause a burn.) 2. This occurs when the water temperature for some cycles exceeds 55°C. In this case, the water will be drained to the discharge level. 3. Thermal sensor error or any incorrect connection of elements. |

| dE (door) | Hatch lock error. | 1. Switch contact error due to door hook deformation. 2. When a closed door was opened by force. 3. This can happen during the boil cycle if the door moves due to pressure differences from internal temperature changes. |

| dE1 | 1. The sunroof lock connector is not connected correctly. 2. The hatch lock connector is damaged. 3. This occurs periodically due to damage to the electrical insulation. 4. The control module is faulty. | |

| dE2 | 1. Occurs when the switch turns on and off spontaneously and gets very hot due to vibration. Rare error. | |

| F.E. | Ventilation error. | 1. The capacitor connector comes out of place when installing the top cover. 2. Fan wiring is damaged. Therefore the fan does not start. 3. Fan blades are blocked or there is no lubrication in the bearings. Therefore, the fan does not turn on. 4. Starting capacitor malfunction. In this case, it is not possible to detect the fault using the tester. Replace the starting capacitor. |

| HE | Heater error (heater) | 1. The heating element is short-circuited or broken. 2. Malfunction of the heating element. No contact, temperature sensor fault. 3. If the sensor detects a lack of water or a water temperature of 100 - 150 'C, then to prevent overheating of the heating element, the washing machine turns off the power. |

| HE1 (H1) | ||

| HE2 | 1. Occurs when the red temperature sensor in the center of the drying heater is triggered (at a temperature higher than 145°C). Corrective action: Press the center button lightly. The washing machine will operate normally. Or replace the temperature sensor if the temperature measurement is incorrect due to functional degradation of the sensor. | |

| HE3 | 1. Occurs when the steam function does not work normally. 2. This error does not occur in existing drum washing machines. Check if the model supports steam function. | |

| LE (LE1) | Water leak error. | 1. Leakage due to the heating element (came out of the mounting). 2. The air hose has come loose and water leaks during the spin cycle. 3. Damage to the tank at the location where the transport bolts are attached. 4. Water leakage occurs at the front with foam due to too much detergent. 5. Water leakage occurs because the detergent connection hose is not connected correctly. 6. The drain pump filter cover is not installed correctly. 7. Water leaks through the drain hose. 8. Damage to sealing washers. 9. The spout diaphragm is set in the opposite direction, or the rubber gasket is lowered. 10. Water leakage occurs because the screws that hold the tank and front panel together are not secured correctly. 11. Leak sensor malfunction. |

| OE (OF) | Overflow error. | 1. The water level sensor (pressure switch) is faulty. 2. Level sensor tube clogged. 3. Water fills continuously due to a foreign object in the water supply valve. |

| tE1 | Temperature sensor error. | 1. The water heating element is faulty (poor contact, faulty temperature sensor). 2. Connectors are not connected correctly or are broken. 3. If the sensor detects a lack of water or a water temperature of 100 - 150 'C, then to prevent overheating of the heating element, the washing machine turns off the power. |

| tE2 | 1. The fan housing temperature sensor is faulty (internal short circuit or open circuit). 2. Malfunction of sensor contacts and connections. | |

| tE3 | 1. Occurs when the condensate flow temperature sensor is broken. 2. Occurs when the condensate flow temperature sensor is open or short-circuited. 3. Malfunction of sensor contacts and connections. | |

| E.E. | For machines with drying, overheating error. | 1. The drying temperature sensor is faulty. 2. The circuits and connectors of the drying temperature sensor are faulty. 3. The drying heating element circuits are faulty. |

| UE | Imbalance error. | 1. Laundry is stacked unevenly, rearrange it. 2. Find the reason for the lack of balance and solve it as indicated in the owner's manual. |

| Sud (SUdS) | Excess foam detected. | Too much foaming. When the removal of foam is completed, the cycle continues as usual. When too much foaming is detected, “Sud” or “SUdS” appears. When foam removal is complete, “End” appears. This error is necessary to prevent errors in the measuring sensors. |

Error codes for Samsung washing machines with and without display (according to data from the dealer website samsung.com/ru )

How to call a technician?

Requests for repairs are accepted daily, from 8 am to 10 pm by phone or using an online application.

8 (985) 181 – 02 – 88

8 (985) 181 – 02 – 88 (Whatsapp)

Leave a request for repairs

Important! When contacting, please provide the following information: Your contact information: name, phone number and address, make of the machine, if possible, send a tag with the serial number and product code of the machine and the day and time of arrival of the technician that suits you.

To carry out repairs and select spare parts for your washing machine, you need to know its model and serial number.

