The history of the Zanussi brand, widely known throughout Europe, dates back to 1916, when, under the leadership of Antonio Zanussi, the first wood-burning kitchen stove of this brand was produced at a small enterprise in the city of Pordenone (Italy). During its first 30 years of existence, overcoming the difficulties associated with two devastating wars, Zanussi made an enormous contribution to the recovery of the Italian economy.

Over time, the company moved from artisanal manual labor to industrial production and increased the range of manufactured goods. In 1954, the first refrigerator rolled off the assembly line, and in 1958 the production of washing machines began. These were the years of success for Zanussi, and household appliances from this brand quickly gained popularity.

In 1984, the Electrolux concern bought a controlling stake from the Zanussi family, and in 1985, Zanussi finally merged with Electrolux. A new rise in the popularity of the brand began. Currently, Zanussi occupies a leading position in terms of production of household appliances in Europe. The company's automated plant in Porcia (Northern Italy), built in 1992, alone produces 1.5 million washing machines of 700 different models annually. Zanussi is famous for its world's narrowest washing machines - there are models just 32 cm deep.

In the field of design, Zanussi confirms its excellence by developing the Soft Tech direction, within which the company creates new trends based on the rejection of straight lines and angles in favor of more natural, soft and rounded shapes. In addition, Zanussi demonstrates an original approach to the use of color in design solutions.

Zanussi washing machines, as well as other Electrolux products, widely use plastics (Carboran material from which the tank and other structural elements are made), washing systems with direct water injection into the tank (Jetsystem), Turbo Dry drying systems, modern electronic control systems (Fuzzy Logic). As a result, the company manages to achieve high results in wash quality. Thus, the FL 1600 input washing machine with the Fuzzy Logic control system has all three classes A (energy consumption, washing quality and spin quality).

The technical characteristics of some Zanussi washing machines are given in table. 1 and 2.

Table 1 Technical characteristics of Zanussi front-loading washing machines

| FLS 414 CN | FL 503 CN | FLS 552 C | FLS 572 C | FLS 872 C | FCS 872 C | FLS 874 CN | FL 904 CN | FLS 1074 C | FJS 974 N | FJS 1174 C | FL 12 INPUT | |

| Loading dry laundry | 4,5 | 3,5 | 4,4 | 4,0 | 4,5 | 3,0 | 4,0 | 2,8 | 4,5 | 4,0 | 5,0 | 5,0 |

| Dimensions (HxWxD) | 85x60x45 | 85x60x32 | 85x60x55 | 85x60x45 | 85x60x55 | 67x49x52 | 85x60x45 | 85x60x32 | 85x60x54 | 85x60x45 | 85x60x58 | 85x60x58 |

| Maximum drum rotation speed during spinning, rpm | 400 | 500 | 500 | 500 | 800 | 800 | 850 | 900 | 1000 | 900 | 1100 | 1200 |

| Tank material | Carborane | Carborane | Carborane | Carborane | Carborane | Carborane | Carborane | Carborane | Carborane | Stainless steel | Carborane | Stainless steel |

| Tank volume, l | 38 | 26 | 41 | 38 | 41 | 27 | 38 | 38 | 42 | 38 | 42 | 46 |

| power, kWt | 2,25 | 1,8 | 1,95 | 1,95 | 1,95 | 1,90 | 2,20 | 1,70 | 2,20 | 2,20 | 2,20 | 2,20 |

| Energy consumption kWh* | 1,3 | 1,2 | 1,39 | 1,3 | 1,45 | 1,03 | 1,20 | 1,00 | 1,20 | 1,20 | 1,30 | 1,07 |

| Water consumption, l* | 80 | 63 | 80 | 80 | 75 | 60 | 74 | 65 | 72 | 54 | 54 | 47 |

| Washing time, min* | 135 | 130 | 133 | 135 | 140 | 135 | 130 | 115 | 125 | 125 | 125 | 128 |

| Energy class | D | E | D | D | E | E | D | F | C | D | C | B |

| Washing quality class | D | D | C | D | B | C | B | C | B | B | B | A |

| Spin quality class | F | E | E | E | D | E | D | D | C | C | B | |

| Residual humidity, % | 85 | 78 | 78 | 78 | 66 | 73 | 64 | 64 | 60 | 62 | 60 | 53 |

| Jetsystem | √ | √ | √ | |||||||||

| Gentle rinse | √ | √ | √ | √ | √ | |||||||

| Weight, kg | 66 | 58 | 65 | 70 | 63 | 57 | 67 | 55 | 71 | 71 | 73 | 76 |

| * - When washing cotton fabrics at a temperature of 60 ° C | ||||||||||||

Table 2 Technical characteristics of Zanussi washing machines with drying and top loading

| With drying | Top loading | ||||||

| WDS 872 C | WDS 1072 C | WD 15 | TL 563 C | TC 874 | TL 870 C | TL 974 C | |

| Loading dry laundry | 5,0 | 5,0 | 5,0 | 4,5 | 4,5 | 4,5 | 4,5 |

| Dimensions (HxWxD) | 85x60x58 | 85x60x60 | 85x60x55 | 85x60x58 | 85x40x60 | 67x40x60 | 85x40x60 |

