Usually, it does not occur to users to deal with the internal structure of a Samsung washing machine, but if any malfunction occurs, interest in this issue arises instantly. To repair equipment yourself, you need to study the diagram of the unit, understand where the parts and components of the machine are located. Most SMAs have a similar structure; the difference can be observed only in some elements; now we will take a very detailed look at Samsung brand washing machines.

Preparing for launch

All modern models of washing machines differ little from each other in terms of launch.

Before turning on the washing machine, check whether there is a power cord and whether the device is grounded. If everything is normal, then you can load laundry into the drum. Each washing machine drum has its own weight category for which it is designed. Be careful, overloading may cause the crosspiece to fail. Most modern models have a function that notifies you if you have put more clothes than necessary.

After loading things, close the door. If you have a vertical drum, first close the door, and then the hatch. In a horizontal drum, close only the door.

The powder packaging must indicate the dose that needs to be poured into the compartment.

It is important to stick to the dose, because if you pour in the powder, foam will appear, and if you do not add enough of it, the clothes may not be washed at all. To make sure you don't make a mistake, use a special measuring cup.

The powder tray has three sections:

- left – main department,

- medium – intended for air conditioning,

- right – preliminary.

Powder tray Basically, the compartments are located like this: on the left - for the main wash, next to it - for rinsing and pre-washing.

Now we need to supply the car with water. Most washing appliances are connected directly to the water supply, but some models have separate tanks. After completing this action, we connect the device to the network.

Next, you select the washing mode. The operating mode is selected by pressing the corresponding buttons. It is worth considering that they are determined taking into account the type of washing and the fabric that they plan to wash.

Selecting a washing mode

At this stage of time, there are the following types of washing:

- gentle wash,

- children's clothing,

- quick wash,

- washing everyday clothes.

As for fabrics, there are separate modes for the following types of fabrics:

Types of modes:

- Special mode: This function is mainly found in new models; it disinfects and protects white items with steam and helps remove stains. It should be described in more detail in your machine manual.

- Delicate wash: slow wash and low rinse speed. It’s good in that it prevents things from looking worn out, but it doesn’t wash very thoroughly. Suitable for delicate items.

- Light spin: First a quick wash, then a slow wash.

- Normal: quick rinse and equally quick spin.

Temperature detection

Temperature ranges from 30 to 95 degrees. Here are some recommendations for choosing a mode:

- The temperature is selected depending on how dirty the clothes are. If you just need to refresh, then choose 30-40 degrees.

- Synthetics wash perfectly in conditions of 40-60 degrees.

- Bed and bath linen and accessories require the highest temperature.

Spin intensity

The intensity is determined by the number of revolutions per minute. Naturally, the more efficient the spin cycle, the less water there is in the clothes; you get almost dry clothes out of the washing machine.

Don’t forget that fabrics that require more care should be washed at a lower intensity. It is generally better to wash silk and chiffon without the spin function.

Washing program

Next we need to set the washing program. The differences between models are quite high with this function. Be sure to take into account the temperature conditions; if you do not turn it on carefully, you can damage things.

All information should be described in detail in your instructions. Expensive models are equipped with touch sensors, while simpler ones have a regular wheel. Now let’s start, to do this we find the “Start” button and press it.

When the washing process comes to an end, depending on your device, it will give a signal or a sound, or the button will flash that the wash has come to an end. We disconnect the device from the power supply, open the door and take out things.

Unscrew the drain filter

The second safest option is draining through a garbage filter. You can resort to it almost always, even when the machine freezes during the washing process. The main thing is to act consistently and remember safety precautions.

The garbage filter is a plastic nozzle in the shape of a spiral, screwed into the drain volute and hidden behind a false panel in the lower right part of the body. The name is explained by the function of the element: waste water passes through the plastic, and debris and dirt cling to the plastic, not reaching the pump, which is more vulnerable to blockages. To start the emergency drain through the “trash can”, you need to unscrew it:

Be careful! Immediately after the end of the high-temperature regime, you cannot drain the water through the filter - you can get burned by boiling water!

Emptying the tank through a filter has only three disadvantages. The first is the impossibility of quickly draining immediately after a high-temperature cycle, since there is a high risk of getting burned by boiling water. The second is inevitable dirt, since it will be difficult to control the flow of sewage; something will definitely spill on the floor and equipment. The third drawback lies in the reverse installation: if the nozzle is not screwed in tightly enough, a leak will occur.

Washing machine: how does it work?

First, it’s worth considering what parts a Samsung washing machine consists of. This determines whether the user can properly disassemble the Samsung machine. Typically they can be described as follows, regardless of the manufacturer:

- There are several panels inside. Front and rear, base versions are available.

- A tray of the appropriate type into which the products are poured and filled.

- The program panel is an essential component of machines, especially modern ones.

- Each model is equipped with a drum, couplings and a tank.

- Tank weights.