The exact model of the machine is indicated on the tag on the body of the washing machine or stickers, as well as in the operating instructions. If you have already purchased replacement parts yourself, please indicate only the make of the machine. For example, SAMSUNG WF B105 NV.

places where washing machines may contain a sticker with all the necessary service information.

1. Under the hatch door on the body. Most often, on front-type washing machines, the serial number is located on a sticker under the hatch door. Either on the door itself or on the body. In most cases, the number consists of numbers, less often of numbers and letters .

2. On the back side of the pump filter hatch. On vertical models, a sticker with a service number is most often located on the inside of the small hatch that covers the pump filter.

3. On the back wall. The back wall of the washing machine is a traditional place for all kinds of service information. If you couldn’t find a sticker with a number on the front, then it was probably preserved on the back wall.

4. In the passport or instruction manual. Finally, the serial number can sometimes be found in the documents that come with the purchase of the washing machine. As a rule, the number is located in the passport or warranty card.

The arrows show the location of the tags.

washing machine manufacturers encode on a tag (sticker) what they produced, when, where and from what parts. This information is encoded in two sequences of numbers (letters) product and serial numbers. Their combination is unique and applies only to one specific instance of the washing machine.

Please take a photo of these tags

To maximize the life of your washing machine, you need to carefully read the operating instructions. If you have lost it, here you can select your model and download it in pdf format.

