There can be many reasons why an automatic washing machine breaks down. The most common of them are: consumer errors made during operation, improper loading of laundry, low-quality detergents for washing, manufacturing defects during production, too hard tap water, etc.

Any element of a household appliance can fail. Depending on the severity of the problem, a simple washing machine repair may be required, which can be done at home yourself. In more serious cases, you will have to seek help from a professional technician who can determine the cause and carry out complex repairs.

The most important part of a washing machine is the motor.

Its main task is to rotate the drum. Its failure can lead to a serious problem, including the failure of the entire washing machine. See also -

The washing machine is electrocuted - what to do?

How to check serviceability

In the assembly of washing equipment, only inverter (direct drive) and collector units are used. To determine their condition and identify a possible problem, it is worth familiarizing yourself with the diagnostic process step by step. First, let’s figure out how the components of the “heart” of the machine work:

- The stator is made of iron plates with copper windings between them. This part is stationary, but causes the rotor to rotate under the interaction of its magnetic field with its own.

- The rotor consists of a commutator, a core, and a winding. The element acts on the brushes, which transmit voltage to the commutator.

- A tachometer is installed on the housing. It records the speed of revolutions and transmits information to the main module. As a result, the module controls rotation depending on the selected washing mode.

Asynchronous type

This unit is no longer installed in modern washing machines because its efficiency level is not high. It has a simple but reliable design, so it rarely fails. Carrying out home diagnostics is not easy because the mechanism is directly attached to the drum. Frequent causes of failure are bearing wear, motor winding breakage, and insulation failure.

To make diagnostics, the asynchronous unit is removed from the housing, having first disconnected the machine from the network. Further:

- unscrew the screws;

- using a pencil, make marks on how the covers should be positioned relative to the body;

- unscrew two bolts and remove the fan;

- remove the engine covers after unscrewing the screws;

- first inspect the rotor: if it has melted or blackened, a spare part needs to be replaced;

- the motor breaks down when there is an interturn short circuit in the stator (visible by the burnt-out insulation varnish). If no damage is detected during a visual inspection, then the mechanism is checked with a multimeter, which shows the integrity of the working and starting windings. When the device shows even minimal resistance, this is a sign of winding breakdown. In such a situation, the spare part will have to be returned to a service center.

Direct drive type

It is not easy to detect a malfunction on your own. It is recommended to use system tests if they are supported by a specific machine model. When checking, codes appear on the display, deciphering which will help identify the breakdown and understand whether the help of a service center technician will be useful.

If you need to remove the motor for a detailed inspection, the diagram of this procedure will look like this:

- Disconnect the device from the power source.

- Unscrew the bolts around the perimeter of the case and remove the back cover.

- Remove the screws under the rotor that hold the wiring.

- Remove the central bolt that holds the rotor. To prevent the latter from moving, hold it with your hand when unscrewing the bolt.

- Remove the rotor assembly. Behind it is a stator assembly with 6 bolts.

- Unscrew the fasteners from the stator and disconnect the wiring connectors.

- After this, inspect for faults using the example of an asynchronous mechanism.

Collector view

The centrifuge motor of a semi-automatic or automatic washing machine operates on a belt drive with a drum and is easily removed from the housing. Installed on Ariston, Indesit, Samsung, Zanussi, Atlant units. The following scheme is used for diagnostics:

- Unscrew the back/front wall (depending on the modification of the washing machine).

- Remove the motor from under the tank. The electrical component of the unit is on terminals that can be easily opened.

- Now you need to connect the rotor and stator in series, and then apply a voltage of 220 V to the ends. If the unit is working and the automatic transformer heats up slightly, this indicates that there are no problems.

- For diagnostics, an autotransformer with a power of more than 0.5 kW is used. If you power it through the stator and rotor windings, the procedure will be safer (speed control).

The motor is the main component of the washing machine, so checking it should be taken seriously. If the diagnosis is performed incorrectly, this will entail a complete replacement of the mechanism. If a breakdown is detected, it is better to contact a service center for help.

