Error 3e appears on a Samsung washing machine. The engine is a mandatory element of the Samsung SMA. It is with its help that the drum with laundry rotates. There are three main types that are used in washing machines - commutator, asynchronous and commutatorless direct drive.

3E, 3E1, 3E2, 3E3, 3E4, 3C, 3C1, 3C2, 3C3, 3C4, EA 300 3000, 8E, 8E1, 8C, 8C1

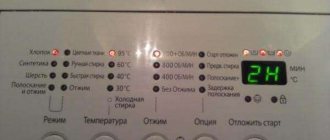

Error display by indication.

A mandatory element is a tachometer generator. This device produces a small direct current, depending on the speed of rotation of the shaft. It is with its help that the electronic module regulates speed, and some of the breakdowns occur due to the tachogenerator. The most common error codes are 3E, 3C, EA and 8E. For Samsung washing machines that are not equipped with a display, a malfunction associated with the tacho is displayed as follows - all program selection indicators, as well as temperatures of 95 and 40°, are lit. Shown in photo.

Errors 3E, 3E1, 3E2, 3E3, 3E4, 3C, 3C1, 3C2, 3C3, 3C4, EA

Which of these codes is displayed does not matter - they are deciphered the same way. EA is typical for older machines that are durable and still in use. Let's consider the reasons for their occurrence:

- Overloading the machine with laundry.

- Motor operation is blocked by a foreign object.

- Damaged contacts or connections.

- Interturn short circuit in the winding.

- The tachometer generator or the wires connecting it to the controller are faulty.

- The problem is in the control module.

Tacho breakdown error.

Let's look at each point and what needs to be done to correct it:

- Any model is designed for a certain amount of laundry, and all the parts that are used are made based on the load. Overload leads to their premature destruction. To prevent this, operation is blocked with subsequent display of a fault code, usually 3E, 3C and EA. Note that the most frequently damaged parts are bearings, shock absorbers and the motor. For further work, you need to turn off the machine and reduce the number of things. And for reliability, it’s better to run empty.

- Blocking occurs quite rarely, because it is difficult for foreign objects to get inside the machine. As a rule, these are some elements of the body, or forgotten tools during repairs. For inspection, remove the back cover. After this there will be access to the drive elements. You need to manually check that the pulley rotates freely with the engine. If there are objects that interfere with this, we remove them.

Do you wash by hand?Oh yes! No

- Using a multimeter, we check the integrity of the contacts and connections on the engine. For this purpose, the “ringing” mode is used, with a sound signal. The wires need to be examined before the module! If we find a fault, we replace it. Please note that this breakdown can occur due to constant overload or operation of the Samsung washing machine without interruption.

- When there is a short circuit in the rotor or stator turns, the engine sharply loses power and does not rotate the drum with the load. You cannot operate such a machine, as the engine may catch fire. Diagnosing this damage without special equipment is difficult. There is a folk way. We connect the motor directly and use a current clamp to measure the current. If its value exceeds 2 Amperes, and the housing heats up noticeably, then there is an interturn short circuit in the motor. In this situation, the engine needs to be replaced. The reasons that lead to this are disclosed in the paragraph above.

- The following breakdowns occur with a tachometer generator: the magnet breaks or jumps out of the mount, the wires or contacts inside are damaged. You can check it using a tester. The resistance of a working tacho is 120-150 Ohms. And when the rotor rotates, it must produce direct current. If this is not the case, then the reason is internal. Otherwise, check the wires. If you wish, you can fix this problem yourself.

Motor tachometer sensor

- With correct diagnosis, the control module can be repaired. For this you need a good electronics engineer who works with washing machines.

Samsung module.

30

Error 30 occurs less frequently, and the following reasons lead to its appearance:

- The engine is overloaded due to a large number of things.

- Motor contacts or connections are damaged.

- Tachometer generator malfunction.

How to fix them is described above, we will not repeat them.

Loose drive belt

A belt drive is used to transmit torque from the electric motor rotor to the drum. To increase operating efficiency, a poly-V-belt is used, which has an increased service life. There is no automatic drive tension, so when the material naturally ages, the belt begins to slip. As a result, code 3E or 8E is displayed on the screen (depending on the year of manufacture of the equipment), the problem appears at the beginning of the washing process or when the drum accelerates during the spin procedure.

To access the belt drive you must:

- Turn off the electrical power and then disconnect the connection hoses.

- Unscrew the screws holding the back cover to the machine body.

- Inspect the belt; there are no scuffs or cracks on the treadmill. It is also possible that the elastic element may delaminate or the pulleys may be damaged. Faulty parts need to be replaced, and then the machine must be checked.

To dismantle the pulleys, a screw puller for rolling bearings is used. The small pulley on the rotor is removed after several warm-up cycles, since a special solution is applied to the joint line to fix the parts. Do not install a new belt on damaged pulleys because the sharp metal edges will destroy the treadmill. It should be remembered that some Samsung machines use a direct drive motor and the belt is eliminated from the kinematic chain.

Direct drive motors

Samsung uses brushless DC motors for some of its models. This is a revolutionary trend in the development of modern washing machines. But LG was the first to use them.

