Repairing the Indesit washing machine has recently become one of the problems. The units themselves are listed as devices in the budget segment, while repairing Indesit can be quite expensive both in terms of money and effort invested in it.

If TOP brands like LG, Samsung, Siemens equip their machines with expensive components, then Indesit, in order to maintain an inexpensive cost, is forced to save on spare parts. How to repair an Indesit washing machine with your own hands, as well as eliminate all faults.

Common breakdowns and their possible causes

If the consumer wants to carry out repairs on his own, then he must find information about the key malfunctions of Indesit washing machines and their elimination.

Most Indesit devices are equipped with small digital displays on which Indesit CMA error codes are displayed.

However, there are budget models that do not have a screen. In this case, the system notifies about malfunctions through certain indicators. Let's look at Indesit WISL 83 error codes. There is no matrix here, but there are indicators by which the source of the malfunction is calculated.

By the way, the WISL 103 Indesit washing machine has the same faults and error codes, since Indesit units are designed on the same EVO II board. The Indesit error code is calculated as follows.

The user must add up the numbers that correspond to the flashing lights. So, F8 = 6 + 2, F10 = 8 + 2, etc. With the CMA Indesit WIUN 100, faults are detected in the same way through LEDs.

What are the most common faults in Indesit:

- The tubular electric heating element is not functioning. This is due to the fact that Indesit used only stainless steel in this part; it did not use any additional protective alloy.

- The surge protectors used by Indesit often stop functioning after 4 years of operation.

- Bearings are another weak point of Indesit devices. They often fall into disrepair.

- Electrics connected to the engine often malfunction.

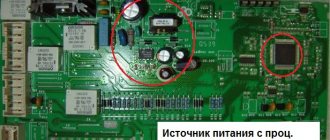

Indesit's weak point is the control unit. This is especially true for models that came off the production line before 2012. Newer configurations are equipped with better quality chipsets, but they are not ideal either.

More serious breakdowns of the Indesit washing machine

These are problems that are most often solved by calling a repairman.

- Bearing

- Drain pump

- Motor brushes

- Shock absorbers

- Drive belt

- Drum

- heating element

Bearing

The most common breakdown of washing machines, and not only Indesit, is bearing wear. If during operation of the machine extraneous sounds appear, such as grinding, knocking, creaking, this is one of the signs of a “dying bearing”.

There is no need to delay replacing this part. In general, it is recommended to completely stop using the equipment. If the bearing is not replaced in time, the shaft may fail. And this means only one thing - you will have to completely change the drum. In some cases, it will be more logical to buy a new machine. So such negligence can lead to serious losses in the family budget.

Getting to the bearing is not an easy task, especially when it comes to older Indesit models. The problem with old Indesit machines is that their tank is sealed. And when a bearing flies (and they fly quite often), you have to literally saw through the drum structure to get to the treasured part. In new models, the tank is collapsible.

How to disassemble the Indesit washing machine, and in particular solve the problem with a non-separable tank, is briefly described in this video:

A new bearing and oil seal cost approximately 600 - 1000 rubles. depending on where you order. Removing the bearing is quite simple. This can be done from the inside using a regular screwdriver, and from the outside using a puller or pressing method.

More detailed instructions for replacing the bearing in an Indesit washing machine are here.

Drain pump

Failure of the drain pump, as well as bearing wear, is a fairly common occurrence. The drain pump can fail for three main reasons: 1. Factory defects (extremely rare) 2. Trivial wear and tear (only for older cars) 3. Careless operation, which involves ignoring the timely cleaning of the drain pump filter (located at the bottom right).

Replacing the drain pump will not cause difficulties even for a person far from repairing. The whole question is in two screws. How to replace the drain pump is described in this video:

Price for self-replacement: 700–2500 rubles depending on the model.

Motor brushes

The electric motor brushes of the Indesit machine last for more than 7 years when used correctly. However, they can fail much faster than the specified period, for example, due to constant overload of the drum.

The following signs will indicate brush wear: strange noise when the drum rotates, loss of engine power, burning smell, program freezing during spinning.

In this case, only one thing is required - to replace the worn brushes. You can watch how to replace the brushes yourself in the following video:

Price of new brushes: 800 – 1200 rubles.

