How to call a specialist

To call a specialist, you need to call the service number (from 8 to 22.00):

+7 (495) 215 – 14 – 41

+7 (903) 722 – 17 – 03

Or send an electronic application from the website (at any time of the day). In your message, please indicate:

- Make and model of the faulty machine.

- Symptoms of dysfunctional behavior. For example, the washing machine does not open, turn on, or remove detergent from the detergent tray.

- The time of arrival of the master is suitable for you.

- Contact information: your name, address, phone number.

On the day of the repair, the repairman will contact you at the number specified in the request to agree on a time of arrival that is convenient for you.

Cleaning the filler filter

Washing machines also have a filler filter element in the form of a mesh that does not allow foreign objects and impurities to enter. Such devices are not provided in all car models.

Signs of a clogged filler filter are:

- reduced pressure of water entering the machine;

- increasing washing time;

- The device works well, but when filling it hums and does not fill with liquid.

The element is connected to the inlet hose and is located near the water supply valve.

The filter for the water intake system is located at the top of the machine; in order to access it, you need to unscrew the water supply hose

Step-by-step cleaning instructions

To fix the problem, you will need to clean the fill filter.

This is done in the following sequence:

- Before cleaning, turn off the water.

- The filler tube is removed, after which the filter mesh will be visible.

- The mesh is removed using pliers. This must be done carefully, as it is very fragile and can break.

- The extracted element is cleaned and washed with water.

- The clean filter is returned to its place and the hose is attached.

Models may differ in design, but the procedure remains the same.

The removed inlet hose or its individual parts are washed to remove dirt under running water. Particularly dirty areas are cleaned with an old toothbrush.

Particular attention is paid to the filter, which is usually located under the cover, within reach.

The inlet filter, which we need to clean, is a mesh that covers the hole. This is a lightweight element consisting of metal or plastic

It is not possible to clean the filter located inside the washing machine body, so it must be removed.

The resulting contamination must be removed. To do this, pull out the filter using pliers or a similar tool with narrow “legs”

When using pliers, you need to be as careful as possible so as not to damage the filter.

The more time has passed since the last filter cleaning, the more dirt accumulates on it, and the worse water flows into the car. The filter removed from the socket is thoroughly washed, cleaned with a soft brush and put back in place.

The performance of the filter is affected by the quality of the water. The tougher it is and the more impurities it contains, the more often it will have to be cleaned. For uninterrupted operation of the machine, you can use special filters that are additionally installed for washing machines.

What breaks most often

Considering that Brandt machines have been sold throughout our country for more than 20 years, service center technicians have long identified weak points and compiled a list of probable malfunctions of such automatic machines.

All models that end up in workshops exhibit almost the same problems:

Pump (water drain pump). This is the main Achilles heel of verticals. The pump life is no more than 5 years. The part begins to worry about malfunctions and malfunctions.

Clogged drain and fill system. This applies not only to Brandt equipment, but also to machines of other brands. Many regions of the Russian Federation are famous for hard water, which clogs the systems. The human factor cannot be excluded - for example, the drain filter most often becomes clogged with debris left in clothing pockets.

- Temperature sensor. In any modification - Economy or Premium class, the temperature sensor is not the strongest point. Masters note that they often change sensors already in the third year of operation of the SM.

- The next vulnerable part is the heating element. And again this is due to the hardness of the water. If the water is soft and you don't indulge in high-temperature wash cycles, the heater should last 10-15 years. If everything is the other way around, the heating element will burn out due to scale in the first years of operation of the equipment.

Important! All other components and parts of Brandt machines, regardless of the place of assembly, are of high quality, so we will pay attention only to problem areas of the equipment

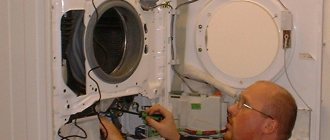

Description of the work progress

Do not forget that the motor runs on electricity, so before dismantling it, disconnect the SM from the power supply

Then you need to very carefully disconnect the engine from the tank; to do this, remove all wire contacts

Before you start replacing brushes, make sure they need it. Look at the rods. The main problem is that the rods wear out and wear unevenly. The brush must be replaced when the length of the handle is 1.5-2 centimeters. If some elements are almost intact, do not touch them, change only those that are really out of order. Be prepared for the fact that you may need to repair the engine more often than once every six months.

Also take a photo or sketch how the brushes are inserted into the grooves, namely: seating depth, bevel direction, etc.

This is important, since if assembled incorrectly, the motor may spark after connecting to the network

Since you are dismantling the motor to replace the brushes anyway, inspect the internal commutator as well. It happens that dirt settles there, or small scratches appear. These defects must be eliminated. Take a rag or dry brush and brush off the dust; scratches can be easily sanded off with a piece of sandpaper.

