What is damper grease? These are organosilicon liquid polymers of one or two-component compounds with high-quality bonds of silicon atoms in glycerin or silicone. Depending on the number of components, a liquid with a wide range of properties is obtained: for example, viscosity, which is measured in centistokes (drops through a calibrated hole at 50C, or measured by special hydrometers). The viscosity of the lubricant is slightly more than water and is designated 160 units. And in 250,000 units. Already, approximately, like solid oil.

Damper grease, or oil as it is also called, is a colorless liquid that works down to a temperature of -50 C. To work with a wider temperature range, ingredients from special additives are added, for example, gas soot to change the performance of the lubricant to -70 C. Aluminum oxides allow you to increase the range to +450 C. This type of silicone damper grease is used in plain or rolling bearings.

[content-egg-block template=offers_list next=2 title “Our offers”]

What are shock absorbers and dampers?

Dampers are used in more modern washing machines.

They differ from shock absorbers in that they consist only of a spring. The shock absorber has a more complex design. Shock absorber device:

- Cylinder.

- Return spring.

- Piston with rods.

- Gaskets.

This type of shock absorber is called spring-piston, and is a cylindrical metal device containing a bushing. The rod moves in it during operation. On its upper part there is a special fit for rubber inserts, with the help of the latter it is connected to the drum.

A piston with a gasket is fixed at the base of the rod. It is impregnated with a special lubricant, which does not dry out for a long time and increases the friction force during movement. The work of the shock absorber is as follows:

- With sharp jumps, linear movement of the rod occurs.

- The piston, pushed by the rod, moves inside the cylinder.

- Lubrication creates the necessary conditions for movement so that it does not slip idle.

- When weakening occurs, the rod returns to its original position.

And everything repeats itself again.

The dampers have the same cylindrical design, only there is only a piston inside the cylinder, and there are holes in the walls for air to escape. The piston is equipped with a gasket that replaces the lubricant in the shock absorbers.

Dampers are divided into two types:

- Collapsible. They replace the compressed liner.

- Non-separable. The damper must be completely replaced.

The load that both of these devices can withstand varies from 100 to 150 newtons.

Application

One of the main features of organosilicon lubricants is that it almost does not change its viscosity at temperatures from +100 to -30 C, which led to its use specifically in damper devices. Oil is used to fill the hydraulic systems of aircraft, trucks and cars, and clutch braking mechanisms.

Good water repellency with high adhesiveness forms a thin film on the product that is not wetted by water, does not decompose rubber and can serve as a lubricating preservative for rubber parts of a car. Electricians often use it to protect wires by lubricating the surface of the insulation, especially rubber, to prevent it from cracking.

Organosilicon oils are also used as a lubricant for engines operating in frosty conditions and in devices used at weather stations. Damper grease is also used for micro-lifting of vinyl disc players or moving parts that work with an aqueous environment, for example, toilets or other hygienic devices.

Car enthusiasts actively use grease to lubricate brake pad drive calipers, steering columns, and other plastic products that make unpleasant noise when touching each other.

You can buy damper lubricant for microlifts in any technical department that sells spare parts for office equipment or auto parts. You can also type the product name in the search bar of any browser. Beware of fakes.

You can get acquainted with the use of oil by watching the video below.

Reviews:

Alex: I drive a Toyota Land Cruiser Prado. I change the pads myself. There were cases where the caliper jammed due to lubrication, I switched to damper, it became smoother and the caliper never jammed. Highly recommend.

Option 1: disassemble the case

- Unplug the machine and turn off the water supply.

- Open the laundry hatch. Remove the clamp - a ring with a screw or spring that tightly secures the rubber seal:

- on screw ones - loosen the screw;

- on spring ones - pry the spring with a screwdriver and pull it towards you.

- Bend the edges of the cuff seal and pull it out. Behind the cuff in the right center there is a block from the machine door lock wires - this also needs to be disconnected.

