The control module in any washing machine is its “intelligence”. If it fails, it is impossible to use the equipment. No system will function properly.

To cope with the problem, you need to correctly determine the cause of the breakdown and eliminate it.

To learn how to repair the control module of an LG washing machine, read the article.

Repair of Indesit module (Ariston)

Failures that occur when a washing machine malfunctions often lead the technician to repair the control module.

Which elements on the board fail most often and how to fix the problem. But let's first decide what kind of electronic boards there are?

After the merger of Indesit with the Hotpoint Ariston company, the machines inside differ almost only in appearance.

- 1. EVO-I board - obsolete models starting with W, WE, WD, WA

The software in the processor ROM is written once at the factory.

If the microcontroller breaks down, the board must be replaced.

Models differ in the type of “firmware” of the non-volatile memory chip (EEPROM), which can be flashed in case of failures.

- 2.EVO-II board with brushed motor

— Models Indesit wisl 103, wisl 83, wisl 82, wisl 102 and . — Ariston AM Series — AMD 129, AML 105, AML 129 — Hotpoint Series — AQSL 109, AVL 105, AVD 127, AVD 129, AVL 100, AVL 95, AVSD 107, AVSL 105, AVSL 109, AVSL 129, AVSL 88, AVXL 109

- 3.EVO-II board with three-phase motor

AQUALTIS:

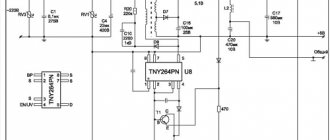

1 NTC thermistor. 2 Capacitor. 3 Throttle. 4 Diode bridge. 5 Power supply. 6 engine control processor. (Q1-Q6) - IGBT transistors.

- 4. LOW END board - Indesit models starting with WIA, WISA, WIU

The 2005 models are also a thing of the past.

- 5. Arcadia module - modern Indesit, suitable for IWE, IWSE, IWDE, PWDE and PWC

1. Anti-interference filter (power capacitor) 2. Heating element 3. Pump (pump) 4. Door locking device 5. Tachogenerator 6. Motor stator 7. Electric motor rotor 8. Main wash water intake solenoid valve 9. Pre-wash solenoid valve 10. NTC (temperature) sensor 13. Water level switch (pressostat) 14. Linear water level switch

Now briefly how to identify a faulty element on the board and replace it.

- How to change the capacitor on the board:

The module capacitor of the washing machine plays the role of a stabilizer. Quite often it is installed on the block along with filters. The board capacitors cannot be repaired.

If the specified element burns out, it can simply be replaced. To do this you will need a similar element, as well as a blowtorch.

Quite often, capacitors are installed with several filters. As a result, the likelihood of re-burnout is greatly reduced. It is necessary to solder the capacitor to the block only to the positive electrode. A tester is used to check the resistance of an alternating circuit.

- Resistor (resistance) burnt out:

For this you only need a tester. On resistors of first-order boards, the average resistance is 8 ohms. In this case, the overload parameter should not exceed 2 A. Second-order board resistors are tested last.

Their overload rating ranges from 3 to 5 A. In this case, the resistance depends on the frequency of the control module. If we consider a simple block, then its above parameter does not exceed 10 Ohms. If the resistance is broken, the resistors on the boards can be resoldered. When repairing the unit, experts recommend replacing the filters.

- How to check the varistor on the board:

A varistor is a resistor that can dramatically change its resistance depending on the voltage. Having a nonlinear characteristic, a varistor very quickly changes its resistance from hundreds of MOhms to tens of Ohms.

This property is used to absorb short voltage surges, and with longer surges the varistor explodes with a loud bang and a lot of smoke. The varistor is switched on in series with the fuse parallel to the mains voltage. With a short jump, the varistor absorbs the pulse energy, and with a long jump, the resistance of the varistor will become so small that the fuse will trip

The first step is to inspect the varistor on the board, looking for chips and cracks, blackening, and traces of soot on it.

If external defects are detected, the varistor must be replaced; you can remove it from the main board for a while; the circuit will work without it. But in this case, it is necessary to remember that during a voltage surge, other components of the circuit will fail and this will entail more expensive repairs.

To check the varistor, switch the tester to the maximum resistance measurement mode. In our case, the resistance of the varistor is significantly greater than the measuring range of the multimeter (reading 1).

- Replacing the EEPROM memory chip:

Of course, you must first make sure that the actuators are in good working order and test them with a tester.

It is necessary to carefully examine the suspicious microcircuit. Unless, of course, we take into account cases where the defect is already obvious (bursted housing, the presence of carbon deposits on the terminals, etc.), sometimes external damage can be insignificant.

