Typical problems

First, let's highlight the most typical causes of breakdowns of Bosch washing machines, which were assembled in Poland and Russia. They have surprisingly a lot in common, at least the weak points are the same. If we talk about possible breakdowns in a broad sense, then anything can break on cars made in Russia. It is unlikely that we would be able to talk about all the faults in one article, so we chose the most possible ones based on the data that our technicians shared with us.

- The system responsible for heating the water does not work correctly or does not work at all. The water remains cold.

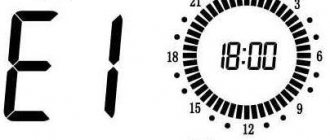

- Frequent spontaneous activation of the self-diagnosis system. Equipment freezes for no apparent reason and displays error codes for Bosch washing machines.

- Problems with the hatch locking device. The door either does not close or does not open.

- The washing machine does not drain water.

These breakdowns are the real scourge of Polish and Russian-assembled Bosch washing machines, and the reasons are the most banal. These washing machines are equipped with low-quality UBLs and heating elements; problems also often arise with the firmware of the control module, since Polish and Russian enterprises do not devote enough time to testing them. Let's look at these breakdowns in more detail and hope that you never have to deal with them.

Doesn't heat water

In 90% of cases, if the Bosch washing machine stops heating the water, you need to start testing with the heating element. Russian and Polish copies have cheap Chinese heating elements, the quality of which does not stand up to criticism. The average service life of such a heater is 2 years. It’s not even worth comparing them with German heaters, since their parts last an average of 10-12 years.

Frequent typical malfunctions of heating elements are associated primarily with harsh operating conditions. If you have a Russian-made Bosch machine, you often wash at high temperatures and have hard water, consider that your heating element is at risk.

To test the heater you will need a multimeter. Remove the front wall of the washing machine. The heating element is located directly under the loading hatch. We remove the wires from it, and then check the element for breakdown. Unscrew the nuts and remove the heating element from the niche. Unscrew the temperature sensor and put it aside. We throw out the faulty heating element and put a new one in its place. We put the front wall of the machine in place and check the operation of the washing machine. At this point, the DIY repair can be considered complete.

Gives errors frequently

Among the typical breakdowns of Bosch washing machines manufactured in Poland or Russia is a serious malfunction of the control module firmware. This breakdown can manifest itself in different ways, so even experts cannot always recognize it correctly. Most often, a firmware failure leads to the constant appearance of various error codes. You start the wash, the machine works fine for a while, and then suddenly freezes and displays some kind of error code. Moreover, this is repeated from launch to launch, and the codes are always different.

Of course, after the error code appears, the machine does not turn the drum and does not even drain the water; it freezes completely. When I try to reset the program, the machine does not start. The problem can only be solved by turning off the machine and turning it on again, but this is a temporary measure; a little later the machine gives an error again.

Unfortunately, self-repair of the control module is extremely difficult. Resetting the firmware or reloading it requires the knowledge of a highly qualified specialist. If you encounter a similar problem, call a technician immediately.

The door doesn't work

If your hatch door has stopped closing and opening normally, you need to check the UBL and the hatch locking mechanism. The locking mechanism rarely breaks, but the UBL breaks quite often. In this case, there is only one way to eliminate the malfunction - complete replacement of the UBL. We described how you can make this simple repair in the article The washing machine door (hatch, door) won’t close; we won’t repeat it.

So, we have discussed the main malfunctions of Bosch front-loading washing machines assembled in Russia and Poland. We did not touch on typical breakdowns of top-loading machines, but we promise to tell you about them in the very near future. Good luck!

Share your opinion - leave a comment

Types of faults

Bosch washing machines enjoy well-deserved attention among buyers. The use of innovative technologies, the use of reliable materials and high-quality assembly maintain the popularity of the models of this company at a high level. But these washing machines also have typical breakdowns.

Doesn't spin the drum

There can be many reasons for such a malfunction. This often happens due to improper operation of equipment, poor quality of tap water, or faulty electrical wiring. How the washing machine is installed and connected also matters.

The main reasons for drum stopping:

- uneven distribution of washable laundry;

- too much load;

- ingress of foreign objects;

- formation of limescale;

- clogged filters;

- drainage violation;

- wear of shock absorbers, stretching of support springs;

- stretching or breaking of the drive belt;

- breakdown of the heating element;

- engine malfunction;

- tachometer failure;

- failure in the control module.

The door won't close

Without closing and locking the door, the washing process will not begin. Sealing the loading opening may not be possible due to skewed hinges, wear and displacement of the locking “tongue,” or the entry of a foreign object. But there are times when the door closes, but does not lock or lock. This malfunction occurs for several reasons:

- deformation of the plastic guide of the lock retainer;

- the hatch locking device (UBL) is broken;

- clogging of the UBL hole;

- control module malfunction.

Inverter not working

There are 3 types of electric motors used in household washing machines:

- asynchronous;

- collector;

- inverter

The latter type of electric motors is used in the latest models. The operation of the inverter is controlled by a special electronic unit. Failure of such a motor can occur due to a defect in the control circuit, lack of power, short circuit of the windings or a malfunction of the frequency converter.

Drain hose defect

A malfunction of such a hose results in the machine refusing to drain water or doing so very slowly, which is why the control module blocks further execution of the program. The main reasons for this malfunction:

- internal blockage;

- kink in the drain hose;

- mud plug at the entrance to the sewer;

- Incorrect location of the drain hose.

