#bosch-washing-machine-mistakes

Published: 26 Sep 2020

You threw the laundry into the Bosch machine, selected a program, but it didn’t start because the lock on the hatch didn’t work. Outwardly, everything is in order, but the door is not locked, and the message F16 or E16 appears on the display of the Bosch washing machine.

Let's figure out what happened and why the SMA refused to close.

Error interpretation

Error code F16 on the display of a Bosh washing machine informs you that the washing machine hatch is not closed or something is preventing it from closing. Error F16 may be caused by a failure or malfunction in the control system of the washing machine, for example, a breakdown of the locking device, hatch locking module or control module. In most cases, such an error indicates that there is a malfunction in one of the washing machine systems. To identify primary faults, you can perform primary diagnostics, which does not require professional knowledge.

A similar problem on washing machines without a display will be indicated by a flashing light - a rpm indicator at 1000 or 800.

Errors F16 or E16 in Bosch without display

Models not equipped with an LCD screen report a problem by blinking indicators.

- Bosch Classixx series (for example, models WLF20(16)260 and WS10F260). An error is indicated by the blinking of the “Rinse” and “Wash” lights.

- Bosch Maxx 4 line without display . On such washing machines, in case of error F16, the “Ready” indicator flashes.

- series 5, 6, 7. With this error, the topmost spin speed indicator flashes (depending on the model - 1000 or 1200 revolutions).

What caused the malfunction

- First of all, you need to check whether the hatch door is really closed. Rearrange the laundry, check if there is anything blocking the door from closing and then try pressing the loading door tighter until you hear a clicking sound when closing;

- Check the lock hole - there may be a blockage or foreign objects in it. Garbage can be removed using a regular toothpick; dirt can be cleaned with a cotton swab dipped in alcohol or vodka;

- check the side hinges holding the loading hatch - due to physical impact they may be damaged or distorted;

- the problem may be caused by the displacement of the locking tongue - pay attention to whether it gets into the lock when closing the door;

- The cause of the problem may be a failure in the control module - in this case, you will need to unplug the washing machine from the network for 20-30 minutes. Then connect the machine to the mains and try running the washing program again. If the cause was a one-time failure in the control module, after a reboot the error indicator will no longer be displayed.

If the above recommendations do not solve the problem, you need to check the washing machine for mechanical problems.

See also -

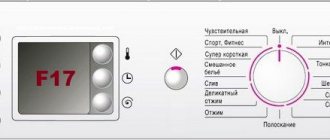

Bosch washing machine displays error F17 (E17) - what does it mean?

Error codes for Bosch washing machines

The codes are displayed on the display or using an indication. The user only needs to look at the instructions, recognize the error and take timely measures to eliminate it. On common models Maxx 4, Classixx 5, Maxx 6, Classixx, as well as others, the following error codes are provided:

- F 16 – the door is not closed when starting the program;

- F 17 – exceeding the time for filling water due to clogged filters and valves;

- F 18 – water is not supplied due to a clogged drain valve or a breakdown of the water level controller;

- F 19 – heating does not occur if the heating element or thermostat is broken, or there is insufficient voltage;

- F 20 – the water does not heat up due to a broken thermostat;

- F 21 – drum failure due to a malfunction of the relay or tachogenerator;

- F 22 – short circuit or broken circuits and wires;

- F 23 – activation of the Aquastop option due to water leakage into the pan;

- F 25 – failure of the turbidity controller;

- F 26 – analog sensor does not work;

- F 27 - signaling device failure;

- F 28 – failure of the compression sensor;

- F 29 – incorrect operation of the electric motor;

- F 30 – no engine rotation;

- F 40 – electrical equipment does not synchronize due to mismatch of power supply parameters;

- F 50 – insufficient or excessive flow rate;

- F 51 – the door is not closed;

- F 53 - functional protection malfunction;

- F 54 and F 63 - failure of the control module.

Problems with hatch door mechanisms

- The side hinges are sagging or skewed, the latch does not fit into the hole for the tongue due to the incorrect position of the door. Over time, or due to the impact of heavy weight on the door, this problem may arise. In this case, you can independently tighten the bolts holding the side hinges so that the door falls into place. In case of mechanical damage, a complete replacement of the hinges will be required;

- the plastic door guide has become unusable and is not fixed in the lock hole - in this case it is necessary to disassemble the car door, most likely the part will need to be replaced;

- If the locking tongue does not work correctly, it is necessary to disassemble the hatch door and check the position of the rod designed to secure the tongue. You can put the rod back in its original place; if damaged, it will need to be replaced.

