Without a pump, the washing machine cannot function, since this part is responsible for pumping out water after the main cycles. If it breaks, the washing process stops and the liquid remains inside the drum.

To learn how to repair or replace a pump for a Bosch washing machine yourself, where you can buy it and how much the repair costs, read the article.

Is the pump really broken?

How to understand that a malfunction of a Samsung washing machine is caused by a pump defect?

First, you should inspect the washing machine for other damage and check the functionality of other parts and elements. First of all, focus on the external signs of a malfunction. All modern machines notify the user of a breakdown by displaying an error code on the digital screen

By seeing the conventional combination of numbers and letters and deciphering it using the instructions for the device, you will understand whether the inoperability of the drain system is the root cause of the problem.

Start checking the system, first make sure that the spin function has been set by the program. If not, then enable this mode again. If nothing happens, check the drain hose; it should not be located above the level of the tank and have kinks. If it is level, disconnect it from the utilities and check for blockages. Direct the free end of the hose into the bathroom and turn on the automatic flush mode. If water begins to flow freely, then everything is fine with the machine, and the root cause of the breakdown is a clogged sewer pipe.

If the problem is not a blockage, you need to move on to the next step. Remove the protective panel (in some models, access to the elements of the drain system is opened by a small hatch) located below, on the front wall of the case. Prepare a container of such volume that all the water from the machine fits into the container, place it and unscrew the drain filter. Drain the liquid from the tank and remove any accumulated debris from the surface of the filter.

Using a flashlight, illuminate the hole in which the part stood. Carefully examine the impeller to see if it rotates freely. If the impeller stands still or moves with great force, it is worth starting to check the pump.

Causes of pump failure

- The pump broke down due to a malfunction of the engine, as a result of which there is no voltage to the pump.

- The seal (rubber or plastic) is damaged by scale and dirt that settles on the impeller.

- Incorrect connection of the pump or failure of the water level sensor causes the pump to constantly operate.

- The pump will not be able to drain water due to a clogged filter.

- Small foreign objects destroy the impeller. It's easy to diagnose. When the pump starts, the machine makes a hooting sound.

For Zanussi, Electrolux and SMA brands with top loading

To remove the back panel yourself, unscrew the screws along the edges. Move the panel aside.

To remove the side wall, you also need to unscrew the screws. They can be located in front or behind the SMA body. Slide the lid and set aside.

- Unclench the drain pipe clamp. If it is secured with a screw in your washer, unscrew it.

- After disconnecting the pipe, disconnect the wiring connectors.

- Unscrew the screws securing the pump and pull it out.

We have considered all possible options for removing the pump. Now let's find out how to check and replace the drain pump on a washing machine.

READ MORE: Gamepad does not work in games on PC: why - MirDostupa

How much does it cost and where to buy?

A new pump for a washing machine is selected according to the following criteria:

- type of fastening (3 screws, 3, 4 or 8 latches);

- type of wire connection (terminals or chip);

- manufacturer (Askoll, Plaset, Hanning, Mainox, Arylux, Coprecci);

- power.

It’s good if you have the opportunity to take a faulty pump with you to the store (in this case, selecting a new unit will become much easier). If this is not possible, to order a drain pump, you must inform the store salesperson or the manager of a specialized spare parts website about the model and year of manufacture of the washing machine.

The cost of a drain pump for a Bosch washing machine varies between 1000–2000 rubles . To avoid low-quality crafts, it is better to buy a new pump for your washing machine at specialized sales points for spare parts for Bosch appliances.

Causes and signs of bearing failure

If the Bosch machine begins to make a lot of noise during operation, you can hear knocking and grinding noises that intensify during the spin cycle, this indicates the need to replace the bearings. During operation, the seal covering these units wears out over time, and water begins to enter the bearing seat through it. It washes away the bearing lubricant, resulting in increased friction and deformation of the bearing.

To finally make sure of the diagnosis, you need to open the car hatch, bend the cuff and manually turn the drum or shake it. Significant play will be noticeable.

To replace bearings and seals yourself, you need to assemble a tool and purchase spare parts, as well as prepare your Bosch washing machine for repairs.

How to repair and replace a pump for a Bosch washing machine?

Without a pump, the washing machine cannot function, since this part is responsible for pumping out water after the main cycles.

If it breaks, the washing process stops and the liquid remains inside the drum. To learn how to repair or replace a pump for a Bosch washing machine yourself, where you can buy it and how much the repair costs, read the article.

Call the master

Replacing bearings in a Bosch washing machine is a task that a beginner cannot handle.

If it is impossible to carry out repairs on your own, you should contact a household appliance repair company. Companies that have been providing support services for household washing equipment for several months now employ experienced craftsmen who can carry out high-quality repairs of any complexity.