Now you can begin installing new parts. The brushes are attached to self-tapping screws. Once again, carefully check that everything is installed correctly. If everything is in order, proceed to reassemble your home assistant using the previously recorded data. Don't forget to put the wiring back in place and attach the motor to the washer tank. Now it's time to test your work in one of the following ways:

- set the wash cycle to idle, turning on the spin cycle;

- run several quick wash cycles.

Don’t forget to periodically inspect the condition of your motor, clean and lubricate it if necessary, and also carry out minor repairs yourself. After all, it is easier to prevent a breakdown than to fix it, and then error D07 will definitely not bother you anymore.

MAINTENANCE OF THE MACHINE Important: To clean the housing, control panel...

Page 22

- Image

- Text

RU

22

5 / MAINTENANCE OF THE MACHINE

Important:

To clean the housing, control panel

When cleaning and plastic parts in general, use a soft cloth dampened only with water or liquid soap.

Never use: – Abrasive powders – Metal or plastic scourers – Alcohol-based products (ethanol, thinners, etc.)

CLEANING THE MACHINE

•

CARE OF INTERNAL MECHANISMS

•

For reasons of hygiene, we recommend: – After washing, leave the lid open for a short time. – Clean plastic and rubber elements in the access path to the camera approximately once a month using products containing a small amount of chlorine. Perform a rinse cycle to remove any remaining product. – Run a wash cycle at 90°C at least once a month.

CLEANING THE DETERGENT CONTAINER

•

Clean the container regularly. To do this: – Press the tabs at the same time

on both sides

container for removing it from the socket (Diagram D20)

. – Remove siphons

from the back of the container

and disconnected

Remove the container and its front cover (Diagram D21)

. – Rinse all elements with tap water (do not forget to drain any remaining water from the container). – Collect the container. Make sure that the container base is firmly connected to the front cover, and then return the assembled container to its original position under the machine cover.

PERIODIC CHECKS

•

To avoid possible damage, we recommend checking the condition of the supply and drain hoses regularly. If you find small cracks, do not delay replacing the hoses. Identical hoses can be purchased from the manufacturer or its Customer Service Department. The procedure for replacing the water supply hose is described in the “CONNECTING A COLD WATER SOURCE” section.

REPLACING THE POWER CABLE

•

Warning:

For safety reasons, replacing the electrical cable and, depending on the model,

All electrical box and auxiliary wiring must be done by Customer Service or a qualified electrician.

The most common faults

The most common breakdowns will be discussed below. To eliminate them, it is not always necessary to call a specialist. In some cases, the situation can be corrected on your own. It will be explained in detail what needs to be done for this.

If there is a blockage

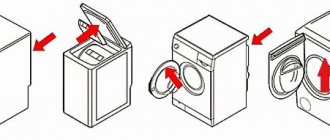

Many people believe that this is the scourge of washing machines. However, you can handle this on your own. With proper operation and proper correction of what happened, no problems should arise. As you know, some machine models use vertical loading, while others use horizontal loading. Their drainage is located differently, but this does not create problems. First, let's look at what needs to be done in horizontal loading machines. There are two options here:

In the first case, we open the washing machine and see approximately the following picture:

After doing this, the problem will most likely be fixed.

On top-loading machines, the drain hole is at the bottom and is easy to see.

In some cases, the blockage remains. This means that the pipes still need to be cleaned. They are quite wide, but this does not exclude the possibility of clogging.

To do this, we do this.

It is advisable to do such cleaning not only when a problem occurs. If done periodically every two or three months, this will be an effective preventive measure to combat blockages.

Repair of inlet valve filters

Unfortunately, the creators of Brandt washing machines created their equipment, assuming that it would use only purified water. Therefore, inlet filters are designed mainly for such water. However, given that in various cases the incoming water can have not only a high degree of purity, but also a very low one, there are often cases when these filters become clogged. If this happens, they need to be cleaned.

It's not difficult to do this yourself.

Although this filter may become dirty periodically and will need to be cleaned each time, it is not recommended to remove it. In this case, water will flow into the machine of the same quality as flows through the pipes. This risks contaminated water getting into the car.

If there are problems with water heating

If the heating of the water stops during washing, or vice versa, the water is hotter than necessary, you need to inspect the heating element (heating element) and temperature sensor. We'll show you. How to do this in washing machines that use top loading.

You can do this yourself as follows.

It is important to remember that only the original heating element must be installed, specifically for this particular model of washing machine. It is not recommended to use a similar unit, it can lead to equipment breakdown

If such a part is not available, you need to order it and wait for delivery.

Faulty drain pump

This part is usually available for all major Brandt washing machines. This unit is relatively expensive, so it makes sense to make sure that it is in fact faulty and needs to be replaced.

This is done in this order.

When inspecting the drain pump, you need to pay attention to the bushing. Debris may accumulate there, which may cause poor performance.