More: DIY vertical washing machine repair

Shock absorbers

If during a spin cycle the washing machine begins to literally jump, shake and vibrate strongly, then one of the possible reasons is wear on the shock absorbers. How can I check this? It is necessary to remove the back cover of the washing machine, disconnect one end of the shock absorber mount and check its operation manually.

Faulty shock absorbers usually move lightly, which leads to strong vibration during operation of the equipment.

How to solve the problem with faulty shock absorbers is described in detail in this video:

Shock absorber price: from 500 rubles

Drive belt

If the drum in your car suddenly stops spinning, one of the possible reasons is that the integrity of the drum drive belt is broken. This can happen due to either prolonged or improper use of the machine. Signs of belt wear can also be indicated by sharply increasing vibrations of the washing machine.

Fortunately, replacing a belt does not seem to be such a difficult phenomenon. For the most part, you don’t even need to disassemble the machine much. The process of replacing the belt is described more clearly in the following video:

Issue price: 500 – 700 rubles.

Drum

One of the most important elements of the Indesit washing machine, the drum, can also fail.

There may be several reasons:

- Foreign object stuck between tank and drum

- Electronic unit is faulty

- The engine is faulty.

The most unpleasant thing is that in some Indesit models, such as INDESIT WISN82, the drum will need to be replaced simply due to bearing wear. The fact is that in these models the bearings are not removable, so you have to buy a new drum, which costs a lot of money - from 7,000 rubles.

Although if the bearings were removable, repairs would be much cheaper. The situation is further aggravated by the fact that the replacement process itself does not look easy enough and you have to literally go through the device. Therefore, if you do not replace it yourself, you will have to fork out for the work of a specialist.

How to replace the drum of an Indesit washing machine is described in the following video:

heating element

It’s not uncommon for a problem to arise when a washing machine suddenly stops heating the water. One of the obvious reasons is a break in the power supply circuit of the heating element. In this case, only one thing is required - to replace the failed heating element.

Buying a new heating element will cost from 1,500 to 4,000 rubles. (not a cheap part), and to replace it you will have to spend more than one hour in front of the machine (for an inexperienced user), since replacement involves serious disassembly of the equipment.

There is really one calming moment. The heating element can simply oxidize and because of this, its operation malfunctions. Therefore, simply cleaning it can ultimately fix the water heating problem. More details on replacing the heating element and cleaning it in Indesit are described in the following video:

How to fix an Indesit machine yourself

This point implies that the user has analyzed the error codes of Indesit washing machines and understood why the Indesit washing machine broke down.

You can fix it by initiating a DIY repair of the Indesit washing machine from malfunctions.

For clarity, you can use a video to guide you through repairs, which shows the Indesit WITL 86 washing machine, common faults and their repair. So, how to fix the problem that caused the Indesit washing machine to break down?

Checking and replacing the heating element

Indesit error associated with heating element malfunctions is marked with codes F07 or F08. There is another sign that indicates that the heating element of the Indesit washing machine is not functioning.

If a faulty tubular electric heating element is causing the Indesit machine to break down, you will need to remove the bottom panel of the machine and remove the wiring from the heater located underneath the tank and sensor. How to repair an Indesit washing machine with your own hands if the problem lies in the tubular element?

Indesit washing machine repair

Washing machines under the Indesit are manufactured by the Italian company Indesit Company SpA. The history of Indesit Company begins in 1975. In 2014, Indesit Company SpA became part of the American corporation Whirlpool Corporation. The company's products are also represented by the following brands: Hotpoint-Ariston, Scholtès. In 2004, a plant for the production of washing machines was opened in Lipetsk.

Indesit washing machines belong to the middle price category; the machines can satisfy any consumer. Models with vertical and front loading are presented. The drum can hold from 3.5 to 9 kg. linen Dimensions are both standard and narrow, and some of the models can fit under the sink. There are machines with a regular list of programs and with extended functionality. Italian assembly and components ensure a service life of approximately 8 years. Chinese assembly and washing machines assembled in Russia using Chinese components will last up to 5 years. The manufacturer has developed Energy Save technology to reduce energy consumption and Eco Time functions, and water consumption has also been reduced thanks to Water Balance technology.

Quick online diagnostics of washing machine faults (Just select a problem from the list and find out the approximate breakdown)

Most modern Indesit washing machines have the function of displaying an error code when certain malfunctions and malfunctions occur. Quite often, understanding what the error code means , you are able or breakdown yourself

For your convenience, a list of error codes for Indesit washing machines is provided with an explanation of each specific code . The table also includes a description of the error, the reasons for its occurrence and possible solutions.