Samsung washing machine operating instructions

| SAMSUNG B 813J | SAMSUNG B 1013 J | SAMSUNG B 1115 J |

| SAMSUNG B 1445 AV | SAMSUNG B 815J | SAMSUNG F 1015J |

| SAMSUNG F 1215J | SAMSUNG F 815J | SAMSUNG P 1005J |

| SAMSUNG P 1205J | SAMSUNG P 6091 | SAMSUNG P 843 |

| SAMSUNG R 1052 | SAMSUNG R 1213 J | SAMSUNG R 813 J |

| SAMSUNG R 852 | SAMSUNG S 1005J | SAMSUNG S 1043 |

| SAMSUNG S 621 | SAMSUNG S 805J | SAMSUNG S 832 |

| SAMSUNG WD 8122 CVB | SAMSUNG WF 0400 N2N | SAMSUNG WF 0508 NZ |

| SAMSUNG WF 1590 NFU1 | SAMSUNG WF 6450 S6 | SAMSUNG WF 6452 S6 |

| SAMSUNG WF 6458 S4 | SAMSUNG WF 6520 N7W | SAMSUNG WF 6520 S7 |

| SAMSUNG WF 6522 N7W | SAMSUNG WF 6522 S7W | SAMSUNG WF 6528 S4 |

| SAMSUNG WF 6600 N7W | SAMSUNG WF 6600 S7 | SAMSUNG WF 6602 S6 |

| SAMSUNG WF 6604 S4 | SAMSUNG WF 6608 S4 | SAMSUNG WF 6700 N7W |

| SAMSUNG WF 6702 S7 | SAMSUNG WF 6704 S6 | SAMSUNG WF 6708 S4 |

| SAMSUNG WF 7102 SKP | SAMSUNG WF 7450 S8 | SAMSUNG WF 7452 S8 |

| SAMSUNG WF 7458 S8 | SAMSUNG WF 7520 S9R | SAMSUNG WF 7522 S9C |

| SAMSUNG WF 7600 S8 | SAMSUNG WF 7602 S8 | SAMSUNG WF 7608 S8 |

| SAMSUNG WF 7708 S8 | SAMSUNG WF 8520 S9 | SAMSUNG WF 8590 NE |

| SAMSUNG WF 8592 NE | SAMSUNG WF 8690 AE | SAMSUNG WF 8692 AE |

| SAMSUNG WF 8694 FE | SAMSUNG WF 8698 NE | SAMSUNG WF B105 NV |

| SAMSUNG WF B125 NC | SAMSUNG WF B145 NC | SAMSUNG WF B85 N |

| SAMSUNG WF F1056 | SAMSUNG WF F1062 | SAMSUNG WF F125 AC |

| SAMSUNG WF F854 S | SAMSUNG WF F861 | SAMSUNG WF J105 AV |

| SAMSUNG WF J1254 C | SAMSUNG WF J1261 | SAMSUNG WF J145 AC |

| SAMSUNG WF J861 | SAMSUNG WF M590AH | SAMSUNG WF M592 AH |

| SAMSUNG WF M592 NMH | SAMSUNG WF M598 NM | SAMSUNG WF M690 NM |

| SAMSUNG WF M692 NM | SAMSUNG WF M694 NM | SAMSUNG WF M698 NM |

| SAMSUNG WF R105 NV | SAMSUNG WF R1256 | SAMSUNG WF R1262 |

| SAMSUNG WF R85 N | SAMSUNG WF S1061 | SAMSUNG WF S862 |

| SAMSUNG WF 0408 S1 | SAMSUNG WF 0500 SY | SAMSUNG WF 0508 BY |

| SAMSUNG WF 0590 FR | SAMSUNG WF 0592 NR | SAMSUNG WF 0690 AR |

| SAMSUNG WF 0692 FR | SAMSUNG WF 0694 NR | SAMSUNG WF 0702 NBF YLP |

| SAMSUNG WF 7450 N1 | SAMSUNG WF 7522 N1 | SAMSUNG WF 7604 N1 |

| SAMSUNG WF 7704 N1 | SAMSUNG WF 8500AM | SAMSUNG WF 8500 NM |

| SAMSUNG WF 8502 FG | SAMSUNG WF 8508 AG | SAMSUNG WF 8508 NH |

| SAMSUNG WF 8590AH | SAMSUNG WF 8590 FG | SAMSUNG WF 8590 NG |

| SAMSUNG WF 8592 AF | SAMSUNG WF 8592 NF | SAMSUNG WF 8592 SF |

| SAMSUNG WF 8598 AM | SAMSUNG WF 8598 GF | SAMSUNG WF 8598 NM |

| SAMSUNG WF 8600AM | SAMSUNG WF 8600 NM | SAMSUNG WF 8602 FG |

| SAMSUNG WF 8604 AG | SAMSUNG WF 8604 NG | SAMSUNG WF 8608AH |

| SAMSUNG WF 8608 NH | SAMSUNG WF 8690AH | SAMSUNG WF 8690 FG |

| SAMSUNG WF 8690 NH | SAMSUNG WF 8692 AG | SAMSUNG WF 8692 FF |

| SAMSUNG WF 8692 NG | SAMSUNG WF 8694 AF | SAMSUNG WF 8694 BF |

| SAMSUNG WF 8694 NF | SAMSUNG WF 8694 SF | SAMSUNG WF 8698 AM |

| SAMSUNG WF 8698 GF | SAMSUNG WF 8698 NM | SAMSUNG WF 9590 GQ |

| SAMSUNG WF 9592 SQ | SAMSUNG WF 9690 BQ | SAMSUNG WF 9692 GQ |

| SAMSUNG WF 9694 SQ |

Washing machines from manufacturers that we repair

Causes of failure

Despite the fact that manufacturers of Samsung washing machines pay enormous attention to the quality of their equipment, the possibility of breakdown cannot be ruled out.

At the same time, manufacturing defects as a cause of drum failure are rarely observed. There are other factors that can cause a knocking or squeaking sound, or the centrifuge to stop completely.

Doesn't turn

The drum may stop rotating for a number of reasons. Among them:

overload of laundry;- belt breakage or slippage;

- wear of motor brushes;

- bearing wear;

- failure of the control board;

- broken wiring.

If reducing the load on the appliance in the form of removing some of the laundry did not help solve the problem, most likely the cause lies in a more serious breakdown. Read more in this article.

Why is it knocking?

The sound of a drum is not normal, but there is no need to panic. First you need to think about what was loaded into the device. Perhaps the unusual sound is the result of the interaction of the metal wall of the drum and some parts of the clothing: plastic or metal.

If this cause has been ruled out, the following issues need to be considered:

- There is a foreign object between the tank and the drum (coin, button, bra wire, etc.). The foreign body must be removed, which will require disassembling the washing machine.

- The surge protector that is attached to the back wall of the machine has come off. It hits the tank, causing a knocking sound. It is necessary to disassemble the equipment and check the quality of fixation of the part.

- The shock absorbers have failed. If they have lost their elasticity and stretched, then when they sink to the bottom, they will begin to make a characteristic knock on the body of the device. It may sound like a drum is beating. The problem can be solved by replacing all shock absorbers.

Sometimes knocking noise occurs because the washing machine is installed on an uneven surface. If a skew is detected, you need to move the device. Do not place it close to the wall or furniture.

Creaks when washing or spinning

If you hear an iron squeak, then the bearing is highly likely to have failed.

This occurs during prolonged use of the device and is a natural process. Over time, all parts wear out. To get rid of the squeak, you need to disassemble the drum, replace bearings and seals .

Another reason for squeaking is when parts of items that are in the wash get on the hatch cuff. Sometimes squeaking is caused by fur or hair that has bunched up in a ball.

The slipping drive belt and the weakened shaft mount respond with a creaking sound . In this case, you need to disassemble the washing machine and fix the problem.

A common cause of squeaking is bearings that are worn out, but not completely. It is better to replace them in the near future, or the machine may fail at the most inopportune moment.

There is water in it

If there is water in the drum and does not drain, this may be due to the following reasons:

- There is a blockage in the drain filter. It can be formed by any small objects. To deal with the problem, you need to clean the filter and put it back.

- The pump is broken or clogged. If no dirt is found in it, the part needs to be replaced.