- Open the drain filter plug at the bottom of the machine. Disconnect the drain hose. Unscrew the screw that holds the casing and remove the casing. Then remove the screw that secures the front panel.

- Let's move on to the back of the machine. Unscrew the two top screws that hold the washer cover in place. Remove the cover - pull it towards you, lifting it up a little.

- Pull out the powder tray. There are two more screws under it - unscrew them.

- Remove any existing screws behind the control module panel.

- Carefully lift the control panel up. You will know that you have removed it when you hear the characteristic click of the latches. Once you have the panel in your hands, place it on top of the machine without removing the wire.

- Remove the screws holding the front panel. Slide the panel itself up and pull it out.

- Access to shock absorbers is open! Take pliers and remove the fasteners - the plastic “fingers” on the top and bottom of the part. Remove the parts from the supports.

- Install new parts.

- Reassemble the machine in reverse order.

If you can’t easily get to the necessary details, move on to option 2.

More nuances of disassembling washing machines are in a separate article, here.

Universal instructions for disassembling washing machines: 23 videos for all brands

Replacing shock absorbers with removing the tank

The second option requires almost complete disassembly of the entire washing machine. To do this, it is necessary to remove all protective covers and the upper part of the housing, and then remove the powder tray. If there is a top part of the control panel, you need to remove it too. After this, you need to remove the springs and disconnect all the terminals from the tank. After this, you need to remove the tank and replace it according to the repair manual for the specific washing machine.

READ MORE: Rating of the best mini ovens, electric ovens with the 2022 convention

It is worth noting that such repairs require quite a lot of physical strength and good skills in handling equipment. If this is your first time repairing a washing machine, then it is best to refrain from this endeavor and carry out easier repairs in the future. In a situation where the tank is removed, you need to contact a specialist or even buy a new car, because... such repairs can cost up to 80% of its cost.

Is it possible to make damper grease at home?

In principle, you can make everything at home. Even high molecular weight lubricant. A simple analogue of damper lubricant made at home is a solution of synthetic resin in oils, for example, industrial oil. It’s even easier to dissolve rosin in oil to the desired consistency. True, such a solution only works at positive temperatures and not higher than +50 C, since after this the resin begins to decompose and can become coked, which to a certain extent will only cause harm. Therefore, it is recommended to use a mixture prepared at home in cases where there is an urgent need or some kind of knocking is very annoying, followed by replacing it with normal lubricant. Damper grease can be purchased on the Internet or at manufacturer dealerships.

Replacing shock absorbers without removing the tank

In the first option, shock absorbers can be replaced without removing the tank. To do this, you need to disconnect the machine from the power supply and water supply system. After this, you need to put the device “on its butt,” remove the front part of the body (if possible) and, using aerosol lubricant, screwdrivers and wrenches, remove the old shock absorbers.

After you have removed the old components, you should contact either an official spare parts dealer or a specialized store. Ideally, write down the complete model and serial number of the machine, take the removed parts with you, and speak with the seller in person, who can select the necessary replacement parts.

The final phase is to assemble the machine, connect it to water and electricity, and then proceed to test its functionality. Moreover, it is important not only to check the machine with an empty tank, but also to carry out an additional wash cycle with the tank loaded to find out how well the shock absorbers cope with their task.

High temperature lubricant Litqui Moly 50 Litho HT 3400

The lubricant is intended for loaded bearings and assemblies. Operating range – -30С- +160С, briefly allowed up to +250С. It is used in components of cars, trucks, agricultural machinery, and tractors.

The grease is ideal for the initial filling of bearing races when changing them and for regular repressing. It is used to lubricate parts that operate under load and are heated. In cars, such parts include wheel bearings, suspension joints, and spring supports.

Well suited as a universal lubricant. Does not change its viscosity when heated, is not subject to melting and leakage from nodes, good adhesion. Supplied in tubes of 200 and 500g. containers of 5 kg. Parameters of the packaged goods in the container: Weight, 5.71 kg; Length – 202 mm; Height 25mm.

