Weaknesses of Zanussi washing machines

Using statistics from service centers, you can quickly understand which components and parts in the Zanussi washing machine are the most vulnerable

- Dependence of details on water quality. By the way, this is typical not only for the Zanussi brand, but also for other cars. Water supersaturated with salts when heated strongly deposits scale on the heater and other elements. The water in our water supply systems is also not very clean, so the filtration systems of the machine can become clogged with dirt and rust over time. As a result, the typing and drainage system suffers.

- Hatch blocker. This is already the fault of the manufacturers: both the blocker and the sensor are slightly unfinished, so they break more often than with SMAs of other brands.

- The heater (heating element) quickly becomes overgrown with scale. Experts believe that this is also due to the fact that the manufacturers made a mistake in the selection of components from which the tubular part of the heater is made.

- Drive belt. It is not reliable, so every 3 months it doesn’t hurt to check its tension and integrity. If you see signs of stretching or damage to the belt, tightening or replacing the assembly is required.

The only good thing is that the malfunction can be identified in time, since the Zanussi “smart” automatic washing machine notifies the user of problems using fault codes.

Common codes for Zanussi washing machines

Typically, a Zanussi washing machine produces the following error codes: E11, E12, E21, E22. Let's look at the most common combinations.

Water does not leave the system - the drain filter needs to be cleaned and the pipes checked for blockages.

It is also necessary to check the functionality of the pump impeller - it should rotate freely in both directions. If movement is difficult, the pump needs to be replaced.

| Code | Problem |

| E11 | Washing water is not supplied. Most often, the code lights up if the valve supplying water from the water supply to the machine is closed. The pressure in the pipe may also be weak. It is possible that the filter mesh on the inlet valve is clogged. The integrity of the hose is checked and the filter is cleaned. It is advisable to check the resistance of the valve coil - a working element will give a reading of 3.8 kOhm. |

| E12 | Problem with water filling during drying. If the cause is the water inlet valve, the code will appear on the display 10 minutes after the start of the wash cycle. |

| E21 | |

| E22 | Indicates a low level of water drainage during drying. The condenser may need to be cleaned. |

Diagnostic modes for washing machines with different control panels

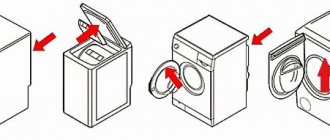

The Zanussi washing machine is considered a reliable unit, but, like any equipment, it needs preventive maintenance and proper care. If you neglect these procedures, you may encounter the device giving an error and refusing to work. You can check the functionality of the elements yourself using the instructions below. Options may vary depending on your device model. A horizontal machine or a top-loading machine may vary in scenario.

All manipulations are carried out in test mode. Entering the diagnostic mode is done by setting the selector to the “off” mode. and then pressing the “start” button and the buttons indicated in the figure.

EWM 1000

This line includes 7 methods for checking faults. You will need to wait a five-minute pause between switches for the diagnosis to be successful. Before proceeding, you should remove all clothing from the tank. Diagnostics of EWM 1000 is carried out as follows.

- The program selection selector is located in the first position. Here you can check the functionality of the buttons. When pressed, they should light up or produce a sound alert.

- When you turn the selector to the second position, you can check the water inlet valve into the wash dispenser. At this stage, the hatch will lock. The pressure switch controls the fluid level.

- The third mode controls the liquid fill valve during prewash. When you select it, the door lock will also work; the dial sensor is responsible for the water level.

- The fourth position will turn on two valves.

- The fifth mode is not used for this type of machine.

- The sixth position is to check the heating element along with the temperature sensor. If the liquid level does not reach the required level, the SM will add the required amount additionally.

- The seventh mode tests the operation of the motor. In this mode, the engine is cranked in both directions with further acceleration to 250 rpm.

- The eighth position is the control of the water pump and spin. At this stage, maximum engine speed is observed.

To exit test mode, you will need to turn the device on and off twice.

EWM 2000

Diagnostics of this line of washing machines is carried out as follows.

- The first position is diagnostics of water supply for the main wash.

- The second position is responsible for supplying water to the pre-wash compartment.

- The third position controls the water supply to the air conditioning compartment.

- The fourth mode is responsible for supplying liquid to the bleach compartment. Not every device has this feature.

- The fifth position is the diagnosis of heating with circulation. Also not present in every model.

- The sixth mode is needed to test the tightness. During this, water is poured into the drum, and the motor rotates at high speeds.