The washing machine consists of units that are complex in design, and if they break down, it is better not to try to repair the devices yourself. Moreover, this is due to high voltage and the possibility of flooding neighbors living on the floor, or even two or three floors below.

When carrying out repairs yourself, remember your safety!

Disassemble without disconnecting the equipment from the mains!

It is best to use the services of an experienced technician who is familiar with any problems and can fix the problem. If your washing machine breaks down, entrust the repair to a professional: he will be able to perform all the steps quickly, efficiently and safely.

Decoding Indesit error codes

Models of Indesit washing machines without a separate display are combinations of LED blinking that reveal the error code. In operating condition, the indicators on the machine panel light up in accordance with the command being executed. At the same time, the LEDs do not flicker with a high frequency, but blink smoothly or shine constantly . LEDs (light bulbs) that light up at random, at the same time as others and begin to flicker quickly, indicate a breakdown . The notification occurs depending on the model range:

1. Electronic-mechanical line Indesit IWDC, IWSB-IWSC, IWUB and its analogues, the fault code is recognized by the illuminated LEDs of the working phases on the right (door block, rinsing, draining, spinning, etc.), the signal is also accompanied by the simultaneous flickering of the upper additional indicators and network indicator ;

2. The Indesit model range marked WIDL, WIL, WISL—WIUL, WITP - on the contrary, the type of failure or malfunction is indicated by the lighting of the top line of LEDs (light bulbs) of additional functions along with the last LED of the left column (most often this is “Spin”), At the same time, the door unit light flashes quickly .

of the WIU, WIUN, WISN model range all LEDs (light bulbs), including the lock LED in indicating the error .

4. The oldest models Indesit W, WI, WS, WT with only two LED buttons for the unit and network - blink continuously and quickly exactly as many times as the number in the error number means.

| Error code | Description of the error | Causes and elimination |

| F01 | Short circuit (triac) in the power supply circuit of the drive motor. | 1. Check for possible water ingress on the contacts of connector J9. 2. Check the contact block of the drive motor (a possible cause of the problem is chemical corrosion of its contacts). 3. Replace the electronic module of the Indesit washing machine. |

| F02 | The drive motor does not work, the tachogenerator (tachometer) circuit is short-circuited or open. | 1. Check whether the motor is mechanically blocked. 2. Check the reliability of the contacts on connector J9 of the electronic module. 3. Check the electrical resistance of the tachometer (about 115...170 0m). Resistance is measured between pins 1 and 2 of J9. If there is a short circuit in this circuit, disconnect connector J9 and check the wires on the tachometer side. If an asynchronous drive motor is installed in the SM, make sure that the electrical connection of pins 6 and 7 of connector J9 with the sensor is reliable. 4. Replace the motor. 5. Replace the electronic module. |

| F03 | The NTC temperature sensor circuit is closed or open, or the heating element relay is “stuck” | 1. Check the reliability of the contacts of connector J8. 2. Check the temperature sensor, taking into account that its resistance at room temperature (20°C) is 20 kOhm (can be measured on pins 11 and 12 of connector J8). If the result is different, check the integrity of the wiring from the module to the sensor. 3. Replace the NTC temperature sensor. 4. Replace the electronic module. |

| F04 | The water level sensor simultaneously generates the “EMPTY TANK” and “OVERFLOW” signals. The reason for this defect is that the “EMPTY TANK” contact group in the sensor is “stuck”, in this case the washing machine fills water to the overflow level. When this water level is reached, the drain pump automatically turns on. | 1. Check the quality of connections at connector J3 on the electronic module. 2. Check the condition of the level sensor (on the connector contacts): 2.1 Contacts 2-4 are closed, the level is “EMPTY TANK”; 2.2 Contacts 2-3 are closed, level “FULL TANK”; 2.3 Contacts 2-1 are closed, the level is “OVERFLOW” (not less than half the level of the glass of the loading hatch). 3. Replace the level sensor. 4. Replace the electronic module. |

| F05 | The drain pump is blocked (does not work) or the level sensor generates an EMPTY TANK signal after completing the water draining procedure. | 1. Check the reliability of connections in connector J9. At the moment the pump is supposed to operate, you can check the presence of 220 V alternating voltage between pins 8 and 9 of connector J9. 2. Check the filter and drain hose. 3. Replace the drain pump. 4. Replace the electronic module. |