If cleaning is done, the pump does not need to be replaced. But such a conclusion can be made only if the values shown by the multimeter correspond to the norm.

Operation of the electronic control module

It may be that a specific fault could not be found, but the machine still does not work. In this case, there is a high probability that the electronics that perform control functions in the washing machine are faulty. In this case, it is not recommended to troubleshoot Brandt washing machines yourself.

It is important not only to know how to carry out repair work correctly, but also to have the necessary experience. In this situation, it would be wisest to contact a specialist.

Removing blockages from the Brandt washing machine

If you want to repair your Brandt washing machine yourself, start by removing the blockages. Moreover, if you have never cleaned your machine, this will only benefit it. Blockages are a real scourge of washing machines, because few people go through things before washing and remove every little thing from them. And we cannot influence the quality of water in pipes at all.

If you need to repair a Brandt top-loading washing machine, then this has its own specifics: they are designed somewhat differently, unlike their vertical “brothers”.

Their drain filter is located inside the housing. For example, in the Brandt WM-1150 SM, the manufacturer provided for the location of the filter in the tank. If this seems complicated to you, we will reassure you: finding a filter is extremely simple:

- We remove one flap of the lid on the drum with our own hands, and do not touch the second, it is not involved in the repair.

- We unfold the drum and open its doors.

- We are looking for a filter (located at the bottom of the tank).

- We take it out, clean it, rinse it under the tap.

- We screw the sash into place and restore the location of the drum.

Attention! Cleaning the filter and pipes should be tightly included in the schedule of your household chores - pay attention to the drainage system at least 3-4 times a year. If you neglect this advice, the quality of the wash will sooner or later drop, and perhaps the wash will stop altogether.

If the filter has been thoroughly cleaned, but the water still stands and does not drain, then the pipes need to be cleaned. They can be accessed through the back panel. Having found the pipes, arm yourself with a screwdriver and loosen the clamps, drain the water and remove the pipes.

Simple problems

First of all, check that there is actually water in the tap. Perhaps there is a short-term shutdown of the central water supply in the house, which is why the equipment is “capricious”, giving error D01. If there is supply, check to see if the shut-off valve on the pipe is closed. What to do if the problem is not simple inattention? Immediately check whether the hatch is tightly closed. The automatic machine will not start drawing water if the system is leaky. Press the door against the body, perhaps the lock will work and the unit will start washing.

If you have not identified any external problems, you can proceed to diagnosing the washing machine. The test should be carried out from simple to more complex. First of all, it is better to inspect the inlet filter, inlet hose and inlet valve.

If the machine makes a loud noise while trying to fill, feel the inlet hose. Loosen the clamp and unhook the “sleeve” from the machine, then rinse it under running water. After cleaning the tube, it is necessary to inspect the filter mesh, which becomes clogged with impurities and dirt and stops passing water. You should proceed like this:

- unhook the inlet hose from the body (which has already been done if you washed the hose);

- find the mesh - it is located next to the inlet valve;

- Use pliers to grab the protruding edges of the filter;

- pull the mesh towards you;

- clean the filter, if necessary, leave it to soak in water with the addition of citric acid;

- install the filter mesh in its original place.

It would also be a good idea to check whether the coarse filter installed in the water pipe behind the shut-off valve is dirty. The nozzle is necessary for the primary filtration of water, so a lot of debris and impurities settle there.

You can clean the coarse filter using two wrenches. One needs to hold the joint, and the other needs to unscrew the nut securing the flywheel. Don't forget to place a basin next to it, as water will rush out of the hole when you remove the fasteners. There is no need to pull out the mesh - the powerful flow will deal with the blockage. Once you see that the nozzle is “like new” again, you need to put everything back.

Cleaning the drain filter

Using a drain filter, waste water is purified from various debris (coins, buttons, etc.). The filter element can become clogged due to the presence of impurities and heavy elements in the water.

Cleaning is necessary to prevent small organic and inorganic impurities from entering the pump and pipes, which can damage the parts.

A clogged filter reduces the throughput of the drain channel, and at the same time increases the load on the system pump. As a result, the pump wears out faster

Signs that cleaning is needed

A drain filter is also called a drain filter, a waste filter, and a pump filter.

Signs indicating the need for the procedure are:

- termination of all functions;

- difficulty draining liquid, during which it slows down or stops completely;

- when switching to the “Spin” mode, the system immediately turns off;

- The “Rinse” function does not work.

Each of the listed signs is a signal to take action to clear the filter of debris.

Procedure sequence

Before removing the filter, you need to stock up on a container for draining water and dry rags, covering the car with them and slipping them under the bottom. The fact is that even after draining, a certain amount of water remains in it. The rags will absorb the liquid and protect the floor from moisture.