How to recognize a breakdown if there is no code?

Bosch washing machines have a device diagnostic option, thanks to which you can independently determine the cause of the failure and eliminate it. Here are step-by-step instructions on how to carry out such diagnostics:

- close the door;

- set the program selection scroll to the Off position;

- after a few seconds select Spin;

- If done correctly, the Start indicator will start flashing;

- hold the Speed button until the Start light starts flashing;

- turn the selector to the Drain position;

The selector should only be turned in a clockwise direction so as not to cause damage to the equipment.

- release the RPM button and select the option that requires a test.

If the diagnostic cannot be started, the fault is in the control module and you need to call a specialist.

To check manually, scroll the selector; each number is responsible for testing a separate element:

- 3 – check the motor;

- 4 – pump testing;

- 5 – heating element;

- 6 – hot water valve;

- 7 – cold water valve;

- 8 – main wash valve;

- 9- valve for pre-wash;

- 10 - sound indication;

- 11 – FCW autotesting;

- 14-15 - quick self-testing.

To exit test mode, press Start and turn the selector.

To return from the mode, scroll to the Off position.

Electronics problems

If the loading hatch of the washing machine is tightly closed, but error F16 still appears on the display and the washing program does not start, then there are problems with the electronics.

- The hatch locking device is faulty . UBL consists of plates that expand under the influence of electricity and thereby help block the door. The plates may be worn out, in which case it is necessary to replace them or the entire locking device.

- The wiring connecting the control module and the hatch locking module is worn out or damaged , resulting in the locking device being de-energized. First of all, you need to check the wiring for breaks and clean it. To do this, you will need to partially disassemble the machine; if you do not have the necessary skills, it is better to entrust this to specialists. If damage to the integrity of the wiring is detected, it will need to be replaced.

- The control module is faulty - to determine this, you will need to fully diagnose the board using a multimeter. The electronic module is the most sensitive part of the washing machine, so it must be handled with care. It may be necessary to reflash the module, solder contacts, or completely replace the board.

If you do not have the appropriate knowledge and qualifications, it is better to entrust the diagnosis and repair of faults to specialists in order to avoid unnecessary money and time costs.

See also:

- 7 best washing machines under 20,000 rubles according to customer reviews

- 8 best narrow washing machines according to customers

- 8 best BEKO washing machines according to customer reviews

- 10 best washing machines from Samsung

- 10 Best Top Loading Washing Machines

Typical malfunctions of Bosch washing machines

The most common problems are:

- no water heating;

- water is not drained;

- the drum does not rotate;

- noise and vibration;

- water does not fill in after starting the program;

- The electric motor does not work.

Let's consider each malfunction, indicating the possible causes that could lead to them.

Water doesn't heat up

The most vulnerable part of the equipment is the heating element (heating element); it is susceptible to breakdowns during intensive use of the device and poor water quality, as a result of which a thick layer of scale from salt deposits forms on it. The solution to the problem in most cases is to independently clean the heating element from scale or replace it. When using a washing machine with hard water, replacement is usually required after 3-5 years of operation.

There may also be no water heating due to the selection of an inappropriate washing program; in this case, re-read the instructions and select the appropriate program and mode.

Water does not fill

Potential reasons:

- low water pressure in the pipeline or shutdown of water supply;

- the filling valve is closed;

- breakdown of the water level controller or inlet valve.

Water does not drain

If water does not drain through the drain hose, you need to check the program selection. Some models have non-draining programs. If necessary, select the water drain mode.

All the reasons why the washing machine stopped draining water are described in this article.

A clogged drain hose that needs to be cleaned and rinsed can prevent water from draining. You also need to check the filter and pipe for the presence of small objects, hair and threads, wool. Other prerequisites may be pump malfunctions or malfunctions of the electronic board.

It is better to entrust the repair of washing machines to professionals!!!

Select your city and artist in the filter: by rating, reviews, price!

The drum does not spin

Most modern models have built-in overload protection, that is, the drum will not rotate and washing will not start until excess items are removed from the drum. If after this, after twisting it with your hand, it rotates, you can start washing.