- Engine.

- Spring mechanism.

- Water pump.

- heating element.

- Pressostat.

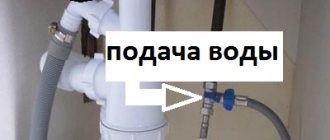

Water supply

The supply from the common line is carried out through hoses and solenoid valves that open and close at the right time. A flow regulator is also installed in the valve, which helps control the pressure regardless of the pressure in the line.

If it exceeds 10 bar, a pressure reducing valve is additionally installed. A pressure value below 1 bar also requires additional measures.

There is a filter in front of the valve to prevent particles from entering. Usually about 1-3 valves are installed, in the latter case a valve is provided for each compartment in the care dispenser.

Troubleshooting and troubleshooting methods for the Indesit IWSB 5085 CIS washing machine

If your Indesit IWSB 5085 CIS washing machine does not work. Before contacting an Authorized Service Center (see Service), check whether the problem can be resolved by following the recommendations in the following list.

| Malfunctions: | Possible causes/remedys: |

| The Indesit IWSB 5085 CIS washing machine does not turn on. | • The plug is not connected to the electrical outlet or has come loose and is not making contact. • There is no power in the house. |

| The wash cycle does not start. | • The car hatch is not closed tightly. • The ON/OFF button was not pressed. • The START/PAUSE button was not pressed. • The water tap is turned off. • A cycle start delay has been programmed. |

| The Indesit IWSB 5085 CIS washing machine does not fill with water (the indicator of the first wash phase flashes frequently). | • The water hose is not connected to the tap. • The hose is bent. • The water tap is turned off. • There is no water in the house. • Insufficient water pressure. • The START/PAUSE button was not pressed. |

| The machine continuously fills and drains water. | • The drain hose is not located at a height of 65 - 100 cm from the floor (see “Installation”). • The end of the drain hose is immersed in water (see “Installation”). • The wall drain hole does not have an air release valve. If after the above checks the malfunction is not resolved, you should turn off the water tap, turn off the Indesit IWSB 5085 CIS washing machine and contact the Service Center. If your apartment is located on the top floors of a building, siphon phenomena may occur, so the Indesit IWSB 5085 CIS washing machine continuously fills and drains water. To eliminate this anomaly, special valves against the siphon phenomenon are commercially available. |

| The Indesit IWSB 5085 CIS washing machine does not drain water and does not spin clothes. | • The selected program does not drain the water: some programs require manual draining. • The drain hose is bent (see “Installation”). • The drain pipe is clogged. |

| The Indesit IWSB 5085 CIS washing machine vibrates strongly during the spin process. | • When installing the Indesit IWSB 5085 CIS washing machine, the drum was not unlocked correctly (see “Installation”). • The Indesit IWSB 5085 CIS washing machine is not installed level (see “Installation”). • The machine is sandwiched between the wall and furniture (see “Installation”). |

| Water leaks from the Indesit IWSB 5085 CIS washing machine. | • The water hose is not screwed on properly (see “Installation”). • The detergent dispenser is clogged (to clean it, see the “Maintenance and Care” paragraph). • The drain hose is not securely fastened (see “Installation”). |

| The additional function indicators and the “start/pause” indicator are flashing, and one of the “current phase” indicators and the “HATCH LOCK” indicator are on without blinking. | • Turn off the machine and unplug the power plug from the socket, wait 1 minute and turn on the machine again. If the problem persists, contact Customer Service. |

| During the washing process, too much foam is formed. | • The detergent is not suitable for washing in the Indesit IWSB 5085 CIS washing machine (the packaging should indicate “for washing in the Indesit IWSB 5085 CIS washing machine”, “for hand and machine wash” or the like). • An excessive amount of detergent has been placed in the dispenser. |

Service of washing machine Indesit IWSB 5085 CIS

Before contacting an Authorized Service Center: • Check whether the fault can be resolved yourself (see “Faults and methods for eliminating them”); • Run the program again to check the machine's health; • Otherwise, contact the Authorized Service Center by phone numbers indicated in the warranty card. ! Never contact unauthorized service centers. When contacting the Authorized Service Center, you must inform: • type of malfunction; • product model (Mod.); • technical number passports (serial number). The serial number and model are indicated on the nameplate located on the rear panel and front of the hatch of the Indesit IWSB 5085 CIS washing machine.

Additionally, you can read other instructions:

Plastic tank and metal drum

The plastic tank is an important part of the washing machine; it is where water is collected and mixed with detergents. It is necessary to ensure that the tank does not lose complete seal. Otherwise, a water leak may begin, which is quite difficult to eliminate.

The drum is made of metal and is located inside the tank. Housewives put their laundry in it. As you noticed, the surface of the drum is corrugated, this is necessary for better washing of contaminated fabrics. The drum is also equipped with plastic ridges (ribs), which allow you to scatter the laundry inside, ensuring that a mixture of water and detergents penetrates into the clothes.