To ensure safety, you will need to turn off the water and disconnect the machine from the electrical network, then drain the water from the washer tank

This is done because some models have components that cannot be disconnected from the power supply instantly. Once you are sure that the machine is completely turned off, you can start working. Before removal, the filter cover is unscrewed and pulled out of the socket.

After this, the following manipulations are carried out:

- Rinsing under running water.

- Cleaning contaminated areas with a brush.

- Cleaning limescale and getting rid of unpleasant odors by soaking in a solution of citric acid and water.

The filter seat in the machine is also cleaned, as debris may get stuck in it. To make the procedure easier, use a flashlight to illuminate dark areas.

The water from the washing machine tank is drained through the drain filter, slightly loosening its connection to the pumping system, or through the emergency hose that is equipped with the latest models from Bosch and Samsung

After removing debris and rinsing under running water, the clean part is installed in place.

Problems and solutions

When cleaning the filter element, you may encounter a problem. It consists in the fact that the lid does not turn.

The drain filter cover should turn freely counterclockwise and clockwise. It does not move when the washing machine has never been cleaned after purchasing it, and the filter has become stuck as a result of long-term use.

In such a situation, if you have an Indesit , lay the machine on its side and remove the pump. If the model is without a cover, you will see the pump. If there is a cover, it must be removed. After this you need to disconnect the wires. Next, you will need to unscrew the bolts holding the part and detach the electrics from the pump.

The filter is then treated with WD-40 liquid, opened and cleaned. After completing the procedure, the steps are carried out in the reverse order. When screwing on the cap, pay attention to how tightly it is screwed on. A poorly screwed lid will let water through.

Machines of different brands and models have different characteristics, so before carrying out work, you must read the relevant section in the instructions. Knowing their features will help you avoid difficulties. For example, in washing machines whose filter is secured with a screw, you will need to first unscrew the screw.

The drain filter, as well as the emergency hose, if the model has one, are located below behind the decorative hatch covering the machine maintenance components

If the design does not include a drainage filter, remove the washing machine body and check the volute, drain pump and pipes. Read more about disassembling units from different manufacturers in this article.

For machines such as Samsung , Ariston and Indesit , the drain filter is located at the bottom on the front side. LG and Bosch models

How to choose?

Choosing a washing machine for your home is an important and responsible task. It must be approached with full responsibility

In this regard, experts recommend that buyers pay attention to several key factors when choosing a household device

Load Type

Today on the household appliances market you can find washing machines, the loading of laundry into which can be done in one of 2 ways. So, there is a frontal and vertical method. The first of them involves loading dirty laundry into the machine using a special door on the front of the machine, and the second involves loading laundry by opening the machine from the top. Both options have both their advantages and disadvantages, so you should rely on your own comfort and convenience in this regard.

Dimensions

Washing machines from Brandt are available in a variety of sizes. Thus, official stores offer full-size, narrow, ultra-narrow and compact models. At the same time, the exact height, width and length data are specified in the operating instructions, which come standard with each device. Depending on the space you have, as well as personal preferences and needs, you can choose a device of one size or another.

Drum volume

The model line of washing machines from Brandt consists of models whose drum volume ranges from 3 to 7 kilograms. The choice of device in this regard depends entirely on your individual needs. For example, a large family needs a machine with a drum capacity of 7 kilograms, but a person living independently will need a 3-kilogram drum.

Washing efficiency

According to the generally accepted classification of washing machines, such an indicator as washing efficiency, which, in fact, is an indicator of the operating efficiency of a household device, is of great importance. So, today, washing efficiency is classified from A to G (respectively, from 5 to 1 points).

Spin efficiency

In addition to the quality of washing, the quality of the spin produced by the washing machine is also of great importance. It is classified from A to G (residual laundry moisture from 45 to 90%). Accordingly, at the end of the spinning process, the laundry can be wet or almost dry.

Required amount of electricity

The level of electricity consumption is classified from A++ to G (from 0.15 to 0.39 kWh/kg). Thus, a household appliance can significantly increase your material costs for paying for electrical energy.

Drying function

Some washing machines manufactured under the Brandt brand have a clothes drying function. It should be borne in mind that such models will cost significantly more than standard devices that are not equipped with such a function.

Appearance

When choosing a washing machine, which is inherently the most important household device, it is important to pay attention not only to its functional features, but also to the immediate appearance of the unit. This is especially important if you are renovating your house or apartment and want to give it a unified style and design. If you pay attention and take into account all these factors when buying a washing machine, then your household device will make your homework easier and will give you a lot of positive emotions.

If you pay attention and take into account all these factors when buying a washing machine, then your household device will make your homework easier and will give you a lot of positive emotions.