Badly

Interesting 1

Super 1

How to diagnose an electric motor at home?

The easiest way to check for proper operation is the commutator motor. It is easier to remove it at home and can be checked without the use of expensive professional equipment.

As for electric motors with direct drive, a control system is needed to diagnose them, and it will have to be removed along with the tank, since it is an integral part of it. The stator is bolted to the frame of the automatic washing machine itself; the rotor also has a rigid mount, which in most cases is not dismountable. Repair of such washing machines is most often carried out only in service centers.

How to check a direct drive motor?

Most often, such an engine can only be checked by analyzing the errors displayed on the display or the service menu of the washing machine. Using the error code that appears on the display, you can detect a turn short circuit, diagnose a power supply break, or brush failure.

More complex and professional testing and repairs are carried out by qualified craftsmen using special laboratory and bench equipment.

How to check a commutator motor?

The most common motor used in modern models of washing machines. You can check the commutator motor of your washing machine yourself at home. First, the electric motor must be removed from the machine body. First, the back or front wall of the case is unscrewed (depending on the model of the washing machine). The motor itself is located under the tank on the rear side and is attached to the metal frame with studs or bolts. The electrical connection is equipped with terminals that can be easily opened.

After the motor is removed, it is necessary to make a series connection between the stator and the rotor, and apply a mains voltage of 220 W to the ends. It is best if it is supplied through additional ballast. You can use a heating element as it, the main thing is that the power of the equipment with active resistance is at least 500W. If, after connecting to the mains, the motor rotates and the autotransformer does not heat up much, at this stage it is possible to diagnose the normal operation of the motor.

Types of engines and causes of their breakdown

Washing machines use three types of motors. This:

- Asynchronous. Used in old style washing machines.

- Collector. Installed in all washing machines.

- Inverter. Used only in the most modern models.

An inverter or direct drive electric motor is the most difficult to check due to the assembly features. A system with such a drive is equipped with self-diagnosis, which, if the motor malfunctions, will display an error code on the display. If this does not happen, then you can inspect the device yourself.

The structure of asynchronous and commutator motors is similar. To check them, you will also need to disassemble the CM and remove the motor. The most common problems that occur in collector systems are:

- With brushes. The soft graphite material will wear out over time, especially if you have overloaded the machine frequently.

- With slats. Due to a short circuit in the network or overvoltage, the lamellas on the collector peel off.

- With windings. An interturn short circuit or open circuit could occur in the stator and rotor windings.

Therefore, if the engine on your car does not turn on, proceed to disassembly and inspection.

Inverter type

Direct drive motors can be found on SMA LG and Samsung models.

You can remove the inverter motor yourself for inspection, but it is impossible to repair it yourself if it is faulty.

- With the machine disconnected from power, unscrew all the bolts around the perimeter of the rear panel.

- To remove the motor rotor, remove the screws securing the motor wiring.

- While holding the rotor stationary, remove the central bolt.

- After removing the rotor assembly, unscrew the bolts around the perimeter of the stator assembly.

- After removing the stator, disconnect its wiring.

During inspection, did you find burnt parts? Contact the service center. If you need to replace the motor winding, it will be easier to buy a new one.

Collector type

This type is used in washing machines of the Indesit, Kandy, Samsung, Ariston, Veko, and Electrolux brands.

To check the commutator motor of the washing machine, you need to get close to it:

- Removing the rear panel reveals the engine underneath the tank.

- Note or photograph the location of the wiring and disconnect it from the motor.

- Unscrew the mounting bolts and remove the motor from the housing.

Brushes

The brushes rub against the rotor and therefore wear out. Then contact is lost and the motor circuit breaks. At the same time, the engine begins to lose power, run jerkily, start and stop.

If you notice sparking when connecting the motor to the network, this may indicate problems with the brushes or lamellas. We described methods for checking the engine in previous articles.

- On the sides of the body you will find protruding elements - brushes.