On different models of Samsung machines, the drums have different volumes and, accordingly, different maximum loads of laundry.

Samsung washing machine circuit diagrams

The design diagrams of Samsung washing machines may have slight differences, depending on the model. However, the general components are always the same. The diagram is shown in the figure:

The main elements of Samsung washing machines:

- the front panel, back wall, top cover and bottom of the device are all fixed with bolts;

- pull-out tray for detergents;

- program panel;

- drum, coupling, tank;

- counterweights - most often there are two of them, they are located in the upper and lower parts of the washing machine;

- engine;

- springs;

- pump;

- heating element;

- pressure switch

In addition to the main circuit of the washing machine, there is also an electronic circuit that is useful when checking the integrity of wires and components. It is shown in the figure:

Locking device and cuff

The hatch locking device is nothing more than an electronic lock that closes the door before the wash starts. The user, having closed the hatch, activates only the mechanical lock, and after starting the program, a click can be heard - this is what turns on the electronic door lock. Only after such a signal will water begin to flow into the tank. UBL prevents accidental opening of the door during washing.

The cuff serves to more securely close the hatch. It is a rubber seal that prevents water from leaking through the gap between the SMA body and the hatch door. Make sure the cuff is clean, dry and undamaged. If the rubber band breaks, you should not use the machine until the problem is fixed, as liquid from the drum will spill onto the floor.

Video

For more information, watch the video on how to disassemble a Samsung washing machine.

She graduated from the author's physics and mathematics lyceum and art school. Received a higher education in economics with a major in innovative management. Freelancer. Married, actively travels. He is interested in Buddhist philosophy, enjoys transurfing and loves Mediterranean cuisine.

Found a mistake? Select the text with the mouse and click:

Threads made of gold and silver, which were used to embroider clothes in the old days, are called gimp. To obtain them, the metal wire was pulled for a long time with pliers to the required fineness. This is where the expression “to drag out the rigmarole” came from - “to do long, monotonous work” or “to delay the completion of a task.”

Stretch ceilings made of PVC film can withstand from 70 to 120 liters of water per 1 m2 of their area (depending on the size of the ceiling, the degree of its tension and the quality of the film). So you don’t have to worry about leaks from neighbors above.

The habit of using an automatic washing machine “sparingly” can lead to the appearance of an unpleasant odor in it. Washing at temperatures below 60℃ and short rinses allow fungi and bacteria from dirty clothes to remain on internal surfaces and actively multiply.

There are special traps to combat moths. The sticky layer with which they are covered contains female pheromones that attract males. By sticking to the trap, they are eliminated from the reproduction process, which leads to a decrease in the moth population.

The easiest way to remove scale and carbon deposits from the soleplate of the iron is with table salt. Pour a thick layer of salt onto the paper, heat the iron to maximum and run the iron over the salt bed several times, applying light pressure.

The dishwasher cleans more than just plates and cups. You can load it with plastic toys, glass lamp shades and even dirty vegetables, such as potatoes, but only without using detergents.

Fresh lemon is not only suitable for tea: clean dirt from the surface of an acrylic bath by rubbing with half a cut citrus, or quickly wash the microwave by placing a container of water and lemon slices in it for 8-10 minutes at maximum power. The softened dirt can simply be wiped off with a sponge.

If your favorite things show the first signs of gestation in the form of untidy pellets, you can get rid of them using a special machine - a shaver. It quickly and effectively shaves off clumps of fabric fibers and returns things to their proper appearance.

Before removing various stains from clothing, you need to find out how safe the selected solvent is for the fabric itself. It is applied in a small amount to an inconspicuous area of the item from the inside out for 5-10 minutes. If the material retains its structure and color, you can move on to stains.

Any washing machine breaks down over time. Units from the South Korean manufacturer Samsung are no exception. Replacing some parts requires almost complete disassembly of the device. In this article we will talk about how to disassemble a Samsung washing machine with your own hands.

Carrying out preparation work

Preparation for further disassembly of Samsung washing machines largely depends on the scheme in which the laundry is loaded - vertically, in the frontal version. Sometimes, to access the internal parts, it is enough to remove a special panel located at the back. This makes disassembly easier.

It is recommended to study in advance the electrical diagram and description of the main components for a specific model of a Samsung washing machine. Only after this can the owner begin the independent repair and disassembly process.

Before disassembling the Samsung washing machine begins, the following steps must be performed:

- First, the instructions are studied along with all the rules described in it. They tell you how to disassemble the case.

- Then you need to start preparing the appropriate equipment.

- At the next stages, the machine is completely disconnected from the supply of electricity and water. The drain hose and the outlet to the sewer must also be disconnected. Disassembly is easy here.

As for the equipment for disassembling a Samsung washing machine, it will consist of the following items:

- Long bent pliers.

- Insulated pliers.