Lack of nutritional regulations. Sometimes there may not be a complete short circuit, but simply a very low resistance of the power input(s) relative to “common”. In this case, you will need to have documentation for the microcircuit itself or at least the connection diagram.

Functionality check. Here everything is much more complicated: many microcircuits have many outputs, and a malfunction of at least one of them can lead to the inoperability of the entire device.

In the EVO I module, we replace the memory chip with a similar (93C86) working one with the firmware for the desired model.

If the module is EVO II, then here we change the microcontroller. Soldering it with a soldering iron is problematic; you will need a soldering station with a hot air gun.

Malfunctions of Indesit (Ariston) boards

- The washing machine does not turn on:

EVO-II models wisl 103, wisl 83, wisl 82, wisl 102:

The power supply provides voltages of 5 V and 12 V to power the elements and components that make up the controller. The IP includes a 22uF capacitor at 400V, an optocoupler type SF46156-2, diode 1 and 2. Microcircuit HD6433662С01Н with firmware.

Arcadia board - models (WIN - WIB):

The SMPS produces 12V. It consists of: protective diode D1, output rectifier and filter D2 and C1, pulse transformer, integrated controller. A voltage of 3.3V is used to power the processor.

Operating principle and signs of control module failure

The more abundant the functionality of the washing machine, the more complex the electronic board is. This part is responsible for the operation of all components located in the machine body. Individual triacs, using wiring, send signals to start working to the following nodes:

- heater (heating element);

- thermistor;

- pump;

- UBL (hatch blocking device);

- solenoid valve;

- Hall sensor;

- electric motor;

- level relay.

As you can see, the entire operation of the equipment depends on the serviceability of the board. Any breakdown that occurs during operation can be associated either with a specific part or with the electrical circuit. Only diagnostics can accurately determine whether it is necessary to repair the “brains” of washing machines. A malfunction can be assumed based on indirect signs:

- The SMA screen displays an error code or the indicators blink. The decoding indicates the washing machine control unit.

- Installed programs are not activated in the machine.

- The equipment does not turn on.

- Water is constantly filling and draining.

- Unregulated engine speed.

- The water overheats or remains cold.

All these signs are ambiguous. Therefore, it is necessary to test both the node itself and the electronics. Most often, the module breaks down for the following reasons:

- Factory defect (rare case). It appears quite quickly, so the problem is solved by warranty repair or replacement.

- Power surges in the network. Lead to burnout of tracks and individual parts.

- Moisture. Contacts with moisture result in oxidation of the board surface.

- Abrupt power cut to the SM during operation. Also leads to voltage drop.

How to check and repair the control board of a washing machine?

It is difficult to determine the cause of the malfunction on your own. Why are users in no hurry to contact the workshop? Their logic is clear. There are several factors that influence the choice of self-examination:

- Removing and taking the unit for repairs is still half the battle. No one will carry out diagnostics for free. What if it turns out that everything is fine with the part? It turns out that the money was wasted.

- Fear of getting to a non-professional. He will take money for the inspection, but you cannot exclude the possibility of his hack work. As a result, there is a breakdown, but no solution.

What to do? If you want to check the “brains” for SMA yourself, we will tell you how.

Visual inspection . To do this, you need to remove the part and inspect it for signs of burns, damage, or oxidation. How to remove the washing machine circuit board:

- Unplug the washing machine.

- Turn off the water supply.

- Remove the top cover by unscrewing the screws at the back.

- Pull out the powder dispenser by pressing the central latch.

- Remove the screws around the perimeter of the control panel. Lift up and remove.

- Take photos of the connectors and wiring. Disable chips.

- Unfasten the latch and remove the unit cover.

Anything can burn out: resistors, thyristors, resonator, relay or processor. A multimeter will help you accurately determine the breakdown. You will find the SMA control board diagram useful:

Capacitors . They serve as stabilizing devices during voltage drops. External swelling of the element already indicates a breakdown. Place the multimeter probe on it.

- The tester beeps or shows 0 on the display - a short circuit (short circuit) has occurred.

- 1 appeared on the screen - break.

If there is a malfunction, it is replaced with a working part. It is secured with a soldering iron and solder to the positive electrode.

Resistor . Elements are divided into first and second order. First order resistors are tested. Their resistance in good condition is 8 ohms. Second order - 10 Ohms. Broken products must be replaced.

A varistor serves to absorb voltage surges in the network. Its burnt surface indicates a problem. The part can be removed from the board, it will work normally. But during the jump, other components will burn. Testing with a multimeter at maximum resistance:

- Attach the probe to the varistor.

- In this case, the values are much higher than the tester (1) can show.