- Unscrew their fastening element and remove it from the housing.

- If they are worn out, replace them in the reverse order.

Even if one brush is worn out more than the other, both parts need to be replaced. Otherwise, this will lead to uneven impact on the rotor and operational problems.

Lamels

During long-term use, the brushes are wiped in the lamellas of the commutator cavity. Also, the lamella may peel off because the rotor is shorted or jammed. You can understand this during a visual inspection. If burrs or irregularities are observed, the anchor is removed and installed on a lathe for grooving.

The gaps between the lamellas are cleaned. To check them, test the gaps with an Ohmmeter. If the device shows a short circuit, it means you need to clean it harder.

You can determine if the lamellas are faulty by turning the rotor. A loud noise indicates a breakdown.

Bearings

Worn motor bearings result in friction between the stator and rotor. Inspect the rotor: if it begins to wear out, it needs to be replaced along with the bearings. When turned, the rotor will rotate unevenly, making scratching sounds.

To remove the bearing from the motor, you will need a special puller. It is selected depending on the size of the bearing. When installing the puller, focus on the inner ring.

To fit the bearing onto the shaft, you can heat it with a blowtorch. After cooling, it will sit firmly in place.

Windings

When the stator and rotor windings are shorted or broken, the engine loses power, hums, but does not turn. If the motor overheats and the thermostat trips, the washing machine will not work and the wash will not start.

The windings are checked with a multimeter - check the wiring and lamellas. It is impossible to reinstall the winding if it malfunctions with your own hands. Therefore, it is easier to replace the SM motor.

Now you know what to check if the engine does not start. Operate the machine according to the instructions, then all its parts will last much longer.

What you need to consider when connecting motors from different types of washing machines

The washing machine is connected to the electrical network in accordance with “PUE 7. Electrical Installation Rules”.

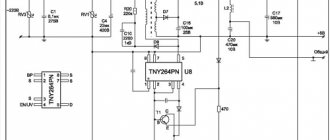

Connection diagram of the washing machine to the electrical network PHOTO: 1stiralnaya.ru

Even a superficial acquaintance with the structure of the machine and its electrical circuit ensures its more conscious operation and the ability to minimize the number of emergency situations. A schematic electrical diagram is a graphical representation of the main electrical components of a machine and the connections between them.

There are three types of electric motors in washing machines.

Asynchronous

Most washing machines from previous years use three-phase asynchronous motors, each of which consists of a stationary stator and a rotating rotor. The alternating current initiates a rotating magnetic field in the stator winding sections, which induces a current in the rotor. This secondary induced current interacts with the magnetic field of the stator, and a rotating force begins to act on the rotor, due to which it begins to rotate and transmit its rotation to the devices connected to it.

Engines of this type are simple in design, unpretentious in maintenance, and reliable in operation. The main disadvantages are large starting currents and difficulties in regulating the rotation speed.

Reversible connection diagram for an asynchronous motor with a starting winding PHOTO: elektt.blogspot.com

Collector

In commutator motors, the windings are located on both the stator and the rotor. Current is supplied to the rotor through a device called a “collector,” which consists of lamellas attached to the rotor shaft and two “brushes” that are stationary relative to the stator.

Connection diagram for commutator motor PHOTO: elektt.blogspot.com

The commutator motor operates on both alternating and direct current. Here it is easy to regulate the speed by changing the supply voltage. As an industrial device, you can use a dimmer from the lighting system that is suitable in terms of power.

Inverter

An inverter motor in a washing machine is the most modern solution. The principle of operation is that in the built-in inverter, the alternating current of the electrical network is converted into direct current, and then again into alternating current of the desired frequency, which determines the speed of rotation of the shaft. It, unlike the commutator type, has no brushes and makes less noise. No brushes - no wearing parts, so nothing needs to be replaced regularly. But you have to pay for an inverter; such a machine is more expensive.