- An ordinary type of wire cutter.

- Pliers and wire cutters used to process self-clamping clamps.

- Phillips head screwdriver.

- Flathead screwdriver.

- Wrenches for 19, 9 and 8.

- Service key. Without it, disassembly is impossible.

When disassembling a Samsung washing machine, you need to take into account that most of the parts are made of plastic. Therefore, you need to work carefully and carefully. Otherwise, the elements may be damaged and will have to be replaced, which will involve additional costs.

Features and technical characteristics of automatic washing machines

The main technical characteristics of household washing units include:

- layout (vertical, front loading);

- energy consumption class (indicated by Latin letters from A to G);

- volume of loaded laundry (for household products usually within 3-5 kg);

- additional features applied by the manufacturer (tank coating, increased efficiency, liquid crystal display, duplication of light and sound signals).

According to the type of loading, washing machines are divided into 2 main types. It makes no sense to state unequivocally and categorically which one is better. The front-facing machine allows you to observe the washing process through a transparent window in the door, while the vertical machine is more compact - it can be recommended for installation in combined units of small apartments.

In terms of energy consumption class, most brands have long been competing with each other within class A: no one is surprised by the designation A+ or AAA, which indicates the increased efficiency of the vehicle’s electrical equipment. The volume of washing directly depends on the needs of the owner: for a small family 3 kg is enough, if you plan to wash often, in large quantities, including down jackets or blankets, you need larger parameters.

Opinions differ regarding options and functional additions: they facilitate the washing procedure, but at the same time, worries about diagnosing one or another stage are shifted to automation and rather complex electronic components (almost a microcomputer), which can sometimes fail at the most inopportune moment.

Water supply control

The duration of the supply depends on the level, which is determined by mechanical or analogue controls. Mechanical ones are implemented in the form of a cell with a membrane, connected to the bathtub with a hose. When the desired level is reached, the pressure increases and the water supply stops.

The analog controller is triggered by an increase in level, it reacts by changing the resistance.

Read more ► Do-it-yourself Indesit washing machine repair, troubleshooting common faults

Sensors are also used to protect the heating element - it turns on only when a certain level is reached in order to avoid damage to the heater.

What to choose: fix it yourself or call a repairman to your home?

If a breakdown occurs, the owner of a Samsung washing machine is faced with the question of whether to repair it himself or call a technician. To make the right decision, you need to carefully analyze the situation.

If the device is under warranty

If the device is under warranty, you should not attempt to repair it yourself.

There is also no need to pay for the services of private masters. Damage that occurs through no fault of the buyer is subject to warranty service. It is free, at the expense of the manufacturer.

If the device breaks down due to external factors, for example, it was dropped or connected incorrectly, you will have to pay for repairs yourself.

Repair it yourself

You can handle minor breakdowns on your own, for example:

- Replacing the pressure switch.

- Clearing the blockage.

- Rebooting the machine due to a controller malfunction.

- Replacing a pump, door hinge or hatch, etc.

If you have experience and capabilities, you can try to carry out more complex repair work, including:

- replacing the heating element,

- hatch cuffs,

- motor,

- shock absorbers.

The cost of repairs on your own is affected only by the price of the part and amounts to 2-3 thousand rubles.

If during the repair process you realize that something is not going according to plan, it is better to call a specialist.

At the service center

It is recommended to entrust your washing machine to professionals in the following cases:

- controller is faulty;

- bearing replacement is necessary;

- dismantling of the tank or cross is required;

- The tank support broke.

Repairs that require complete disassembly of the washing machine are complex and time-consuming. Only experienced craftsmen can cope with it. If you try to intervene on your own, you can completely damage the washing machine.

The cost of repair by specialists will be from 2 to 7 thousand rubles for each breakdown, depending on the cause.

You will find all the most important and useful information about Samsung washing machines in this section of the site.

Prevention of breakdowns

The operation of any household appliance, including a washing machine, must be carried out strictly in compliance with the rules of use. Remember that careful handling of equipment can extend its trouble-free service life. To prevent breakdowns, you need to follow some recommendations :

- Clothes with metal parts should be washed in a special bag. Washing small parts should be done in the same way as

- after finishing washing, be sure to unplug the machine to protect the unit from power surges,

- It is better to install the machine in a room with less humidity,

- try not to overload the tank of the car,

- if there is poor quality water in the system, install a water purification filter,

- When washing, use only high-quality washing powder.

special instructions

For efficient and trouble-free washing, the following recommendations must be carefully followed:

- Before starting work, it is necessary to sort the laundry by color, degree of color fastness, fabric structure, and the presence of decorative elements.

- When stowing things, it is necessary to check them for the presence of foreign objects in the pockets. Even a small metal object during machine operation can cause irreparable harm.

- It is recommended to stack dirty laundry taking into account the permissible load of the drum.