Watch the video on the topic:

Next, a sequential diagnosis of all components is carried out. An example is shown in the photo:

Repairing a control unit with your own hands is an impossible task for a novice master. Therefore, we recommend that you contact a trusted service center, preferably one that specializes in repairing your particular brand of SMA. There you will be given a guarantee for the work performed. Good luck!

see also

Comments 6

“The drum turns slowly and rarely.”

Is this about a specific mode, or does it spin slowly and rarely in all modes?

I’ll put it in bookmarks, today the recently repaired car flew again, I’ll take it to the dacha for now, under the fence in the company of Samsung, also without brains, in my spare time I’ll try to revive it for use in the village, either one or the other

Hello. I have been looking for an inexpensive universal module for SMA for a long time, and even found it last year at a price of about 1,600 rubles, but its control panel is completely disgusting and there is no description. The design is externally different from this one. It hangs on the Alishka to this day with several orders and without a single review. I also saw a module like the one you ordered from dealers in Russia; they sold it through Avito for more than $100. Naturally, also without a description or demonstration of the work - in my opinion, these are the most arrogant freeloaders who can’t even find out information about what they are selling at exorbitant prices. Well, the dog is with them. Today this module accidentally popped up on Ali at a price of about 3,600 rubles, and I finally saw the marking in the description. It’s already available on eBay for 2,600, I was quite happy with it and ordered it right away. What I would like to know from you: 1) Are you sure that the device works correctly with a 5 kOhm temperature sensor? If yes, then in more detail about the temperature sensor - parameters (temperature/resistance graph), where/how much, and everything that you can explain about this. 2) Did you measure the temperature of the water during washing? Does it differ from the given one? 3) What do you think and/or hear about the spin speed? 4) How correctly is the firmware done, does it damage underwear/clothes? 5) Well, other features/advantages/disadvantages, for example, how the weighing system works and eliminates imbalance during the spin cycle - does it turn off the mode or spin it no matter what, does the pump run when there is no water, how long does it keep the fill valve open, if not water flows (is there any protection against burning it) - in general, tell me everything that you noticed, good and bad, if it’s not difficult. At one time I had enough of minicel modules, and as a result, two mechanically excellent ardoshkas are gathering dust in the utility room - I can’t throw them away in this time of lack of quality things, but I don’t want to buy new modules at the price of a whole washing machine. And the modules, again, are very delicate - if the UBL, valve or motor winding breaks down, they most often burn out forever. Let this Chinese module be inconvenient to operate, the main thing is that it is reliable and works correctly.

Hello. 1. Yes, I'm sure. I wrote to a Frenchman who sells these modules in Europe - he answered me according to the characteristics of the sensor: NTC There are a great many of them on Ali, I took them embedded in metal. 2.No, I didn’t. 3. Maximum. I think 900-1000 for sure. 4.Everything is fine. No problems noticed. 6. Elimination of imbalance? I think there is no such thing there. 6.1 I haven’t tested with the tap closed and I can’t answer about the valve how long it will take to fill the water. 6.2 Everything else is above in the text, I can’t add more, because there’s nothing.

Thank you, everything is clear. A long-awaited topic for many.

When choosing an automatic machine, users are guided by the functionality that the equipment offers. The abundance of technologies and programs makes you happy until the electronics fail. What to do? Is it possible to repair the control board of a washing machine yourself? We will discuss the features of diagnostics and repair in the article.

Is it worth doing repairs to electronic modules yourself?

Electronic modules of washing machines are the most complex parts of this household appliance. They are based on a printed circuit board, on which the control elements for each unit of the washing machine and its parts are located in a special order. The microprocessor, the most expensive part of the control module, synchronizes the operation of the elements. Electronic modules of modern washing machines can break down, and this is where the main problems begin. In this article we will discuss these problems and outline ways to resolve them.

Features of the structure of Samsung models

Samsung appliances have long established themselves in the market and washing machines of this brand are not the least popular. Modern Samsung models include several washing programs, the choice of which determines the duration of the process. The general principle of operation is not much different from other brands; the electrical circuit is responsible for all operations. The functioning of the equipment directly depends on the integrity of the network elements of the electronic unit.

Samsung technology has fundamental differences. The Japanese manufacturer equips the models with additional sensors to monitor water quality, load level and other indicators, so the electrical circuit is equipped with additional elements.

Some Samsung models have a direct drive motor, which provides better quality washing and shorter process times. However, the principle of connecting to the network is not much different, like models of other brands, Samsung equipment is not protected from power surges, despite the fact that a capacitor is included in the package. The solution in this case may be the ability to connect Samsung equipment not directly, but through a stabilizer.