- The seventh position checks the drain, spin, and level sensors.

- The eighth mode is needed for models with a drying mode.

Each step tests the door lock and fluid level, along with the functionality of the pressure switch.

Troubleshooting common problems with Zanussi cars

Complex breakdowns should be entrusted to a professional, but easy repairs of Zanussi washing machines can be done yourself.

Next, we will look at how to repair a Zanussi washing machine with your own hands.

Clean filter – perfect performance

All filtration systems require periodic cleaning. If you neglect this rule, then problems cannot be avoided later. If a blockage occurs in any of the filters, problems arise with the intake or drainage of water.

In the Zanussi SM, it is the filler filter that most often gets clogged. What should I do to normalize the operation of the machine?

- Simply unscrew the inlet filter - it is located on the water supply pipe.

- If you have not installed such a filter, then you need to clean the filter mesh.

Attention! Experts advise installing the inlet filter on a pipe with a special filtration cassette that softens the water.

To clean the filter mesh, proceed as follows:

- Find the connection point between the water intake hose and the washer body.

- Remove the top cover of the CM to unscrew the valve and filter.

- Disassemble the filter and rinse it under the tap.

- Reinstall the filter.

- Reassemble everything in reverse order.

Important! The design of a Zanussi horizontal-loading washing machine differs from the front-loading design, but cleaning the filter occurs in the same way.

By the way, pollution can accumulate not only due to “errors” in the water supply system, but also due to the very clothes that you put into the drum. From things that are too dirty, sand, dirt, debris, and threads penetrate into the machine systems.

Craftsmen often find small coins, seeds, hairpins, and crumpled checks in the drain filter. All this “nonsense” can cause the SMA to stop working.

Important! Remember to clean the filter at least once every 3 months.

Repair of Zanussi washing machine lock

The problem with UBL is a common malfunction of the Zanussi Aquacycle SM, but it also occurs in other models: for example, Zanussi Easyiron.

It is difficult to immediately say why the blocker breaks - due to the fault of the manufacturer or user negligence. But there may also be problems with the control board - then the blocker has nothing to do with it.

The plastic components of the device that blocks the hatch are unreliable and can break even if you simply slam the hatch shut with force. The metal hook will survive, but due to the breakdown of the UBL, washing will still be impossible.

The blocker is usually not repaired - it is easier to replace it with a new one. For Zanussi cars, UBL costs about 1,500 rubles. A little expensive, of course, so first you should remove the old blocker to be 100% sure that it is broken.

Remove the device according to this scheme:

- Open the door.

- On the right you will see a small hole for the locking hook, and next to it are two screws that hold the UBL. Unscrew the fasteners.

- Remove the sealing gasket (cuff). It is held in place by a wire clamp that runs in a circle along the entire elastic band. Use a thin screwdriver to pry it off and remove it. Then remove the cuff - do this by hand, without tools, so as not to damage the delicate elastic band.

- Remove the blocker by disconnecting the wires.

- Conduct a visual inspection of the device and make sure the plastic part is intact. If the plastic is broken and the records have popped out, take the device with you and go get a new one.

- Show the UBL in the store so they can sell you exactly the same one.

- Install the blocker in reverse order.

Important! Carefully close the hatch until it clicks, pressing down on the edge to prolong the life of the device.

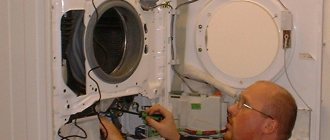

Replacing the heater in a Zanussi car

As we said above, the heating element is one of the most vulnerable points of any washing machine, especially Zanussi. If a washing machine breaks down in this way, it may display error E05, and the water in the tank stops heating.

To make the repair yourself, you will have to slightly disassemble the SM body:

- Turn the machine with the front wall facing you.

- Remove the bolts from the panel to remove it.

- At the bottom of the tank you will see the heater shank - there are 2 contacts and wires coming from them.

- Measure the resistance using a tester. If the device shows a value close to zero, the heating element will have to be changed. The readings of a working heater will be 20-40 Ohms.

- To remove the heating element, unscrew the nut located in the center of the shank.

- Disconnect the wiring going to the heater.

- Make an effort to remove the heating element from the groove. If there is a lot of plaque on it, then it could become stuck. Take WD-40 and lightly spray the cracks. Loosen the old heating element and pull it towards you.

- Clean the hole thoroughly.

- Install the new heater and connect the wiring.