| F06 | Button error code is displayed in the Ariston Dialogic family (AD series) | 1. Check the presence of contact in the connectors and the harnesses between the controller and the control panel. 2. Check the serviceability of the control panel buttons. 3. Consistently replace the control panel and electronic controller. |

| F07 | After the water filling operation, the level sensor does not remove the “EMPTY TANK” signal. If there is no water in the tank after the water filling operation, power is not supplied to the heating element. This is a protective function, since without water the heating element can burn out. | 1. Check if there is water in the water supply or if the water pressure is too low. 2. Check the water inlet valve. 3. Check for blockage in the water inlet system. 4. Check the water level sensor (pressostat). After filling with water (if any), the “EMPTY TANK” contact group of the level sensor must be open. Its condition is monitored, for example, on pins 2 and 3 of connector J3 of the electronic module. Otherwise, replace the level sensor and electronic module sequentially. |

| F08 | The heating element relay on the module turned out to be constantly on (“its contact group is stuck”) or the level sensor simultaneously generates “EMPTY TANK” and “FULL TANK” signals. | 1. Check the level sensor - see error F04. The heating element control relay on the module is checked by replacement. 2. Check the connection of wires from connector L to the level sensor. 3. Check the connection of the heating element to the module (see pins 5 and 6 of connector 3). 4. Check the serviceability of the heating element. 5. Replace the level sensor. 6. Replace the electronic module. |

| F09 | Error (failure) of the contents of non-volatile EEPROM memory, program error. | 1. Re-flash the contents of the non-volatile EEPROM memory. 2. If the EEPROM chip is working, replace the entire module (pay attention to the fact that the memory chip installed on it has firmware designed for a specific model of washing machine). |

| F10 | After the start of the water filling process (during the allotted time), the level sensor does not generate a FULL TANK signal (provided that the EMPTY TANK signal is passive, that is, there is already water in the tank). | 1. Check the level sensor - see error F04. 2. Check the reliability of the electrical connections between connector J3 of the electronic module and the level sensor. 3. Replace the level sensor. 4. Replace the electronic module. |

| F11 | There is no feedback signal about the functionality of the drain pump (the power supply circuit of the pump is broken or its winding is broken). | 1. Check the reliability of the connection between the drain pump and the electronic module. 2. Check the resistance of the drain pump winding at connector J15, pins 1 and 2 (if the machine is equipped with the Easy Door function) or at connector J9, pins 8 and 9. The resistance of the drain pump winding should be about 170 Ohms. 3. Replace the drain pump. 4. Replace the electronic module. |

| F12 | No communication between display module and electronic module | 1. Check the reliability of the electrical connections between connector J11 of the main electronic module and the display module. 2. Replace the main electronic module. 3. Replace the display module. |

| F13 | The drying temperature control circuit is faulty (for Margarita 2000 washing machines with drying, EVO-I controller) | 1. Check the connection between the CAN connector of the electronic controller and the drying temperature sensor. 2. Check the serviceability of the drying temperature sensor and electronic controller (by replacing). |

| F14 | The dryer does not turn on (for Margarita 2000 washing machines with drying, EVO-I controller) | 1. Check the connections between the electronic controller and the drying heating element. 2. Check the drying heating element and the electronic controller (by replacing). |

| F15 | Drying does not turn off (for Margarita 2000 washing machines with drying, EVO-I controller) | 1. Check the presence of a contact in connector CN1 on the connecting board. 2. Check and, if necessary, replace the level sensor and connecting board. |

| F16 | Drum is blocked (top-loading washing machines only) | Check the drum locking (power circuit of the locking electromagnet). |

| F17 | The hatch door is not locked or the door is open (for washing machines with the Easy Door function). | 1. Check the presence of 220 V voltage on pins 3 and 4 of connector J4 (not in “STANDBY” mode), as well as between pins 3 and 5 of the door lock. 2. Check the operation of the lock feedback microswitch (with the door closed and the machine turned off) on pins 1 and 2 of connector J4 of the electronic module. 3. Check the reliability of the connection of the wires from connector M to the hatch lock. 4. Check that the lock is securely latched. 5. Replace the door lock. 6. Replace the electronic module. |

| F18 | Communication error between the controller chips and the DSP (asynchronous drive motor control processor) on the main electronic module. | Replace the control module. |

How to call a specialist?