The cost of work depends on the price list of the company and the type of repair. If other work needs to be done in addition to bearing replacement, the cost will be higher. On average in the capital, the price for replacing bearings in Bosch washing machines ranges from 4,000 rubles and more.

After the replacement has been carried out and the Bosch washing machine has been assembled, the technician performs a test run of the washing machine, after which a warranty is issued.

How to choose a drain pump

For more information about the drain pump: where it is located in the washing machine, its operating principle and structure, you can read in this article: what is a water pump for a washing machine

When replacing a drain pump, you must choose a complete analogue in terms of design and technical parameters. All drainage devices differ both in power and performance, and in the method of fastening. You should only choose from proven and reputable manufacturers. Sometimes it happens that the connection of electrical wires to both the drain pump and the circulation pump may have a different location than those that have failed. This nuance usually does not matter and does not affect the installation of the element in its normal place. All replacement operations are carried out in the reverse order of dismantling, with mandatory quality checks of all fasteners and connections.

Frame

All Bosch models have 28 parts in it. Their arrangement is the same in all cases, making it easy to disassemble these devices without the use of special tools.

This group of parts includes:

- Top cover of the washing machine.

- Intake valve cover.

- Cover for the service hatch.

- Special mount for inlet hose.

- Right transport bolt.

- Left transport bolt.

- The right, left and rear walls of the machine connected together are considered as a single element.

- A key that is used to adjust the height of the machine legs. They can be installed at a certain height, ensuring the correct position of the Bosch washing machine even if it is installed on an insufficiently level floor.

- A tray that is designed to protect against water leaks. The Bosch automatic washing machine uses the Aquastop protection system. There is a sensor on the pan that is triggered if water gets there.

- Legs designed in such a way that their height can be adjusted. To do this, they have a thread that makes it possible to tighten or unscrew them.

- Lower short front panel.

- Lower front extended panel.

- Fastening element for the front panel.

- A loop for the hatch through which laundry is loaded for washing.

- A clamp that is a fastening element of the cuff.

- Base for manhole cover.

- Glass part of the hatch window.

- This is a decorative outer hatch panel.

- Mounting pins that fix the position of the hatch.

- A handle that can be used to close the hatch through which laundry is loaded.

- The mechanism that ensures the operation of the device that locks the hatch. If it malfunctions, it will be impossible to lock the hatch in the closed position.

- Bushings that hold the hatch.

- Front wall of the washing machine.

- Fastening elements for holding the front panel.

- A device designed to lock a hatch.

- Upper spacer bar.

- Bottom spacer bar.

- Latches that are designed to fix the top panel of the Bosch washing machine.

The design of the washing machine is such that disassembly does not require special tools or special skills. In Bosch max 4 machines the body depth is 40 cm, while in other models it is larger - 60 cm.

Possible difficulties

When repairing a Bosch washing machine, you may encounter various difficulties:

| Problem | Ways to solve the problem |

| The screwdrivers provided do not fit the mounting screws. | You should take care in advance of a large set of screwdrivers and heads |

| The tank cannot be removed from the housing after disconnecting | You should check whether all fasteners have been disconnected, and whether the counterweights, which significantly weigh down the structure, have been removed. |

| After assembly and during the first start, a puddle appeared under the washer | To determine the location of the leak, the washing machine will have to be disassembled and diagnosed |

| Screws missing during installation | Screws lost due to carelessness can be replaced with similar ones. |

| Bearing cannot be removed | WD-40 can help remove stuck parts. |

| Some screws won't come out | |

| The new bearing does not fit the seat | It is likely that the bearing you purchased does not fit your existing washing machine model. |

Where and at what price can I buy it?

You can purchase a new pump in stores that specialize in selling original spare parts, or order it online.

When planning to make a purchase, you need to clarify the model of the washing machine, since the pumps will be different for different devices.

To buy a part that suits all parameters, you should count the number of fasteners, as well as find information about the power of the motor .

The cost of the motor depends on the model of the washing machine. The more modern it is, the more expensive the part is. The average cost of a pump for a Bocsh washing machine is 1,500 rubles. There are parts on sale at prices of 1200 and 1800 rubles.

Cost of replacement and repair

Since the Bosch washing machine has a complex device, technicians charge 2,000 rubles to replace the pump . If the pump can be repaired, then you won’t have to spend money on buying the part itself. However, you will still have to pay for the specialist’s work.

If the repair was entrusted to a private master, then you should choose the specialist who has positive reviews. An employee who values his reputation will be sure to provide a receipt for the work performed and give a guarantee for at least a year.

