The principle of operation of the tachogenerator in a washing machine

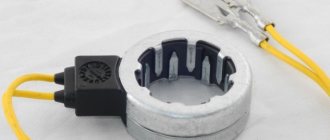

The principle of operation of the tachometer is quite simple. The tachogenerator itself is located on the motor shaft and is a small ring with wires. When the motor rotates in a ring, voltage is generated due to the magnetic field (generator principle), the higher the speed of rotation of the motor, the higher the voltage. Accordingly, by measuring this voltage, you can obtain the engine rotation speed.

It is to measure the engine rotation speed that the tachometer in the washing machine is used. The operating principle is as follows. Let's say the engine spins up and begins to rotate the drum, in order to activate the spin, you need to increase the engine speed to 800 rpm. The control module gives a signal and commands to increase engine speed, but when should you stop raising the speed? This is why a tachogenerator is needed; it constantly provides engine speed parameters and thereby allows the control module to make decisions about the engine rotation speed.

What is a tachometer and how it works

This device looks like a small iron ring with a pair of wires. It is located on the electric motor shaft. When the latter rotates, the tachogenerator is subject to voltage, which is influenced by the electromagnetic field. Then, in accordance with the increase in the number of revolutions, the voltage also increases.

This creates the resistance needed to measure the speed of the rotating motor shaft through voltage force. Then all data is sent to the management module.

Thus, using a tachogenerator, the number of revolutions in the washing machine is controlled.

Symptoms of a faulty tachometer

If the tachometer in a washing machine breaks down, it begins to behave as follows. Since the number of revolutions is not controlled, the machine begins to rotate the drum at the wrong speed. During washing, the speed may be too high, but during spinning, on the contrary, the speed does not rise. The machine may not spin the laundry at all. Such “glitches” indicate that one of the reasons for their appearance may be the tachometer. To check the tachogenerator of a washing machine, you must first get to it.

These symptoms can occur not only due to a breakdown of the tachometer, but as a result of other malfunctions of washing machines.

Getting to know the device

Before you are interested in how to check the tachometer on a washing machine, you need to get an idea of what this part is. A tachometer, or tachogenerator, is a small measuring device located at the rear of the engine shaft. Tachogenerators have a magnetic rotor and a coil, through which an alternating voltage of varying amplitude is generated, which depends on the speed at which the shaft rotates. In general, the tachogenerator is a sensor that provides feedback between the control electronics and the engine, due to which the engine rotates at a stable speed under any load.

The question of how to check the tachometer in a washing machine arises if you need to check the performance of the engine. Washing machines use a synchronous AC tachometer. Thus, if the rotor rotates faster, this will affect the amplitude of the signal. Read more about the signs of breakdown and how to check the tachometer below.

Where is the tachometer located in a washing machine?

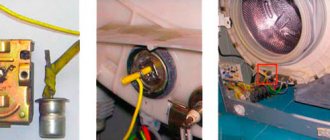

The tachogenerator of the washing machine is located on the motor shaft, which is installed at the bottom of the washing machine. To get to the engine, you will need to remove the back wall of the machine. To do this, unscrew the bolts that secure this wall and remove it. The engine is located at the bottom and is connected by a belt to a pulley, you can see it right away.

The tachometer is located on the rear of the engine on the shaft. To check or replace it, you will need to remove the engine; this procedure is described in detail in the article on repairing a washing machine engine with your own hands.

Sensor location

Finding the sensor is not difficult, since on all washing machines from LG and other brands (except for models with an inverter motor), it is located on the rotating motor shaft. To remove the tachometer, you will first have to dismantle some elements of the washer: disconnect the rear panel of the case and remove the drive belt.

Before any repair work, unplug the washing machine and turn off the water.

When you get to the motor, look for a small iron ring on the shaft - this is what the tachometer we need looks like. Carefully remove the entire engine, since you cannot immediately detach the tachogenerator from it. If you have no experience in electrical installation, then it is better not to experiment, but to call specialists so as not to damage the washing machine even more.

How to check the tachometer on a washing machine

To check the tachogenerator, it is not necessary to remove it from the engine, but the engine itself will have to be removed from the washing machine. First you need to remove the belt from the motor shaft. Next, tighten the bolts securing the motor, pull the motor out, having first disconnected the wires from it.