Water flows from below

Leaking during washing is an unpleasant breakdown, but often easily corrected. First you need to determine where the water is leaking from. It can come from the hatch, from below or from behind the washing machine. To identify the location of the leak, carefully inspect the housing and accessible elements of the unit. Classic reasons for water appearing under the car:

- Damage to the shell of the drain hose or loss of tightness at its connection point.

- A crack in the tank body or a leaking seal. Water appears under the bottom of the car.

- Wear of seals. When inspecting the tank, characteristic leaks are visible at the bearing locations; new seals will need to be installed.

- Damage to the pipe for filling water into the tank or violation of the tightness of the connection.

- Broken or loose connection of the drain pipe.

- Water leaking from the drain pump due to wear.

- Loss of seal in the loading hatch.

- Detergent dispenser malfunction (clogged or broken).

The machine knocks out when turned on

The operation of the circuit breaker when the washing machine is turned on occurs due to a malfunction in the device itself or for other reasons. If it is new and this is the first time it is turned on, then perhaps the circuit breaker for the line is selected incorrectly. When the load was turned on, the current in the wires exceeded the limit value for this device. The defect is corrected by installing a more powerful machine.

The line may be disconnected due to the connection of other powerful consumers (electric stove, water heater, oven). A large current arises in the electrical network, which causes the machine to trip. Poor wiring or a broken socket can also cause this situation.

Reasons for protection tripping due to malfunctions in the washing machine:

- short circuit of the power cord (plug);

- broken power button;

- breakdown in the control board;

- short circuit in the motor windings;

- The heating element is broken;

- current leakage to the housing as a result of insulation failure or moisture ingress.

Doesn't heat water when washing

At some point, the home assistant suddenly stops heating the water, and the washing result leaves much to be desired. The main defects leading to this:

- heating element malfunction;

- thermostat damage;

- control module failure;

- error in choosing a program;

- incorrect connection of the device.

Doesn't respond to touch buttons

Models with touch controls are convenient, but this unit can also break as a result of improper handling or moisture. Lack of response to pressing occurs most often due to a controller error. It can be corrected by flashing it - replacing the control program. To do this, you need to have the appropriate software and hardware.

The second cause of the malfunction is a broken contact in the electronic module cable connector. Sometimes it is enough to move and press the block with wires to revive the washer.

If the sensor breaks or burns out, the machine also does not respond to button presses. The defect is corrected by completely replacing the entire assembly.

Problems with the heating element

If the wash is carried out without visible failures, the failure of the electric heater is detected by touching the hatch with your hand during operation. It will be cold, and powder stains will appear on the washed clothes.

Typically, the machine’s self-diagnosis system displays one of the error codes: F19, F20 or F22, which indicates the need to check the heating element. Sometimes, due to a defect in this element, when you try to turn it on, the network protection circuit breaker or residual current device (RCD) is triggered. This occurs due to a short circuit or current leakage to the machine body.

Design of Bosch washing machines

According to a number of sources, in all Bosch washing machines the body consists of 28 parts. They are always located in the same way, and disassembly can be performed without the use of special tools. The drum pulley is attached to a special bolt. Enhanced protection against leaks is required. There are also the following elements:

- stabilizers that prevent shaking;

- overload protection system;

- Accurate pollution sensors.

As for the connection, it can be done in various ways. The direct connection method is possible for almost any model produced by the German company. But the problem is that installing a hose directly into the water supply is not available everywhere. It is often necessary to use plumbing “doubles” and even “tees”. In systems with old mixers, water is supplied through adapters with a tap installed at the inlet of the mixer. An extension coupling is then used to supply hot water. In the second method, the hose is connected through a tee mounted in the shower head line. Sometimes a simple connection to flexible hoses is used.

Old metal pipes allow you to use various DIY tapping methods. But polypropylene pipes used after major repairs do not provide this opportunity. You will have to connect to them using a special soldering iron. And almost all people should call a professional plumber. Cross-linked polyethylene and metal-plastic are usually connected through special fittings.

Laundry is not distributed correctly

A common reason why a washing machine does not spin. Modern machines recognize that objects are unevenly placed inside the drum and do not turn on the spin program until they have resolved the problem, or they stop the wash and indicate an error code on the screen.

To avoid this situation, you need to cancel the spin cycle when washing clothes, especially duvet covers. At the end of washing, rinsing and stopping, you need to take out the laundry and straighten it, and then throw it back into the drum and set the spin program.

Some machine models have a built-in function for analyzing the condition of the laundry: if the device has detected that the items do not meet the requirements, then you need to check the “No spin” button. It is possible that the no-twist function was enabled accidentally.

The washing machine draws water, but does not wash: self-diagnosis

If water build-up and problems with drum rotation are detected, self-repair is not recommended. The user can only perform diagnostics.

Emergency water drain

After disconnecting the equipment from the network:

- Unclench the fasteners on the back of the housing and disconnect the pipe from the sewer drain;

- Place the hose in a bucket to drain the water;

- Place a container under the hatch and unscrew the plug.

Important! Modern automatic machines have a special valve for emergency draining.

Tank and Drum Inspection

The device is disconnected from the network, after which:

- The side panels are removed;

- The drum is checked - it needs to be turned a little;

- Debris or foreign objects between the tank and drum are removed.

If there is no blockage and the drum does not spin, contact a technician.

Cleaning filters

The machine needs to be turned off. Further actions:

- Removing the front hatch, under which the filter is located;

- Rinsing the clogged element with running water.

Advice! When unscrewing the filter, water will flow from the hose, so place a basin under it.

Checking the drive belt

The part must remain in place. If it is not on the pulley, install it with the calculation of 1 clove per 1 pulley. The torn belt is replaced by a technician.