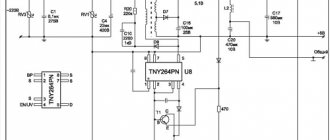

Principle of operation

The drain pump of a Bosch washing machine consists of two parts: a low-power electric motor (enclosed in a sealed housing) on the shaft of which an impeller and volutes in the form of a plastic pipe are fixed.

On one side the snail is attached to the pump body, on the other side it is connected by a pipe to the tank of the washing machine.

As soon as the control module sends a signal, the process of pumping water from the drum begins: the rotation of the pump impeller starts, which pumps waste liquid out of the washing machine drum through a pipe.

During the draining process, the water passes through a filter element located in the pump volute (protects against the entry of small debris), after which it flows through the drain hose into the sewer pipe of the house. The pumping process continues until the water level sensor in the tank (pressure switch) transmits a signal to the control module that the drum is completely empty.

Pump repair and replacement

After the part is disconnected, you need to check the washing machine pump. Before disassembling the part, you should inspect the impeller and all holes and make sure that they are not clogged and that there is no hair, thread, wool or other debris wrapped around the blades. You need to pull out the drain filter and inspect the part visually, and then try to turn it. A working unit should turn with pauses due to the coil installed on the magnet. If there is no debris, the impeller rotates with difficulty, and the device will need to be disassembled. To do this you need:

- Remove the pump cover by unscrewing the fasteners or turning it counterclockwise.

- Pry the impeller housing latches to release it.

- If the cross does not give in, you need to heat the shank with a hairdryer and then pry it off with a screwdriver.

- Remove and clean the magnet with impeller.

- Remove the magnet from the shaft and a bearing will appear.

- Apply pump grease to ensure proper bearing function. If it is deformed, install a new element.

- It is also necessary to inspect all rubber gaskets. If they are noticeably damaged, they will need to be replaced with new ones.

- Reassemble the pump in reverse order.

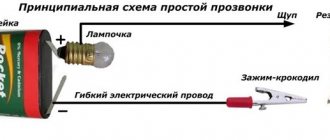

Next you need to ring the pump. Procedure:

- Take a multimeter and set the voltage measurement mode.

- Place the probes on the pump contacts.

- If the screen shows “1” or “0”, the unit is faulty and the pump needs to be replaced.

- If the value consists of several digits, this means that the pump is intact, but the fault is in something else, possibly in the control unit. For accurate diagnosis and subsequent repairs, it is recommended to contact professionals.

If the sump pump needs to be replaced, a new part will need to be purchased. This can be done in a service center, a specialized store or via the Internet. In order not to make a mistake when purchasing, you need to tell the seller the exact make and model of the washing machine or bring the faulty unit. The same should be done with other components that need to be replaced.

Preparing for work

You need to prepare to disassemble the Bosch washing machine. This is done so that in the process of performing basic work, you do not have to be distracted by searching for tools and other little things.

Actions that are performed at the preparatory stage:

- Clear the area where the equipment will be dismantled. It is inconvenient to do this in the bathroom. It is better to take the machine out into an open space with good lighting.

- Cover the floor with cardboard or thick film. This will protect the coating from debris and scratches.

- Prepare boxes for bolts. It is better to label each of them so as not to mix up the screws.

- Disconnect the device from all communications, remove the drain hose from the drain, and turn off the power to the device.

- Prepare a phone that is convenient for filming the disassembly process. Subsequently, the photographs taken will allow you to quickly and accurately assemble the washing machine.

- Prepare a container to drain any remaining water from the emergency hose. Rags to collect liquid will not be superfluous.

Minimum set of tools:

- a set of screwdrivers or a screwdriver with different attachments;

- hammer;

- pliers;

- socket and open-end wrenches;

- lubricant, for example, VD-40 - it will be needed if parts or bolts are rusty.

When all the tools are prepared, you can proceed to the main stage.

Scheme for removing and installing the drain pump

First of all, before starting work, you need to disconnect the washing unit from the network and turn off the water, then disconnect the water supply hose.

When starting repairs, you need to know exactly where the drainage device is attached. Depending on the brand and type of washing unit, the pump can be located in the front or rear of it, and access is provided:

- directly below;

- through special hatches at the bottom or in the front, rear and side walls;

- by removing the trim from the front, rear or side.

Recently, models from well-known manufacturers began to be equipped with circulation pumps, which ensure the circulation of liquid in the machine system during operation and improve the quality of washing. For example, in some models of the Korean manufacturer Samsung, the drain pump and circulation pump are made as a monoblock in a single housing, so they are changed together.

If the circulation pump is made separately, it is usually located next to the drain pump. To dismantle it, you need to remove the inlet and outlet pipes, unscrew the fastening screws and remove the device. On Electrolux units, circulation pumps are fixed on the bottom, on a special rubber base to reduce vibration and noise.