Differences between electric motors

The differences between electric motors by type are given in their descriptions. The asynchronous motor is the simplest in design. The collector has the ability to easily adjust the rotation speed. And the inverter motor is directly connected to the drum shaft without belts and gears. In short, more modern engines make less noise and are subject to speed control, but are more expensive.

How to turn on an asynchronous type motor

The asynchronous system consists of:

- The stator is a fixed base.

- Rotor - the element that rotates the drum.

The SM used three-phase motors that can fully operate at a voltage of 380 V. Connecting the motor from the washing machine to a single-phase 220 V network requires connecting a capacitor.

It will reduce the power of the device, but will make the work safer.

Choose a capacitor more powerful than the motor, then it will withstand voltage surges.

Three-phase connection diagram

You will need a set of accessories:

- multimeter;

- capacitor;

- wire - a plug at one end, three terminals at the opposite;

- intermediate wire, terminals at the edges.

Connection:

- Take the power cable and connect the capacitor.

- Attach the intermediate jumper wire to the other side of the capacitor.

- Ring the winding to find the lowest resistance outputs.

- Insert the straight wires that will connect to the outlet.

- Connect the capacitor.

If you cannot hear the motor noise after plugging it into the outlet, most likely the starting capacitor is connected incorrectly. You will have to look for the right terminal using the “scientific poking method”. A detailed description and the result of the experiment with three wires can be seen in this video:

During the spin cycle the program freezes or the function does not work

The reasons for the lack of spin can be either mechanical or software at the level of control electronics. To exclude a breakdown at the electronics level, you need to run the spin function separately and see if fault codes appear on the control panel of the washing machine. If the machine has a touch control and a large screen, then a failure of the function will be accompanied by the symbols “ERROR”, followed by a digital error code. The analog control system is a little more complicated. It is represented by indicators that, when an error occurs, begin to glow or flicker.

One of the most common reasons for the failure of the spin function is the failure of the tachometer sensor or a break in the wires transmitting the control signal from the tachometer to the engine. In this case, DIY repairs seem to be quite problematic. Since it is necessary to have professional testing equipment.

Tachometer sensor

Mechanical causes of failure or poor performance of the spin function can be eliminated independently:

The belt transmitting torque from the motor to the drum has stretched. This problem occurs especially often in compact (narrow) washing machines.

Drive belt

Wear on engine brushes occurs during intensive use over a long period of time. At the same time, the washing machine works quite successfully at low speeds, but for spinning (maximum speed) the power is no longer enough.

Remove the electric motor

Remove the brushes

To replace the brushes, you need to remove the engine and find the brush holders on it (they may look different for different models), remove one of the brushes and purchase similar ones in the store. The need to replace brushes can be determined by the size of their protrusion from the brush holder. If at least one of them has less than 7 mm, then both cheeks need to be replaced.

Kinds

The first thing you should do before starting diagnostics is to determine what type of motor is installed in your washing machine. There are several types of motors that manufacturers use to equip washing machines. Let us present brief information about them in the form of a table.

Asynchronous washing machine motor

Commutator motor of a washing machine

Brushless washing machine motor

| View | Main design elements | Advantages | Flaws |

| Asynchronous | starter and rotor |

|

|

| Collector | starter, rotor, tachogenerator, electric brushes |

|

|

| Brushless (direct drive) | starter and rotor |

|

|

Solving the problem with the activator

Some problems are caused by a faulty activator in the car. Leaks can occur due to improper connection of equipment or wear of O-rings and various rubber bands. But don't get ahead of yourself

It is important to first understand what an activator is

This is a movable element, due to the rotation of which washing occurs. Impaired mobility leads to a stop in the work process. Sometimes the thermal relay is triggered and the machine simply turns off. Before making repairs, you should familiarize yourself with the main problems caused by the activator. You also need to understand how to troubleshoot such problems.

So, if the tank is overloaded, then the activator will not spin normally when starting. He may even stop altogether. The machine will start humming, and the solution to the problem will be to unload it. After this, you need to wait about 15 minutes and restart. Repairing the Malyutka washing machine may involve simply removing threads and foreign objects, as well as rags from the shaft. It is part of the activator.