Removing blockages from the pipe

To check the drain hose:

- Unscrew the fasteners on the drain;

- Remove and inspect the hose, feel it with your fingers;

- Carefully remove debris with a long wire or knitting needle.

After cleaning, the hose is reinstalled.

Diagnostics of heating element and motor

After turning off the machine:

- Check the heater with a tester - current should pass through it;

- Inspect the engine. If the part is bent, the brushes need to be changed.

Brushes and heating elements are purchased for a specific washing machine model.

There are many reasons why a washing machine fills with water but does not start. Some are easy to fix on your own, others require contacting a professional. To prevent damage, load the recommended amount of laundry and check pockets for small items. In case of voltage surges, it is worth installing a stabilizer. Filters should be cleaned once every six months.

Watch a video on how to fix a washing machine

What to do if the Bosch spin does not work?

Make sure to check the “safe” options: drain hose, sewer siphon, washing in other modes.

- If the problem is in the drain, you can try clearing the clog from the problem area. Be careful: if you use a cable, do not scratch the hoses; Do not use too aggressive household products, otherwise the hose or filter will have to be changed.

- Have you cleared the blockage, but the machine won’t spin? Spin problems can have several causes. Invite a specialist for a comprehensive diagnosis: order a call or fill out an application with a brief description of the malfunction on our website.

- Wait for the technician to arrive. We are traveling to Moscow and the region: authorized Bosch service is now available in every home. A specialist will arrive exactly at the chosen time, with tools for diagnosing faults, checking the integrity of the electrical circuit and urgent repairs.

- Get a summary of the technical condition of your washing machine. An integrated approach to diagnostics guarantees the absence of problems in the future. The technician will determine why the appliance is not spinning clothes and suggest a repair plan.

- Wait until the work is completed. Home repairs take from half an hour to 3-5 hours. Our clients do not have to wait for the parts to arrive: the technician arrives at the site with a full set of spare parts from the manufacturer.

- Check the results and get a guarantee. Make sure that the device spins clothes in different modes and conditions. If the washing algorithm goes astray in the future - the machine stops spinning again or the clothes are damp after spinning - contact us, we will fix everything for free!

Breakdowns of machines from different manufacturers

The vast majority of manufacturers implement the latest ideas when creating their washing machines. All this leads to the fact that units of different brands have their own specific operation, as well as malfunctions unique to them.

Indesit

This is one of those brands that do not cover their heating elements with a protective layer. Medium category stainless steel is used here, and this makes the unit more affordable in terms of cost. But when using hard water, such an element with a probability of 85-90% becomes overgrown with scale and fails after 3-5 years.

This brand is characterized by software failures: the specified modes are not fully executed, they work in the incorrect sequence, and some buttons become completely inoperative. This directly indicates a breakdown of the control system and the need to reflash it. The cost of such repair work is so high that it is often more profitable to purchase a new structure.

Another problem with such machines is bearings. Repairing them yourself can be very labor-intensive, since such work requires disassembling the entire drum structure.

LG

The most purchased units of this brand are direct drive models. In them, the drum is fixed directly, and not through a belt drive. On the one hand, this makes the equipment more reliable, since it minimizes the risk of wear of moving elements. But the downside is that such a design inevitably leads to frequent equipment breakdowns: the drainage tract of such machines becomes clogged much more often. As a result, the drain does not turn on, and the machine shows an error.

Equipment of this brand often encounters breakdowns of the valve and water supply sensors. The reason is a weak sealing rubber and a stuck sensor. All this leads to overflowing of the tank, when, with constant self-draining, the machine is forced to draw water without stopping.

Bosch

Models from this manufacturer are considered the highest quality in the middle price segment. The manufacturer placed special emphasis on the ergonomics of the equipment and its stability. The breakdown rate here is not too high, but mistakes still happen. The weak point is the heating element controller, failure of which does not allow the water to heat up. In addition, users often encounter loose belt drives.

Ariston

These are economy class cars with a high level of reliability. Malfunctions mainly arise due to incorrect operation: for example, too hard water and insufficient care of the equipment. However, there are also typical problems. The vast majority of users note the appearance of an unpleasant odor from the gum, strong noise and vibration during operation. All this leads to rapid wear of moving elements. Unfortunately, most of the elements of the unit cannot be disassembled at home, and their malfunction requires the intervention of a specialist.

Electrolux

These machines have poor electrical systems: in particular, the power button often breaks down or the network cable becomes deformed. Usually, to diagnose a breakdown, such machines are called with a special tester.

Some users note software glitches that occur with machines of this brand. For example, equipment can skip entire rinsing and spinning steps. This indicates incorrect operation of the control unit, which entails the need to reprogram it.

Samsung

Washing machines of this brand are characterized by high build quality and reliable electronics. The risk of malfunctions of such equipment is negligible, so machine owners rarely turn to service centers. In most cases, malfunctions are associated with the failure of the heating element: such a breakdown occurs in at least half of the cases. This type of malfunction can be easily fixed at home.

Typical disadvantages of machines include too light a counterweight and, as a result, strong vibration. Under these conditions, the belt may stretch or even break. Of course, you can fix such breakdowns at home, but in this case you will need an original part.

The output filter is located extremely inconveniently (behind the rear panel of the case), and it can be difficult to open. This is why users are very reluctant to clean it. As a result, the system quickly generates an error.

For information on the main faults of washing machines, see below.

Broken pressure switch

Signs of a faulty water level switch, as this part is also called? these are problems with diagnostics, lack of liquid when starting the wash and exceeding the normal water level. The problem leads to the start of the heating element, a malfunction of the heating device. The result is poorly wrung out laundry and water in the tank.