You may find this article useful: What to do if the washing machine drum stops spinning?

Other causes of malfunction:

- rupture or displacement of the drive belt;

- the heating element is burnt out;

- breakdown of the tachogenerator or pump;

- The electric motor does not work.

Excessive noise and vibration

If you notice a lot of noise and vibration during the first wash, turn off the unit and check that the shipping bolts are removed, as they may cause the unit to vibrate and hum.

A common cause is also wear of bearings and seals, clogged filters and pipes, and problems with the drain pump. All these malfunctions can be solved by independently replacing failed elements, or by cleaning the filter and pipe.

Washing machine won't turn on

First of all, check if there is electricity in the outlet, if the outlet is working, if there is water in the pipeline. If there is water and electricity, then the breakdown may be caused by a malfunction of the electronic module; the corresponding error code should be displayed on the display.

The video describes the diagnosis and step-by-step elimination of the spin error. Such problems are associated with breakdowns of the pressure switch, electric motor or control module.

If it is impossible to identify the malfunction and the error code is not shown, then you need to contact a technician for special diagnostics.

This is interesting: Dishwasher does not dry dishes and does not heat water - causes of malfunction and repair

What is the reason?

Most often, the reason for the appearance of code F16 is a loosely closed machine door. Closing may be prevented by laundry falling onto the edge of the hatch or debris trapped inside the lock groove. In addition, the door may not close due to banal overload and too large a volume of things placed in the drum.

On the technical side, error F16 can be caused by 3 types of faults:

- Failure of the hatch locking device (UBL);

- Damage to the central control board;

- Violation of wiring integrity.

In addition, this error can be caused by a malfunction in the machine software.

Signs of occurrence

A Bosch washing machine can alert you in different ways about a poorly closed door. It all depends on the features of the model. On electronic versions, the code is displayed on the display. For example, the Bosch Maxx 5 version has it. Electromechanical versions do not have a screen, so when error F16 occurs, a light appears near the 1000 rpm mark (or 800, if the machine spins clothes at lower rpms)

Most often, code F16 appears after selecting a work program. This error rarely occurs during or at the end of washing.

Reasons for the problem and ways to solve the problem

Error code F16 on the display may be due to a random combination of circumstances. To check this point, you can unplug the washing machine for half an hour and turn it on again. If the fault code has not been reset, you should proceed with a more detailed analysis.

After loading the laundry, the Bosch hatch door is closed. If the clicking sound is not heard and the hatch remains open, then the problem with E16 concerns parts involved in purely mechanical work.

Otherwise, if the door closes with a click, but the door does not lock when the program starts, it is highly likely that the reason is in the electronics.

Incorrect user actions

It often happens that the door is not completely closed, not until it clicks. In this case, it is not blocked, and the control module does not send a command to start the cycle.

You should carefully inspect the Bosch hatch door, the cuff itself and the lock location. If a foreign object (for example, laundry from the drum) gets under the door, blocking does not occur.

The solution to the problem is to carefully move things deep into the drum and close the door tightly until it clicks.

Failure of door hinges

Despite all the reliability of Bosch equipment, breakdowns often occur. Door hinges can become deformed over time. This may be due to both long-term service and careless attitude towards equipment.

If possible, the hinges should be repaired and the retaining bolts tightened. Otherwise, the hinges will have to be replaced. How to replace Bosch hatch door hinges can be seen in the video:

Broken locking tab or handle

If the door handle is broken and the tongue that should fit into the lock is deformed, the door will not lock. Broken plastic elements cannot be repaired - they are replaced with new ones.

If the plastic handle is broken, it must be replaced. This situation can occur if excessive force is applied when closing/opening the door, slamming it hard, etc. The plastic handle cannot be repaired.

You can learn more about the procedure for replacing the handle in the video:

UBL broke

If the hatch blocking device breaks down, it can cause error F16 to appear. The operating principle of the unit is based on the expansion of the plates under the influence of an electrical signal.

If the plates are worn out, the locking will not work. You can check the functionality using a multimeter. The solution to the problem is to replace the element.

Control unit malfunction

The control module in a Bosch washing machine is a board with elements that controls the entire process of operation of the washing machine according to a given program.

To carry out diagnostics, the block is removed. If a breakdown is detected, the contacts are soldered and the necessary elements are replaced.