If the machine starts to hum and then turns off, then the repair consists of cleaning the shaft. Sometimes it happens that the node being described turns out to be skewed. It continues to spin, but after washing the laundry is often severely wrinkled or even torn.

When the activator touches the walls of the tank, you will hear a strong hum. The machine may turn off for no apparent reason. The solution is to unfold the device and remove the plug. The activator is unscrewed, and then the thread is cleaned. The assembly is again installed in place until it stops. After this, the device should work properly.

Pros and cons of the profession

pros

- The master receives a very good income.

- Different formats of work and profit are possible: private customers, piecework payment, service center or manufacturing companies.

- There is enough work both in megacities and on the periphery.

- You can quickly complete initial training, which lasts 3-4 months.

- The opportunity to take courses at the employer’s company, which allows you to gain knowledge, a number of practical skills and subsequent stable orders.

Minuses

- The master is not protected from unforeseen situations and claims from clients.

- The working day may be irregular.

- Possible unfavorable working conditions.

The windings are broken or shorted

Acceleration problems also arise when the winding is damaged: the motor does not start or the drum rotates very weakly. The fact is that short circuits occur in the wire turns, the engine begins to overheat, the thermistor is triggered, and the system urgently turns off the power for safety reasons. At the next start, the situation repeats until the temperature sensor burns out, and then the engine itself fails.

The winding is checked with a multimeter according to the following algorithm:

- turn on the tester in the “Ohmmeter” mode;

- we attach the probes to the adjacent lamellas;

- We evaluate the resistance (the norm is from 0.1 to 0.4 Ohms).

Repairing the winding yourself is very dangerous. It is better to turn to professionals or purchase a new engine.

Share your opinion - leave a comment

How much does SMA consume?

When choosing a washing machine, buyers evaluate it according to a standard set of criteria. Usually they are interested in modes, drum loading, dimensions, loading type, drum illumination and other visible functions. But people are rarely interested in kilowatts. The lower the energy consumption class, the more electricity is spent, the higher the electricity bills. Today, almost all SMAs belong to group A. The exception is devices with a drying function - but here you have to sacrifice savings for the opportunity to receive dry laundry.

Energy consumption can be easily determined by the energy efficiency class. Thus, models A+++ consume 0.13 kWh, and, for example, group C - 0.25 kWh. Power consumption of class A SMA is up to 0.31 kWh. Equipment of groups E, F and G is not used in everyday life. Its consumption is respectively 0.39 and 0.4 kWh.

Carrying out disassembly

If you are wondering how to disassemble the Malyutka washing machine, then first you must remove the plug from the hole located in the back of the electric motor casing. The oblong hole of the impeller must be aligned with the hole in the casing. Through it, a screwdriver is inserted into the engine rotor. The activator is unscrewed.

You must insert a key into the hole in the activator housing and unscrew the housing. This will allow you to disconnect the tank. Disassembling the Malyutka washing machine at the next stage involves unscrewing six screws. Next, you can remove the flange and unscrew the locknut, as well as the rubber nut. They fix the switch. Now you can remove the washer and unscrew the screws that hold the casing halves together. Below it is an electric motor and other equipment elements.

The most common causes of engine failure

- Failed electric brushes;

- Broken winding in the rotor and stator;

- Collector lamellas.

Replacing electric brushes

These are conductive graphite cubes with wires that rub against the commutator.

The reason for replacing motor brushes may be:

- loss of rotational force of the drum or its complete stop;

- unusual noise when the washing machine is operating.

The most common cause of failure is tank overload. Also, electric brushes wear out quickly when spinning at maximum speed or due to a short circuit in the turns of the electric motor winding, a problem with the belt that connects the motor to the drum, it can jump off the pulley or break.

A visual inspection of the brushes will also help you understand the need for replacement. If they spark during operation or there is a black coating on the surface, the parts need to be replaced.