Replacement from the bottom of the unit

Companies such as Ariston, LG, Samsung, Whirpool, Ardo, Bosch quite often resort to this method of installing the pump so that replacing it does not require disassembling the washing unit. Access to the elements is provided due to the absence of a bottom cover. To replace you need:

1. After turning off the power and turning off the water, the machine must be placed on its side, preferably with something soft on it, so as not to scratch the body of the unit.

2. Then use a flat-head screwdriver to remove the plastic panel that is held in place by latches. Remove carefully as the latches may break!

3. If there is still a plastic tray at the bottom of the machine that covers the bottom of the unit, unscrew the screws and remove it.

4. Next, you need to unscrew the screws securing the snail to the machine body and thereby separate the snail from the body.

5. Then you need to disconnect the drain pipe and drain hose from the volute; usually they are tightened with clamps; they can be loosened using pliers. It is advisable to prepare a container in advance to drain the remaining water from the pipes and snail.

6. Now you can disconnect the power contacts from the pump.

7. Unscrew the screws securing the pump with the snail, then separate them from each other.

On some models, the drain pump can be attached to the volute without screws; to remove it, just turn it counterclockwise and freely pull out the pump.

Before installing the pump in its place, be sure to clean the volute from blockages, especially the connection with the pump for reliable tightness. Installation occurs in reverse order. After installation, check the connections of all pipes and the power contacts of the pump.

Replacing the drain pump on a Bosch washing machine

On some models of Samsung, Bosch, Siemens, access can be achieved through hatches or by removing special plastic or metal panels. Typically, hatches and panels are secured to the body using several self-tapping screws and special latches. To remove them, all you need is a flathead or Phillips screwdriver. Removing plastic or metal bottoms is also not particularly difficult, it’s just that the number of fasteners is greater than for a small hatch.

There are models of washing units, mostly premium class with a large load, in which shock absorbers, floats to protect against leaks and other elements can be attached to the bottom, which greatly complicates and delays repairs. In this case, it is advisable to get to the drain device through one of the side walls.

Replacing the drain pump for top-loading washing machines

Speaking about access through one of the walls, it should be noted that this is both a simple and rather complex process. For example, to get to the pump on some Zanussi top-loading models, it is enough to unscrew several screws securing the side cover; removing it, we get full access to the drainage device.

On top-loading washing machines, replacing the pump is carried out in the same way as with a front-loading one. The only difference is that with top loading you need to remove the side and other walls instead of the back.

In order to get to the drain part through the front wall, on Samsung units with front loading, you need to remove the top cover, control panel, rubber cuff and unscrew many fasteners. It is worth paying attention that without good skills and without knowing the location of the fastening parts, you can spend a lot of time just on the process of removing the cover, and there is also a high probability that the plastic latches from the cover may break.

When removing the front cover, you need to pay attention to the connection terminals of the cover lock lock, and if necessary, carefully disconnect them. The easiest way to access the pump is through the back wall, on many Electrolux and Ariston models. The back cover is replaced by unscrewing the side, top and bottom fasteners. Typically, the inlet valve is mounted directly to the rear wall of the unit, so it also needs to be unscrewed. To remove the walls and unscrew the fasteners of the washing machine, you may need special keys and socket heads.

Step-by-step instructions for troubleshooting yourself

To remove and repair a faulty part, first determine the location of the pump, which depends on the manufacturer and model of the equipment (you can view instructions for disassembling washing machines of different brands here).

Location of the pump inside the device

In washing machines from LG, Samsung, Ardo, Indesit, it is easiest to get to the pump, since the part is located at the bottom. To get to it, just lay the car on its side, covering the floor so as not to scratch the body, or simply tilt it.

Disassembly and cleaning

The instructions for repairing the pump of a washing machine with your own hands look like this:

- before removing the pump, the washing machine is disconnected from the electrical network;

- the water supply is shut off before disassembly;

- the machine is placed on its side so that the pump is at the top;

- remove the protective panel on the bottom (if any);

- Having unscrewed the screws on the bottom, remove the lower pan (if any) or unscrew the lower part of the front panel, gaining access to the pump with a filter attached with screws;

- remove the pump protective cover;

- then they feel the pipes, determining the presence of blockages, loosen the clamps, and pull them off the pump;

- unscrew the fasteners holding the pump;

- Disconnect the wiring and take the pump out.

If the pump is attached to the volute, it is disconnected from the pump by unscrewing the fasteners or turning it counterclockwise (depending on the model). At the same time, they determine how easily the impeller turns - it most often fails. A working impeller rotates irregularly due to the rotating magnet in the coil.