Requests for repairs are accepted daily, from 8 am to 10 pm by phone or using an online application.

8 (985) 181 – 02 – 88

8 (985) 181 – 02 – 88 (Whatsapp)

Leave a request for repairs

Important! When contacting, please provide the following information: Your contact information: name, phone number and address, make of the machine, if possible, send a tag with the serial number and product code of the machine and the day and time of arrival of the technician that suits you.

To carry out repairs and select spare parts for your washing machine, you need to know its model and serial number.

The exact model of the machine is indicated on the tag on the body of the washing machine or stickers, as well as in the operating instructions. If you have already purchased replacement parts yourself, please indicate only the make of the machine. For example, INDESIT WG 824 T.

places where washing machines may contain a sticker with all the necessary service information.

1. Under the hatch door on the body. Most often, on front-type washing machines, the serial number is located on a sticker under the hatch door. Either on the door itself or on the body. In most cases, the number consists of numbers, less often of numbers and letters .

2. On the back side of the pump filter hatch. On vertical models, a sticker with a service number is most often located on the inside of the small hatch that covers the pump filter.

3. On the back wall. The back wall of the washing machine is a traditional place for all kinds of service information. If you couldn’t find a sticker with a number on the front, then it was probably preserved on the back wall.

4. In the passport or instruction manual. Finally, the serial number can sometimes be found in the documents that come with the purchase of the washing machine. As a rule, the number is located in the passport or warranty card.

The arrows show the location of the tags.

washing machine manufacturers encode on a tag (sticker) what they produced, when, where and from what parts. This information is encoded in two sequences of numbers (letters) product and serial numbers. Their combination is unique and applies only to one specific instance of the washing machine.

Please take a photo of these tags

To maximize the life of your washing machine, you need to carefully read the operating instructions. If you have lost it, here you can select your model and download it in pdf format.