The problem is solved by reconfiguring the level relay. A specialist who understands washing machines of a certain brand has the right to do the work. If the issue cannot be resolved this way, then the pressure switch needs to be replaced with a new one.

Repairing a Bosch automatic washing machine: getting to the equipment yourself

You can fix the malfunctions from our list below with your own hands, provided that you pay close attention to the process of assembling and disassembling the device and correctly perform replacement or other manipulation regarding the internal equipment.

The drain pump has failed: how to replace it

Before disassembling the device, be sure to drain the water from it, otherwise you will wet all the parts in the machine. To get to the drain pump of the machine, you need to disassemble the back and top wall of the housing of the household appliance. Then turn the car on its side, having first secured the drum with bolts. Then remove the pump by disconnecting the terminals. After the manipulation has been done, we take a new structure suitable for this model of machine and securely fix it in its original place.

Repairing a bearing yourself: stages of the procedure

The bearing in the washing machine is responsible for the correct operation of the drum; if it wears out, it must be replaced so as not to damage the drum itself. To do this, follow the algorithm:

- We remove the body from the washing machine, remove excess water and debris from the tank.

- The difficulty is that you need to disconnect all the panels, the powder dispenser, remove the door clamp and cuff, and pull out the lock.

- Once these steps have been completed, we proceed to detach the tank. To do this, remove all the fixing bolts.

- The drive belt should be pulled to the side to avoid accidentally damaging it.

- Unscrew all the bolts that hold the plastic tank and remove it from the springs.

- Having reached the metal part of the drum, remove the pulley and existing bolts from it.

- A metal bearing is installed on the back of the drum.

- Knock out the damaged part and install a new one, performing all the steps exactly the opposite.

Good to know! In order not to confuse all the connections during assembly, it is best to photograph complex stages of work. Thus, you will be able to design a washing machine without errors.

How to remove and change the drive belt on a Bosch washing machine

Replacing the drive belt is carried out within a few minutes, so this work is considered elementary. All you need to do is remove all the screws on the rear convex cover. Opening it, you will see the motor drive and the drum along which the belt moves.

To remove it, you need to carefully pull it away from the parts, slightly turning the drum wheel. Put on the new belt in the same way. For clarity, watch this short video.

Heating element replacement procedure

If the water in the washing machine tank is cold and does not heat up during the operation of the device, this indicates that the laundry is unlikely to be washed. If you look inside the problem, then the damage to the heating element is to blame. To extract it, consider the following short instruction.

| Illustration | Description of action |

| Unscrew the fixing bolts and remove the top surface of the washing machine. | |

| Remove the detergent dispenser. To do this, just press the button located in the middle of the tray. | |

| To remove the front panel, you need to unscrew 4 screws, as shown in the photo. | |

| Remove the front panel by unscrewing all the fastening screws, and at the bottom of the drum you will see the attached heating element. Remove all contacts from it. | |

| Having unscrewed the nut of the heating element, we take out the part and install a new heating element in its place in the same way. Then we assemble the washing machine. |

As you can see, disassembling a Bosch washing machine to replace the heater is a very lengthy and painstaking job, so you should pay close attention to all the points.

How to clear a clogged drain hose when repairing a Bosh washing machine at home

During the long operation of the automatic machine, you may have noticed that when you turn on the water does not enter the tank as quickly as it did initially. If this is not a problem with your water supply pressure, then the water supply hose filter is clogged.

In order to clean it, you need to unfasten the tube on the back of the machine body. Remove the mesh that is placed inside the hose and screwed on using a thread. Rinse it well under running water and dry. Then install it in place and enjoy excellent water pressure.

Electrical or electronic malfunction

Not being a specialist in the field of electronics or electrics of automatic washing machines, it is better to contact a service center that will carry out diagnostics and necessary repairs. You can learn more about the nuances of repairing this part of the device from the video below.

We remove UBL

You can probably diagnose a faulty part only by removing it and inspecting it. To do this, do the following:

- Disconnect the machine from the power supply.

- Close the inlet valve, preventing water from entering the tank.

- Open the hatch door.

If the door is stuck closed, this can cause problems. However, there is a solution to the problem. You need to place your unit on its side, unscrew the screws on the bottom wall of the washing machine and remove the bottom. You will see that you can easily put your hand inside the unit and push the latch out of there, after which the door will immediately open.

Now you can begin to dismantle the locking device. First you need to deal with the hatch cuff. Bend its edge, there you will see a clamp. If it is plastic, simply “unfasten” it; if it is metal, carefully pick it up and remove it. After this, you can easily tuck the cuff inside the drum so that it does not interfere with work.

Unscrew the two bolts in the locking part and stick your hand into the hatch behind the body. You can easily feel the lock and realize that now only wires are holding it in place. To avoid confusion in the future, take a photo of their location and then disconnect the device from the contacts.

Error codes

Most modern models of automatic washing machines are equipped with a self-diagnosis system. This means that the user does not have to independently identify the problem; the device can easily determine at what stage of operation the failure occurred and provide the information obtained in the form of a combination of letters and numbers on the display.

If the booklet for your washing machine is lost, you can use the tables below with data on the most popular appliances.

