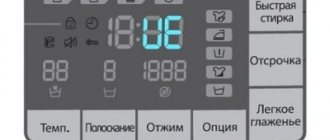

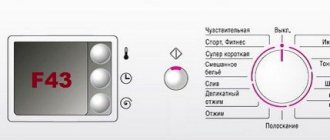

Why does the Indesit washing machine show error F12 on the display? Models with electromechanical control display a fault code with the “Super Wash” - “Wash Delay” indicators on, or the “Revolution” light is flashing.

These signals indicate problems in management. To accurately determine the cause of the breakdown, you need to understand in detail what the error code means.

What does error F12 mean on an Indesit washing machine?

Error F12 is noted in the instructions for the Indesit washing machine and indicates a lack of interaction between the main module and the control panel. In other words, the connection between the buttons located at the front of the unit and the main electronic unit that receives user commands is disrupted.

If the Indesit washing machine is equipped with a display, then error F12 will be displayed on it in the form of an alphanumeric designation. If the model does not have a screen, the unit will report a malfunction in other ways:

- flashing speed sensor;

- simultaneous lighting of the “wash delay” and “super wash” indicators.

Typically, error F12 occurs when the device is connected to the network. At this moment, a contact appears between the control module and the buttons with light indication. If it is of poor quality, the machine immediately displays a corresponding message. But in some cases, the malfunction becomes noticeable already during the process of drawing water or even in the middle of the wash.

Attention! When error F12 appears, Indesit may instantly freeze and not respond even to pressing the “On/Off” button. In this case, the only thing left to do is turn off the power completely.

Error F12 can occur in both old and completely new Indesit machines

Deciphering the error code

Of course, the actual decoding of the F12 code can be easily found in the instructions for the washing machine, so first you can simply decipher the error as provided by the manufacturer.

But then you will still have to dwell on some aspects in more detail, because the problem may be much more complex than it seems at first glance. In its standard form, the operating instructions explain the appearance of the F12 code approximately as “the control module does not communicate with the control panel.” In different variations, but the essence is the same. Moreover, this error can appear not only on washing machines with a display, but also on units of previous, non-display generations.

Although some kind of connection still remains, since the owner can see a message about the problem. And if so, then to a certain extent, the Indesit electronic brain still retains partial control over its control panel, although it is no longer able to use it in any way (sometimes even the “On-Off” button ceases to function and generally shows signs of life).

Reasons for error F12 appearing on the Indesit washing machine

The interaction between the controls of the Indesit washing machine may be disrupted for several reasons:

- Unit overload. If you put more laundry in the tank than the instructions allow, the machine may overheat during operation. In some cases, water also gets from the drum to the microcircuits during spinning, causing a short circuit.

- Software glitch. The connection between the central module and the front panel may be interrupted due to a sudden loss of water in the water supply or during a power surge.

- Burnout or separation of cables. The control unit and indicators are connected to each other by thin wires, the connection quality and integrity of which may deteriorate.

- Damage to control buttons. If the device has been in use for a long time, then the buttons themselves, which are responsible for launching certain work cycles, may fail.

In case of serious damage, the Indesit washing machine can only be sent in for repair. But first, it’s worth taking simple home measures; in some cases, they can return the unit to good condition.

Decoding

Code 12 usually appears immediately after turning on the washing machine. Indesit freezes and does not respond to button presses. The documentation for the SMA states that there is no connection between the modules: the electronic board (the “brain” of Indesit) and the control panel. At the same time, the indication actually works, informing the user about the problem. Error f12 should be interpreted as follows: partial loss of control over the launcher on the part of the electronic device.

Reload Indesit

Experienced experts recommend starting with this in case of error f12. The technique is not new; this action helps to clear any code if there is a malfunction in the electronics. Reasons: low voltage, sudden surges, interference in the network. Owners regularly encounter such “surprises” in energy supply.

Methodology

- The button is pressed. "Off" washing machine.

- The Indesit power cable is disconnected from the outlet.

- Time delay – 15 minutes.