Indesit washing machine operating instructions

| INDESIT IWB 5083 | INDESIT IWC 5083 | INDESIT IWD 5085 |

| INDESIT IWDC 7105 | INDESIT IWSB 5085 | INDESIT IWSC 5085 |

| INDESIT IWSC 5105 SL | INDESIT IWSD 5105 | INDESIT IWSE 5105 |

| INDESIT IWSE 71251 | INDESIT IWUC 4085 | INDESIT IWUE 4105 |

| INDESIT PWC 7108 S | INDESIT PWE 7108 S | INDESIT PWSC 5105 W |

| INDESIT PWSE 6104 W | INDESIT PWSE 6127 S | INDESIT SISL 106 S |

| INDESIT SIXL 106 S | INDESIT W 43 T | INDESIT W 84 TX |

| INDESIT W 101 | INDESIT WDS 105 T | INDESIT WG 421 T |

| INDESIT WG 431 T | INDESIT WG 624 T | INDESIT WG 824 T |

| INDESIT WG 836 TX | INDESIT WG 1031 TX | INDESIT WI 81 |

| INDESIT WIDL 126 | INDESIT WIDXL 106 EX | INDESIT WIE 127 |

| INDESIT WIL 105 | INDESIT WIL 82 | INDESIT WISE 107 X |

| INDESIT WISL 103 | INDESIT WISL 83 | INDESIT WISN 81 |

| INDESIT WIT 61 | INDESIT WITE 877 | INDESIT WITL 1067 |

| INDESIT WITP 102 EU | INDESIT WITP 827 RU | INDESIT WIUE 10 |

| INDESIT WIUN 102 CSI | INDESIT WIUN 82 | INDESIT WN 421 XWS |

| INDESIT WN 665 SS | INDESIT WS 642TX | INDESIT WT 80 |

| INDESIT IWB 5103 | INDESIT IWC 6085 B | INDESIT IWD 5105 |

| INDESIT IWE 6105 | INDESIT IWSB 5105 | INDESIT IWSC 5085 SL |

| INDESIT IWSC 6085 | INDESIT IWSD 5125 SL | INDESIT IWSE 5125 |

| INDESIT IWTE 71280 ECO | INDESIT IWUC 4105 | INDESIT NWS 7105 L |

| INDESIT PWE 7128 W | INDESIT PWSC 6107 S | INDESIT PWSE 6107 S |

| INDESIT PWSE 6128 S | INDESIT SISL 129 | INDESIT SIXL 126 |

| INDESIT W 105 TX | INDESIT W 63 T | INDESIT W 93 T |

| INDESIT WE 105 X | INDESIT WG 1231 TX | INDESIT WG 421 TX |

| INDESIT WG 432 TX | INDESIT WG 624 TX | INDESIT WG 830 TX |

| INDESIT WGS 634 TXR | INDESIT WIA 81 | INDESIT WIDL 126 EX |

| INDESIT WIDXL 86 EX | INDESIT WIE 127 EX | INDESIT WIL 125 |

| INDESIT WIN 101 | INDESIT WISE 127 | INDESIT WISL 105 |

| INDESIT WISL 86 | INDESIT WITP 82 | INDESIT WIU 102 |

| INDESIT WIUL 103 | INDESIT WIUN 105 CIS | INDESIT WIUN 82 CSI |

| INDESIT WN 461 WO | INDESIT WN 668 XWO | INDESIT WT 102 T |

| INDESIT WT 82 T | INDESIT IWB 6085 | INDESIT IWC 6105 |

| INDESIT IWDC 6105 | INDESIT IWE 6105 B | INDESIT IWSB 6085 |

| INDESIT IWSC 5105 | INDESIT IWSC 6105 | INDESIT IWSD 6105 B |

| INDESIT IWSE 6125 | INDESIT IWUB 4085 | INDESIT IWUD 4085 |

| INDESIT NWSK 7125 L | INDESIT PWC 7128 S EU | INDESIT PWE 8148 S |

| INDESIT PWSC 6108 S | INDESIT PWSE 6107 W | INDESIT SISL 106 |

| INDESIT SISL 129 S | INDESIT SIXL 129 | INDESIT W 125 TX |

| INDESIT W 83 T | INDESIT WD 104 T | INDESIT WE 8 X |

| INDESIT WG 420 | INDESIT WG 422 X | INDESIT WG 530 T |

| INDESIT WG 630 TX | INDESIT WG 834 T | INDESIT WGS 834 TXR |

| INDESIT WIDL 106 | INDESIT WIDL 86 | INDESIT WIE 107 |

| INDESIT WIE 127 XS EX | INDESIT WIL 125 EX | INDESIT WIN 102 |

| INDESIT WISE 87 | INDESIT WISL 62 | INDESIT WISN 100 |

| INDESIT WIT 51 | INDESIT WITE 1077 | INDESIT WITL 106 |

| INDESIT WITL 86 EU | INDESIT WITP 82 EU | INDESIT WIU 102 CSI |

| INDESIT WIUL 83 | INDESIT WIUN 61 | INDESIT WIXL 105 |

| INDESIT WN 463 WT | INDESIT WS 105 TX | INDESIT WT 52 |

| INDESIT IWB 6105 | INDESIT IWC 6105 B | INDESIT IWDC 6105 EU |

| INDESIT IWE 7105 B | INDESIT IWSB 6105 | INDESIT IWSC 5105 S |

| INDESIT IWSD 5085 | INDESIT IWSD 71051 | INDESIT IWSE 71051 |

| INDESIT IWUB 4105 | INDESIT IWUD 4105 | INDESIT PWC 7105 W |

| INDESIT PWDE 7125 S | INDESIT PWE 91273 S | INDESIT PWSE 6104 S |

| INDESIT PWSE 6108 S | INDESIT SISL 106 S | INDESIT SIXL 106 |

| INDESIT SIXL 129 D | INDESIT W 145 TX | INDESIT W 84 TK |

| INDESIT WD 125 T | INDESIT WES 9 X | INDESIT WG 420 T |

| INDESIT WG 424 T | INDESIT WG 622 T | INDESIT WG 633 TX |

| INDESIT WG 835 TX | INDESIT WI 61 | INDESIT WIDL 106 EX |

| INDESIT WIDL 86 EX | INDESIT WIE 107 EX | INDESIT WIE 127 XS |

| INDESIT WIL 62 | INDESIT WIN 81 | INDESIT WISL 102 |

| INDESIT WISL 82 | INDESIT WISN 101 | INDESIT WIT 51 EU |

| INDESIT WITE 87 | INDESIT WITL 106 EU | INDESIT WITL 867 |

| INDESIT WITP 827 | INDESIT WIU 81 | INDESIT WIUN 102 |

| INDESIT WIUN 81 | INDESIT WN 421 WS | INDESIT WN 663 WO |

| INDESIT WS 431 TX | INDESIT WT 62 |

Washing machines from manufacturers that we repair

Failure search algorithm

To detect the original source of the machine malfunction, you need to decipher the Indesit WITL 106 error codes. In fact, the decrypted codes are identical for other models, so the washing machine error codes are also suitable for Indesit WISL 102.