Error codes for Indesit and Ariston washing machines:

| Code | Decoding |

| F01 | There is a short circuit in the control system, as a result of which the engine does not start. |

| F02 | A failure occurred in one of the sections of the control system electrical circuit. |

| F03 | The signal to start operation is not sent to the heating element. |

| F04 | Error in the operation of the water level control sensor. |

| F05 | Drain pump malfunction. |

| F06 | The signal from the control panel buttons does not pass through. |

| F07 | Damage to the heating element (heating element). |

| F08 | An error in the operation of the heating element caused by a breakdown in the water level switch. |

| F09 | Malfunction of the central control system. |

| F10 | The water level sensor does not send a signal to the control system. |

| F11 | The drain pump does not receive a signal to start working. |

| F12 | Error in the interaction circuit between the central control system and the selector. |

| F13 | Drying control system malfunction. |

| F14 | No signal to start drying. |

| F15 | No signal indicating the end of the drying operation. |

| F17 | The door does not lock. |

| F18 | CPU failure. |

Error codes for Bosch washing machines:

| Code | Decoding |

| F01 | The door does not lock. |

| F02 | The drum does not fill with water. |

| F03 | Drain malfunction. |

| F04 | Leak in the tank. |

| F16 | The door is working, but not closed tightly. |

| F17 | Water enters the drum too slowly. |

| F18 | The drain pump is running slowly. |

| F19 | The water does not heat up, but the wash will continue. |

| F20 | Uncontrolled activation of the heating element. |

| F21 | Error in the operation of the electric motor. |

| F22 | The heating sensor is faulty. |

| F23 | The leak elimination mode is enabled. |

| F25 | Water hardness is not determined. |

| F26 | Pressure sensor error, washing impossible. |

| F27 | The settings of the pressure sensor are lost; operation occurs according to random parameters. |

| F28 | The pressure sensor does not respond to the control system. |

| F29 | Stream error. |

| F31 | A volume of water exceeding the nominal volume has entered the tank. |

| F34 | The door lock is faulty. |

| F36 | Error in the operation of the blocker at the control system level. |

| F37 F38 | Damage to the heating sensor. |

| F40 | Control system settings have been changed. |

| F42 | The engine is running at high speed. |

| F43 | The drum does not rotate. |

| F44 | The motor does not rotate in one direction. |

| F59 | There is a problem with the 3D sensor. |

| F60 | The water supply pressure exceeds the norm. |

| F61 | The door does not respond when interrogated by the control system. |

| F63 | Problems with the security system. |

| F67 | Invalid card code. |

| E02 | Engine failure. |

| E67 | The main module malfunctioned. |

Error codes for LG washing machines:

| Code | Decoding |

| P.E. | Error in determining the water level. |

| F.E. | The volume of water entering the tank is higher than normal. |

| dE | The door is not closed. |

| I.E. | No water is collected. |

| O.E. | Damage to the drainage system. |

| UE | Drum malfunction. |

| tE | Temperature violation. |

| L.E. | Blocker problem. |

| C.E. | Motor overloaded. |

| E3 | Load detection error. |

| A.E. | Auto shutdown faulty. |

| E1 | Tank leaking. |

| HE | Damage to the heating element. |

| S.E. | Drive motor switching error. |

Samsung washing machine error codes:

| Code | Decoding |

| E1 | Error in the water supply system. |

| E2 | Error in the drain system. |

| E3 | A larger than rated volume of water has been loaded. |

| DE | The door lock is broken. |

| E4 | The permissible amount of laundry has been exceeded. |

| E5 E6 | Problems in the water heating process. |

| E7 | Problems detecting water level. |

| E8 | The water temperature does not match the selected washing mode. |

| E9 | Tank leaking. |

If your washing machine gives an error, you don’t need to immediately panic and choose a new appliance; many problems can be fixed on your own, for example, a door malfunction or a drainage problem caused by a clogged filter. If everything is done correctly, the error code will disappear from the display and the machine will operate as usual.

Where to begin

Reboot the SMA circuit.

Imported equipment, even Russian-assembled, is sensitive to network parameters. Failures (jumps, phase imbalances, low voltage, interference) are the causes of Bosch errors. If the problem is caused by power instability, the fault code will be cleared.

Method: remove the plug from the socket - wait up to 15 minutes - restart the washing machine.

Check power and signal cables.

The Bosch SMA is operated in damp conditions and vibrates during operation. The causes of washing machine errors are broken connections and moisture in the connectors. Regardless of the symbolism of the malfunction, the condition of the contacts and internal wiring is assessed. Breaks, short circuits, and damaged lines are easy to identify and repair without the involvement of a professional.

Check power and signal loops

This is the “brain” of the washing machine that generates errors. If no other reason is identified, the module should be tested. How to proceed is described at the end of the article.

Comparison of the best Bosch washing machines

I suggest you familiarize yourself with the ratings of all the above washing machines:

| Model | Loading (kg) | Spin speed | Size (WxDxH) | Peculiarities | Price, rub |

| WLG 20060 | 5 | 1000 | 60*40*85 | temperature selection | 19690-21111 |

| WLG 20261 OE | 5 | 1000 | 60*40*85 | delayed start by 24 hours. | 20151-23990 |

| WLG 20061 | 5 | 1000 | 60*45*85 | temperature selection | 21990 |

| WLG 2426 W | 5 | 1200 | 60*45*85 | Speed Perfect | 22560-24990 |

| WLL 24266 | 7 | 1200 | 60*45*85 | Energy efficiency A+++ | 24473-29990 |

| WLG 20160 | 5 | 1000 | 60*40*85 | delayed start by 24 hours. | 24990 |

| WLT24440 | 7 | 1200 | 60*45*85 | Energy efficiency A+++ | 27700-28210 |

| WLT 24460 | 7 | 1200 | 60*45*85 | Energy efficiency A+++ | 28769-33310 |

| WIS 24140 | 7 | 1200 | 60*56*82 | built-in | 53470 |

| WIS 28440 | 7 | 1400 | 60*56*86 | built-in | 61290 |

Faulty motor brushes

Signs of breakdown: the machine sparks and does not gain speed during the spin cycle, and the parts themselves are worn out and come into weak contact with the collector. Because of this, the power unit does not create enough torque to rotate the drum during the spin cycle.