- Restarting the washing machine.

Check the electrical circuit

- Integrity of signal lines. Open circuit, short circuit - causes of error f12. A technician is not required to fix the defect.

- Connector condition (J11). Washing machines have been used for years in rooms where there is excessive humidity. In addition, Indesit is equipped with commutator motors. As the brushes wear, dust from them scatters to the sides, getting into the contact groups, and acts as an abrasive. Removing dirt, carbon deposits, oxides, and drying help to cope with the Indezit f12 error.

Inspect the boards

Electronic and display.

Electronic module of the Indesit washing machine The Evo2 module of the Indesit washing machine burned out

Only visual control of the condition, nothing more! Recommendations from outsiders, from the Internet regarding module repair, should not be taken into account. Depending on the series and year of manufacture of the washing machine, these units differ in diagram

Without experience and detailed technical documentation, it is unlikely that it will be possible to revive it, but it is certain to “ruin it.” To find the cause of error f12, the front panel is opened, the module is removed from Indesit and inspected from both sides. In some models, access after removing the back wall.

The fault is caused by:

- Dust on the board. By absorbing moisture, dirt turns into a conductor of electric current. Hence the short circuits and fault codes. Careful cleaning removes the f12 error and restores Indesit control;

- Condensate. The solution is to dry it;

- Damage to paths. Such a defect is easy to detect by examining the surface of the panel through a magnifying glass. The gap can be easily repaired by carefully using a soldering iron;

- Faulty radio components. Error f12 is caused by loss of capacitance or increased leakage current of the capacitor. There are electrolytic “C” on the board. If the “barrel” is swollen, definitely change it;

- Burnt areas. With a slight thermal effect, the dark place is carefully cleaned with a scalpel. Based on my experience in eliminating the error, Indesit f12 helps.

If you are unable to restore the washing machine’s functionality, contact service. Accurate diagnostics of the electronic module is possible on a stand simulating SMA. This service is much cheaper than purchasing a new node.

How to resolve error F12 in an Indesit washing machine

In some cases, it is not even necessary to disassemble the washing unit to eliminate the error. In other situations, you will have to gain access to the internal circuits of the device.

Troubleshooting a software glitch

If error F12 appears on the Indesit iwsb 5085 or another model for no apparent reason, and the unit itself is still new, it makes sense to try to fix the software failure. To do this you need:

- Turn off the Indesit washing machine from the network.

- Wait 15 minutes.

- Reconnect the device to the outlet.

- Set any washing program.

- If error F12 persists, repeat the algorithm twice more.

There is another way to fix a software failure. Necessary:

- Completely unplug Indesit from the outlet.

- Leave the washing machine inactive for half an hour.

- Connect the unit to the electrical network.

- Press the “On” and “Start” buttons simultaneously and hold them for 30 seconds.

If the internal parts and microcircuits of the device are working properly, then one of the methods will help restore communication between the controls and return the device to working condition.

Simply turning off the machine helps if water gets on the microcircuits - the tracks have time to dry

Internal Troubleshooting

If the device does not respond to attempts at a software restart, then repairing error F12 in Indesit wisl 103 and other models will have to be carried out using the physical method. To do this you will need:

- Unscrew the screws from the rear panel of the unit and carefully remove the cover.

- Remove the control module, usually located on the bottom left side.

- Carefully inspect the unit for melted wires, swollen capacitors and other defects.

- If necessary, clean contacts or replace small parts.

- Disconnect and reconnect the cables connecting the module to the front control panel.

- If there is no visible damage to the machine block, ring its elements using a tester.

If during the process of inspecting and checking the control module it turns out that it is seriously damaged, it would be better to go to the store with the part and buy exactly the same new one. This will be more expensive, but it will be simpler and more effective than trying to repair the unit yourself, especially if you have no experience in carrying out the relevant work.

When dismantling the Indesit control module, it is necessary to write down or sketch the connection diagram

Advice! If error F12 appears during the washing process, you need to drain the water from the drum into a substitute container. Most likely, the device will not be able to remove the liquid on its own.