- Clothes are placed with all buttons and zippers fastened. To better preserve the accessories of products and the drum of the washing machine, you can use a special bag.

- Before storing items, it is recommended to study the labels and marks on the tags in order to make sure that the manufacturer allows machine washing, or to find out the special conditions specified by him.

Do you wash your shoes in the machine? Oh yes! No - Be sure to use a special powder that does not form a lot of foam.

- Detergents are placed in accordance with the purpose of the tray compartments. There is a left compartment for pre-wash, a middle compartment for the main wash, and a compartment on the far right for rinsing.

- For optimal balance, large and small items of clothing are best placed together.

- Before pressing the “Start” button, you must make sure that the unit is connected to the power supply.

- When washing in cold water, half the amount of powder is required.

- To avoid damage, program selection can only be made when the unit is stopped.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Be sure to unplug the plug from the socket! The fact is that the design of the Indesit SMA is designed in such a way that when the machine is turned on, part of the control module is energized. And during surges in the electrical network, it can be damaged!

Indesit equipment does its job flawlessly if used correctly. The management of the washing machine should be treated with the utmost responsibility. A thorough study of the capabilities of the unit and its functions will not only allow you to achieve high quality work, but will also keep the device in good condition for a long time.

Main details

The story about how an automatic washing machine works must begin with a description of its parts. In the diagram below you can see the main internal elements and their location. In addition to them, the car may also have additional parts, for example, various sensors, relays, etc.

Here is a schematic representation of the structure of a washing machine

The main components of the washing machine include:

- body (panels, top cover and hatch door);

- control panel and electronic module;

- tank and drum;

- engine;

- tubular electric heater (TEH);

- water intake system (valve, water level sensor, etc.);

- water drainage system (drain pump, filter, etc.);

- balancing system (springs, shock absorbers).

Additional components can be entire systems, for example a leakage protection system, or individual sensors, for example a laundry moisture level sensor in units with a drying function.

Let's talk about the main components in more detail.

Housing and its elements

The body of the washing machine consists of a front, rear and two side panels, as well as a top cover. A hatch door, a lock mechanism and a rubber cuff are mounted in the front part. The door sometimes has a small window (opening separately), through which you can add items to the washing machine drum during washing.

In some models of washing machines, you can add items during the washing process through a small window in the hatch door

The rubber cuff serves to ensure a tight fit of the door and protect against water leakage. The lock mechanism is connected to the control module, which blocks the hatch when the washing program is turned on. At the bottom of the front panel there is a door behind which the drain filter is located.

The back panel, as a rule, is solid, but there are models of washing machines in which part of the back wall can be removed separately.

On some models, part of the back wall can be removed

Control panel and electronic module

The control panel is the “face” of the washing machine, and the electronic module is its “brain”. The panel contains levers and buttons that allow you to select the required washing mode, start the operation of the unit and monitor its progress. Most modern models are equipped with a liquid crystal display, which displays all the necessary information (how many minutes are left until the end of the cycle, whether the hatch is locked, etc.), and in case of problems, information codes are displayed, by which you can recognize the nature of the malfunction.

Using the dashboard, you can select the washing mode, start the washing machine and monitor its progress

The electronic module is located directly under the panel; it transmits commands to all units of the unit and controls their operation. The module's memory contains washing programs and functions that the equipment can perform. For proper operation, the board needs information from different parts of the machine, which it receives thanks to signals from sensors (tachometer, thermostat, etc.).

Pictured is a washing machine control module

The control module and other electronic parts of the unit are especially sensitive to voltage fluctuations.

Tank and drum

A tank is a plastic container with a drum inside. Together they occupy most of the internal space of the case. The structure of the washing machine drum is quite simple - it is made of metal, and there are holes in the surface of the part through which water passes during washing.

In the photo you see a washing machine tank with a drum inside

A bearing unit is installed in the drum - a connecting link between the shaft, pulley and motor, which transmits torque to the drum. The unit consists of two bearings and a rubber seal; the smooth rotation of the part during washing depends on its performance. To extend the service life of the unit, do not overload the washing machine drum with laundry.

The arrow in the photo indicates the location of the bearing assembly.

Engine

The electric motor rotates the washing machine drum. The belt-driven motor is located under the tank, and its shaft is connected by a belt to a pulley - a wheel attached to the drum shaft. With this design, torque is transmitted from the engine to the drum using several parts.

In the photo you can see the structure of the motor with a belt drive

In units equipped with direct drive, the motor is located directly on the tank; there are practically no connecting links between it and the drum - the torque is transmitted directly.

The photo shows an inverter motor with direct drive

heating element

A tubular electric heater is responsible for heating the water to the temperature required for washing. Essentially, it is a curved metal tube that, when heated, transfers thermal energy to water. The part is usually installed in the lower part of the tank under the drum. The water temperature is controlled by a special sensor – a thermostat.

