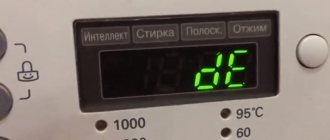

You, as usual, put your things in, selected a washing mode and started the program. The Ariston or Hotpoint-Ariston washing machine blocked the hatch, took in water, but the drum never started spinning, and the code F01 or F1 lit up on the display. However, for the first time the error could appear at any stage of the washing machine’s operation: washing, rinsing or spinning. But in the future, it is displayed immediately after starting in any program, even Spin, Rinse or Drain.

Note! In rare cases, error F 01 may appear and disappear. If this is exactly the situation you have, do not hesitate to repair it; in this mode, the washing machine will not last long. Soon your Ariston will display error F01 immediately after turning it on, you will not be able to wash your clothes at all, and repairs will cost much more.

If you have an Ariston washing machine without a screen, then it will report error F01 as follows:

- On the most “ancient” models, with two indicators - power and hatch lock (Ariston Margherita type), the on / off indicator will blink (one flash). In this case, the program selector knob will click and rotate in a circle in a clockwise direction, and the hatch locking lamp (“Key” or “Lock”) will be constantly on.

- More modern Ariston AGRs, with indicators of program stages (models AVL, AML, AVSL, etc.) will show error F01 by flashing the indicator of the “Additional rinse” button (the first from the bottom in the column of additional function buttons) and more frequent flickering of the “Key” indicator hatch lock.

- In Hotpoint-Ariston Low-End models (ARSL, ARMXXL, ARXL, etc.), the “Key” light (the first indicator from the bottom in the vertical row) will blink. All horizontal buttons for additional functions may also light up.

- In Hotpoint-Ariston Aqualtis machines without a screen (AQSL models), error F 01 will be indicated by flashes of the cold water wash temperature indicator (the first temperature light on the bottom).

Code options

At the initial stage, it is necessary to understand what options the error code F01 represents. Here you can’t expect tricky surprises from the manufacturer of the unit. If the washing unit has a screen, then up to eighty-five percent of the products at the time of a characteristic malfunction will generate an F01 signal, and the rest will display an F1 error code.

If the SM does not have a display, then recognizing error F01 is more difficult. But if you have the necessary knowledge, you can cope with this problem. Let's look at the available options:

- On Ariston AQSL machines, error F01 will be indicated by the blinking temperature indicator located at the bottom of the panel.

- Low-End will display an error by flashing the key light or lighting up horizontally located lights.

- Ariston units from the AVSL product line will display error F01 by flashing the indicator light for the “extra rinse” function while the indicator light is on, indicating the door is blocked.

- Outdated Margherita models signal a problem by constantly lighting the “Key” lamp and periodically blinking the “on” indicator light.

Features of information reading

On Indesit without a display, errors are determined by indicator signals. In older models of washing machines there is one light bulb, and the code is read by the number of flashes. The process is cyclical - after a pause everything is repeated.

It’s more difficult with Indesit with several warning lights. Different models have their own table of their correspondence to errors.

When deciphering the code, focus not on the names of additional functions, but on the indicator numbers.

With EVO-I module

Constant rotation of the program selection knob informs about the Indesit error. The code is determined by the number of blinks of the network indicator.

Identify indesit errors using indicators

With EVO-II module

Indesit LOW END series indication

The error is determined by a combination of flashing indicators according to the code table.

Combination of idesit indicators

Indesit LOW END series

Indesit LOW END series

Indesit washing machine indicator combination

Washing machine with Arcadia module

Determine Indesit errors with the EVO-II module using indicators

Indesit washing machine indicator combination

What does this error code mean?

The F01 error options are clear, all that remains is to learn how to decipher them. This code indicates that there has been a malfunction in the electrical circuit responsible for the operation of the Ariston car’s motor. Such a dry formulation does not explain anything to the average user. But if we talk about error F01 in more detail, it should be noted that the control module sending signals to the engine does not receive anything in response. It turns out that there are three possible options:

- the control board has failed and is issuing incorrect commands;

- the motor broke down, losing the ability to obey the board’s commands;

- the problem has occurred in the circuit connecting the motor and the control module, and you need to look for it in the wiring or contact group.

Initially, this decoding of error F01 may seem somewhat scary. There is a feeling that the malfunction is serious. But in reality, everything is much simpler, since such a failure often occurs due to a normal failure of the electronic module.