Tips for the Brandt WTD6384K washer dryer

August 15, 2011 +13

"Consumer" school

Cultural washing rules

It would seem that the machines in almost every home are automatic, the powders used are from global manufacturers, and washed clothes are not always pleasing with their whiteness and freshness, colored fabrics fade, and stains sometimes remain. And complaints are heard: the machine does not wash well, the powder does not wash well. Few people realize that the blame for poor quality washing falls not on the machine, not on the powder, but on the housewives’ inability to use it all correctly!

January 8, 2011 +1

professional advice

Typical washing machine breakdowns

Repairing a washing machine is not at all as simple as it might seem at first glance. Of course, the main thing is to correctly determine the cause of the breakdown. The time required for repairs primarily depends on this. We do not advise you to “diagnose” your washing machine yourself. This is not at all necessary, if the water is not heating, then the heater is broken, and if the water is not drained, the pump is broken. When the technician arrives to you, he may discover that the problem is not in the pump, but in the machine’s control unit...

January 8, 2011

"Consumer" school

Intelligent washing for blondes: which modes to choose?

No one does more dress-up work than fashion models and washer-dryers. There is one more similarity between them: both of them like to paint themselves in a radical white color. Blonde girls willingly participate in beauty contests, and we decided to organize an intelligence competition among washing machines. We have to evaluate our gorgeous blondes on a generally accepted point scale...

January 3, 2011 +2

"Consumer" school

May the machine serve you for a long time!

The durability of heating elements in a washing machine largely depends on the load: how often the house is washed. Heaters become overgrown with scale much faster when washing old clothes (a large number of individual particles of fabric are formed, which precipitate and thus create “soil” for lime deposits). But the main enemy of the washing machine is hidden in hard water.

January 3, 2011 +2

educational program

What class is the washing machine?

Cars equipped with the Fuzzy Logic system cost 3000-4500 rubles more than conventional models of the same class. And, along with ease of use, they provide significant (up to 20%) savings in energy and water.

Brandt faults

Check out our tips for repairing a brandt washing machine at home!

The birthplace of Brandt equipment is France. Devices of this brand are highly reliable and have original functionality. Top-loading washing machines assembled in France or Poland are supplied to Russia.

Moreover, the Polish assembly turned out to be of worse quality.

For disassembly you will need a star screwdriver (the French do).

- Error codes:

If there is no display, look at the flashing indicators. d01(1+2)- No filling d02(1+3)- No drain d03(1+4)- No heating d04(1+5)- Heating switch d05(2+3)- NTC sensor d06(2+4 )- No signal from the taxi generator d07(2+5)- Door does not lock d09(3+5)- Program selector error d10(1+3+5)- Water overflow d11(1+2+3)- Heater breakage d12( 1+2+4)- The door does not unlock d13(1+2+5)- The maximum spin speed is not reached d17- Parking sensor d18(2+4+5)- The network frequency is different from 50Hz d20- Incorrect floor release of hand d21- Electronic module

You should not rely on reliable information indicated in the transcript. First check the actuators with a tester.

- For example, error D07 for Brand is a UBL for ordinary people. And for the pros, these are first of all BRUSHES and only then UBL.

Specific malfunctions of the Brandt equipment are associated primarily with the vertical structure of the devices. The breakdowns that machines of this type suffer from include: failure of bearings, scale fouling of heating elements, clogging and breakdown of the pump, failure of electronics. Control units are usually reliable, but they can fail, especially if we are talking about a Polish assembly.

- Checking the drain pump:

There is one drawback: older models do not have a filter on the pump. Naturally, any debris from the tank gets into the pump blades.

Since there are problems with the supply of French spare parts in Russia, use analogues. For example, Plaset, Askoll.

You need to check the pump assembly on a typewriter. Water should come out of the drain hose under pressure when the drain (or spin) mode is turned on.

At idle it can rotate, but stand still under load. Due to dirt and debris, the impeller simply jams due to the axial excavation and that’s all.

- Motor brushes and block:

The motor can be commutator or asynchronous.

The exit of the brushes from the holders should be more than 10mm.

When the block is shorted, the motor stator windings may burn out.

It happens that the wear of the coals is slight, but they are jammed - pinched in the body by dust accumulated in the cracks. The seat needs to be cleaned.

The heating element is responsible for heating. An aggressive cleaning solution and hard water lead to scale fouling and overheating of the heating element.

Result: short circuit, broken heating element or breakdown to the housing.

Checking the heating element with a tester

Use anti-scale to soften the water, which will increase the service life of the heating element.

The most common breakdowns of Brandt machines

Over 20 years of operating French Brandt machines, domestic workshops have already collected a huge knowledge base about breakdowns and the reasons for their occurrence. At first glance, these are very reliable washing machines, but in the CIS countries, mostly cheap models are in demand. Brandt machines from a low price category have parts that are not so reliable, and the assembly is not always excellent.