The heating element is installed in the washing machine tank under the drum

Over time, due to constant contact with hard water, the heating element becomes covered with limescale, so in order for it not to fail, it must be cleaned periodically.

Water supply system

The water intake system consists of an inlet valve, an inlet filter and pipes connecting the detergent compartment with the water supply hose and tank. The inlet filter traps large debris that can get from the water supply into the unit, and is installed at the point where the water supply hose is attached to the washing machine. Usually this is a small round mesh made of plastic or metal.

The inlet valve is responsible for the water supply

The inlet valve ensures the supply of water to the tank and detergent tray, and also shuts off its supply when the pressure switch (water level sensor) sends a signal to the control module to fill the tank to the required level.

Water drain system

The main element in the water drainage system is a pump or pump. On one side, the part consists of a volute containing a filter, and on the other, an electric motor with a cross impeller. When the control module transmits a signal to the pump, the motor begins to pump water out of the tank and discharge it through the drain hose into the sewer.

Here is a schematic representation of the structure of a washing machine

The filter protects pump parts from debris. It needs to be cleaned from time to time by removing it through the door on the front panel of the case.

Balancing system

The tank and drum have a fairly large volume and weight, and when washing they vibrate quite strongly. To balance the resulting vibration, a system of counterweights is installed in the body of the machine - concrete blocks that are attached to the top and bottom of the tank.

Counterweights help dampen vibrations that occur during operation of the washing machine.

In addition, the tank is installed on shock absorbers, and suspended from above on special springs, which also helps dampen vibrations that occur during the washing process.

Next, let's look at the general operating principle of a washing machine.

Spin

In spin mode, the rotation of the drum reaches maximum speed, and water is removed from the fabric through holes in the sides under the influence of centrifugal force. If the laundry is incorrectly distributed around the perimeter of the drum during spinning at high speeds, significant vibration of the drum occurs, sometimes leading to the machine moving along the floor surface.

The operation of the washing machine may be accompanied by noise and vibration. To soften them, a counterweight system consisting of concrete blocks is placed at the top and bottom of the tank. At the end of the full washing cycle, the loading hatch lock is automatically unlocked.

Springs, shock absorbers and counterweights

Using these components, the washing machine is prevented from oscillating and “bouncing” during operation. This is very important, otherwise the machine would simply destroy itself from the inside during the spin cycle. What details are we talking about?

- Shock absorbers fasten the lower part of the tank to the body of the SMA, and prevent it from bouncing during spinning and hitting the walls.

- Springs support the reservoir from above, their function is very similar to the purpose of shock absorbers.

- Counterweights are weight blocks, they are connected to the outer surface of the tank and serve to maintain balance.

During operation of the machine, the counterweights may be destroyed under the influence of strong vibration. However, in most cases, their fastenings simply become a little loose, and by tightening them you can cope with the problem of the washer “rattling.”

How does automatic washing work?

The process is started by pressing the “Start”, “Start” button or something else designated. The water begins to flow through the fill valve while the drum rotates to more evenly wet the laundry. Some modifications of washing machines additionally have a device that supplies water from above the hatch to optimize this process.

As the tank fills with water, the pressure in it begins to change. Based on this parameter, a special sensor (pressostat), when the water level required for a specific amount of laundry is reached, sends a signal to the control unit about the need to stop its supply. The control module, in turn, closes the solenoid fill valve. During the pouring process, powder is washed out of the detergent dispenser and dissolved with water in the drum. If fabric softener is used, the moment it is taken out is determined by the installed program.

Under the control of the control module, at a certain moment, the soap solution is rinsed out several times. The most advanced automatic machines are often equipped with a water transparency sensor. Then rinsing will be carried out until the remaining powder and contaminants in the water are completely washed away. Everything ends with draining (the drain pump is turned on) and spinning by turning on the engine at a given speed (if the program without spinning is not installed).

Level sensor and filling valve

The liquid level relay (also known as a pressure switch, level sensor), as the name implies, controls the volume of water in the tank. The pressure switch measures the pressure in the tank and sends an information signal to the control unit. The electronic module, having received the information, commands the filling valve to stop drawing water from the communications.

The inlet valve can have from 1 to 3 coils. It is to them that the voltage is transmitted, which allows the valve membrane to open and begin to function. When a signal is received from the control unit to start drawing water, the membrane opens and begins to operate. As soon as the voltage stops being supplied to the coils, it closes.

These two elements are described together for a reason; they constantly interact. The scheme is as follows: the filling valve takes in water, and the level sensor controls the optimal volume of liquid, preventing underfilling or overfilling.

Control module problems

If the equipment turns off when washing starts, the cause of the defect may be the control unit located in the upper part of the housing. The controller contains electronic components that can move away from the contact paths or fail due to vibration or moisture. Service center employees note poor soldering of electronics and poor quality of printed circuit boards, from which the metal substrate peels off.