- Reattach the back panel and run a test wash. If the water heats up and code E05 disappears, it means you did everything correctly.

Important! When choosing a heating element for a Zanussi washing machine, buy only original parts. Don't buy cheap Chinese analogues - they won't last you long. An unsuitable heating element can also cause a breakdown of the control unit, and then the repair will definitely cost a pretty penny.

Checking the drive belt

Failures caused by the drive belt are accompanied by the fact that the motor in the washing machine does not stop working, but the drum does not rotate. To check the integrity and location of the belt, proceed as follows:

- Remove the back cover by unscrewing the fasteners.

- In the niche you will see a drum pulley on which the belt should be placed. The electric motor pulley is much smaller and must also have a belt on it.

- Adjust the belt if it has moved.

- If the drum does not rotate and the belt is in place, then replacement is needed.

- After adjusting or installing a new belt, secure the panel in place and run a test wash.

As you can see, repairing Zanussi washing machines involves eliminating typical failures and breakdowns. Fortunately, these faults are such that you can easily fix them without the help of a specialist.

We only advise you not to touch electronics. Even if you have a Zanussi washing machine diagram, to repair or replace an electronic module you need special tools and relevant knowledge and experience. If you don’t want to provoke additional breakdowns, trust complex problems to a specialist.

This video may help you:

Source

What types of malfunctions are there?

There are many possible problems that can affect the performance of your washing machine. Let's look at popular problems with the Zanussi washing machine and how to fix them.

Drum doesn't move

The drum may jam during operation, which will naturally lead to disruption of the functionality of the equipment. The reason may be various mechanical inclusions that get inside with loaded items.

The hatch is blocked

Locking the hatch will not allow you to open the machine chamber and load clothes into it. In this case, the problem most often lies in the jamming of the lock, which will have to be removed manually.

Self drain is broken

Lack of water drainage may be due to clogged filters or drain system. Cleaning all key elements solves the problem.

Water does not fill

If water does not fill into the tank during operation, the problem may be low pressure, a faulty valve, or a broken control unit. The last option is quite rare in practice and can be solved by replacing the module.

Increased speed

Rapid operation of the motor indicates a malfunction of the tachometer, a malfunction of the control module, or poor tension of the drive belt. In this case, the drum begins to move too quickly, which threatens the reliability of the entire system.

No water heating

The heating element is responsible for heating the water in the washing machine. Its malfunction will naturally prevent the device from using heat during operation. Also, sometimes the water level sensor may not allow you to enable the option. You can solve such problems yourself by replacing components. If this does not help, it is better to contact a specialist.

Puddle formation

Puddles under the machine form when the pipe leaks, the cuff is damaged, or simply wear out the gaskets on the key components of the machine. This is one of the simplest problems that can be solved without major investments.

Rumble during spin cycle

Loose drum mounts, broken counterweight, or other similar factors may cause the unit to not operate smoothly. The result is constant shaking and rumble during washing, which is especially audible during the spin cycle. First of all, in this case, it is important to check all bolts and fasteners for their tightness.

Zanussi - washing machine: do-it-yourself repair of the mechanical component of the unit

If you love automatic washing, you also love fixing your machine! This is exactly how any owner of a washing machine could paraphrase the famous saying.

Zanussi brand units are no exception. Although there is no reason to complain about the quality of these machines, they sometimes present an unpleasant surprise. So, Zanussi - washing machine: faults and do-it-yourself repairs.

DIY Zanussi washing machine repair

But such malfunctions occur relatively rarely. In most cases, failures in the operation of Zanussi cars are due to very banal reasons, which the owner himself can cope with.

Let us list the weak points of these units:

- Dependence on water quality: this feature, it must be said, is characteristic of all washing machines. At high temperatures, the hardness salts present in the water are intensively deposited on the heating element in the form of scale, and dirt and rust clog the filters, as a result of which the collection of fresh water and the removal of waste water slows down or completely stops.

- Poorly thought out design of the locking device on the hatch: in Zanussi cars this mechanism, as well as its sensor, are clearly unfinished and fail very often.

- Heating element: some experts believe that the heater in these machines is especially susceptible to scale formation due to the poor choice of tube material.

- Drive belt: another relatively unreliable element. Zanussi owners should check the condition of the belt at least once every 4 years, tightening or replacing if necessary.

Now let's look at the typical symptoms that manifest themselves in certain malfunctions.