All Brandt machines are united by the following typical failures:

- Drain pump failure. This problem most often affects vertical models. Pumps in such machines last no more than 5 years.

- System blockages. This is a common breakdown of any car, regardless of make and model. Blockages prevent the machine from washing normally or make this process very problematic.

- Thermal sensor. This is the “Achilles heel” of any Brandt machine – expensive or budget. Often temperature sensors require replacement 3 years after purchasing the washing machine.

- Thermoelectric heater (TEH). This is also the weak point of any machine under the Brandt brand. Moreover, the heating element can break either after 15 years of operation or in the first year of service. This depends not so much on the quality of the part, but on external factors - water quality and compliance with operating rules.

Fault codes can also help you understand the problem. The decoding of such codes is usually given in the manual. Most often, Brand washing machines produce error codes: d01, d02, d03, d07 or ER12.

Brandt washing machine error codes

Mostly models are equipped with separate software options that allow self-diagnosis. Therefore, if any problem occurs, the equipment will display the error codes of the Brandt washing machine on the display.

D01

No water is collected. There may be a malfunction of the water level sensor, the fill solenoid valve or the control electronic controller. It would be a good idea to check the fill hose for integrity, places of strong kinks, and also check the pressure level in the water supply system.

D02

Water drains from the SMA very slowly or does not drain at all. Check the drain hose and the corresponding pipe for blockages and, if necessary, clean thoroughly. Also inspect the drain strainer located at the bottom of the front of the machine for integrity and cleanliness. Often this code is displayed if the electronic control controller, the drain pump is broken, or there are defective connections.

D03

The water does not heat up to the set temperature.

Out of order:

- temperature sensor;

- electronic controller;

- main heating element (TEN); check with a tester by opening the SMA housing.

D04

Drive motor faulty. It works constantly, without stopping. Professional diagnosis is required. It may be necessary to repair/replace the triac or module completely.

D05

Temperature sensor malfunction.

You should:

- open the machine body;

- find the sensor itself, located on the heating element;

- test the part;

- if necessary, replace.

D06

Stopping the electric motor. The cause may be a breakdown of the engine itself, the electronic control controller, or a simple violation of the integrity of the electrical wiring. It is recommended to call a service technician to conduct a thorough diagnosis and accurately determine the cause of the malfunction.

D07

The hatch door lock does not function. Quite often, to reset this code, you just need to press the door tighter. If the error is displayed again, you should check the serviceability of the lock mechanism, the integrity of the handle, and the locking device.

D09

Software selector malfunction. It is necessary to test the operation of its module, check the integrity of the connections between the selector itself and the control controller.

D10

More water enters the tank than is needed for the wash cycle. The solution to the problem is to repair or completely replace an element such as a water level sensor and/or an electronic module.

D17

Incorrect drum position.

Pay attention:

- presence of defects in the drive belt;

- a pulley responsible for supporting the magnet;

- the magnet itself, as well as the reed switch (elements of the AquaStop system).

D21

SMA does not turn on.

What to do:

- reboot;

- replacing the power module;

- inspection, maintenance of items such as wiring, electrical cord, surge protector, socket, plug and the like.

FILT

There is no connection between the electronic controller (control unit) and the program selector (display unit). Check the integrity of each connection step by step.

Many of the above faults can be easily fixed on your own; some will require professional intervention. But over time, the appearance of both can be avoided if you follow the rules for using SMA, regularly care for it, and also select the correct type of detergent.

What may indicate a breakdown

Most often, Brandt washing machines with vertical loading are found on sale.

Fault warning systems for such units react to breakdowns in two ways:

- Fault codes are displayed on the electronic display.

- Failure is reported by flashing lights on the control panel.

Thus, in the BWT 6008 E model, the warning system is triggered in case of failures by flashing diodes. These are the following combinations:

- If the light indicated in the picture is blinking, the shut-off valve that supplies water from the water supply system to the CM fill tap is most likely closed. This indication also alerts you to a poor connection of the drain hose. Make sure the hose is securely connected and the water tap is open, and restart the program.

- The following signal alerts the user that there is a blockage in the pump filter. Clean the filter, and also check the drain hose to make sure its connections are secure, and restart the wash.

- If the lights light up as shown in the following picture, there are two problems. First: the lid of the machine is not closed properly. Press the door tighter and restart the program. Second: drum blocking. A small item, such as a handkerchief or sock, has become lodged in the space between the tank and the drum and is blocking its rotation. Remove the foreign body and start the wash.

In models equipped with a screen, such as the WTD 6284 SF, the malfunction is expressed by an error code (these are alphanumeric combinations d01, d02, d07, 4 and others). Let's look briefly at what they mean:

- d01 - the water supply to the machine is interrupted.

- d02 - violations in the water drainage system.

- d07 - problems with blocking the lid.

- 4 - the drum is full, drying does not start.