If the part rotates easily, without delays, or, conversely, movement is difficult and there is no debris inside, you will have to disassemble the pump. To do this, perform the following steps:

- disconnect the impeller by prying the housing latches;

- The crosspiece, which cannot be disassembled, is heated with a hairdryer at low temperature and pryed off with a screwdriver;

- remove the magnet with the impeller, the part, and clean the joint;

- the shaft is disconnected from the magnet, the bearing that appears is cleaned and lubricated;

- the bearing located at the bottom of the housing is also lubricated;

- worn gaskets, rubber seals are replaced with new ones;

- assemble the pump, make sure that the o-ring fits tightly into place;

- Don’t forget to inspect the oil seal and replace it if necessary.

We offer you to watch a video on how to check the pump of a washing machine:

Bearing replacement

The reason for the incorrect operation of the pump is not only the accumulation of debris and small objects.

Bearings often fail, causing friction between the volute and the impeller, which causes noise and knocking to be heard during shaft operation. In advanced cases, the pump may stop completely. The problem is eliminated by installing new elements, which are purchased at specialized points of sale and service centers that service household appliances (read about how to repair or replace bearings here). If it is impossible to postpone the wash and a new part is not at hand, emergency measures are taken: the impeller blades are shortened by 2 mm. Do this with a sharp knife, carefully so as not to cut off too much and reduce the performance of the pump. Then the body with the blades is returned to its place in the coil and secured with latches. All that remains is to check the functionality of the repaired part.

After installing the pump and connecting the machine to the network, it will launch diagnostics and display the results on an electronic display. If the repair is performed incorrectly, an error code will appear on the display. If the car model does not have an information display, the test is carried out with a multimeter by connecting the probes to the contacts. A three-digit number indicates a malfunction of the electronic control module, a two-digit number indicates a malfunction of the pump.

We offer you to watch a video on how to replace a bearing in an LG washing machine:

Do-it-yourself pump repair

If the drain pump in the washing machine fails due to burnout of the electrical winding, then in this case it is necessary to replace the part. In other cases, it is often possible to restore the device to full functionality, for which you should first clean the impeller and filter. To clean the impeller, you will need to disassemble the device housing. The two halves of the working cavity of this part are usually held together with 3 screws, so it is enough to unscrew the hardware holding the pump parts together to gain access to the impeller.

Disassembling the drainage device

The cause of deterioration in the performance of the drain mechanism, as well as complete jamming of the working shaft, may be threads, hair or long wool. It is necessary to carefully inspect the impeller and shaft and, if such contamination is detected, clean them using a thin screwdriver. The inside of the cochlea also needs to be wiped to remove soap deposits on its walls.

When the parts are cleaned, wash the two halves in water without immersing the engine. Then you need to assemble the housing, connect the pipes and electrical terminals to it and install it in its original place.

When the process of installing the cleaned pump is completed, turn the machine into rinsing mode and check the operation of the drain mechanism. If the device operates in normal mode, then no more

no measures are required; if it was not possible to repair the pump in this way, then it is necessary to replace the electric drain pump in the washing machine.

Disassembling the washing machine

To disassemble the device yourself, you will need a number of tools: Phillips screwdrivers 4-6 mm, slotted 4-10 mm, wrenches 8/9 and 18/19, pliers. Disassembly begins with removing the protective side casing. To do this, you need to unscrew the screws around the perimeter and pull out the side cover towards you. After removing the left side panel, access to the main units of the unit opens. Having gained access to the elements of the device, you can carry out maintenance, check components or replace failed parts.

Before removing the heating element, it can be checked on site. To do this, after releasing it from the terminals, the resistance is measured using a tester; it should be about 20-50 Ohms. To replace it, you need to unscrew the nut on the tightening bolt, then press on the bolt, pushing it inward

Carefully prying the outer part of the heating element around the perimeter with a flat screwdriver, remove it from the tank. It is impossible to repair the heater if the spiral breaks, so it will need to be replaced

If you need to repair the motor, you will need to remove it. Before removing the engine, the drive belt is removed, the terminal block is disconnected, then the screws are unscrewed and the engine is removed from the skids. The brushes in the engine mechanism need to be checked. They are usually located outside the housing and pressed tightly against the collector. When they wear out, the motor power is lost, and the automatic machine begins to malfunction. This is especially evident during spinning.

One of the most common failures of a washing machine pump is the failure of the impeller. Before you begin to remove the pump, you can open the drain filter located on the front of the machine and clear the compartment of debris, then rotate the impeller by hand. If you decide to remove the pump, you will have to unscrew the plastic part connecting the pump, drain pipe and drain hose. To do this, unscrew the mounting screws.