The washing machine does not spin: what to do or how to replace and change the brushes:

- Disconnect from the network.

- Close the water inlet valve.

- Drain some of the water from the tank by unscrewing the inlet pipe. Attention! Water may suddenly start flowing.

- Remove the lower front part by removing the drain filter and draining some of the water using an emergency hose.

- Position the machine so that it is convenient to work with it.

- After this, you need to remove the engine by removing the back cover - it is secured with screws.

- Remove the drive belt. To do this, pull it slightly towards you and turn the pulley counterclockwise.

- Take a photo of the location and connection of the wires and disconnect them.

- Inspect the motor without dismantling.

After that, proceed to replacement:

- Unscrew the brush holder bolts and remove;

- carefully select the carbon rods;

- remove the brush from the socket;

- install a new product;

- repeat the procedure for another carbon contact.

If the unit is equipped with a direct drive, then the sequence of actions is different:

- Remove the rear cover.

- Remove the rotor. This is required to access the brush holders.

- Replacement brush is similar. You need to watch the direction of sharpening.

- Before installing new parts, you need to wipe the collector with a cotton swab to clean it of carbon deposits and dust.

Checking the control module

This component is responsible for all machine system programs, in particular spin execution.

The spin function cannot be started due to a module malfunction. You won’t be able to check the control unit at home, so you will need the help of a specialist.

If the control unit malfunctions, the technician diagnoses the board, replaces the broken parts with new ones, and then solders the tracks and contacts.

Why did the breakdown occur?

If a modern machine stops working during the washing process, then usually, after a few minutes, an error is displayed on the display. By deciphering the fault code, you can find out what kind of failure occurred in the system. If the washing machine is not equipped with a display, it will notify you of a breakdown by flashing the display on the control panel.

The worst thing is when the machine does not want to show an error code. Then you will have to diagnose the equipment, eliminating one probable cause after another.

The reason for a Bosch washing machine freezing may be:

- Drum overload, imbalance. Perhaps, during the washing process, the laundry was unevenly distributed inside, and therefore the machine refuses to work further;

- random unlocking of the hatch;

- wiring damage. Sometimes some wiring gets disconnected, a terminal comes off, or a sensor breaks;

- element failure. It's probably the heater, drain pump, or motor;

- activation of the emergency leakage protection sensor;

- failure of the main control module;

- inconsistency between the washing program and the type and weight of fabric loaded into the drum (this is true for some of the latest Bosch models).

There may be problems with the drainage. So, if the filters or pipes are clogged, the machine simply cannot drain water into the sewer, and, therefore, it cannot continue to work. In addition, the filling valve may be faulty. You will have to check each element to identify the cause and repair the unit.

Spin does not work - what is the reason?

Lack of spin in a Bosch washing machine does not always indicate a serious breakdown. Very often the cause of trouble is user errors.

If, after washing, the laundry removed from the drum is wet, the fault may be due to the user’s carelessness:

- The spin was accidentally (or intentionally) turned off. The solution to the problem is to load the laundry again after finishing the wash and put it in spin-only processing.

- Wrong choice of washing program. For example, using the mode for wool or for delicate items that do not give a strong spin.

- Overloading/underloading of the drum, as a result of which things are not wrung out well enough.

To analyze the situation, you should make sure that not a lot of things were included, and that a suitable program was set. If simple options for the cause of the spin failure are not confirmed, you need to move on to serious diagnostics and checking for technical faults.

The reasons that lead to spin problems in Bosch include:

- engine breakdown;

- wiring problems;

- clogged drain or sewer system in the apartment;

- tachometer failure;

- foreign object entering the tank;

- wear of engine brushes;

- drive belt damage;

- destruction of bearings;

- control module malfunction.

Troubleshooting

Some minor breakdowns can be repaired at home, without the involvement of specialists. What you need to know about DIY repairs? What kind of repair is best to entrust to a service center?

Self-repair and prevention

You can cope on your own by replacing some external parts of the washing machine, the rubber seal or cleaning the drain. In addition, cleaning the drain filter should be a mandatory preventative measure. It is also necessary to periodically check the permeability of all drain hoses, especially at the junction with the sewer.

The machine must be unplugged after each wash. It is recommended to leave the drum and detergent compartment open after finishing the wash cycle. This will protect the electronic filling of the machine from moisture and prevent the board contacts from oxidizing.

Call a specialist

The newer the washing machine, the more complex its design. In case of complex breakdowns, for example, electronic failures, you should seek the help of specialists. You should not trust private technicians. It is better to resort to the services of large service centers, where a guarantee of work is given.

In such companies, special attention is paid to thorough diagnostics, and only then repair tactics are chosen.

Call the master

In cases where error E32 appears regularly, in order to establish the cause of the problem and carry out repairs, you can seek help from a company that repairs washing machines. Finding such companies is not difficult on the Internet. There you can read customer reviews and get acquainted with their impressions of the work of the masters.

The cost of the work depends on the complexity of the breakdown and is based on the company’s price list. In the capital, the average cost of work is:

- replacement of bearings - from 4000 rubles;

- removal of transportation bolts – from 1000 rubles;

- replacement of shock absorbers - from 2200 rubles;

- replacement of springs - from 2000 rubles;

- replacement of counterweight - from 1800 rubles.