If restarting the Indesit washing machine, checking the connections and trying to repair it yourself does not bring results, all that remains is to send the unit for service. In principle, it is not recommended to open new devices that are still under warranty, since you will no longer be able to count on free repairs after that.

Ability to find and fix problems

First of all, a proven method comes to mind, namely rebooting a faulty machine. But with Indesit this needs to be done not just like that, but in accordance with a certain scheme:

- First you need to turn off the machine using the “On/Off” button. If it still functions, of course.

- Unplug the electrical cable from the socket.

- Wait a couple of minutes.

- Re-insert the cable plug into the socket and press the “On/Off” button.

- If these manipulations do not lead to a positive result, then repeat the entire process 2-3 more times.

But if even then the error does not go away and the machine does not work, further attempts must be stopped, otherwise there is a danger of completely ruining the control system. That is, the futility of a reboot clearly indicates that the defect in the control module is really serious.

Or we are dealing with the oxidation of the electronic contacts that connect this module to the panel bulbs. Unfortunately, this means that the possibilities for self-repair are almost exhausted. All that remains is to look at connector J11, which connects the control panel to the module. Wiping his contacts didn't help? This means that only the control module remains - this is the reason.

Self-repair of electronic modules of Indesit washing machines is strictly not recommended! Such attempts almost always end in the complete failure of the machine and a trip to the service center for its owner. Only repairs in this case will cost several times more, because expensive parts in the machine will have to be replaced.

Prevention

Error F12 in the Indesit washing machine most often appears in old devices or in devices that are subject to increased loads. Following simple rules and recommendations allows you to extend the life of the unit and avoid problems:

- You need to load as much laundry into the washing machine as the instructions allow. If the drum is packed too tightly, the device will work with overload and will also not be able to wring out clothes efficiently. As a result, internal parts will overheat. In some cases, moisture may get on the microcircuits - this will lead to a short circuit and failure of the device.

- Washing machines are damaged by sudden voltage changes. If the current in the home electrical network is unstable, you should install a simple stabilizer at the output; it will protect the equipment from overload and prevent burnout of its main elements.

Heavy scale deposits on the heating element and other spare parts lead to overheating of washing machine parts. To ensure that the unit lasts longer and does not display errors, it is recommended to install cleaning filters and use chemicals that soften the composition of tap water.

When should you call a specialist?

You can't always cope on your own. If the cause of error F12 is a failure of the control board, then you will not be able to do it without the help of a specialist. Replacing the “brain” of a device is a complex task that requires certain knowledge and skills. The cost of work will vary depending on the model of the washing machine.

Approximate prices in the Russian Federation:

- Replacement of a control or display unit – from 2000 rubles. Working time is from half an hour to 1.5 hours.

- Repair of control or display board – from 2500 rubles. In case of a simple breakdown, work is carried out on site. If the board needs to be re-flashed, the technician will take it to the service center.

The stated price only includes machine repairs. If you need to buy a board, the user will pay for it separately. The cost of a new part starts from 8,000 rubles.

You can find a specialist by looking at advertisements on the Internet and in newspapers. You can use the services of private specialists and service center workers. Before making a choice, you need to read the reviews left by other people. This will minimize the risk of encountering scammers.

Professionals always provide a guarantee for the work performed, documenting this. The forms must contain the seal of the service and the signature of the employee.

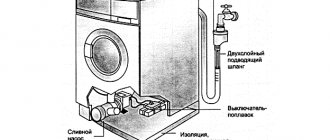

Problems with wires

The interaction between electrical components in the SMA occurs through wire connections. These elements are fastened with plastic ties or combined into cables. This means that one of the likely causes of problems may be the wires laid between the control board and the display module of the washing machine.

High humidity, leaks containing washing powder, and often rodents and insects through their waste products or direct interference can lead to damage to wires, oxidation of contacts and other problems in the electrical circuits of interaction between the module and the board.

