This article describes in detail the electronic module (EM) used in washing machines (SM) ATLANT series 35M102-xxx, 45U82/102-xxx and 50C85/102-xxx. For the first time, the electrical circuit diagrams of the EM and the submodule included in it are presented.

More recently, SM ATLANT was represented on the Russian market by only a few models of the old series: 5FB520/840T/ 1040T-xx. They were replaced by SMs with full electronic control, such as: 35M102-xxx, 45U82/102-xxx, 50S82/102-xxx, as well as 45U124-xxx, 50S124-A-xxx and others.

This article describes in detail the EM, which is used in the SM “ATLANT 35M102-xxx”, “ATLANT 45U82/102-xxx” and “ATLANT 50С82/102-xxx”. Its appearance is shown in Fig. 1. In the models under consideration, the SM modules do not differ in appearance from each other, the main difference is in the contents of the non-volatile memory chip (EEPROM) as part of the EM. The main software (software) of the EM is recorded in the internal protected memory area of the microcontroller (MC) chip and, as far as the authors know, it has no differences within the same SM series. The EM EEPROM chip contains the configuration of a specific SM model, which reflects, for example, the type of control panel (CP), maximum spin speed and other additional functions.

As an example in Fig. Figure 2 shows a diagram of the cable connections of the SM “ATLANT 50S82-xxx”, and in Fig. 3 - schematic electrical diagram of connecting the main components as part of the same SM series.

In table Figure 1 shows the explanation of the digital designations of the cable connections of the SM “ATLANT 50S82-xxx” (see Fig. 2).

The full article can be read in the paper version of the magazine

Washing machine won't turn on

If the display does not light up when you press the power button, make sure the power cord is plugged in and there is electricity in the house. If the problem is in the washing machine itself, then the troubleshooting options and methods for eliminating them are as follows:

- Plug fault. Disassemble the plug and check the contact connections.

- Broken power cord. You need to ring the cord.

- There is a fault in the electrical wiring in the car. Remove the outer panel of the unit and check the condition of the terminal clamps, they may be oxidized.

If the display of the machine automatically reacts to turning on, the washing program is selected, and the machine does not work, the reason is as follows:

- Wrong washing mode selected.

- The door is not closed tightly enough. Check the integrity of the door seal and whether the item being washed has gotten between the door and the body.

- Water is not flowing into the machine due to the water supply taps being closed.

- The timer is faulty. In this case, the washing mode of the selected program does not start due to a broken time relay. To check, turn the program switch until the drum begins to rotate. If this happens, it means that the timer is faulty and requires replacement.

Washing machine drum does not fill with water

First of all, check whether the water supply taps are open. Next, make sure that the inlet hose is not deformed or clogged. Rinse it if necessary.

If the inlet filter is clogged, perform the following manipulations:

- Close the water supply tap.

- Disconnect the hose from the unit inlet valve.

- Remove the filter and rinse thoroughly under running water.

- Install the valve, connect the hose and open the water supply valve.

If the intake valve breaks, it will need to be replaced. You can also do this yourself. It is necessary to remove the valve from the inlet pipes and replace it with a new one.

The water intake system is a weak point in Atlant machines. In good condition, when the water level in the drum rises, the water compresses the air in the pressure regulator compartment. When the pressure reaches the required value, the switch operates and the inlet valve closes. At the same time, power is supplied to the heating element and the switch for prohibiting premature opening of the drum door is activated. If the tube is damaged or clogged, the water supply system will not work.

To troubleshoot:

- Check how the tube is installed on the water level switch. If the end of the tube has hardened, cut it a couple of centimeters and put it back on the switch.

- To check that the switch is working properly, blow into the tube. The click of the switch should be heard.

- Afterwards, loosen the clamp on the hose that secures the pressure chamber to the drum.

- Flush the chamber so that the inlet and outlet ports are clean and free of blockages. Inspect the camera for cracks and deformations.

- Make sure the switch is working properly: test it with a multimeter. If damaged, replace with a new one.

Washing machine drum fills with water too slowly

Standard reasons why water fills slowly into the washing machine:

- The inlet hose is clogged or deformed. In this case, rinse the hose under water pressure.