The results of the heating test and its lubricating properties of the grease can be viewed in the video below.

| Attention Bearing Buyers Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: Delivery of bearings throughout the Russian Federation and abroad. Bearing catalog on the website |

Attention Bearing Buyers

Dear customers, send your questions and requests for the purchase of bearings and components by email or call now: +7 [email protected] Delivery of bearings in the Russian Federation and abroad. Bearing catalog on the website

themechanic.ru

Replacing suspension springs

Another shock-absorbing element is steel springs, with the help of which the drum is suspended inside the housing. They are located in the upper part of the machine body. These are quite reliable elements, the replacement of which is required extremely rarely. Sometimes the spring hooks pop out of the eye holes due to vibration; to easily install them in place, just lift the drum.

Not only the quiet operation of the washing machine, but also protection from vibration loads of other elements depends on the reliable operation of the dampers. If shock absorbers break down, it is best to replace them in a service center with a warranty.

How to repair washing machine shock absorbers

New vibration dampers for modern cars cost from 500 to 3,000 rubles per pair, depending on the model. Although this amount is not critical, in some cases it is possible to restore the old shock absorber. Owners of washing machines simply remove the remaining sealing elements from the body. Using the selection method, homemade parts from cut rubber pipes, leather belts or pieces of linoleum are installed in their place.

The main thing with such a restoration is to achieve a high-quality seal of the connection of the rod in the body. The cut parts are fixed in the body; for smoother operation, the connection is lubricated with technical or other grease. This type of repair can hardly be called reliable. In the best case, such a damper will last several dozen washing cycles, and malfunctioning or jamming will lead to breakage of other parts.

With modern repairs, the faulty damper element assembly is replaced with a new one, and both shock absorbers must be replaced, even if one of them is in perfect condition!

How to repair a broken shock absorber

We warn you: self-repair, lubrication, or installation of a repair kit will only help for a while. It is safer to replace the shock absorbers for your washing machine with new ones than to try to restore them.

Let's assume you have already disassembled the machine and removed the necessary parts. Let's make a new gasket instead of the old one:

- Take a flat-head screwdriver. Press the plastic ring onto the part.

- Now you have access to the rubber gasket in the lubricant. Get it out.

- Clean the entire shock absorber thoroughly.

- Take a leather belt and cut 2 strips from it. The length and width of the strips are based on the gasket. The thickness of the strips should be 3.5 mm. The length should be “overlapping” so that the strips form a “ring” inside the part.

- Check the density. The rod - the metal sleeve - should move with noticeable force.

- Put a little thick lubricant inside so that the spare part does not rust and the movement is not “dry”.

- Reinstall both parts. Assemble the machine.

READ MORE: Top 10 best top-loading washing machines - 2022 ranking

How to check when purchasing and replace a shock absorber?

When buying a new part, as well as when dismantling an old one, you need to compress the damper several times. If the compression is tight, then everything is in order. If it is easy, this indicates wear of the seals.

Important! Two elements are changed at once, regardless of the degree of wear.

Now you know how to restore and repair shock absorbers in a washing machine. If you don’t want to bother with repairs, then buy a new set of spare parts and install them in the washing machine.

What damage could have happened?

What caused the problem:

- Wear of gaskets due to frequent use.

- Defective parts, improper transportation of the machine.

- The rod that secures the shock absorber is faulty.

Whatever breakdown occurs, it is important to know how to restore the shock absorber in a washing machine with your own hands. Read about it below.

How to remove and check shock absorbers from a washing machine

All damping elements are protected by the body and lining; in order to get to the damper mounts for different models of washing machines, different disassembly approaches are required.

When replacing dampers on a washing machine, there is no need to completely disassemble it. For example, to provide access to shock absorbers on Bosch washing machines, simply remove the front cover. In these models, the dampers have a classic single-bolt mount, located at the bottom of the unit. The upper part of the attachment to the tank is held on by latches that are part of it.