The following photo shows a small clipping from the instruction manual:

Read about all the fault codes that are found in different models of the Brandt SMA in a separate review.

Model overview

Let's look at some particularly popular models.

BWT 6412DS

This top-loading version is suitable for a large family. You can put 6 kg into the drum at a time. There is automatic dosing E-DOSE - the device itself will take as much detergent for washing as needed. The powder is placed in a special container. There is no display, but there is a delay start timer. The process can be postponed for 24 hours. The tank is made of plastic, and the heating element is made of stainless steel. Partial protection against leaks is provided. Estimated cost: 25,000 rubles. Characteristics of BWT 6412 DS.

| Maximum load, kg | 6 |

| Spin speed rpm | 1 200 |

| Energy class | A++ |

| Washing class | A |

| Number of programs | 7 |

| Dimensions (HxWxD), cm | 85x40x60 |

| Weight, kg | 58 |

BWF 47 TCW

Freestanding machine with classic design and front loading. Spacious - enough for a large wash. White body and hatch on the front door. No drying function. Electronic control type. There is a digital display. You can change the spin speed. There is leakage protection and imbalance control. There is a program for woolen products. And:

- mode for delicate fabrics;

- super rinse;

- anti-crease;

- sports items;

- express mode;

- soak;

- stain removal and more.

The machine operates quietly - the noise level is limited to 78 dB. The tank is plastic. The user can set the water temperature.

| Maximum load, kg | 7 |

| Spin speed rpm | 1 400 |

| Energy class | A+++ |

| Washing class | A |

| Number of programs | 12 |

| Dimensions (HxWxD), cm | 85x50x60 |

| Weight, kg | 61 |

BWT 2812 T

An example of a modern washing machine. A stand-alone option. Loading is vertical. No drying. The body is white. There is a digital display. Partial protection against leaks, control of foam formation and imbalance, and child protection are provided. Start delay.

| Maximum load, kg | 8 |

| Spin speed rpm | 1 200 |

| Energy class | A+++ |

| Washing class | A |

| Dimensions (HxWxD), cm | 85x45x60 |

| Weight, kg | 69 |

WTC 1051K

Budget vertical version. It costs only 18,500 rubles. There are wheels for easy movement. Equipped with many useful functions - from creasing, super rinsing and others.

| Maximum load, kg | 5 |

| Spin speed rpm | 1 000 |

| Energy class | A |

| Washing class | A |

| Dimensions (HxWxD), cm | 85x40x60 |

| Weight, kg | 62 |

WTD6284SF

The vertical version with a drying function is presented on the Russian market quite modestly. WTD6284SF is equipped with different programs that allow you to wash items from different fabrics and at different temperatures. Also in the car there is:

- OptiA is a 45-minute program for dirty clothes at 40°C.

- Chemises X'Press - for shirts. They are washed, dried and ironed in 1 hour 45 minutes. All operations are performed automatically - one after another. Smoothing is facilitated by special rotation of the drum and steam treatment, which starts during drying.

The machine can dry things separately from washing or immediately after it is finished. Steam activation is automatic. White color. Approximate price - 40,000 rubles.

WTD6284SF Specifications:

| Maximum load, kg | 6 |

| Spin speed rpm | 1 200 |

| Maximum drying load, kg | 4 |

| Energy class | A |

| Washing class | A |

| Dimensions (HxWxD), cm | 90x45x60 |

| Weight, kg | 70 |

The free-standing machine is equipped with a digital display - you can monitor the washing process. The screen shows how much time is left until the cycle ends. There is a special program for wool fabrics. Delicate fabrics should not be spun at high speeds. If the user sets the wool mode, the electronic control will not allow the spin speed to be set to 1,000 rpm, thereby preventing damage to wool items.

The rotation speed of the drum during spin determines the class of spin efficiency - this indicator is indicated in the technical documentation. In the WTD6284SF modification, the spin class is B. Foaming control is provided. Each rinse ends with draining the water, then spinning. The pump removes the remaining foam from the drum - this improves the quality of rinsing. At the same time, it is possible to prevent depressurization of the chamber.

The tank is not made of plastic, like most models, but of stainless steel. Steel tanks are much stronger and more durable, resistant to rust and aggressive substances. But there is also a minus: versions with steel tanks are noisier than those with plastic ones.

Heating element and temperature sensor in a Brandt car: mutual problem

In vertical Brand machines, checking and changing the heating element and thermistor (temperature sensor) is much easier than in conventional machines. If the water does not heat up or overheats, then you need to check both units - both the heating element and the sensor.

We act sequentially:

- Unscrew the back panel (use a 10mm Phillips screwdriver).

- Once you remove the panel, you will see a pulley that holds the drive belt. Next is the wall of the tank, the engine and on the side – the pump. Immediately above the motor there is a plug, under which what we need is hidden - both the heating element and the sensor.