The most time-consuming operation is removing the tank. You will need to remove the top cover. To do this, you will first have to free the electronics unit. It is usually screwed on with screws and held in place with clips around the perimeter. Then we disconnect the dispenser hopper by lifting it up and, loosening the clamp with pliers, pull out the pipe. Remove the upper counterweight and other parts of the machine.

In practice, to remove the drum you will need to disassemble the entire machine. The weak part in the tank is the bearing. To get to it, you need to install the tank with the oil seal facing up and knock out the bearing using a chisel and hammer. Modern models are produced with a cast bearing, i.e. it cannot be replaced separately from the tank.

For example, one of the first machines that went on sale, the Bosch WFC 1600 WMV 3800A / Maxx 4, has removable bearings; replacing them is possible, but very labor-intensive.

Electronic unit repair

Such repairs must be carried out with special knowledge. If you suspect an electronic unit, you can remove the board from the plastic container, having first disconnected all connectors, and carefully inspect the soldering areas. Often, due to the vibration of the machine, they are destroyed. Also, if washing powders are ingested or in the event of a leak, plaque may appear on the PCB board. In this case, it is recommended to wash the board with an alcohol solution.

One of the important parts of machine control is the programmer. Another name for it is the command apparatus. This part is responsible for selecting modes. It can be mechanical or electronic. In the case of electronic type, a microprocessor is used. The mechanical programmer also tends to fail

When disassembling it, you must be careful, as there are springs inside. The programmer consists of a set of gears and a synchromotor

In principle, the command apparatus is quite complex, and without experience you should not disassemble it

Particular attention should be paid to the contact group; it often oxidizes, which leads to malfunctions

Causes of pump failure

- The pump broke down due to a malfunction of the engine, as a result of which there is no voltage to the pump.

- The seal (rubber or plastic) is damaged by scale and dirt that settles on the impeller.

- Incorrect connection of the pump or failure of the water level sensor causes the pump to constantly operate.

- The pump will not be able to drain water due to a clogged filter.

- Small foreign objects destroy the impeller. It's easy to diagnose. When the pump starts, the machine makes a hooting sound.

Symptoms of a problem

A malfunction of the Bosch heating element is indicated by the lack of water heating. This can be determined by the display of code F19 on the display.

But in some cases, the work cycle may not even stop. At the same time, you can determine that heating has not started by the fact that the glass of the Bosch hatch remains cold at all stages of laundry processing, including during washing.

Also, at this time, the electricity meter does not work intensively, and the laundry after such a wash is washed worse than usual.

If a problem with the heating element occurs for the first time, you can try to reboot the washing machine. To do this, the device is turned off for 20-30 minutes, after which it is turned on again.

If the cause of the failure was an accidental coincidence, the heating problem will not recur. Otherwise, it will be necessary to conduct a thorough diagnosis of the node.

How to change?

Replacing the rubber seal on the hatch door of a Bosch washing machine consists of three main stages: dismantling the old cuff, installing a new seal, and reassembling the washing machine.

How to remove?

To quickly get to the desired element - a worn cuff, you need to carry out a series of sequential actions:

- Using a Phillips screwdriver, unscrew the fasteners holding the top panel of the washing machine.

- Gently pushing forward, remove the cover from the washer body.

- Remove the detergent dispenser. To do this, you need to press a special latch inside the tray, after which the powder receptacle is very easily pulled out of the grooves.

- In the opened niche of the detergent dispenser, unscrew the fasteners holding the control panel. Carefully, trying not to damage the wiring contacts, remove the panel from the washing machine body.

- Using a flathead screwdriver, press out the latches holding the decorative panel located at the bottom of the washing machine.

- Open the hatch door of the washing machine. Feeling the edge of the rubber seal with your fingers, find the retaining clamp (thin metal ring).

- Using a flat-head screwdriver, carefully pry the clamp off the cuff.

- Place the rubber seal into the washing machine drum.

- Unscrew the fasteners holding the hatch lock device (located on the right side of the loading hatch), disconnect the UBL wiring.

- Unscrew the fasteners around the perimeter of the front panel and remove it from the washing machine body.

- Using a flat screwdriver, carefully pry off the second clamp (metal ring) together with the rubber seal.

On the cuff, in the upper part, the manufacturer provides a special mark, which must coincide with the mark on the tank.

If there are no additional marks, before dismantling the old cuff, the point of contact of the tank with the rubber seal must be marked with a marker. This will help avoid mistakes when installing a new cuff.

Installation of a new part

Installing a new rubber hatch door seal yourself will not be difficult, provided you follow a clear sequence of actions:

- carefully inspect the new part, turn the rubber with the drain holes down;

- lubricate the grooves of the cuff and the seat with a soap solution (sliding simplifies the process of tightening the rubber seal);

- placing the cuff in a special recess located along the edge, evenly stretch the rubber seal to the right and left sides, pulling it onto the seat;

- secure the new cuff with a metal clamp.