Of course, this is an inexpensive engine element, and repairs can be done at home. It is enough to purchase a suitable brush model from a specialized store or service center. The main thing is to choose and replace the brushes on the washing machine correctly; they must fully match the type of motor and it is better if it is an original set from the washing machine manufacturer.

Slats need replacement

This is precisely the component of the commutator along which the electric brushes slide. They transmit current through the rotor winding to the motor. The plates themselves are rarely subject to wear; the cause of failure can be the breaking of the cord in the winding in the places where the lamellas are attached or their detachment.

This happens, most often, also due to improper operation of the device, for example, in a top-loading machine, the washing process was started with the drum flaps open or failure of the bearings.

If the delamination is small, repairs are made on a special machine by grooving the collector. At home, you can get by with simple fine sandpaper. The principle is the same - the lamellas are sharpened, then the space between them is thoroughly cleaned of dust and shavings.

You can check the electric motor for this malfunction by slowly turning the rotor; if a characteristic sound appears, then most likely the reason is in the lamellas.

Open circuit or short circuit in the rotor or stator winding

These are the most common causes of loss of engine power or complete cessation of its operation, which can be a consequence of:

- overheating of the motor housing resulting from short circuits in the winding. The normal temperature should not be higher than 80 degrees; if it rises to 90 degrees, the thermostat is triggered, stopping the engine;

- winding insulation failure. In this case, repairs at a service center are inevitable. Most often the entire engine has to be replaced. Re-winding at home is not recommended.

A break in the winding can be detected using a multimeter in the mode of measuring the resistance between the lamellas. The norm is 0.1-0.4 Ohm.

A breakdown or short circuit in the electric motor of a washing machine can cause a malfunction and failure of other parts of the device, for example the command device (another expensive part of the machine), power triac, and reverse relay. As you can see, the most common causes of breakdowns are non-compliance with operation instructions or instability of the electrical network. To increase service life, it is recommended to use the device according to the instructions, and to protect against power surges, install a circuit breaker and connect the washing machine only through this protective device.

- 10 best ATLANT washing machines according to customer reviews

- 10 best built-in washing machines

- 10 best washing machines under 15,000 rubles according to customer reviews

- 10 best washing machines under 25,000 rubles according to customer reviews

- 13 best washing machines from 40,000 to 50,000 rubles according to customer reviews

Power and energy consumption

The level of energy consumption of the entire machine directly depends on the power of the electric motor for the washing machine. It is this parameter that affects how many kilowatts per hour your washing machine will “wind”. When choosing a washing machine, it is this, and not the power of the engine, that worries the buyer.

In general, energy consumption is influenced by a lot of factors:

- Engine power.

- Heater power. On average, a heating element can consume from 1.7 to 2.9 kilowatts. At high temperature conditions the power increases.

- Drain pump power. It ranges from 24-40 watts. This indicator is quite enough to pump waste water out of the tank.

- Total power of sensors, control and display unit. Within 5-10 W.

The general indicator for the entire SM is calculated only for one mode - “Cotton”, with heating up to 60 degrees and with the drum fully loaded.

According to the obtained indicators, the machine is assigned an energy efficiency class. Classes are designated by Latin letters from G to A, where G is the lowest class, A is the most effective.

Important! The number of drum revolutions during the “Spin” mode directly depends on the motor power.

So, the higher the engine power, the more revolutions the drum can make during spinning. These indicators are also calculated by the manufacturers, which is reflected in the spin classes.

So, a washing machine spinning at 1600 rpm is class A. But even 800 rpm will be enough to fully spin the laundry. And if you are going to wash delicate fabrics often, then the number of revolutions shouldn’t really worry you at all - the fewer, the better: things will be intact.

How to choose?

Choosing a washing machine is an important and responsible task that requires a lot of attention and effort.

Experts recommend taking into account a number of factors.