- The control board has malfunctioned. Sometimes simply rebooting the device helps. It is enough to turn it off for 15 minutes and then start it up again. If this does not help, repair is required.

Samsung washing machine fault codes

To localize breakdowns, error codes are used, which are displayed on the displays, thus helping to eliminate damage. Below is a table with a list of the most common faults and their corresponding alphanumeric combinations.

| Error code | Malfunction |

| 5E, 5C, E2 | The water does not drain from the tank, or the water decreases too slowly. The reason is a blockage in the drain pipe, pump filter, drain hose or sewer. The drain pump may not be working or the drain hose may be squashed. |

| 4E, 4C, E1 | Water is not poured into the tank. The reason may be a lack of water in the water supply. The water supply tap may be closed, the inlet strainer may be clogged, or the cold and hot water hoses may not be connected correctly. Other sources of malfunction: there is no connection between the hose and the dispenser (pinched or leaking), contact in the inlet valve connector is broken. The Aqua Stop protection for the inlet hose has probably activated. |

| HE, HE1, HE2, H1, HC, E5, E6 | The water in the tank does not heat up. The electric water heater is damaged or the temperature sensor is not working. The contact in the connectors leading from the electronic control unit (hereinafter also referred to as the ECU) to the heating element or temperature sensor is probably broken. The ECU is faulty. There is a possibility that there is no water in the tank or it is heated to +100 ℃, as a result of which the SM blocks switching on |

| UE, UB, E4 | The balance is disturbed - the laundry is unevenly distributed or clumped in the drum. The reason is most often that there is too little or too much stuff in the drum |

| SUD, 5D (SD) | Too much foaming in the tank. The reason is the use of the wrong powder or too much of it. The error is temporary: after the foam settles, the machine will continue cutting |

| LE, LC, E9 | Water spontaneously drains from the tank. A common mistake is that the drain hose is connected incorrectly to the sewer or is positioned too low. Maybe the SM tank is leaking |

| 0E, 0F, 0C, E3 | There is too much water in the tank. The reason is that the drain hose is not connected correctly to the sewer. The fill valve may be stuck open. |

| 1E, 1C, E7, OE, OF | The water level sensor (pressostat) tube is clogged, pinched or disconnected. Damage to the pressure switch or ECU. Lost contact in connectors |

| 3E, 3C, EA | Damage to the motor windings. It is possible that contacts in the cables going to the motor or tachogenerator may be damaged. The electric motor may be jammed by a foreign object |

| 3E1, 3C1 | The contact in the cable going to the motor is broken. The tachogenerator is probably faulty. Drum overload with laundry |

| 3E2, 3C2 | Problems with signals from the tachogenerator - the contact may be broken or the tachogenerator is not working |

| 3E3, 3C3, 3C4, 3E4 | Incorrect information comes from the tachometer. The engine may be damaged. There is a possibility of contact failure |

| 4E2 | Water too hot for delicate wash cycle (more than +50 ℃) |

| 9E1, 9E2 | The input mains voltage is outside the permissible limits. The ECU may have failed |

| UC, 9C | Mains voltage is more than 286 V or less than 177 V for a long time |

| DE, DC, ED | The hatch door is not closed tightly or does not open. The door hook that fits into the latch of the hatch locking device (hereinafter also referred to as UBL) may be bent. |

| DE1 | Lack of contact in the UBL connector. The wire is probably damaged |

| TE, TE1, TE2, TE3, TC, TC1, TC2, TC3 | The temperature sensor has failed and there is no signal. Perhaps there is no contact with it or the ECU is faulty |

It should be noted that there are many more error codes that indicate problems with Samsung washing machines. The most common faults are presented above.

The presented video talks about the error codes of the Samsung brand SM:

Call the master

You need to contact a professional if you cannot solve the problem yourself . Repairing a control board is a difficult task that cannot be completed without special knowledge.

For help, you can contact service centers or private specialists. Contacts for a specific locality can be found on the Internet.

Many repairmen publish advertisements in newspapers. Another option is to use word of mouth if you have friends who have already used the services of such specialists.

When contacting private craftsmen, there is a risk of meeting a scammer . Therefore, before calling a repairman to your home, you need to study reviews on the Internet. As a rule, negative comments about unscrupulous craftsmen are found on various forums.

If a specialist promises a free visit and diagnostics, and then demands payment, you need to threaten him with going to the police.

How to call a specialist

A technician will come out for diagnostics and repairs upon prior request. You can make a call by phone or through the form on the website. Provide the service manager with the following information:

- Make and model of the washing machine (see the instructions on the body).

- What happened, when, after what, the main symptoms of the breakdown (needed to select tools and components before leaving).

- Optimal time for repairs.

- Contact details.

SHOW MORE