It is already known that in almost all Ariston machines the error code F01 is explained in the same way. But every rule has exceptions. And the Ariston machine from the AD series is slightly different in the principle of self-diagnosis - in it, error F01 indicates an interruption of communication from the modular zone to the control panel display. Simply put, such a problem means that the management module has lost the ability to contact the panel responsible for control, and it has begun to show “inadequacy”.

Explanation of the designations of washing machines “Indesit”, “Ariston”

Indesit

| W |

|

| I | Brand I – Indesit |

| S | Structure:

|

| A |

|

| 8 | RPM:

|

| 2 | Execution option:

|

| CSI |

or X – Tank material:

S – Case color:

|

Ariston

| A | Brand A – Ariston |

| V | Product line:

|

| S | Structure:

|

| D | Panel:

|

| 11 | RPM:

|

| 2 | Execution option:

|

| CSI |

or H – Height:

S – Body color:

|

Ariston – Big Size

| B.S. | Big Size |

| 1400 | Spin speed |

| IT |

|

The main causes of the error

Let's look at the more common options for error F01:

- moisture has entered the connecting contacts of the motor and controller;

- a short circuit occurred in the electrical circuit connecting the engine and the block of the Ariston machine;

- corrosion has formed on the motor contact;

- the problem lies in the connecting harness from the motor to the controller.

Sometimes error F01 appears periodically and signals that urgent repairs to the Ariston unit are required.

Error identification

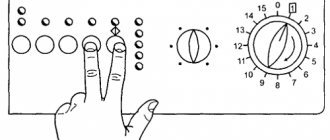

Washing machines that do not have a digital indicator display the fault code as a binary code on the LED indicators. The LED locations for various models and the code recognition table are shown below1.

Location of LEDs for various Indesit CM models

| Indesit – “EVO II”, “Arcadia” |

| Indesit – “Arcadia” (new panel, 2008) |

| Indesit – “Low End” (EVO II) (mod. WIA122, and others) |

| Indesit – “Moon” (mod. SIXL, SISL and other SI**) |

Location of LEDs for Ariston SMAs of various models

| Ariston (models AVL, AVSL, AVTL) |

| Ariston – “Aqualtis” (mod. AQSD, AQSF and other AQ**) |

| Ariston – “Nuova Esteticha” (mod. ARXL, ARSL and other AR**) |

Note:

1CM series ARCADIA (“New Platform”) have a different error coding system from others

Table of coding error numbers on panels with LED indicators

| Malfunction | LED 5 | LED 4 | LED 3 | LED 2 | LED 1 |

| F01 | Does not burn | Does not burn | Does not burn | Does not burn | Lit |

| F02 | Does not burn | Does not burn | Does not burn | Lit | Does not burn |

| F03 | Does not burn | Does not burn | Does not burn | Lit | Lit |

| F04 | Does not burn | Does not burn | Lit | Does not burn | Does not burn |

| F05 | Does not burn | Does not burn | Lit | Does not burn | Lit |

| F06 | Does not burn | Does not burn | Lit | Lit | Does not burn |

| F07 | Does not burn | Does not burn | Lit | Lit | Lit |

| F08 | Does not burn | Lit | Does not burn | Does not burn | Does not burn |

| F09 | Does not burn | Lit | Does not burn | Does not burn | Lit |

| F10 | Does not burn | Lit | Does not burn | Lit | Does not burn |

| F11 | Does not burn | Lit | Does not burn | Lit | Lit |

| F12 | Does not burn | Lit | Lit | Does not burn | Does not burn |

| F13 | Does not burn | Lit | Lit | Does not burn | Lit |

| F14 | Does not burn | Lit | Lit | Lit | Does not burn |

| F15 | Does not burn | Lit | Lit | Lit | Lit |

| F16 | Lit | Does not burn | Does not burn | Does not burn | Does not burn |

| F17 | Lit | Does not burn | Does not burn | Does not burn | Lit |

| F18 | Lit | Does not burn | Does not burn | Lit | Does not burn |

Error codes for control module EVO I, EVO II (Low End, Moon, Aqualtis, Nuova Esteticha)

| Code | Description |

| F01 | The motor triac is short-circuited.

|

| F02 | The electric motor does not work, the tachogenerator of the electric motor is open or short-circuited.

|

| F03 | Wash temperature sensor (NTC) is open/short-circuited, or wash heating element relay contacts are stuck.