- The inlet filter is clogged. Remove and wash the filter.

- The water pressure in the system is not high enough. Make sure the water supply valve is fully open. If yes, then there is insufficient water pressure in the line. It needs to be raised. For example, install a pressure tank under the ceiling of an apartment, or in the attic of a house. The minimum required pressure is 12 atm.

The water in the washing machine does not heat up. Heating element failure

Causes of breakdowns and options for eliminating them:

- The water level regulator is faulty. A faulty water level switch does not recognize that the drum is full, so it does not turn on the heating element. Check the switch with a multimeter and, if faulty, replace it with a new one.

- Scale has formed on the heater. Due to increased water hardness, limescale appears on the heating element, which affects the operation of the heater. Disassemble the washing machine and descale it.

- Malfunction of heating equipment. The heater contacts need to be tightened and oxidation removed. Using a multimeter, check the heating element for an open circuit by first disconnecting one wire from the heater. If necessary, replace it with a new one.

- Thermal relay failure. It is used to measure the temperature of the water in the washing machine tank and turn off the heating element when the desired temperature is reached. A malfunctioning thermal relay turns off the heating element incorrectly: too early or too late.

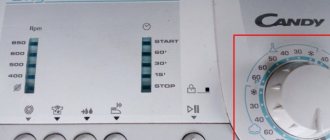

Electrical diagram of the washing machine Atlant SMA 5FB 840T

- A - electronic module;

- VK - temperature sensor;

- HL—indicator;

- M1 - electric pump;

- M2 - electric motor of the command device;

- M3 - electric motor;

- KA - command apparatus;

- R - temperature controller;

- SA - electric door lock;

- SB1 - mains switch;

- SB2..SB5 - additional buttons. functions;

- SK - thermal switch 90 degrees;

- SL—level sensor;

- Y—electric valve;

- EK - heating element;

- Z—RP filter.

Automatic stopping of the washing machine during a cycle

If the washing machine stops on its own during an incomplete wash cycle, check the presence of power in the outlet using a multimeter. If everything is in order with the power supply, the reason for the stop may be a clogged inlet or outlet hose. To remove the blockage, rinse the hose under the tap.

The next step is to remove and check the serviceability of the pump. It may be clogged or broken.

Next, check the serviceability and cleanliness of the intake valve. If necessary, replace with a new one. Next, check the operation of the thermostat, heating element and timer. If the timer malfunctions, replace it with a new one, as repairs are too difficult for a non-specialist.

A typical case when repairing an Atlant washing machine is the failure of the electric motor. The “weak link” in it is the brushes. Such repairs require special skills and it is better for the user to contact a service center. The good news is that in most cases the engines can be repaired and there is no need to buy a new one.

Typical breakdowns and their causes

You can find out the cause of the breakdown and unstable operation of the washing machine by the characteristic symptoms that appear during washing, spinning, and drawing water. Most often, Atlant machine users turn to specialists with the following symptoms:

- The machine stopped turning on. There may be several reasons in this case. Malfunction of the socket, wiring inside the machine, failure of the “Start” button or control module.

- The machine does not spin clothes. If the laundry remains damp, even wet, this means that the motor has broken down, or the contacts on the motor have oxidized. It is possible that the cause of poor spinning is a faulty control module. If the spinning process does not start at all, and the machine “freezes,” then, most likely, the laundry is stuck in the drum and there is an imbalance in the load.

- The machine does not drain water. In this case, the cause is a broken drain pump or a clogged drain hose.

- The machine “jumps” and knocks during the spin cycle. This indicates the need to replace the bearings.

- The machine washes in cold water. This is a common breakdown caused by the failure of the heating element.

- Water is leaking from the machine. The causes of this malfunction must be sought depending on where the water flows: under the machine, through the hatch door or through the powder receptacle. This means that the breakdown must be looked for in the corresponding parts: the drain hose has burst, the pipes or seals have worn out, the cuff has torn.

By listening carefully and looking closely at your washing machine, you will not miss the moment and detect a malfunction in time. In some cases, you simply cannot delay repairs.