- Remove the plug.

- Release the sensor and heater from the wires.

- Take a tester and first check the sensor - first at room temperature, then by heating it in a glass of warm water. A working sensor will display different indicators on the tester screen. Broken will show 0-1.

- Check the heating element if the sensor is working properly. If the resistance value is not in the range of 20-40 Ohms, then the heating element has burned out or shorted. Together with the gasket, take it out of the tank and install a new heater.

- Return the sensor to its place. Connect the wiring.

If you quickly did not find the original heating element for your model, do not install a similar one! It’s better to order an original part and wait for it, otherwise you risk also breaking the electronic module.

The water drain pump (pump) in the Brandt machine is broken

A pump for a Brandt washing machine can be easily purchased in the Russian Federation - there will be no difficulties with it, since the part is in demand, and it is carried regularly. You can easily replace the pump yourself, but pay attention to one important point: make sure that you really need a pump replacement.

Do the following:

- Clean the pipes (you can also clean the water drain hose).

- So, as described above, get through the back of the machine to the pump.

- Remove the wires from it (remember, take a photo or mark the location of the wires, so that later you can assemble everything as it was, otherwise you will burn the board).

- Measure the resistance on the winding using a tester.

- Remove the pump from the mounts by unscrewing the bolts.

- Slowly remove the pump.

- Try turning the impeller in both directions. In a broken pump it turns with difficulty.

- Buy the original part and install in reverse order.

Attention! After removing the pump, inspect it for blockages - often they are in the bushing, which significantly interferes with operation. If the cause of the failure is a blockage, then the pump does not need to be changed, especially if the tester shows no deviations.

About the company: interesting facts in favor of Brandt

The first thing you need to know about this company is that it is French. Another question is where are Brandt appliances made? Unlike many changeover companies, whose brand can be registered, for example, in the USA, and products are assembled in China, Brandt produces its products directly in the country where the brand is registered: in France. Of course, French quality is different from German, and perhaps the company produces less reliable and durable products, but this is clearly not China and the price category of the products is also far from German - the cheapest models cost less than 20,000 rubles.

A few facts:

- Brandt is not an independent brand. The trademark belongs to the larger Fagor Group corporation, which also includes Polish and Spanish companies.

- The Fagor group of companies, to which Brandt belongs, is one of the five largest European manufacturers of household appliances.

- Fagor-Brandt is the leader of the French market.

- The Fagor-Brandt group owns almost 2 dozen factories, most of which are located directly in the European Union.

- In addition to washing machines, the Brandt logo also produces dryers and dishwashers, refrigerators and freezers, wine coolers and some built-in appliances - much of this can be easily found on the Russian market.

Self-repair Brandt: how practical is it?

Often, owners of SM Brandt begin to experience the first failures only after 10 years of use. Moreover, until the first breakdown, the machine can work absolutely without failures.

If the SMA is too old, the first difficulty will be finding parts for it. Dealers who carry parts from Europe often only stock the most popular parts. The easiest way to buy the following parts for a machine of this brand:

- Drain pumps.

- Pulleys.

- Drive belts.

- Shock absorbers.

- Hoses and pipes.

- Drum doors.

- Gaskets and rings.

- Top panels.

- Heating elements.

Electronic controllers and display panels keep comparatively low prices, although they cannot always be found in the Russian Federation and will have to be ordered from abroad.

The engine is no less difficult to find. You can wait more than a month for an original part, and it can cost a pretty penny.

Having collected all the opinions and advice of experts on this issue, we conclude that before you begin self-repair, you need to thoroughly study the problem and calculate the possible cost of repairs.

Often, spare parts for used machines are more expensive than the washing machines themselves, but you still need time and effort to repair them yourself.

Is it worth repairing the Brandts?

Many users learn about the need for repairs only after 7 or even 10 years of uninterrupted operation of the machine. It will be difficult to find parts for the old version of the SMA. It is not recommended to install low-quality analogues. Dealers who supply parts from abroad usually have stocks of replacement parts for popular brands such as LG, Samsung, Siemens, Bosch, etc. But some parts can be found, and these are:

- drive belts;

- pulleys;

- shock absorbers;

- pipes and hoses;

- activators;

- top covers;

- drum doors (doors);

- gaskets, rings, seals;

- Heating elements.

There are also inexpensive control modules and display panels, but you will have to wait for them from abroad. The most serious difficulties arise when it is necessary to replace the engine - the original will be sent no earlier than in a month, and given current exchange rates, the part will not be cheap.

Therefore, experts advise you to think carefully before you start repairing the Brandt washing machine yourself. Calculate the cost of the work in advance. And if you are not ready to do the repairs yourself and use the services of a specialist, then it will be more profitable to acquire a new unit.