Repairs require special tools and experience with electronics. If the module is badly burned out, it is replaced entirely.

Wiring irregularities

If the contact in the circuit between the UBL and the control module is broken, the signal may not pass through, which is why the blocking will not be performed. Violations can even be caused by chafing of wires due to vibration; in a private building, rodents can also damage it.

To check the condition of the wiring and contacts, it is necessary to inspect the wires themselves. If necessary, twist or replace the wires with a whole cable.

How to fix it?

Before resetting such an error, you need to determine why it appeared. There are several variations of scenarios that can be used to fix the failure code. Typically, troubleshooting starts from basic to complex actions, one at a time. You need to act by elimination.

Foreign object entering the drum

If you try to turn the drum by hand with the machine turned off, a foreign object will knock or grind, interfering with the scrolling. To remove a foreign object, several steps will be required.

- First of all, you should rotate the unit so that there is unobstructed access to the MCA.

- If there is a service hatch, it will need to be opened. Otherwise, you will have to resort to dismantling the fasteners and the rear wall.

- Then you need to disconnect the wires that lead to the heating element.

- The heating element itself is also pulled out from the body part. At the same time, you can descale it.

Due to perfect manipulations, a small hole will appear through which you can pull out a foreign object. This is done using a special device or by hand.

Voltage drops

This is a dangerous phenomenon that adversely affects equipment. Voltage surges may make further use of the machine impossible. Buying a voltage stabilizer will help prevent future breakdowns. It will prevent such risks from occurring.

Tachometer failure

If the cause of a malfunction in a Bosch washing machine is a malfunction of the tachometer or Hall sensor, the following procedures will be required.

- You need to unscrew the back wall of the unit and remove the drive belt. The second action will be required to ensure that nothing interferes during the repair.

- In order not to get confused in the location of the wiring with fasteners, it is recommended to photograph them before removing them.

Then you can just press on the body part and lower it. With these simple steps, removing the motor will be quick and easy.

The Hall sensor is located on the engine body. Therefore, after the engine is dismantled, all that remains is to remove the tachograph and carefully examine it. Sometimes there is oxidation or lubricant on the inside of the ring. If such a phenomenon is detected, it should be eliminated. After this, you need to use a multimeter, which will report the status of the sensor.

Motor fault

Most often, electric brushes fail. This part cannot be repaired, so you will need to buy new ones. Experts advise buying original components and replacing a pair at once. The replacement process itself is easy; an ordinary user can handle it. The main difficulty lies in the correct selection of the parts themselves.

In this way, you can use a sample to ensure that the selected part will be suitable.

Also, on a Bosch washing machine, error F21 may appear due to a breakdown of the winding turns in the motor. Due to this, there is a leak directly onto the unit body. This type of fault can be determined by using a multimeter. In most cases, if such a malfunction is detected, it is recommended to buy a new engine, since repairing the old one will cost a large sum and is characterized by numerous difficulties.

Designation and decoding of the code

The appearance of code E16 on the display indicates a problem with the heating element.

Almost always, such a situation indicates the need for repair work. Moreover, in modes that do not require heating of water, the program can be processed completely without failures, and without issuing E16. A malfunction occurs when Candy stops working immediately after turning it on, or when washing starts. In some cases, water may not even begin to fill.

On devices without a display, information about a failure is indicated by blinking indicators - 16 times without breaks, with a repeat after a short pause.

The following may also blink (in relation to a specific Kandy model):

- in Smart - the topmost indicator in the countdown system plus the “Intensive wash” light;

- in Grand – “Intensive wash” in combination with the leftmost indicator “90”;

- in Holiday and Aquamatic - the “cold water wash” indicator.

In older models, there may be other combinations of LEDs involved, and only the number of blinks will matter - there should be 16 of them.