The unit is checked under the service conditions. The user cannot find microcracks in the elements or determine an incorrectly functioning diode or transistor. To remove damaged parts and install new parts, special soldering equipment is required. A controller with fatal damage must be replaced.

Snail, filter, pump

A pump is a special pump that is used to pump waste water out of the drum after the pre- or main-wash process or rinse cycle. In Samsung washing machines you can find two types of pumps:

- synchronous;

- asynchronous.

The internal contents of the pump are standard: a motor and an impeller. A volute is attached to the top of the pump, to which a pipe and a drain hose are connected. In most cases, the pump fails due to foreign objects entering the system.

If there are coins, wrappers, small toys, etc. left in the pockets of clothes loaded into the drum, all this may end up in the drain pipe. Because of this, not only the filter and hoses become clogged, but also the pump itself. The garbage filter is installed in a snail, which is attached to the pump. As you can see, these three elements are very closely interrelated.

Features of the machine

In a normal situation, all components and sensors of the washing machine work smoothly, without failures. Each element strictly performs its assigned functions. The process is controlled by the main control module, the “brain” of the machine. The board monitors the order of operations, receives and transmits signals, and ensures communication between components.

The most voluminous element of the washing machine is the tank. It is a large plastic or metal cylinder, the position of which is controlled by shock-absorbing springs and dampers. A drum made of stainless steel is placed in the container. It actively rotates during washing, thanks to the “wheel” attached through the cross. The pulley is spun by the drive belt, which in turn is driven by the engine. It is due to the increased speed that the laundry in the drum is washed.

After starting the wash, the drum begins to fill with water. The user, by pressing the “Start” button, sends a signal to the control board, which gives a command to the solenoid valve. It opens, liquid flows into the system, and the pressure switch controls the degree of filling of the tank. When the water reaches the desired level, the sensor will notify the “brain” about this, and the set will stop.

Next, the heating element is activated to heat the water to the set temperature. The control unit controls the stages of the cycle, moving from soaking to main wash, then to rinsing. In between, a command is given to the pump to drain the water.

This is exactly the general picture of almost every wash. In fact, there is nothing complicated in the principle of how the machine works. To understand even better how the machine works, you need to disassemble each of its components separately.

Motor and tachogenerator

This pair of parts also works together. The motor “forces” the drum to rotate, and the tachogenerator ensures that the number of revolutions corresponds to the specified one. The tachometer helps the control module control the speed of the motor, since for each washing mode the rotation speed must be different.

The electric motor of the washing machine promotes the correct rotation of the drum at a given pace. Most modern Samsung washing machines are equipped with inverter motors. In this case, the motor is attached directly to the drum, resulting in greater efficiency and engine power. This design is reliable and durable; failure of the inverter motor is extremely rare.

The commutator motor drives the drum thanks to a special belt. In this case, the electric brushes wear out, so from time to time the motor will need to be repaired.

How to recognize a breakdown: Atlant error codes

| Code | Decoding |

| Sel | The interface module selector is broken. This item needs to be replaced. |

| None | Increased foaming. This can be caused by three reasons:

In this case, you need to reduce the amount of powder, change the product or wash in other modes. |

| F2 | Thermal sensor failure. The sensor itself could “fly”, or the contacts or wires could fail. May indicate a breakdown of the heating element. |

| F3 | Malfunction of the thermoelectric heater (heater). The heating element needs to be replaced. |

| F4 | Damage to the drain pump (drain pump). There are many reasons for this breakdown: clogged or incorrectly installed waste water drain hose, clogged coupling, pump failure, malfunction of the electronics. Repair depends on the diagnostic results. The drain pump may need to be replaced. |

| F5 | The fill valve is the cause of the breakdown. There could be a blockage or a broken hose. The error also occurs when the pressure in the water supply system is low or the control module is damaged. Self-repair or in a workshop - it depends on the nature of the identified breakdown. |

| F6 | Electric motor failure. The motor must be replaced with a new one. |

| F7 | Electrical breakdowns. In some cases, it is enough to replace the interference filter, test whether there is voltage in the power supply, or replace the electronic board. |

| F8 | Too much water in the tank. Culprits: water level sensor (pressure switch), fill valve, wiring that could have burned out or contacts that have oxidized due to high humidity. Depressurization of the cylinder or malfunction of the controller are also quite possible reasons. |

| F9 | Tachometer failure. If you started repairs at home, you will have to check the wiring and contacts with a tester, and maybe replace the engine. A controller failure can also mean error F9, but replacing the module yourself is a difficult task. |

| F10 | Locking failure, which is also associated with board failure. |

| F12 | Motor triath failure. Requires engine or controller replacement. |

| F13 | It means a whole range of breakdowns. First you need to check the contacts and wiring, and if the cause is determined to be a module failure, you should call a specialist. |

| F14 | Software glitch. It is recommended to restart the program. In severe cases, the board needs to be repaired or replaced. |

| F15 | The machine is leaking. This is caused by a violation of the drum seal, wear of the cuff, drain hose, pipes or coupling. It is easier to determine the malfunction by localizing the location of the leak. |

| door | The lock is broken. Maybe you didn't lock the hatch properly. An error also occurs if wires come loose or the board burns out. |