Bosch washing machine care

To ensure a long service life of a Bosch washing machine, you need to use it correctly and not forget about maintenance. After each wash, the hatch and powder receptacle must be wiped with a dry cloth and left slightly open - this will protect the equipment from the appearance of mold and unpleasant odors. There is no need to use aggressive detergents to care for the drum - this will shorten the life of the washing machine.

We suggest you familiarize yourself with the smell in the shower from the drain, what to do

When putting things into the washing machine, you need to make sure that there are no small objects in the pockets that could get into the drum. To wash some items (bras, clothes with metal fittings), it is recommended to use special covers or bags to avoid breakage. You cannot put laundry in the machine that exceeds the permissible weight limit; this leads to overload and premature wear of the drum compartment and engine.

It is necessary to periodically clean the garbage filter and hoses, otherwise they become clogged and debris remains inside the machine, causing the laundry to have an unpleasant odor after washing.

Before carrying out any maintenance procedures, make sure that the machine is disconnected from the power supply.

Drum doesn't move

If you can clearly hear that the engine is running, then the problem is most likely in the drive belt. To inspect it, you need to remove the back panel of the machine body by unscrewing the screws that secure it.

Next we act on the situation:

- If the belt has come off one of the pulleys, it needs to be put back in place.

- If the belt breaks, you need to purchase and install a new one.

- If the belt is intact and in its place, but does not transmit rotation due to slipping, it means that it has exhausted its service life and must also be replaced.

If, during inspection, you find that the electric motor pulley does not rotate, it means that there is a more serious breakdown and you need to contact a service center.

Hatch lock

Let's consider two situations:

The washing is completed, but the hatch still cannot be opened

If the lock is jammed, the hatch can be opened using the emergency cable by pulling it towards you. You can find it behind the bottom panel (you need to unscrew it), on the right, near the filter. The cause of the malfunction lies in the electronics, so you will have to contact a workshop.

The hatch won't close

The latches that hold the hatch in the closed position are made of fragile plastic, so they often break.

To make sure that this is the case, you need to disassemble the lock:

- Having opened the hatch, unscrew the two screws that secure the lock to the body;

- remove the hatch seal (cuff), having first removed the clamp holding it (you need to pry it off with a screwdriver);

- After removing the cuff, the lock can be pulled out.

If the plastic parts of the mechanism are really broken, you need to purchase a new lock and install it in place.

To make the lock last longer, close the hatch as gently as possible.

The hatch does not open after washing

There is also such a malfunction when the washing is finished, but it is impossible to remove the laundry - the hatch does not open. This is where the blocker most likely jammed. To begin the repair, unscrew the bottom panel and pull the cable found there. The hatch opens, we take out the laundry. Then we remove the hatch lock and check the integrity of the latches. If they are not broken, then you will have to take the lock to the service center - there is a problem with the electronics. And here, without special knowledge and equipment, independent repairs are impossible. If it is discovered that the latches are broken, the lock must be replaced.

The algorithm for repairing a machine with vertical loading is the same, but the design of the parts is slightly different.

Important! To avoid damage to the lock, the hatch should always be closed smoothly, without slamming.

Self-draining device

The situation when, simultaneously with the collection of water, it is discharged through the drain hose (before the drum begins to rotate), may be due to the low location of this hose.

Its free end should be raised by 50 - 70 cm. Self-draining will also occur if the drain pipe is damaged, only in this case water will not flow out from the hose, but from under the machine.

More serious causes are failures in the control module or level sensor, which mistakenly turn on the drain pump.

Water does not fill

We are looking for the cause of the malfunction:

- First you need to make sure that the water has not been turned off.

- Next, you need to check the capacity of the filling hose by disconnecting it from the machine and turning on the water supply.

- If water flows through the hose properly, install it in place and check the condition of the filter. Together with the filling valve, it is located in the place where the hose enters the unit body. After removing the top cover, the assembly (valve + filter) must be unscrewed, after which the filter can be disassembled and cleaned.

Cleaning filters, both inlet and outlet, must be done regularly, without waiting for problems to arise.

If the water supply has not resumed, you need to check the functionality of the filling valve. The resistance of its winding should be 3.75 kOhm, and when the voltage indicated on the case is applied to the contacts, the device should open. A malfunctioning valve must be replaced.

This problem may also indicate that the level sensor is broken or its tube is clogged.