|

| F04 | Presence of “Empty tank” and “Overflow” signals at the same time. If the pressure switch contacts are stuck in the "Empty Tank" position, the washing machine will fill with water7 until it reaches the overflow level. The drain pump starts automatically using the “Overflow” contact.

contacts 2–4 are closed “Empty tank” contacts 2–3 closed “Full tank” contacts 2–1 are closed “Overflow”

|

| F05 | The drain pump does not work or the level sensor does not generate an “Empty tank” signal.

|

| F06 | Only for EVO I error in communication between the module and the service key |

| F07 | No heating. After filling the water, the level sensor does not remove the “Empty tank” signal, and power is not supplied to the heating element (heater protection function) or the heating element is faulty. Possible reasons:

|

| F08 | Sticking contacts of the heating element relay (power is supplied when the “Empty tank” signal) or the pressure sensor simultaneously generates the “Empty tank” and “Full tank” signals.

|

| F09 | Error (failure) of the contents of the non-volatile EEPROM memory, the EEPROM chip is not programmed or is faulty).

|

| F10 | Simultaneous absence of emptying and filling signals (there is water in the tank, but the washing level has not been reached)

|

| F11 | No feedback signal from the pump (the drain pump motor winding is broken or not connected)

|

| F12 | No communication between display board and main board

|

| F13 | Drying NTC sensor circuit is open or short circuited (only for SM with drying)

|

| F14 | The drying heating element does not work (only for SM with drying).

|

| F15 | The drying heating element is constantly turned on (the contacts of the drying relay are stuck or the drying thyristor is short-circuited) Check the power supply circuit of the drying heating element and the heating element itself. |

| F16 | Drum lock (top loading machines only) Check the power supply circuit of the locking solenoid. |

| F17 | The hatch door is not locked (or the door is open).

|

| F18 | Communication error between the central microprocessor and the DSP (3-phase motor control processor) Replace control module |

EVO II module connection diagram

Error codes for the Arcadia 2 control module (WARNING! Codes are different from EVO II)

| Code | Subcode | Description |

| F01 | 0x01 | The motor control triac is short-circuited. |

| F01 | 0x02 | Motor control triac is in diode mode. |

| F01 | 0x03 | Motor feedback fault. |

| F01 | 0x12 | Feedback fault with washing heating element. |

| F01 | 0x21 | Feedback fault with drain pump. |

| F01 | 0x23 | The drain pump control triac is in open mode. |

| F01 | 0x24 | The drain pump control triac is in diode mode. |

| F01 | 0x31 | The resistance of the “Full tank” contacts of the level sensor is outside the normal range. |

| F01 | 0x32 | Contact resistance "Overflow" of the level sensor is outside the normal range. |

| F01 | 0x33 | Presence of “Empty tank” and “Overflow” signals at the same time. |

| F02 | 0x01 | The electric motor does not work / the electric motor tachogenerator is open or short-circuited. |

| F03 | 0x01 | Washing NTC sensor circuit is short circuited. |

| F03 | 0x02 | Washing NTC sensor circuit is open. |

| F05 | 0x01 | There is no “Empty tank” signal from the level sensor or the drain pump is blocked. |

| F06 | 0x01 |

|

| F06 | 0x02 |

|

| F07 | 0x01 | The relay circuit for turning on the washing heating element is open / the switching relay is stuck on the side of the drain pump. |

| F08 | 0x01 | The washing heating element is shorted to the body / relay for turning on the washing heating element - stuck. |

| F09 | 0x01 | The main board or display board has detected an EEPROM content error. |

| F09 | 0x02 | The display board has detected an EEPROM content error. |

| F11 | 0x01 | Pump power circuit - pump control triac is open or short-circuited. |

| F12 | 0x01 | Communication error between power board and display board. |

2 Externally SM equipped with ARCADIA

do not differ from the SM with the EVO II module.

ARCADIA

platform modules are equipped with:

- new models originally developed as Arcadia WIN – WIB

- older models that became Arcadia, with a production code ending in 75 (eg: 80 38598 0075) and having a "/ Y

" at the end of the model name

Note

: Fault subcodes can only be “seen” in the microprocessor’s memory, so they can only be displayed when using a pocket computer and

Doctor

.

What to do in such cases?

Let's consider the labor-intensive process of finding and eliminating the reasons why error code F01 was displayed. Experienced specialists advise starting the search for possible problems with simpler ones, moving towards more complex issues that involve disassembling the Ariston machine.