In many cases, the error codes that appear on the display of the Atlant washing machine help to determine the cause of the malfunction. It is also worth noting a good self-diagnosis system for faults in some car models. Detailed instructions on how to launch the self-diagnosis mode cannot be described in one article. The fact is that on different machine models, startup may differ, so it is best to read the instructions included with the machine, or download the instructions for a specific model on the Internet.

The machine does not turn on: eliminating the reasons

If the machine does not turn on, then the first thing to check is the functionality of the outlet. To do this, you can turn on another household appliance. If the problem is not in the outlet, you will have to check the power cord, surge protector and control board one by one. To get to the machine's electrics, just open the top cover, which is secured with two bolts.

Having provided yourself with access to the electrics, inspect all the terminals and wires; perhaps already at this stage you will see burnt and oxidized elements. After the inspection, you need to take a multimeter and test the surge protector and cable. If it turns out that the cable is faulty, it must be replaced with a new one. Sometimes the cable is sold complete with a surge protector.

If the electrics of the machine have nothing to do with it, then the reason that the machine does not turn on is the electronics, in particular the “Start” button may not work. It is difficult to cope with such a problem on your own. Therefore, it is better to entrust the diagnosis of the exact breakdown and its elimination to a specialist.

Important! When working with the control module, you need to have certain knowledge in this area, otherwise, if at least one wiring is connected incorrectly, a working board may burn out.

The drum does not rotate

First, rule out the simplest reason - a broken door latch. If the lock is faulty, the drum will not rotate. To check, press the door button several times, it may be stuck.

If the drum in the washing machine is not mounted on a direct drive to the motor, but on a tension belt, the belt may come off. Move the engine down a little and adjust the belt tension tighter. Be careful not to overdo it. Too much belt tension will cause rapid bearing wear and failure. With the correct belt tension, when pressed, the belt moves about 12 mm. If your washing machine does not have a belt tensioner, the best alternative is to replace the belt with a new one.

Replacing the washing machine drive belt

Another possible reason for the drum stopping is a breakdown of the electric motor. In this case, you should contact a specialist.

Problems with draining water

The first possible reason for water retention in the drum is a clogged outlet hose or its deformation. Check the hose for blockages and flush if necessary. The exhaust filter may also be clogged. You can clean and replace it through the hole located at the bottom of the washing machine.

Cleaning the drain filter

The next possible reason is a clogged pump. Remove it and check for foreign objects. To do this you should:

- Prepare a rag for water in advance.

- Remove the clamps securing the hoses to the pump. Check the hose for blockages.

- Using a pencil, check the rotation of the impeller. If the impeller rotates slowly, remove the chip with wires and mounting bolts from the pump. Then remove the clamps or screws that connect the two parts of the pump.

- Mark or take a photo with your phone of their location so as not to confuse them when assembling. Check the impeller chamber for debris, and also make sure there are no threads wrapped around the shaft.

- Clean and reassemble the pump. If the above manipulations did not help, replace the pump with a new one.

Loud or unusual noise during wash or spin cycle

If your washing machine suddenly starts making loud noises or clanking noises during the wash cycle, you may have left coins, keys, or other foreign objects in your clothing pockets. If small metal objects from the drum fall into the tub, the washing machine may be seriously damaged. Therefore, it is important to check pockets before washing.

Another reason for unusual sounds may be a broken latch or door lock. The sound in this case will be buzzing and will stop when the door is closed.

If a squealing sound appears when washing at high speeds, this indicates that the drive belt is slipping. Tighten the belt or replace it with a new one

If you hear a rattling noise when the drum rotates, the drum bearing is broken and needs to be replaced.

Other “filling” of the washing machine

To fully understand how a front-facing washing machine works, you will have to understand not only the main components and sensors, but also additional elements. Although we consider these details as secondary, in fact, without them the machine will not be able to perform its functions. Any, even the smallest element plays an important role in the design of the device.

So, we are talking about the following components:

- door cuff. The sealing rubber ensures the tightness of the system;

- locking device. It is activated by the “brain” after mechanically closing the hatch and starting the wash. When the UBL has triggered, it will be impossible to simply open the door until the end of the cycle;

The control module automatically activates the UBL after starting the washing mode.