In many cases, the owner of the washing machine can repair it himself. Repairing a Bosch washing machine yourself - an overview of the main types of breakdowns and methods for eliminating them.

What criteria should be taken into account when choosing a shower cabin, read in this topic.

Failure of the heating element, wear of the bearing, failure of the control unit - these types of faults in washing machines are the most common. Here https://aquacomm.ru/cancliz/mnogokvartirnyie-doma/santehnika/stiralnaya-mashina-indezit-neispravnosti-remont-svoimi-rukami.html you will learn how to fix Indesit machine breakdowns yourself.

No water heating

Most often, the cause of such failures is the breakdown of the heating element - due to natural wear or due to scale accumulation. Follow these steps:

- After unscrewing the fasteners, remove the back panel of the case.

- Check the resistance of the heating element using a multimeter (its shank with the wires connected to it protrudes from the tank in its lower part). At room temperature, the device should show 30 ohms.

- If the resistance is different from normal, the heating element must be replaced. The wires are disconnected from it, and then the nut located between the contacts is unscrewed. After this, the heater can be pulled out. This should be done with caution, gently rocking the element and without applying excessive force. If the heating element is stuck and does not budge, you need to soften the scale with WD-40 liquid. After dismantling the heater, its seat needs to be cleaned, after which a replacement can be installed. The new heating element must match this model of washing machine. A heating element from another model may burn out, along with the control module.

- If the resistance measurement shows that the heating element is working properly, you need to check the condition of the temperature sensor. Its performance is also checked by measuring resistance. At room temperature it should be 5.7 - 6.3 kOhm.

The reason may also be the “sticking” of the contacts of the heating element relay located near the control module.

Zanussi washing machine does not heat water or washes with cold water

To understand whether the machine is heating water, you just need to place your palm on the glass on the washing machine door. If, after conducting this kind of test, you find that the water in the drum is cold, you should think about why this happened.

When you notice that your Zanussi washing machine is not heating the water

, do not be sure that the electric heater has burned out. Of course, there are exceptions, but when the heating element is in excellent condition and the water is cold, then the problem lies in the temperature sensor and the electronic control module. In any case, you cannot cope with this breakdown yourself; you must call a specialist. Using special equipment, he will quickly conduct a complete diagnosis of the washing machine and determine what the reason is. To correct such breakdowns, as a rule, transportation to a workshop is not required.

You can also check whether the equipment is connected correctly, because it often happens that, having decided to save on the quality of the connection, water randomly flows into the sewer and does not have time to heat up in the tank.

Puddle formation

If water is detected under the washing machine, the following components should be checked:

- Gasket at the connection point of the filling hose. If excessive wear occurs, it must be replaced.

- Hatch seal. Over time, this element may become deformed or crack. To dismantle a worn cuff, it is necessary to remove the clamp holding it. It fits quite tightly, but if you pry it with a screwdriver, it comes off quite easily.

- The drain pipe or the location where the drain hose is attached to the pump. If there is damage in this area, water will begin to seep in as the machine fills. A damaged part - a hose, pipe or pump - must be replaced.

- Car tank. Leaks may be due to its depressurization.

In the latter case, specialized equipment will be needed for repairs, so you will have to contact a service center.

Recommendations for replacing parts and assembling a Zanussi washing machine

After repair, reassemble the Zanussi washing machine in the reverse order. If photographs were taken during the work, it is recommended to check them, especially when connecting wiring, in order to avoid mistakes.

If the tank was disassembled, then during reassembly the joints of both halves should be carefully coated with silicone sealant that can withstand aggressive environments and high temperatures. After assembly, the machine should sit for the amount of time recommended by the sealant manufacturer to allow it to dry completely.

In addition to replacing the main part, you need to carry out preventive maintenance on other components of the washing machine: descale the heating element, tank, inspect and clean the shaft and cross, etc.

After the machine has stood for the time required for the sealant to harden, it should be connected to the communications and a test wash should be performed, adding a small amount of powder. If during the execution of the program there are no water leaks under the washing machine, the equipment behaves correctly, there are no signs of malfunction, this indicates that disassembling and repairing the device was successful.

Error codes

The machine itself informs the user about some breakdowns by displaying a special alphanumeric sequence on the display - an error code. Here are some of them:

- E11 – insufficient water supply during washing. As already mentioned, you need to check the water fill path, filter and valve.

- E13 - there is a water leak into the pan.