When code F01 appears on the screen, the control module of the Ariston machine is first checked for the origin of a local failure. Everything happens simply:

- de-energize the machine from the electrical network;

- wait from five to seven minutes;

- We turn on the Ariston unit and try to activate the washing program.

If this method does not give positive results, we repeat the reboot attempt several more times. Sometimes such a failure is eliminated after two or three restarts.

One of the indirect reasons for such a failure and the appearance of error F01 is excessively low voltage in the network. This happens in small towns. Ariston does not always respond to this problem with error code F01, but it is necessary to check because a problem with the electrical supply can lead to quite serious failures. If this happens often, it is recommended to buy a device for stabilizing the voltage and connect the Ariston washing machine to the network through it.

Now you need to use a multimeter and check the socket and cord for integrity.

The chances of getting results are slim, but sometimes the problem lies here. When all the easy reasons are over, you will have to look inside your Ariston washing machine. To do this, perform the following steps:

- we install the Ariston washing unit in a room with sufficient free space so that nothing interferes with the repair work;

- remove the tray for washing powders and put it aside;

- unscrew the screws holding the back panel of the machine;

- remove the drive belt;

- We photograph the wires on the engine of the Ariston car, disconnect them;

- Unscrew the motor mounts and remove the engine.

First we inspect the brushes, then the winding. Make sure that there is no leakage to the body part. For this:

- on the sides of the Ariston washing machine motor we look for small screws that secure the brushes and unscrew them;

- remove the brushes, check for wear, and replace if necessary;

- We set the multimeter probes in turns, systematically checking them in search of a breakdown;

- If everything is normal, we move on from the winding to checking the housing part.

If a breakdown is detected in the winding or a leak to the housing, you can throw away the motor without any doubt. Repair in such cases is expensive and does not justify itself.

If the engine is working, use a multimeter to check all the wires powering it. Each element is checked repeatedly to eliminate the F01 error and not repeat such work.

Now it's the turn of the control board for the Ariston washing machine. According to the old tradition, one should not go into such details. Without the appropriate experience, you can only cause additional harm by increasing the cost of repairs. It is best to entrust this type of work to an experienced service center professional.

If you have tried all the testing methods, but the Ariston washing machine still refuses to work and displays error F01, you can confidently state that it is broken. Only a master knows how to fix it.

What to do if the control module breaks down

The Ariston machine gives an error after starting, the drum is motionless. Before fixing the problem, check the board with a tester, checking all the details. If the problem is in the processor, the unit must be replaced. If the track is burned out or the firmware is damaged, repairs are possible.

Also, the reason for the drum stopping may be the motor brushes, which wear out over time. In this case, replace the brushes as shown in the video:

Motor problems, wiring problems

The washing process has started, but the motor does not work. The drum does not spin, the display shows error F1, F01.

Perhaps the motor winding has burned out, then it needs to be replaced. The wire or contact may also be damaged. If the contact burns out, soldering is necessary; if the wiring is faulty, the wires must be replaced.

Using our recommendations, try to fix the Ariston machine yourself. If it does not work, contact the service center.

Every model from this company has a similar error. As a rule, deciphering it is not difficult, but in a certain situation it is sometimes difficult to identify the malfunction that caused it. Let's try to figure out what error F01 means on an Ariston washing machine.

We solve problems on our own

Let's give some tips that can help you avoid unnecessary financial costs:

- The appearance of error F01 may be caused by an increased level of humidity in the room in which your Ariston machine is located. It is recommended to ventilate more often.

- Problems with voltage in the network can only be corrected by an electrician, or you will have to spend money on a stabilizer.

- If error F01 occurs due to the power cord with socket, replace these elements. You should not use extension cords to avoid making the situation worse.

- Check the contacts, remove traces of corrosion and moisture from them. Perhaps a block has come loose in the engine.

- You should periodically check the wiring connections leading from the motor to the control board of the Ariston machine.

How is the problem defined?

Considering the year of manufacture and model range, the machine may signal differently about the problem of starting or completing a full wash cycle. In Indesit this can be a combination of continuously flashing buttons. If the program fails, the indicator on the panel may periodically light up red and flash a number of times equal to the code digit. In new generation technology, the display will display a direct error code that characterizes a particular breakdown.

As a rule, technical documentation describes all the characteristics of possible errors and recommendations for further actions.