In order to remove the shock absorber from the tank, the connection is drilled with a long drill with a diameter of 13 mm, then you need to remove the part through the front of the machine.

On some LG models, you do not need to remove any covers to remove the damper. To do this, just put the unit on its side, having previously disconnected it from the power supply, water supply and sewerage. The shock absorber is secured on both sides with plastic pins with locking latches. By pressing the latch, you can easily remove your finger from the hole, freeing it from the fastening. If the finger is very difficult to remove, you can use a special tool such as a car VD shk.

In Samsung washing machines, bolts of size M8 or M10 are most often used to secure dampers. They are unscrewed using spanners or socket heads, 12-13 mm in size. Bolt-on mounting is used on models from Miele, AEG and many other manufacturers. In Wirhpool models, the shock absorbers on both sides are fastened with special latches; by pressing them, you can freely remove the damping elements.

Regardless of the method of fastening, removal must be done carefully, without using an impact tool that could damage the plastic tank or other elements of the device. Checking the damper is carried out by simply pressing the rod and pulling it out of the body. In this case, there should be noticeable resistance to pressing by hand.

If the rod extends freely and there is no lubrication, and traces of rust are visible inside, we can talk about wear and tear and unsuitability of the shock-absorbing devices.

Damper and shock absorber - what is it?

You've probably noticed that at high speeds the washing machine starts to hum a lot and sometimes jump. It is to dampen these vibrations, the beating of the tank against the body, that shock-absorbing devices are installed. There are no particular differences between their types. The design is only slightly different.

Earlier models of washing machines used shock absorbers. These devices consist of a cylindrical body. Inside it is a piston, the movement of which is ensured by a return spring. The device also includes gaskets to reduce friction.

A modern washing machine damper is also located under the tub. Its only difference is the absence of springs in the body. Now they are brought upstairs and the tank is hung on them. Thanks to this difference, parts break much less often, because the springs can now be replaced separately.

Restoring a shock absorber for a washing machine with your own hands is a doable job. To do this, you need to understand the principle of operation of the devices.

The operation of the product is based on the resistance that the gasket creates during friction. Over time, this seal wears out, which leads to the need for replacement. Main signs of failure:

- Strong vibration during spin cycle.

- The machine cannot stand still and moves around the room.

- The tank hits the walls of the hull hard.

It is unacceptable to operate the washing machine in this condition. This will lead to rapid wear of other components. Then expensive repairs cannot be avoided.

How to check if dampers are working properly?

It is not necessary to disassemble the equipment for diagnostics. Do this:

- Disconnect the SMA from the network.

- Unscrew the bolts securing the top cover. They are at the back.

- Remove the lid and press the tank down with your hands.

- Lower it and watch the movements. If it was difficult to lower the tank and it immediately jumped up and stopped, the parts are in good working order. If you easily lowered the tank, and then it quickly jumped up and began to swing, the shock absorbers need to be replaced or repaired.

To finally verify the breakdown and carry out work, you need to get to the parts. Therefore, how to remove and restore shock absorbers will depend on the brand and model of the SM.

DIY damper repair

In some models, it is enough to turn the washer on its side to gain access to the springs. How to do it correctly:

- After unplugging the machine, disconnect the inlet hose.

- Open the small door under the loading hatch.

- Place the container. Unscrew the filter plug counterclockwise.

- Wait for the water to drain.

Now you can turn the case on its side. If there is a bottom underneath, then unscrew the fasteners and remove it.

It’s more difficult if you have to dismantle the front wall to check:

- Remove the top cover.

- Remove the detergent drawer.

- Unscrew the screws around the perimeter of the control panel. Remove it and leave it hanging on the wires.

- Open the loading door.

- Pull the cuff, remove the clamp using a screwdriver.

- Thread the sealant into the drum.