Direct drive motor

On such washing machines, errors related to the engine are also displayed. The table below provides an exact interpretation of their meanings.

| Fault code. | Description. |

| 3E | Washing motor malfunction cars:

|

| 3E1 | Hall sensor malfunction:

|

| 3E2 |

|

| 3E3 | Damage to the rotor or stator:

|

| 3E4 | Faulty control module board or motor. |

| 8E | For model H1245A: Error "Abnormal water temperature." The water temperature sensor readings exceed 50 °C in the woolen or delicates washing modes. For model WF7102SKS: Engine fault:

|

The information turned out to be quite extensive, but it describes all the breakdowns that occur with Samsung washing machines. Most errors can be corrected with your own hands, without the involvement of a household appliance repairman.

Error interpretation

Codes 3E, 3E1, 3E2, 3E3, 3E4, 3C, 3C1, 3C2, 3C3, 3C4, EA on a Samsung washing machine mean an error in the tachometer (Hall sensor) of the motor. The control module receives an incorrect or too weak signal from the sensor, or the tacho is simply “silent”. Therefore, the “control brain” stops the engine. And the Samsung machine tells you about the problem with code 3 E, EA, 3C, etc.

Note! In the new generation SMA, in case of such a problem, a group of codes 8E / 8E1 / 8C / 8C1 is displayed, which indicate an error in the VRT+ vibration sensor. This is a new, improved tachometer that can control both engine speed and three-dimensional drum vibrations.

Most often, the EA / 3 E / 8E error on a Samsung washing machine indicates significant failures in motor control. But sometimes you can eliminate the cause of the code without calling a technician.

General recommendations for use

Despite the fact that modern manufacturers use innovative techniques to protect and improve the performance of equipment, you should listen to certain recommendations from experts.

- Any household appliance is not friendly with excessively high humidity. If you are going to install a washing machine in the basement, where there is constant dampness, it is better to choose another room.

- Modern household chemical stores offer a wide range of products designed specifically for automatic washing machines. Use only suitable washing powders and gels.

- The appearance of new sounds during operation of the equipment may indicate the presence of malfunctions. In this case, carry out diagnostics as soon as possible or use the services of a specialist.

- Buy household appliances from trusted and reliable stores that offer customers certified products. When purchasing large household appliances, you are required to provide a warranty, which is confirmed by the relevant document.

How to fix the problem

After analyzing the reasons for the fault codes popping up on the washing machine display, it is important to find out how to fix the fault on your own. Here's what you need to do to resolve the error:

- If the washing machine is overloaded, turn it off and remove the excess laundry. Then start the machine again.

- If the drum jams, remove the foreign object through the hole for the heating element. To get the heating element, you will need to remove the front wall of the washing machine.

- If there is a temporary control failure, you must turn off the machine by unplugging the cord for a few minutes, and then turn it on again.

- Replace the burnt tachometer with a new one.

- Check the motor brushes and replace them if necessary.

- If the connection with the tachometer is broken, check and clean the element.

- If the drive belt becomes loose, replace this element.

- If the control module malfunctions, solder the burnt elements on the board or completely replace the module.

Now you know how to fix problems in a Samsung machine - most often you need to involve a specialist in this matter who will fix problems with the engine or tachogenerator. But in the first three cases, you can cope with the problem yourself.

When can you cope on your own?

What to do if such an error appears? In some cases, the breakdown can be fixed on your own. Next, we’ll look at the main situations in which you can fix a problem with your washing machine yourself.

- If the drum is overloaded with laundry, divide the laundry into several parts. Even the instructions specify the maximum load for the machine - the more laundry you load, the more often this error will appear.

- Random control failure in the system - modern units have a lot of different electronics, and the error itself can occur for no reason. In this case, they say that the system is “frozen.” Just unplug the machine and unplug it from the socket, and after a couple of minutes turn it on again.

If this does not help, you should call a specialist, because if the problem and malfunction lies in a more serious breakdown that requires replacement of parts, you will not be able to cope on your own.

The moment this code appears

Quite often, error code 3e itself appears randomly. Most often, the error occurs at a certain stage of the unit’s operation, be it washing or spinning. In this case, the machine will draw water as expected, the drum begins to spin, and suddenly the SMA freezes and shows this system error.

But it could be different:

- The washing program starts.

- The unit draws water and washes.

- Then drains the water and collects clean water for subsequent rinsing.

- Next should be a spin, but instead the system simply freezes and displays an error on the display.

To fix the problem and understand whether the breakdown can be repaired or not, it is important to understand what this code means.

Control module problems

If the equipment turns off when washing starts, the cause of the defect may be the control unit located in the upper part of the housing. The controller contains electronic components that can move away from the contact paths or fail due to vibration or moisture. Service center employees note poor soldering of electronics and poor quality of printed circuit boards, from which the metal substrate peels off.

The unit is checked under the service conditions. The user cannot find microcracks in the elements or determine an incorrectly functioning diode or transistor. To remove damaged parts and install new parts, special soldering equipment is required. A controller with fatal damage must be replaced.