To check the tachometer for functionality, do the following:

- First, disconnect the tachometer wires from the connector, and then measure the resistance on them. To do this, you will need a multimeter, which must be set to resistance measurement mode. The normal resistance of the tachogenerator should be around 60 Ohms. By the way, you can perform this procedure without removing the engine from the washing machine.

- To make sure that the tachogenerator is working and producing current when the engine rotates, switch the multimeter to voltage measurement mode. While measuring the voltage at the tachometer terminals, turn the engine by hand. The tension must rise. When the motor is rotating, it is usually around 0.2V.

- If everything is fine, check the tachometer generator mounting bolt, very often it loosens and the sensor begins to “glitch”. If he is relaxed, tighten him up.

If your tachogenerator does not pass these tests and its mounting bolt is too tight, then it is time to change it. The tachometer most often breaks down due to the washing machine being overloaded.

The tachometer itself rarely fails, because it is a fairly reliable part, so check all its connection contacts, as well as other faults.

Symptoms of a problem

In the system of an automatic washing machine, a speed sensor, also known as a tachometer, also known as a tachogenerator, the role of which is performed by a conventional Hall sensor, is necessary to correctly maintain the speed of the drum. The most common form factor of this sensor is a coil, the contacts of which are included in the common block of the electric motor power wires. The principle of operation of a tachogenerator is that a magnet (rotor) rotates inside its coil (stator), securely attached to the motor shaft. When a difference occurs in the rotation speeds of the rotor and stator, the resistance and voltage on the coil turns change. The control unit reads these readings and compares the rotation speed of the electric motor and the washing machine drum. If the speeds do not match, the controller adjusts them as needed.

If the tachometer fails, the washing machine may experience the following symptoms:

- Arbitrary uncontrolled change in rotation speed during a single cycle.

- The machine washes too quickly (more than 50 rpm).

- The machine spins too slowly (less than 400 rpm).

However, behind such symptoms there may be other malfunctions that do not require dismantling the housing elements. To exclude them, you must:

- check if the spin button sticks;

- allow the electronic control module to reboot by disconnecting the washing machine from the home power supply for 15-20 minutes.

If these actions have no effect, it is necessary to check the correct operation of the tachometer or replace it with a new one.

How to replace the tachometer in a washing machine

First, we need to remove the tachometer from the washing machine. To do this, you first need to disconnect the tach sensor connectors, if you have not already done so. The connectors can either simply be pulled out or be secured in a common socket, from where they need to be carefully pulled out. Using a thin slotted screwdriver. Next you need to remove the tachometer cover; it usually snaps into place. Lids can be metal or plastic. The cover can also come with the tachogenerator and is secured with bolts. We unscrew the bolts that secure the tachometer and remove it.

Assembly occurs in reverse order. In the video below you can see how to remove the motor from the washing machine.

In a machine with an inverter motor

Where is the Hall sensor located in washing machines of this type? It is located inside the electric motor. However, this arrangement will not prevent you from freely approaching the element. The sequence of actions will be as follows:

- remove the rear wall of the unit housing by unscrewing the bolts holding it. On some models of washing machines, the top cover may interfere with this, in which case it will have to be removed;

- inspect the inverter motor cover. It is located on the cross of the rear wall of the drum;

- Loosen the locking center nut and carefully remove the motor cover.

Removing the cover, you will see the tachometer. Once the location of this part has been determined, diagnostic measures can begin.

About replacement

Replacing the tachogenerator in a washing device is carried out as follows:

- Disconnect the wires from the connector.

- Remove the top cover of the tachogenerator, which is secured with a latch.

- Unscrew the fasteners on which the sensor is installed.

- We dismantle the broken part and install a new one.

Call the master

Repair of Hall Sensor SMA LG (6501KW2001A)

Manufacturers of washing machines strive for constant improvement and creation of competitive advantages, the Korean company LG is no exception, and many craftsmen have already encountered their drum drive motors, which differ from the classic design in the absence of a drive belt and additional “wear elements” (commutator brushes, armature bearings and lamellas)

On the one hand, direct drive washing machines are more reliable, but on the other hand, they also received additional elements unique to their class of electric motors

Article on the topic: Is it possible to pour vinegar into the washing machine?