- drive belt. It is he who transmits the impulse from the engine to the drum pulley, after which it spins the container to the required speed. If the elastic band breaks or slips, the wash will stop and the drum will “freeze” in place;

- counterweights. These are concrete blocks necessary to give the machine stability. Without them, the washing machine will not be able to withstand the centrifugal force that occurs when the drum moves;

- garbage filter. Protects the drain pump by preventing debris, hair, threads, and foreign objects from entering it. Needs periodic cleaning;

- door. No explanation is needed here. Without a hatch, putting things into the machine would be problematic;

- powder receptacle. The dispenser is divided into sections, each of which is loaded with a specific product - for preliminary or main washing, rinsing. The cuvette helps the ingredients enter the tank gradually, thereby achieving maximum washing effect;

- pipes Elements connecting the main components of washing machines. For example, the drain pipe is located between the main container and the pump, other hoses lead from the dispenser to the tank. Thanks to them, water circulates freely in the system.

Having understood how the Atlant washing machine works, you can independently analyze the operation of the equipment and notice the first “symptoms” of breakdowns. It is important to read the factory instructions to understand the design of the “home assistant” and promptly fix minor problems.

Interesting:

- How does a Whirlpool washing machine work?

- How does a Zanussi washing machine work?

- How does a Kandy washing machine work?

- How does an Electrolux washing machine work?

- How does a Hansa washing machine work?

- How does a Samsung washing machine work?

Reader comments

- Share your opinion - leave a comment

Strong vibration, spontaneous movement of the washing machine on the floor

If a similar problem occurs for the first time, the reason lies in an overloaded drum of the unit or in clothes unevenly distributed in the drum. Remove excess clothing from the drum and continue to follow the recommendations of the Atlant washing machine manufacturer.

If the unit vibrates more than once, while moving along the floor, it means that the washing machine was installed incorrectly, not level. Re-align the unit by adjusting the height of each leg.

Atlant washing machine device diagram

Any repair requires disassembling the washing machine, and for this you need to know its structure. The device is enclosed in a metal case with top, front and rear walls, as well as side panels. To get to the parts and components located inside, they will have to be twisted.

The main operating components of the Atlant washing machine:

- Motor and belt.

- Tachogenerator responsible for controlling the rotation speed of the drum.

- Tank. This is the largest element of SMA. It consists of two plastic halves, which can be disassembled if necessary.

- Drum. It is located inside the tank, made of stainless steel, and has perforations.

- A pump that is responsible for draining water. Atlant machines most often have a rotary asynchronous pump installed.

- Shock absorbers.

- Control board. It is this small part that controls the entire operation of the device, sending commands to different systems.

- heating element. It heats the water during washing.

- Pressostat – water level sensor.

Washing machine door won't open

The most common reason for the door blocking is water remaining in the tank after washing. Drain the water from the drum using the drain mode. Check for blockages in the drain pipes and whether the pump is working correctly.

We shared with you the most common causes of breakdowns of Atlant washing machines and gave fairly detailed instructions for eliminating them. Follow the manufacturer's recommended operating rules, and your assistant will serve you longer.

Rules that will help extend the life of your washing machine:

- Before loading items, check pockets for coins, keys, and other items and debris.

- Clean the heating element regularly to remove scale.

- Use hard water softeners and a cleaning filter.

- Regularly clean the drain filter of debris and dirt.

- Wipe the powder and additive drawer dry after each wash to prevent mold from forming.

How is water heated?

The water “reaches” the desired temperature thanks to the heating element. The heating element is located directly under the drum, on the back side of the housing. You can access the tubular heater by removing the wall and removing the drive belt.

The heating element is one of the most frequently damaged and replacement elements of Atlant washing machines.

The heater breaks down because:

- constantly comes into contact with hard water, as a result of which scale forms on its surface;

- the settled layer of limescale interferes with the heat transfer of the heating element, which leads to overheating and burnout of the element.

Therefore, it is better to avoid constantly using high-temperature washing modes. Especially, run several cycles in a row with water heating to 60-90 degrees. The heating element should be allowed to cool for an hour, and only then turn on a new program. If we talk about the power of the heater, it consumes approximately 1800-2200 Watts. These values are identical to those of other heating devices.