Machine type. There are several types of automatic washing machines: frontal and vertical. However, they differ from each other in the way they load and unload laundry. Thus, front-loading washing equipment has a hatch for laundry on the outer front part of the body. At the same time, vertical machines are equipped with a hatch on top. The choice of one device or another depends solely on your personal preferences.

Device dimensions. The detailed size range of washing machines is described above. This characteristic is the most important when choosing a device. First of all, you should focus on the size of the room in which the equipment will be placed.

Drum volume. This indicator is the most important when choosing a device. So, depending on the number of people living in your house, you should choose a machine that is more or less voluminous. Load volume can range from 1 to ten kilograms. Please keep in mind that the volume of the drum affects the overall dimensions of the washing machine.

Functionality. Modern automatic washing machines are equipped not only with washing, rinsing and spinning functions, but also with a number of additional features. Such additional functions include a leakage protection system, the presence of additional modes (for example, a gentle or quiet wash program), drying, etc.

Control type. There are 2 main types of control: mechanical and electronic. The first type is characterized by the ability to set washing parameters using special buttons and switches located on the front panel of the device. Electronically controlled cars only require a mode task, and they configure the remaining parameters independently.

Washing class. There are several washing classes of modern washing machines. They are designated by Latin letters. In this case, A is the highest class, and G is the lowest. Amount of energy consumption. Different models of automatic washing machines have different levels of energy consumption. This indicator is regulated by the amount of money you will pay for the electricity used.

Price. High-quality home appliances cannot be too cheap. That's why if you see a low price, it should make you suspicious. The low cost may be due to the fact that you are dealing with an unscrupulous seller or purchasing low-quality (or counterfeit) products.

Appearance

When purchasing a washing machine, you should pay attention to its functions, safety indicators, and external design. Choose a device that will fit perfectly into the interior of the bathroom, kitchen or any other room where you will place a household device.

Automatic washing machines are devices that are real helpers in everyday life. Today, there are a large number of types and models that differ in a number of key characteristics.

For information on choosing an automatic washing machine, watch the following video.

Which car with an inverter motor to choose

The modern market is overflowing with household appliances. In this regard, people have a question: “Which machine to choose?” The housewife should compare all the characteristics to choose what is most suitable.

Indesit machines are equipped with additional functions that save energy. In addition, they have a mode that allows you to deal with dirt and grass marks. This function will be useful for those who have athletes in their family. If you wish, you can even wash your sneakers. The inverter motor handles the load perfectly.

Another leader is Bosch. In addition to the silent engine and original design, the advantage of these machines is that they are capable of washing up to 10 kilograms of laundry at a time. The drum does a great job with carpets, long curtains and other bulky items.

Each housewife must choose the machine that suits her best.

Repair of washing machine faults

Minimal repairs

washing machine can be accomplished by any owner or housewife. Even a child can fix a machine if the cause of its malfunction is a simple misunderstanding.

It is not difficult to understand the structure of a washing machine and understand the principle of its operation. But to eliminate serious

a malfunction, even knowing its cause, is an unsafe activity both for the owner of the washing machine and for the washing machine itself.

To carry out work of medium complexity and particularly complex repairs, special knowledge and experience are required. Serious breakdowns are repaired by a qualified washing machine repair technician.

How does a washing machine work? What kind of malfunction may occur? How to distinguish a banal misunderstanding from a serious breakdown that should be fixed by a professional?

Conclusions about engine power

How to find out how many revolutions a washing machine motor has? How to determine motor power? How can you avoid making mistakes in choosing technology based on this?

It's simple: washing machines made after 2000 are supplied to stores with brushed or brushless motors. Their power may differ, but this is not the most important indicator for the consumer, since the more pressing issue is the optimal energy efficiency class.

Therefore, if you don’t want to understand the technical nuances of motors, just choose a class A or A+ machine.

A useful video will tell you even more about the SM engine:

Types and their characteristics

All motors that are found in modern automatic washing machines are divided into three types.

Collector

This motor is the most common today. Most washing machines are equipped with this device.