| Maximum drum rotation speed during spinning, rpm | 800 | 1000 | 1500 | 500 | 800 | 800 | 900 |

| Tank material | Carborane | Carborane | Stainless steel | Carborane | Stainless steel | Carborane | Carborane |

| Tank volume, l | 42 | 42 | 46 | 42 | 42 | 42 | 42 |

| power, kWt | 1,95 | 1,95 | 2,20 | 1,95 | 2,30 | 2,30 | 2,30 |

| Energy consumption kWh* | 1,30 | 1,20 | 1,15 | 1,30 | 1,20 | 1,20 | 1,20 |

| Water consumption, l* | 42 | 42 | 45 | 79 | 79 | 78 | 68 |

| Washing time, min* | 125 | 125 | 130 | 135 | 135 | 135 | 115 |

| Energy class | C | D | B | D | C | C | C |

| Washing quality class | C | B | A | D | D | C | C |

| Spin quality class | D | C | D | F | D | C | C |

| Residual humidity, % | 66 | 60 | 53 | 80 | 64 | 64 | 62 |

| Jetsystem | √ | ||||||

| Gentle rinse | √ | √ | |||||

| Weight, kg | 78 | 76 | 88 | 67 | 74 | 63 | 67 |

| * - When washing cotton fabrics at a temperature of 60 ° C | |||||||

The designations of Zanussi washing machines and their explanation are given in table. 3 and 4.

Table 3 Designations of Zanussi washing machines

| Model | 1st group of letters | Group of numbers | 2nd group of letters | ||||||

| 1 | 2 | 3 | 1 | 2 | 3 | 4 | 1 | 2 | |

| WDS 1072 C | W | D | S | 1 | 7 | 2 | C | ||

| FLS 874 CN | F | L | S | 8 | 7 | 4 | C | N | |

| TC 563 C | T | C | 5 | 6 | 3 | C | |||

Table 4 Explanation of the designations of Zanussi washing machines

| Position | Meaning | Example |

| 1st group of letters | ||

| 1, 2 | Type of machine, body, presence of Jetsystem | FL - front loading, standard housing FC - front loading, compact model FJ - front loading, Jetsystem system TL - top loading, standard housing TC - top loading, compact model TJ - top loading, with Jetsystem system WD - machine with dryer |

| 3 | Design line | S - Soft Tech design |

| Group of numbers | ||

| 1,2 | Maximum drum rotation speed during spin cycle | 4 - 400 rpm. 7 - 650/700 rpm. 9 - 850/900 rpm. 15 - 1500 rpm |

| 3 | Design option | |

| 4 | Number of function buttons | |

| 2nd group of letters | ||

| 1,2 | Design Features | N - depth 42 or 31.5 cm E - electronic control system C - plastic tank (Carboran) H - economical energy consumption I - built-in version (Incasso) |

Puddle formation

Typical breakdowns include problems with major parts.

- Failure of the pipe.

- Formation of cracks on the hatch cuffs.

- Poor quality gasket of the supply pipe.

- Drum leak.

You can replace the gasket of the supply pipe yourself. For other types of repairs, you should contact a specialist.

Zanussi washing machine: 6 faults and their elimination

The most common malfunctions of Zanussi cars include:

- inability to open the hatch at the end of the washing process;

- difficulty closing the hatch;

- difficulties with getting water into the system;

- increased noise level of the unit during spinning;

- drum static;

- The machine leaks - a puddle forms under it.

In order to properly repair a Zanussi washing machine with your own hands, you need to establish the cause of the breakdown.

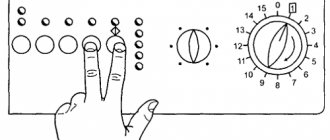

Disassembling a top-loading machine

By design, such lt;pgt;SMA - automatic washing machines.lt;/pgt;”gt;SMA differ from front-facing ones. Some work is more convenient to perform because there is good access to parts.

Don't forget to disconnect from electricity, water supply and sewerage.

Let's look at the step-by-step actions:

- Remove the side panels.

To do this, unscrew the screws at the back and one at the bottom at the front. As a result, we will have good access to all elements. View of a top-loading washing machine with the side of the body removed - We dismantle the engine, pump, water level sensor.

We use the same tools and approaches as in the case of front loading. Disconnect the terminals and contacts. We bite off the clamps. Pull off the drive belt. Top loading sma pulley - Lift the top cover and take out the powder dispenser.

It is attached with latches. Vertical washing powder tray - We dismantle the cover, releasing the fastenings.

We pull off the rubber. There are several fastening screws there. We take out the plastic strip. Removing the cover - We unscrew the screws connecting the upper part to the body and lift it.

After this, we will have access to lt;pgt;UBL - washing machine hatch locking device.lt;/pgt; lt;pgt;There are mechanical and electronic devices.lt;/pgt; “gt;UBL and cuff. Removing the top part - Remove the control panel.

There is a module inside. Disconnect the contacts and pull it out. Panel with control module - We dismantle the shock absorbers.

- We remove the counterweights.

- After this you can remove the tank. It hangs on 4 springs.

Important! To replace bearings in top-loading washing machines, the tank cannot be removed!

We invite you to read How to clean a washing machine from scale, dirt and odors: step-by-step instructions

To do this, just remove the calipers. As a rule, they are replaced. A short video to help.