Important! Self-diagnosis of SM Atlant is possible not only in models with an electronic display. In electromechanical models, an error is indicated by indicators flashing in a certain sequence or combination

Open the hatch door

When it is not possible to drain the machine through a hose or filter, a more extreme option remains - open the drum and scoop out the water. But it’s better to first estimate the volume of liquid that has not been drained and be sure to tilt the equipment back. If the tank is very full, then after a sharp “opening” a flood cannot be avoided. The instructions are simple:

The difficulty arises at the stage of opening the door. If the machine freezes in the middle of a program, you cannot unlock the drum by pressing the handle - the electronic lock will remain on. We'll have to do it differently:

Emptying the washing machine through the drum cannot be called easy. First, you will have to scoop out the soapy liquid for a long time, and then clean the room - dirty splashes and puddles cannot be avoided. It is worth considering that the result will not be one hundred percent: a certain part of the water will remain at the bottom of the tank and in the drain system.

What should you pay attention to?

When starting up a Samsung washing machine for the first time, it is very important to monitor the entire washing cycle in order to identify problems in time. Normal operation of the washing machine requires:

Normal operation of the washing machine requires:

- slow rotation of the drum during washing, accelerated during spinning;

- heating the water in the drum seven minutes after switching on;

- absence of leaks and extraneous sounds;

- spinning and draining water without delay.

You should be wary:

- strange sounds

- grinding and knocking

- digital signals appearing on the scoreboard,

- incorrect operation of the selected washing program (for example, frequent draining of water),

- body rattling during the spin process.

If you have any doubts about the correct functioning of a household appliance, this is a reason to contact the service center for advice and warranty service.

Fluid Removal Options

It is safest to empty the washing machine in automatic mode - through the provided one. Everything is simple here: scroll the selector to the appropriate position and start the cycle. However, if the system freezes, this option does not work. If the “tidy” does not respond to the user’s commands, you will have to forcefully drain the water manually. “Manual” draining is started in the following ways:

Before forced draining, equipment should be disconnected from communications: power supply and water supply.

Each of the forced options has its own risks and benefits. Much depends on the situation - sometimes only “opening” the drum is possible. In any case, you first need to turn off the power to the machine, turn off the water and assess the scale of the situation, and then choose the appropriate drainage method.

About troubleshooting basic problems in Samsung devices

Unexpected stops during washing

Insufficient water pressure is the most common reason why this happens. The car just stops. To fix the problem, the device is turned off and on. If there is too much laundry, then the excess is simply removed. Because of this, Samsung washing machines can also stop.

Periodic shutdowns also occur in situations where there is a failure in the power cord and the power button initially has poor contact. Another reason for stops is a slight misalignment. In this case, disassembly is not required.

Problems while collecting water

First you need to check how water flows throughout the entire plumbing system. Separately, you need to make sure that the valve involved in the water supply is open.

Only compliance with certain conditions protects against water pouring out of the device. The free end of the hose is connected from below. Its standard height is no more than 2/3 of the device itself. This is taken into account when disassembling.

If there is a leak from the unit

Problems with a Samsung washing machine can occur for several reasons.

- Sometimes simply cleaning the container where the powder is stored is enough to fix the problem.

- If the hoses have been checked and everything is fine with them, the cause is definitely only the O-ring.

- Checking the tightness of the seals is carried out in the door, at the junction of the hoses.

- If some of the material is worn out, it is replaced.

- The hose and the drain pump are checked separately. Problems may arise due to clogging of these parts in a Samsung washing machine. Disassembly requires minimal time.

Wear of the heating element, failure of this part

If the Samsung washing machine is really broken, the washing water simply will not heat up. But do not rush to change the heating element itself - in some cases, the cause is electrical wiring.

It is recommended to carry out a thorough check of the entire electrical network. The same applies to the contacts of the heating element. For work, a so-called multimeter is used. If everything is in order with the voltage, then the heating element of the Samsung washing machine itself is changed.

A new device is installed only after thoroughly cleaning the area where the previous one was installed. Disassembly is carried out carefully.

The appearance of noise and vibration during operation

The noise often appears due to the fact that the machine itself was not installed correctly. Because of this, a strong hum appears during the spin cycle. Then the position of the Samsung washing machine is simply leveled and checked with a special level.

Another possible cause of the noise is that the bearings are very worn. The parts cannot be repaired; the owner can only make a replacement. This is a difficult task for those who have no experience at all. It is necessary to saw and then glue the tank behind which the bearing is located. It is recommended to seek qualified help if you are not completely confident in your abilities. Then disassembling the Samsung washing machine will go faster.