- Unscrew the screws of the front wall and remove it from its place. Remove the UBL wires.

How to change and repair dampers?

The parts are located under the tank. Remove the spring fastening to the SMA body, and also unfasten the latch on top. Sometimes the elements are tightly fixed to the tank, so you have to drill out the plugs using a drill.

Home craftsmen offer a solution to the problem with gaskets. A leather belt is used for this.

- Remove the rod from the body.

- Take the belt. Its thickness should not exceed 3 mm.

- Estimate by eye how much material you will need to replace the seal. Measure and cut the desired piece of belt.

Quality of components

We should also talk about the quality of components that will be used to repair the washing machine. Unfortunately, most manufacturers supply original spare parts at a very high price, which significantly increases the cost of repairs. Most craftsmen use low-quality fakes, passing them off as original products, thereby earning more money from their services.

We strongly do not recommend installing such shock absorbers, because... they can quickly fail and damage the bearing block, which in turn will result in even more expensive repairs. If a master wants to install Russian or Chinese shock absorbers, you need to study reviews about them on the Internet and install them at your own peril and risk. High-quality repairs can only be achieved using original components.

Properties of organosilicon liquids:

- low freezing point and preservation of its properties over a wide temperature range;

- chemical inertness to metals, rubber, plastics, many organic compounds, even when heated to 150C;

- high dielectric properties;

- good compressibility, 1L cylinder can be compressed by 14%;

- low flammability;

- resistance to dilute acids and alkalis (reacts only in concentrated solutions);

- not allergic.

Causes and symptoms of malfunction

Malfunctions in the operation of washing machine dampers occur for the following reasons:

- Wear of mating elements (o-rings);

- Long-term loads and vibrations;

- Drying of the lubricant inside the cylinder and violation of operating rules. Branded shock absorbers in Samsung, LG, Siemens, AEG, or Ariston washing machines usually last 5-7 years without any visible disturbances in their operation.

With constant overload of the washing drum, especially in spin modes, the service life of the damping elements decreases. You can determine that the shock absorber is faulty based on several signs:

- strong vibration of the washing machine body, especially at high speeds; characteristic knocking sound when washing;

- The engine drive belt constantly weakens and falls off;

READ MORE: Apple tablet > buy an iPad tablet - prices from Russian online stores - in Moscow, St. Petersburg

Due to the beating of the drum, its sealed connection with the rubber cuff is broken (for washing machines with horizontal loading) leading to water leaks.

There are several ways to check dampers for working condition:

- Remove the top cover of the washing machine. After removing the cover, press firmly on the washing tank, it should smoothly return to its place, but if the tank returns jerkily, this means that the devices are not working properly and require replacement.

- The second, more reliable way to check is to completely remove the shock absorbers from their seats.

Testing and diagnostics

How to independently check the proper operation of shock absorbers? First, pay attention to the characteristic signs of breakdown:

- If the part is poorly lubricated, the drum begins to rotate slowly.

- Producing high speeds, the washing machine makes a lot of noise, knocks, and vibrates.

Secondly, diagnose the shock absorbers for the washing machine. How to do it yourself:

- It is necessary to remove the top cover of the CM. Unplug it, then unscrew the two screws that hold the cover in place at the back. Push it in the direction opposite to you and remove it from the body.

- With a little force, press the tank with your hands so that it drops down. Now let go quickly.

- Observe the movements of the tank. If it jumps up and doesn't move anymore, the dampers are fine. If it starts to swing in different directions, you will have to repair the shock absorber or damper of the washing machine yourself.

Symptoms of failure

The most common symptom of shock absorber failure is vibration, which cannot be eliminated by leveling the machine. The longer it works in this state, the stronger the vibration becomes and the machine can even “dance” around the bathroom or laundry room. In this case, it is necessary to carry out repairs - replace the worn shock absorbers.