It is necessary to ensure that the drain holes are located clearly in the center, otherwise problems with draining water may occur.

Reassembly

The process of reassembling a Bosch washing machine occurs in the following order:

- The UBL contacts are connected.

- The front panel is attached to its original place.

- The hatch locking device is secured with fasteners.

- The rubber cuff is fixed with a metal clamp.

- The lower decorative panel returns to its original place.

- The control panel is attached, the lid is mounted, and the detergent dispenser is inserted.

The reassembly process is completed, the washing machine is connected to the communications, after which a test wash is started.

How to change cuffs - in the video:

Don't forget to take care of your machine

Cleaning the pump can be avoided if you properly care for the equipment. The bulk of the garbage ends up in the washing machine due to the fault of the “owner”, so it is better to reconsider your attitude towards washing. So, the following recommendations will help avoid blockages:

- use detergents marked “for vending machines”;

- remove strong stains on hands;

- wash clothes with decor in special bags;

- organize an incoming filtration system;

- Clean the dust filter regularly.

If you have dogs and cats at home, it is recommended to clean your washing machine every month. In other cases, cleaning once every six months is sufficient.

We remove what we usually use to manage

Now things are back to normal again. At the third stage, we dismantle the control panel - the part where all the buttons, indicators and display are located

It is important to be careful not to yank the control panel too much from side to side: we don’t want to just disassemble the washing machine and forget about it

Our goal is to return the assistant of German origin to her ability to work. But before removing the control panel, you need to remove the detergent tray - in Bosch washing machines, the screw holding the panel is hidden behind it. Only after all the screws have been removed can you try to lift the control panel with a slight movement.

Again, everything must be done carefully so as not to damage the wires and contacts. If the panel gives way, then it is enough to hang it on a special hook built into the side of the washing machine for such cases and forget about it until assembly

In general, you can also disconnect the control panel from all communications, but this is usually only required if the fault affects the control panel itself. There are plenty of detailed instructions on how to disable the control panel on the Internet.

Operating rules

In order to operate the washing machine for as long as possible without repairing (replacing) the drain pump, you must follow certain rules:

- When connecting yourself, carefully ensure that the end of the drain hose is located at least 50 cm from the floor.

- Heavily soiled clothes (especially those with traces of soil) are soaked for some time in a warm soapy solution before loading into the drum.

- Before each wash, carefully inspect and clean the pockets of small debris and small objects.

- To prevent scale build-up on the inner walls of the drain pipes, add a special agent that softens hard tap water along with the washing powder.

Compliance with basic operating rules guarantees up to ten years of uninterrupted operation of the drain pump.

Maintenance and operation

To prevent the pump from breaking down or to prevent the situation from reoccurring with a pump that has already been replaced, you must adhere to the following recommendations:

- Operate the machine according to the user manual.

- Before loading dirty items into the drum, check the contents of the pockets. They most often contain debris that leads to pump failure.

- Fasten buttons and zippers on clothes before washing.

- Clean the drain filter and its seat at least once every 3 months.

- Don't delay repairs. If unusual sounds and noises appear, you need to disassemble the housing and evaluate the condition of the pump.

The pumps installed on Bosch washing machines are of high quality, so with proper and timely maintenance they will work for at least 10 years .

How to repair it yourself

When repairing a washing machine pump, you need to perform a series of steps sequentially. To avoid common mistakes and not to provoke additional malfunctions, you need to follow the instructions.

Dismantling

To repair the washing machine pump, you need to dismantle the element. The process of removing the pump depends on the type of equipment.

The simplest options

The easiest way to remove the pump is in top-loading machines from manufacturers Electrolux, LG and Zanussi. Dismantling is carried out using a set of screwdrivers and pliers, following the following sequence of actions:

- Disconnect the washing machine from the power supply, disconnect all communications and drain the water from them.

- Move the washer away from the wall and unscrew the screws located on the edges of the rear panel.

- Slide the panel and remove the side panel held in place by screws.

- Unclench the drain pipe clamp. In some models, it may be held in place by a screw that will need to be removed.

- Disconnect the pipe and wiring connectors.

- Unscrew the fastening elements of the pump and remove it from the housing.

Complex models

In complex washing machine models, the dismantling procedure is different. To disassemble the machine and gain access to the pump, you need to lay the equipment on its side, first placing a soft cloth that will prevent damage to the case. Then unscrew the screws on the bottom and remove the bottom panel. This method is relevant for equipment manufactured under the brands Samsung, Beko, Whirlpool, Candy, Ariston.