- E21 – problems with draining water. Most likely the drain filter needs to be cleaned. Along with clothes, sand, seed husks and other small debris, buttons, pins and other small objects can get into the machine, so it is recommended to clean the drain filter after every 3 washes. If this measure does not give a positive result, it is necessary to check the functionality of the pump. The resistance of its winding should be approximately 170 Ohms.

- Codes E23 and E24 indicate a malfunction of the control semistor of the drain pump in the control module.

- E35 - the water level in the tank has exceeded the permissible threshold. The most likely cause is a broken level sensor or a clogged tube.

- E41 - E45 indicate a malfunction of the hatch lock or its blocking elements.

A washing machine breakdown is not that uncommon.

Some brands of units have their weak points. Kandy washing machine - do-it-yourself repair of basic faults, read on. We will analyze the types of mixer taps and the features of their design in this material.

Washing machine prevention

To avoid breakdowns of the washing machine, you must follow simple operating rules.

The equipment must be leveled; for this you need to use adjustable feet.

You should only load the washing machine with the amount of laundry that is allowed by the technical characteristics of the device and the program being run. Overload has a negative impact on the condition of the equipment.

If you need to wash bulky items, you need to load them into the machine with care, distributing them evenly inside the drum. Imbalance also harms technique.

The washing machine should be connected to electricity through a stabilizer or at least a surge protector. Voltage surges are detrimental to the device.

When washing clothes, you can only use automatic powders; periodically it is recommended to use products to clean equipment from scale and other contaminants.

Rumble during spin cycle

Loud noise when the drum rotates at high speeds may be due to the following reasons:

- The position of the machine is not strictly horizontal.

- The drum is underloaded, as a result of which the center of gravity of the laundry has deviated from the center of rotation (strong vibrations will occur at high speeds).

- One of the bearings is broken.

Bearings in Zanussi cars can be replaced independently. This is done like this:

- Having completely disassembled the machine, you need to remove the tank with the drum.

- After removing the drum pulley and unscrewing several bolts around the perimeter of the tank, the latter needs to be disassembled into two parts.

- Using careful blows of a hammer through a wooden lining, you need to knock out the drum axle shaft from the bearing assembly in the rear half of the tank.

- Next, using a puller, remove the bearing itself along with the seal.

- The drum axle shaft and bearing seat must be thoroughly cleaned.

- A new one is installed in place of the old bearing, and its seal is filled with special lubricant.

Having lubricated the axle shaft and the inner ring of the bearing, the drum and the rear part of the tank are again assembled into a single unit, after which both halves of the tank are fastened together, coating the joint with sealant.

Changing units on the pulley side

In some models of Zanussi washing machines, the bearing assembly - the so-called caliper - is unscrewed.

After removing the drive belt, you need to remove the drum pulley (it is held in place by a screw). Next, you need to disconnect the grounding plate and unscrew the caliper, turning it to the right.

The caliper on the side opposite the pulley (in machines with vertical loading) is unscrewed in the opposite direction. The direction of rotation at each node is indicated by arrows labeled “Open” and “Close”. After installing the new caliper, the unit is assembled in the reverse order.

To ensure that the screw holding the pulley holds securely, the threads should be lubricated with Loctite glue before screwing in.

Features of model repair

Most Zanussi washing machines have a similar design, so you don’t have to rack your brains about finding certain elements. However, there are some features that, if taken into account, will save time.

Top loading

Top-loading washing machines are extremely common due to their compactness and functionality. There are also almost never any problems with their repair, since all the main elements are located under the back cover. These machines do not require any special lid sealing as there is very little chance of water leaking through the top.

Horizontal loading

Horizontal loading machines seem more familiar to many. However, this type of work requires some specific repair methods. Malfunctions of a horizontal-loading Zanussi washing machine are very often associated with a leak in the hatch. In this case, in addition to the main possible malfunctions, a leak may also occur at the seals.

Filters in such machines are often located at the front, hiding them under special decorative panels.

Aquacycle 1000

Aquacycle 1000 washing machines boast reliability, durability, functionality and fairly simple repairs. All key elements are located under the back cover and often it is not even necessary to completely disassemble the equipment.

Most often, the heating element fails here, the malfunction of which leads to the appearance of an error on the device display. After replacing the component, the device's functionality will be restored.

Zanussi produces reliable, affordable washing machines that are easy to repair. In most cases, do-it-yourself repair of Zanussi washing machines comes down to replacing certain components, for which the user only needs instructions and a minimum set of tools.