In case of detection of malfunctions and defects in the wires, weak contact on connectors or in soldering areas, individual wires are replaced or defective areas are reliably insulated, stripped, degreased and oxidized areas are connected

Circuit integrity is important for stable operation of the device. If there is severe contamination - dust, cobwebs, waste products of rodents or insects on boards, connectors or wires - everything is carefully swept away with a brush and cleaned

How to repair a board yourself

To determine the breakdown, inspect the board for traces of damage and burnout of elements.

When to change the entire module

A complete replacement of the control board is required if it cannot be repaired. Controllers for popular models are sold in hardware stores. You can purchase and replace it yourself. In all other cases, it is better to contact persons competent in this matter.

The most common types of controllers: Arcadia / Arcadia, AKO, Computime / Computertime, Invensys / Invensis, Samsung MFS.

Where is the controller located

The control unit is located behind the front panel of the washing machine. You can see it when you remove the top cover. The location may vary depending on the type of laundry load, but in general it should not be difficult to find.

Dismantling

To remove the processor from the machine body, you need to perform several steps:

- be sure to unplug the power cord from the outlet;

- turn off the water supply;

- remove the top cover;

- remove the powder compartment;

- disconnect the chips with wires;

- unscrew the fastenings of the board to the case;

- get the part.

To facilitate the subsequent installation process, we recommend taking photographs and notes on the parts.

Functionality check

It is impossible to check the board's functionality when removed, without special instruments. You can only visually assess the presence of burnouts, oxides, and mechanical damage. Any part can fail. Most often these are diodes, resistors, thyristors, relays and other small components.

An example of checking a board with a multimeter:

We fix soldering ourselves

Due to the enormous vibration load on the machine during operation, the soldering of electronic elements may fail. To eliminate defects you will need a soldering iron, solder, flux and the ability to solder.

Capacitors

The capacitor performs voltage stabilization. You can determine the breakdown by swelling of the element or with a multimeter. If the device displays:

- "0" - short circuit

- "1" - break

When replacing, be sure to note that the capacitor has polarity.

Resistors

Checking resistors is divided into two stages according to the order of the elements:

- 8 Ohm, up to 2 A - first order resistors,

- 10 Ohm, up to 5 A - second order resistors.

If the specified parameters do not comply, mandatory replacement of the elements is necessary.

Thyristor block

The unit fails due to frequent changes in the network or impulse noise. Carry out the test only after you are sure that the capacitors are working properly. For the operation, you will need to install a negative resistance. The voltage of first order diodes should not exceed 20 volts. The burnout of the output contacts is checked with a multimeter in continuity mode. The voltage on the filter should be within 12 volts. Observe the polarity of all elements and handle the thyristor ports with care, otherwise repairs will result in large financial expenses.

Checking trigger status

Often its failure is also due to problems with capacitors. The trigger itself breaks quite rarely. Poor or vibration-damaged soldering leads to problems with the assembly. To eliminate them, solder the output contacts. The output voltage should not deviate too much from 12 volts. If the module has been replaced, before commissioning, measure the threshold voltage and output resistance, which should fluctuate within 12 volts 20 ohms, respectively.

How to re-flash the controller of an automatic machine

If the control board is intact, but problems remain, you can try to reflash the machine program. To do this, the module must have connectors for connecting equipment (if they do not exist, new firmware will be installed only in a service center, but directly into the processor).

You will also need a program or driver for flashing. They can be downloaded from the official websites of manufacturers or special resources - for example, bineep.ru and eeprus.ru.

To flash via USBDM:

- Connect the programmer to the appropriate connector and then to the computer.

- Install the driver that comes with the programmer on your computer.

- Open Windows Device Manager. Find the ESBDM item.

- Select the Target tab. Click Detect Chip to have the system detect the board model. If the model is not recognized, check the controller, semiconductors, triacs and other elements again with a multimeter - perhaps it is damaged after all.

- If everything is fine, click Load Hex Files... and select the program for the machine.

- Click Program Flash and wait for the process to complete.

https://www.youtube.com/watch?v=qaIXqShtdZQ