How to understand the blinking of indicators if there is no screen? To perform repairs, the code is calculated as follows. The user must add up the numbers that correspond to the flashing indicators (the correspondence between the LED and the number is shown in the manual).

By flashing the indicator of the Indesit washing machine, you can decipher the error code, and then find out what caused the failure.

Indesit error codes can be viewed on the Internet. There is no need to worry about the differences between models and control boards. All lights flash according to the same algorithm on all modules. The codes will help you make repairs quickly and reliably.

Error codes for Indesit washing machines

What are the most common error codes for an Indesit washing machine? To carry out repairs, you do not need to know the device model.

For WISL 82 Indesit the error codes are the same as for the W105TX Indesit model there are similar error codes:

- F04 – the pressure switch, or water sensor, is damaged, simultaneously sending signals about overflow and an empty tank;

- F07, F08 – problems with the heating element (tubular electric heating element): the heating element is not immersed in water or current leaks into the housing;

- F10 – the system does not send either a notification about a full tank or a message about an empty tank;

- F12 – connection between the indication and power modules is not made;

- F15 – the heating element is permanently functioning;

- F17 – the drum door is not closed or power is not supplied to its lock. For WITP 82 Indesit, the error codes are also the same, which will simplify repairs.

The machine does not respond to the on/off button

Despite their convenience, there are malfunctions that Indesit washing machines and their error codes cannot cope with.

If the power key fails, this does not mean that the entire control module is faulty.

The Indesit washing machine and its error codes, indicating problems with the control unit, do not indicate a problem with this button. To repair it, you need to dismantle the cover under which the electronic unit is located and remove it.

If there is external damage, the power switch must be replaced. Then, using a multimeter, you need to ring two wires, zero and phase. To understand whether current is flowing or not, the key must be turned on.

Advice: you should trust the Indesit wisl 62 indicators. The displayed error codes (F18) may indicate problems with current in the electronic unit. But there are times when repairing the power switch does not solve the problem and after turning on the program the button stops working.

If the key does not function during operation, the program may have crashed. In this case, you need to unplug the power cord and reconnect it after 10 minutes. As you can see, repairing the Indesit power button is easy.

How to disassemble the tank and drum

Washing machines of the Indesit brand usually have non-separable tanks, that is, if any element located inside fails, the manufacturer recommends replacing the entire part. Such repairs can be expensive, so if it is necessary to replace, for example, a bearing, it is still better to disassemble the tank.

In the photo you see a non-separable washing machine tank in which the drum is located

Dismantling begins by removing the pulley (the wheel through which the belt passed). The bolt that secures this part is subject to significant stress, and it is important that it holds tightly. Therefore, when assembling a machine, it is often not just screwed on, but also additionally secured with glue. It is better to use a T40 hexagonal star wrench and loosen the bolt, gradually loosening it. If the part does not give in, spray it with WD-40 or carefully knock it off the glue with a hammer.

In order to unscrew the bolt securing the pulley, you need to use a T40 hexagonal star wrench.

Next, we lay the tank on its side and carefully cut it with a hacksaw along the seam (where the two halves of the part are soldered). First, use a drill to drill holes around the entire perimeter of the seam (during assembly, the halves can be easily fastened with bolts).

When the tank is open, unscrew the bolts securing the drum, unfasten the fastenings and remove the tank wall. Now you can disassemble the drum, that is, remove the oil seal and bearings from it.

We start with the bearing located closer to the outside of the drum. We lay the part with the hatch hole down, place the chisel on the outer rim of the metal ring and hit it with a hammer.

You will need a hammer and chisel to remove the bearing from the drum.

We carefully monitor the position of the chisel when knocking out the bearing - if the tool slips and the inner ring is struck, it may fly out, and it will be quite difficult to remove the remaining bearing from the seat. We dismantle the inner bearing in the same way, and then remove the oil seal.