Having reached the drain pipe, it is carefully probed to detect blockages. Then the clamp is loosened and removed from the pump. Next, all that remains is to remove the fasteners holding the pump, unscrew the wiring and pull out the part.

The most complex models

In some models from Bosch, Siemens and AEG, the dismantling process is the most complicated compared to other types of equipment. Pump removal is required to remove the front of the equipment.

To do this, do the following:

- Unscrew the mounting screws from the back of the machine and slide the top cover forward.

- Pull out the detergent compartment by holding your finger on the latch and pulling it towards you. The latch is located in the central part of the powder compartment.

- Remove the screws holding the control panel and use a screwdriver to unfasten the latches around the entire perimeter.

- Remove the plinth panel located at the bottom, under the loading hatch.

- Bend over the sealing material next to the hatch door, pry up the clamp and pull it off.

- The cuff is tucked inside the drum, pulled to the location of the hatch lock and the wiring is disconnected.

- Unscrew the screws holding the front wall at the edges, after which access to the pump will be open.

Disassembly

After removing the pump, you need to disassemble it to determine the malfunction. First, disconnect the pump from the element called the volute by unscrewing the mounting screws. In some models, to unscrew the pump, simply turn it to the side counterclockwise to disconnect.

The next step is to check the condition of the impeller. To inspect it, you do not need to disassemble the entire structure - by pulling out the drain filter, you will be able to visually understand whether it is broken. If you need to find out whether the impeller rotates or is firmly fixed in place, you will not be able to do without complete disassembly. In operation, the impeller should not rotate easily - it rotates with slight delays due to the magnet rotating in the coil. If rotation is difficult and there is no visual interference in the form of accumulated debris, you should disassemble the entire pump to determine the exact breakdown.

Preparing equipment for repair

Replacing the pump yourself is not very difficult. The work will take about an hour. Before you begin the repair, you need to prepare the equipment and figure out where the drain pump is located in Bosch washing machines.

Be sure to follow safety rules - before work, turn off the power to the washing equipment, disconnect the device from the house communications.

For most Bosch washing machines, the elements of the drainage system are located in the lower part of the body, covered with a protective panel or a special hatch. To release the latches, it is recommended to use a slotted screwdriver. Carefully prying the panel with a tool, you need to remove it.

When the false panel is removed (or the hatch is opened), you will see the location of the garbage filter. This is a plastic structure that protects the drain pump impeller from debris and foreign objects. You will have to unscrew the filter element and wash it in warm water.

Once the filter is removed, the pump impeller can be accessed through the hole. You should inspect it and scroll it with a long stick. The blades should rotate with slight jerks, but freely. If the movement of the element is difficult, there may be hair wrapped around it or other debris stuck to it. To clean the part, you will have to remove the drain pump from the machine.

The next step is to lay the washer on its side. Before putting the machine down, it is necessary to lay a blanket or carpet on the floor to prevent damage to the body. Next, the machine carefully and smoothly lowers. Some models are equipped with a tray that must be removed and put aside. Looking under the base of the Bosch washing machine, you can see the pump and the snail.

Before you start replacing the drain pump, it is recommended to check the element with a multimeter. The probes of the device should be connected to the pump terminals and the alternating voltage should be set on the tester to 700 V. Next, the automatic machine must be plugged into a power outlet and the “Drain” program must be started. After a while, you need to see what value is displayed on the multimeter screen. If the display shows 220 Volts, but the pump does not drain, you can start replacing the part.

If the water drainage program works, but voltage does not reach the element, it is highly likely that the control module is broken. You should not get into the electronics of the washing machine with your own hands without sufficient experience and knowledge. It is better to resort to the help of a specialist.

Signs of a broken heating element in a washing machine

Regardless of what Bosch model you have - Bosch Maxx 5, Bosch Maxx 4, Bosch Classixx 5 or any other, the symptom of a heater malfunction is the same - cold water.

To verify the problem, 20 minutes after the start of the cycle, touch the glass hatch with your palm. You will feel whether the glass is warm or not. Cold will indicate a heating problem.

Cold washing is not able to provide high-quality washing of clothes. Dirt is not removed 100% and a musty smell appears. If the self-diagnosis system alerts you to a problem by showing code F19, prepare for the fact that you may need to replace the heating element in your Bosch washing machine.

What is this part and why is it needed?

A pump is a water pump. It is installed on all Bosch washing machines. The main purpose of the pump is to pump water from the tank into the sewer pipe. This small detail never goes unused. The pump will be activated during every wash cycle, rinse or other operation .

The Bosch washing machine has a circulation pump. It is used in conjunction with a classic pump. Water enters the tank and circulates throughout the system, which improves the quality of washing.