Possible faults requiring repair

If the tips above did not help, and Bosch continues to signal error F 16, a breakdown has probably occurred. According to the experience of RemBytTech specialists, the appearance of code F16 / E16 is associated with the following breakdowns.

| Signs | Breaking | Repair or replacement | Cost* (work only) |

| Bosch does not lock the door; the display shows code E16 or F16. | UBL is broken. Most likely, the hatch locking device has burned out or been mechanically damaged. Failure of the UBL is the most common cause of this error. | A faulty hatch locking device must be replaced with a new one. | from 1600 rub. |

| The control unit is faulty. Probably, the radio elements have failed or the tracks in the UBL circuit have burned out. | The technician diagnoses the board, and based on the results:

In difficult cases, the technician completely changes the control board. | from 2500 rub. | |

| The wiring or contacts in the UBL circuit are faulty. Over time, due to prolonged use and vibrations during operation, the wiring/contacts fray, rot or burn out. Sometimes wiring is damaged by mice or rats (especially in the private sector). | The technician “rings” the circuit and finds the break point. Then:

| from 1900 rub. | |

| The door does not physically close; the tongue does not fit into the groove. The display shows code E16. | The hatch hinge/hinges broke/sagged . Mechanical damage to the hinges may be due to incorrect operation of the machine: perhaps you slammed the hatch with force or a child rode on it. Due to the skew, the tongue does not fit into the groove of the lock and it is impossible to close the door. | The hinge(s) need to be replaced with new ones. | from 1500 rub. |

| Warp of the tongue in the lock. The tongue was probably damaged mechanically or the guide was broken. | The master changes the lock to a new one. If the fastening on the door breaks off, the entire hatch will need to be replaced. | from 1500 rub. |

*Prices are indicated only for the work of the master. Spare parts are paid extra.

Note! After fixing the problem in most Bosch models, you need to reset the error from memory. If you turned to a third-party technician or carried out the repair yourself, do not forget to reset the code after the work is completed. How to do this - read our article How to reset an error in a Bosch washing machine.

Bosch washing machines are high-quality equipment with high maintainability. Of course, if you entrust its repair to professionals, such as the masters of RemBytTech. To call a specialist, call:

+7 (495) 215 – 14 – 41

+7 (903) 722 – 17 – 03

RemBytTech specialists have repaired more than 5,000 Bosch washing machines. They will help yours too. We leave promptly - within 24 hours from receiving the application. We provide a guarantee for repairs of up to 2 years. We work to ensure that your equipment pleases you for many years to come!

Faulty wiring and control module

It is possible that the hatch locking mechanism is working properly, but code F16 still appears on the display of Bosch equipment. Then you need to check the wires between the control module and the UBL.

To perform this work, it is necessary that the wiring of the interlock device be freely accessible. This is achieved by removing the rubber cuff.

After gaining access to the wiring, you need to check it for breaks. It is also necessary to check and clean the contacts. If after this the fault does not manifest itself, then the electronic module is probably the culprit for error F16.

You only need to check and repair the control module of a Bosch unit yourself if you have the appropriate knowledge and experience. The best solution is to entrust this work to a specialist. Then you will be able to avoid unnecessary waste of money and time.

Preventive measures

To avoid the problem of Bosch hatch blocking, you should remember the following preventive measures:

You should not slam the hatch door or close it in a big way.- Do not forcefully close or open the door as this may cause damage.

- The Bosch washing machine must be protected from the pranks of children and the pranks of pets.

- When putting things into the drum, it is necessary to ensure that the laundry does not interfere with closing the door and does not fall into the lock.

- You should not compact things into the drum, since the application of force negatively affects not only the functionality of the hatch locking device, but can also lead to other malfunctions and breakdowns of the Bosch washing machine equipment.

- If power surges often occur in the apartment, this can have a detrimental effect on the control unit of the Bosch washing machine and other components. In order not to put the device at risk, you can install a voltage stabilizer by connecting the washing machine to the network through it.

How is the hatch blocked?

In a Bosch washing machine, blocking the hatch door takes place in two stages . First, the door closes mechanically. At the same time, a characteristic click is heard, which indicates the lock is closing.

After the mechanical part is completed, a signal for electronic blocking comes from the control board. If a failure occurs at one of the stages, the washing process does not start, and the display shows the coding F16 (E16).

Emergency actions if an error occurs in the dishwasher

All methods of handling the dishwasher are described in detail in the instructions. There is not always time to choose and think for a long time about what actions to take. In such situations it is necessary to interrupt the program. To do this, turn off the device for 20 minutes or press the Start button for 15 seconds. After this, they begin to understand the cause of the problem.

If the breakdown is simple, for example, the water drain hole is clogged and the PMM has not completed the program, then you can fix it yourself. In the first case, the drain is cleaned, in the second, the program is restarted. But there are situations when the reason is completely unclear. This requires the help of a master.