Some mechanics prefer to replace a worn damper seal or replace only one shock absorber. But we recommend changing the pair immediately, because... this will cause significantly fewer problems in future operation. If you replace only 1 shock absorber, the second one will fail faster and another repair will be required, which takes extra time and leads to additional expenses.

Replacing shock absorbers is a rather serious procedure that should be entrusted to specialists, because... Cars from different manufacturers are disassembled differently, have different mounts and brands of shock absorbers. Also, you cannot “randomly” change them for similar models of the same brand - shock absorbers are selected according to the permissible loading weight of the tank.

If you nevertheless decide to replace the tank yourself, then you need to collect a rather impressive list of tools: a set of screwdrivers and wrenches, a bolt organizer, aerosol lubricant.

Replacing a part if there is a malfunction

To repair the shock absorber yourself, it is recommended to remove the insert. See how the rod moves without the insert. If it moves easily, then the gasket is worn out. This is what needs to be replaced.

- From a belt three millimeters thick, cut a piece to the diameter of the device.

- Install it instead of the gasket.

- Lubricate to improve friction before installing the rod. It is recommended to use regular lubricating oil.

- Insert the rod back.

When a shock absorber has mechanical damage from wear or defects, it is better to replace it with a new one. Read and remember the brand and model of the damper and tell your dealer. Do not buy parts at random, they may not fit the machine.

It is best to go to the store with an old shock absorber. This method is more reliable. The seller will see the part and select the one he needs in return.

Important! Prices for shock absorbers are low, so it will be cheaper to replace the part yourself.

Damper lubricant PMS-60

A lubricant with a viscosity of 60,000 units is intended for use in mechanical components to smooth out sharp impacts, more precise operation of the mechanism, reduce friction and reduce wear of parts. It is used for both metal products and plastic, rubber products, applied to wires to prevent their insulation from cracking.

It is supplied to retail outlets in 2 ml bottles. or in tubes with a capacity of 5-10 mm. Where to buy damper grease can be answered simply - it is sold in any auto parts store or online resource dealership centers.

Washing machines from the gorenje brand

Instead of repairing an outdated washing machine that will inevitably break down in the future, you should consider buying a new machine from the famous Slovenian brand Gorenje. Devices from Gorenje compare favorably with other brands by their low consumption of water and electricity.

Such machines are low noise and have an increased level of reliability. The new machine will not only work for a long time, but will also improve the quality of washing due to the presence of a modern electronic control module that carefully controls all processes. Our catalog offers models in various stylistic solutions that will satisfy even the most demanding customers.

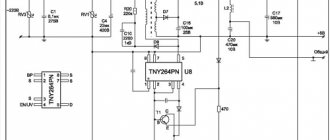

The device of shock absorbers and dampers of the washing machine

The friction shock absorber (1) is designed for centrifugal drum washing machines. The shock absorber contains a housing (2) and a movable pusher (4) installed in it parallel to its longitudinal axis (2a) and removed from the housing (2); at its end, located in the housing (2), a friction lining is movably installed.

The friction lining (8) or the body carrying the friction lining (8) is equipped with an installation socket (22) for receiving a spacer (23). The friction lining (8) is movably mounted on the pusher (4), the guide element (20) is pre-tensioned between the friction lining (8) and the guide surface or sliding surface (21) matched with it, and a spacer (23) is provided. to establish a frictionally effective geometric parameter (24) and/or to tension the friction lining (8) to influence the frictional force between the friction lining and the matched sliding surface. The spacer (23) is made in the form of a fixing or fastening element of the guide element (20) matched with the friction lining (8). 2 n. and 21 salary f-ly, 9 ill.

Similar articles:

- What do the icons on a washing machine mean: what symbols are on different brands of machines, photos

- Washing modes in a Zanussi washing machine

- How to turn off the beep? — Bosch SPV 40M20RU [Answers 1]

- A Quick Guide to Margherita 2000, Argherita | Ariston AL 109 X Operating Instructions | Page 2 / 14