After the repair is completed, the technician starts the washing machine for testing. Before leaving, he issues a guarantee for the work performed. During repairs, parts may need to be replaced. Their cost is paid separately by the customer.

The main reasons for the malfunction of automatic washing machines

Each breakdown of an automatic washing machine has its own main degrees of severity. Some problems can be fixed on your own, while others are best left to a specialist. It happens that the automatic washing machine breaks down, but there is no money to buy a new one. In such situations, you can try to figure out the cause of the malfunction yourself. Although this is a risky and rather troublesome business. But it’s up to you to decide, and we will help you with this.

First, read the instructions carefully. Perhaps you will find useful information in it, since the instructions contain brief descriptions of breakdowns and ways to eliminate them.

You can repair your washing machine if the following malfunctions occur:

Washing machine filter dirty

The machine is equipped with a special filter that traps large particles, objects, and fuzz that can clog the water drain.

In order to clean such a filter, you need to perform the following necessary actions:

— before removing the filter, place a regular rag on the floor so that it absorbs all the moisture contained in the pump; — remove the drain system filter and clean it; — after cleaning the filter, inspect it for its integrity and put it back in place.

Drain pump malfunction

A centrifugal pump is used to remove all excess water from the machine after the washing process is completed. Such a pump consists of a filter-trap and a motor with an impeller combined with it.

The problem is that the machine does not drain the water. There may be several reasons:

1. Impeller jammed 2. Drain pipe clogged 3. Sewer pipe clogged

The failure of the pump itself is checked last. Most often, electric motors in such pumps fail. If the engine is faulty, you need to: - remove the drain unit from the machine - disconnect the pump from the drain unit - replace the faulty motor with a new one. And in reverse order, perform all previous steps to install the pump. All electric motors for automatic washing machines can be purchased at specialized service centers without much difficulty.

Malfunction of the heating element

The most common fault with modern automatic washing machines is insufficient heating of the water for the main wash. This defect can be detected by poorly washed laundry, or by touching the machine door during washing and discovering that it is cold. The main reason for such a malfunction of the machine is scale on the heating element. (See how to get rid of it)

You should not believe advertising that says that if the heating element breaks down, you need to buy a new car. Such an element can also be purchased at the nearest service center, and you can install it in place yourself.

Malfunction of temperature sensors

Using a temperature sensor (thermistor), the washing machine processor responds to changes in water temperature. When the temperature set by the program is reached, the processor turns off the heating element. If the temperature sensor malfunctions, it is necessary to drain the water, loosen the nut securing the heating element, disconnect the wires and remove the sensor from the rubber seal. We install the new temperature sensor in the reverse order.

Faulty drive belts

Damage or breakage of washing machine drive belts is a fairly common breakdown. Replacing a faulty belt with a new one is not difficult at all. To do this, just contact the service center and purchase a new belt there. To replace the belt in the washing machine, you must remove the back cover and thereby free access to the drive belt. After this, you can safely make a replacement.

This article describes the most common malfunctions of an automatic washing machine. Remember that all faults cannot be eliminated only on your own. Many complex repairs will require the assistance of a specialist. To fix a breakdown of an automatic washing machine, you don’t need to get too carried away, so that later you don’t have to pay twice for its repair and elimination of your defect.

In this article you will learn everything about choosing automatic washing machines.

And here you will get acquainted with connecting a washing machine.

And here you will learn about the advantages and disadvantages of a combined bathroom

In the video - repair of the pump (drain pump) of the automatic washing machine:

Codes and their decoding

F01 – the washing machine door is not closed

Open does not mean that it is wide open. It just didn't close tightly enough. The hatch lock did not fix it in the correct position and does not allow the wash to start. You just need to open and close the door until it clicks. Check to see if anything is preventing the lock from closing.

F02 - no water flows into the machine

A standard set of actions will be required to correct such a problem. Make sure that there is water in the water supply (and that the tap itself is not closed). Then inspect the inlet hose - is it pinched? The inlet filter mesh is cleaned of rust particles from the incoming water. This description is valid for machines with a standard fill hose. More about AquaStop later.

F03 – water does not pour out of the machine

Nothing new again. Possible causes are a clogged sewer pipe (if the machine is permanently connected to it), a clogged drain filter, a malfunction of the drain pump or control module. The drain hose cannot be kinked or clogged. It's easy to learn how to clean a washing machine filter.

F17 – the time for filling the machine with water has been exceeded

If after 5 minutes the water flow does not resume, the washing machine will automatically start draining it. Actions to correct the situation are similar to those indicated for item code F02. But since the problem may be caused by a software glitch, you will still need to try restarting the machine after draining.

F18 – drain time exceeded

The machine shows with this code that it cannot drain water. The reason is a malfunction or clogging of the drain pump or pressure sensor (aka pressure switch). To correct the situation, you may need to clean or replace the drain pump. Or the same thing, but for a pressure switch.

F19 – again time exceeded, but already heating water

In the event of such a malfunction, the washing program will be completed, but washing will be done with cold water. What can cause a problem is low voltage in the network, breakdown of the heating element, incorrect operation of the temperature sensor. What to do? Check the voltage in the outlet, the functionality of the heating element and the temperature sensor using a multimeter. Parts that have become unusable are simply replaced with new ones.