The number of rotation speeds is controlled by a microcontroller, which “sees” this information using

In the last article I wrote about the hall sensor in Whirlpool washing machines, but there are design differences from LG

The PCB has Part Number EBR375603! Let's get acquainted with the Sensor pins, according to the pinout on the printed circuit board: 1 pin - Sb 2 pin - Sa 3 pin - NC 4 pin - GND 5 pin - VCC

Resistance between the contacts of the working sensor: Between pins 5(VCC) and 1(Sb), 5(VCC) and 2(Sa) is equal to - 10 kOhm (10.32 kOhm is a very good indicator, but in practice it can be 9.32 kOhm , are considered to be the performance indicators of the sensor - tested experimentally). If you do not have readings between the terminals, then it is often enough to replace the SMD Resistors: - Between terminals 5 (VCC) and 1 (Sb) these are resistors - R03S 681 (1206) = 680 Ohm and R04S 681 (1206) = 680 Ohm - Between pins 5(VCC) and 2(Sa) are resistors - R01S 681 (1206)=680 Ohm and R02S 681 (1206)=680 Ohm

But even if you have a resistance of 10 kOhm, you shouldn’t rejoice in advance, the sensor may still not be working due to the Hall Sensor - W12C! If this is pin 1(Sb) – IC02S and 2(Sa) – IC01S! When there were no “donors”, I found a working analogue of the Hall sensor: bipolar - Hall Sensor SS41 (4.5-24v), which had to be modified with an SMD resistor - 103 (1206) = 10 kOhm as shown in Figure 2 and Figure 3!

Article on the topic: How a Zanussi washing machine works

Consider the fact

– if you install the resistor not at the same level with the TO-92 Hall Sensor housing and leave excess solder, the board will not fit into the plastic housing, and if you try to connect it with force, the resistor will come off or damage the Hall Sensor! When replacing Hall Sensor SS41, take into account the height of the mounted part, it is 12.1 mm! (Fig. 4) SMD parts included in the LG Hall sensor: IC01S - W12C (analogue of Hall Sensor SS41) IC02S - W12C (analogue of Hall Sensor SS41) R01S SMD marking - 681 (housing 1206) = 680 Ohm R02S SMD marking - 681 (housing 1206 )=680 Ohm R03S SMD marking - 681 (case 1206)=680 Ohm R04S SMD marking - 681 (case 1206)=680 Ohm C01D (C3)- 100 nF case 0805 C02S (C2)-10 nF 50V case 0805 C01S (C1 )-10 nF 50V housing 0805

It is also possible to install resistors R1 and R2 marked SMD - 331 (case 1206) = 330 Ohm (Fig. 7). The sensors differ from each other in the location of the elements, this can be seen in Fig. 5, Fig. 6, Fig. 7!

We draw conclusions: I removed all the SMD elements from the board and replaced them with new ones! The sensor was assembled and tested for SMA, the entire washing cycle was successful! After that, I filled the board with transparent sealant Ceresit CS 24 and a business card, aligned the contours - it turned out no worse than the factory.

Article on the topic: How to install a sink above a washing machine

The role of the sensor in the SZ system

If the sensor or DC malfunctions, problems arise related to the direct functioning of the engine. The car may not start at all or behave extremely poorly on the road. Is it really possible for such a small element as DH to have such a powerful effect on a car’s engine? Yes, yes.

What is DH? This is a controller capable of sensitively responding to any changes in the magnetic field. If the DC is faulty, the injector stops functioning.

The interaction of the DC with the ignition system in the electrical sense is carried out through a switch or conductor. As a result, a magnetic field appears.

Source

The role of the sensor in the SZ system

If the sensor or DC malfunctions, problems arise related to the direct functioning of the engine. The car may not start at all or behave extremely poorly on the road. Is it really possible for such a small element as DH to have such a powerful effect on a car’s engine? Yes, yes.

What is DH? This is a controller capable of sensitively responding to any changes in the magnetic field. If the DC is faulty, the injector stops functioning.

The interaction of the DC with the ignition system in the electrical sense is carried out through a switch or conductor. As a result, a magnetic field appears.

DIY tachometer

Manufacturing and replacing a Hall sensor is possible in several ways, it all depends on the type of chip used:

- Purchase an ACS711 chip, the output of which is connected to a differential amplifier. To power the circuit, you can use any DC source that provides a voltage of at least 3.5 V.

- Make a contactless electromagnetic relay with the required characteristics.

- Buy a ready-made tachometer. For washing machines, the recommended regulator is type MLX91206, used in the automotive industry.