The design of the commutator motor consists of the following elements:

- body made of aluminum;

- rotor, tachometer;

- stator;

- a pair of brushes.

Commutator motors can have a different number of leads: 4, 5 and even 8. A brush design is necessary to create contact between the rotor and the motor. The collector power units are located at the bottom of the washing machine. A belt is used to connect the motor and the drum pulley.

Brushed motors are not as bad as they might seem. They also have positive parameters:

- stable operation from direct and alternating current;

- small sizes;

- simple repair;

- clear diagram of the electric motor.

Inverter

This type of motor first appeared in washing machines only in 2005. This development belongs to LG, which has held its position as a leader in the global market for several years. This innovation was then used in models from Samsung and Whirlpool, Bosch, AEG and Haier.

Inverter motors are built directly into the drum. Their design consists of a rotor (a cover with permanent magnets) and a cage with coils, which is called a stator. The inverter brushless motor is distinguished by the absence of not only brushes, but also a transmission belt.

The armature is assembled on magnets. During operation, voltage is supplied to the stator windings, having undergone preliminary conversion to inverter form.

Inverter power units have many advantages:

- simplicity and compactness;

- economical energy consumption;

- very low noise generation;

- long service life due to the absence of brushes, belts and other wearable elements;

- reduced vibration level during spinning even at high speeds, which can be selected for operation.

Advertising tricks of manufacturers

In the instructions for washing machines, manufacturers indicate all the parameters and characteristics, and the user, studying them, realizes how much new products benefit in many respects, such as energy efficiency and durability. Companies under no circumstances deceive customers, but sometimes they leave out small nuances that significantly reduce the value of new technologies. This is done for advertising purposes to increase sales.

Energy efficiency

As the advertisement says, inverter machines help save up to 20% of electricity compared to collector models. Yes, this is indeed true and the savings occur due to more precise adjustment of the load on the motor - with a small load of laundry, the drum is not fully spun up and energy is saved.

But the most important thing is that in the machines, the largest amount of electricity is consumed not by the motor, but by the heating elements that heat the water. Therefore, real savings are 2-5%, and when fully loaded they are reduced to zero.

Silence

Brushed motors make a lot of noise, while inverter motors operate as quietly as possible and do not make any sounds. This is partly true, motors with brushes are noisier, but inverters also have a characteristic squeaking and whistling sound.

Spin speed

The new products can actually spin clothes at the highest speed, reaching 2000 rpm. This is a very significant advantage of an inverter washing machine for buyers who dream of quick washing and almost dry laundry. But few people know that with such a spin speed, things quickly become unusable and sometimes, instead of a well-wrung item, people take out shreds of it. And delicate or woolen items a priori do not require a strong spin, so think about how necessary such speeds are.

Durability

Now ask yourself a question: how long do you want to use your washing equipment? Typically, users expect a maximum of 15 years, but even during this time, technology will make significant progress and new, improved and more technologically advanced models will appear. A service life of 10-15 years is established for the commutator drive.

Most buyers worry about brushes that wear out, but their service life is up to 15 years with a daily load of two hours. Even if they wear out, the cost of replacing them is negligible.

Another point that affects durability is the combined location of the drum shaft and engine. Indeed, such an arrangement has a lot of advantages and the absence of various additional loads, and an increased mechanical life, but there is also a minus - one, but significant.

No rubbing parts

This statement can be called an outright lie. There are no brushes in the inverter motor, but there are bearings and they have the same service life and wear rate as in conventional motors.

Manufacturers provide warranties for inverter motors for up to 10 years, but for other parts of the washing machine, warranties are limited to 3-7 years. Equipment is also affected by such factors as, for example, voltage surges, which reduce all newfangled technologies to banal breakdowns not included in the warranty service. And the cost of repairing inverters is very high. Therefore, it is recommended to correctly connect and install the washing machine, as well as operate it carefully, following the basic rules, and the equipment will delight you for many years.

Source