F20 – unscheduled activation of water heating

The heating element turns on when it shouldn't. If such an error occurs, the operation of the machine will stop and a notification of a serious breakdown will appear. The most common cause of the problem is failure of the temperature sensor. Most likely you will have to change it. Another option is that the problem is in the heating element relay. It is necessary to check the relay contact group for sticking.

F21 – the control system or the washing machine drive motor is faulty

The problem may manifest itself as uneven rotation of the drum or a complete lack of rotation. The car will try to start the engine. If it cannot, it will issue the “Important fault” command.

Probable causes are a short circuit in the triacs, a malfunction of the tachogenerator or reverse relay. The motor is being checked. It is repaired or replaced as necessary. The tachometer on the engine may become dislodged. Or the integrity of his contacts has been compromised.

F22 – temperature sensor malfunction

It may fail or short out. The problem may be caused by faulty wiring. The washing machine completes the washing process as usual, but the water will not heat up.

Having seen the indicated error code, you need to check the wiring and the NTC sensor itself. It is checked by replacing it with a working one. Or by measuring resistance at room temperature and when heated.

F23 – activation of the AquaStop leakage protection system

This system consists of a pan with an electronic filling sensor and a double hose with a solenoid valve connected to the sensor in the pan via a wire. When the pan is filled with water or the internal hose ruptures, the protection system is activated.

What can you do? Check the integrity of the connecting chain of the protection and the internal hose (the outer casing is usually transparent). If the AquaStop system is working properly and there is no water in the pan, check the pressure in the water supply and restart the washing machine.

F25 – AquaSensor does not work

Simpler - a water turbidity sensor. With this problem, washing will be performed, but without rinsing. The problem may be due to contamination of the sensor itself or a blockage in the drain system. Another possible reason is a broken level sensor.

F26 - code indicates a breakdown of the pressure switch

With this error, the washing process stops, the water is drained and the door and control system are blocked. Unlocking is done with the on/off button. The sensor and its circuit will need to be checked.

Features of repair of different brands

Different models of Bosch washing machines are similar in design, but the shape, location and fastening of internal components are different. For proper disassembly and repair, you need to know the specific features of the devices, then access to the faulty part can be easily found.

Bosch Maxx 4

To troubleshoot the Bosch Max 4 washing machine, several disassembly methods are used. To get inside the case, remove the panel and control module, you need to take out the powder dispenser, unscrew the 3 T20 star screws hidden behind it, which hold the top panel and front facing. The first element is still fixed on the side with a screw and plastic clips. They are easy to remove, except for the middle retainer. It is loosened by pressing a thin screwdriver from above through the hole in the frame.

To remove the module, you must release the plastic latches. But first, mark all the connectors with a marker - this will make subsequent assembly easier.

Bosch Maxx 6

The top cover of the device is fixed with self-tapping screws for the T20 sprocket, after unscrewing which it moves back along the guides and is removed. Further disassembly is performed as for the previous model. To get to the tank and pipes, you need to unscrew the screws securing the front and middle top strips. The powder dispenser is released and the connected pipes can be inspected.

Bosch Maxx 7

To get to the heating element, release the top cover and front trim in the manner described. All external fasteners are made with an asterisk. But before removing the front wall, you need to unscrew the screws covered by the bottom plastic panel and release the seal of the loading hatch.

After these manipulations, access to the tank, heating element, engine and shock absorbers is opened.

If you have the desire and confidence, then it is possible to repair a Bosch washing machine with your own hands. Not everyone can fix defects in electronics, but you can replace the tubular heater, sensors, pipes and other elements yourself.

How to recognize a breakdown if there is no code?

Bosch washing machines have a device diagnostic option, thanks to which you can independently determine the cause of the failure and eliminate it. Here are step-by-step instructions on how to carry out such diagnostics:

- close the door;

- set the program selection scroll to the Off position;

- after a few seconds select Spin;

- If done correctly, the Start indicator will start flashing;

- hold the Speed button until the Start light starts flashing;

- turn the selector to the Drain position;

The selector should only be turned in a clockwise direction so as not to cause damage to the equipment.

- release the RPM button and select the option that requires a test.

If the diagnostic cannot be started, the fault is in the control module and you need to call a specialist.

To check manually, scroll the selector; each number is responsible for testing a separate element:

- 3 – check the motor;

- 4 – pump testing;

- 5 – heating element;

- 6 – hot water valve;

- 7 – cold water valve;

- 8 – main wash valve;

- 9- valve for pre-wash;

- 10 - sound indication;

- 11 – FCW autotesting;

- 14-15 - quick self-testing.

To exit test mode, press Start and turn the selector.

To return from the mode, scroll to the Off position.

Adviсe

Some users are interested in information on how to reset error F21 themselves. However, not every person knows why it is necessary to reset the error, because there is an opinion that it will disappear on its own after the cause of the failure is eliminated. This opinion is wrong. The code will not disappear on its own even after repair, and a blinking error will not allow the washing machine to start working. Therefore, professional craftsmen recommend using the following recommendations.

- First of all, you need to turn the program selector to o.

- Now you should turn the switch selector to the “spin” mode. You will need to wait a little until the error code information appears on the screen again.

- Then you should hold down the key for a few seconds, with which you switch the drum speed.

- Next, the switch selector should be set to the “drain” mode.

- It is worth holding down the speed switch button for a few seconds.

If after the above steps all indicators begin to blink and the machine beeps, it means that the error was reset successfully. Otherwise, you will need to repeat all the manipulations again. You can prevent the occurrence of such an error by regularly diagnosing the washing machine, installing a voltage stabilizer, as well as checking your clothing pockets and paying more attention to the contents of the drum.

See the video for the causes of error F21 and their elimination.