The most modern Samsung models are equipped with an intelligent Smart Check system, which allows you to check the serviceability of the electronic module itself, the engine, and the main components of the equipment using a special application for mobile devices. This principle of prevention allows you to avoid serious repairs.

How can you tell if a module is broken?

The most basic problem is to understand whether the control module is actually broken and needs repair, or whether one of the units of the washing machine is actually broken, and it is this that creates the appearance of damage to the electronics. Resolving this issue is of priority importance, because if you start immediately repairing or changing the module without sufficient grounds, you will throw money down the drain and the problem will not be solved.

“Brains went flying” at the washing machine!

“What is a washing machine control module and what is it for? How to determine its malfunction? What failures may indicate a breakdown? Why do we recommend only professional repair of electronic modules?”

One of the most important components in a washing machine is the control module. Without it, it is impossible to launch the program and operate the nodes. If the control module of the washing machine becomes unusable, further operation of the household appliance is simply impossible. Unfortunately, the electronic unit sooner or later fails, both in cheap and more expensive devices. There can be many reasons for this, and all because electronic components, sensors and boards are very sensitive to any influences and adverse factors that can cause failures.

In general, all electronics, in fact, are very capricious and unpredictable. Therefore, users should be cautioned that repairing the control module

should not be carried out by an inexperienced craftsman or, even worse, resort to such work on your own.

The most correct and adequate decision is to order professional repair of washing machines

from a trusted company with good reviews of the specialists working there.

Checking trigger status

The trigger in washing machines rarely fails. The causes of failure are most often associated with malfunctions of the capacitor. To check the functionality of the trigger, it is important to test the voltage at the output pins. The specified parameter must be within 12 V. Many models have a filter installed next to the trigger. The average resistance on it is 20 ohms.

Replacing the trigger on the control unit takes quite a lot of time. First of all, it is important to start soldering the output contacts. In this case, it is necessary not to touch the cathode of the capacitor. After soldering, you can install a new trigger. The last step is to test the threshold voltage and check the output resistance on the modulator.

See also:

- 13 best washing machines from 40,000 to 50,000 rubles according to customer reviews

- 14 most reliable washing machines

- 15 best washing machines

- 15 best washing machines from 30,000 to 40,000 rubles according to customer reviews

- 5 Best Whirlpool Washing Machines Based on Customer Reviews

What is a washing machine control module?

The control module is a printed electronic board with control elements for each individual node and its parts located on it in the required order. The microprocessor, which is the most expensive element of the module, is responsible for synchronizing processes. Its malfunction paralyzes the operation of other electronic components, signals stop being sent to the components and systems of the washing machine, and as a result, the control module needs to be replaced.

This type of repair is very painstaking and requires certain knowledge in the field of electronics, so the cost sometimes reaches almost half the price of the household appliance itself. Before taking restoration measures, evaluate the economic feasibility of the upcoming repair measures.

Malfunction of the electronic module of the washing machine

The main problem in diagnosing a module malfunction is its identification, because a breakdown of one of the nodes or components has the same symptoms as a breakdown of the programmer. Therefore, before you begin replacing the electronic unit, you need to eliminate all related and characteristic problems. Otherwise, you will simply waste money and not achieve the desired result. This is where professional help is required, as well as the necessary test equipment and devices.

In approximately half of the cases, it is possible to determine that the electronic control module of the washing machine has become faulty based on certain signs. To determine the breakdown, it is enough to observe the behavior of your household appliance. If you notice one or more of the above, there is a good chance that you are on the right track. The spin cycle does not start after washing. In this case, the program freezes and the buttons do not respond to pressing. The error code is not displayed. The indicators may go out instantly or start flashing simultaneously.

- The lights begin to flash alternately or simultaneously. Setting a new wash program is not possible. The washing machine does not respond to the set parameters.

- The control panel does not respond to the washing parameters specified. Washing and rinsing is not possible due to constant drainage of water. Also, there may be no water intake into the tank at all. After this, the device may freeze completely until the next restart by disconnecting from the power supply.

- The washing machine allows you to select a washing program, but it washes for several hours without stopping. The water does not drain and does not go into rinse mode. Time is not counted. As a result, the device may freeze.

- When selecting and installing the required program, the household appliance immediately turns off.

- The program is installed, the countdown has begun, the indicators are flashing, showing the progress of the wash, but, in fact, the machine does not perform any action. Water does not fill, the washing drum does not spin, and the water does not drain.

- The engine will spontaneously change its speed. The revolutions occur either at higher or lower speeds. It can spin only in one direction or only in the other direction. Increased vibration, as in the rinsing mode, which is in no way justified and unacceptable in the washing mode.

- The water can be heated to boiling or remain cold. The sensor ignores temperature readings and does not turn off heating of the heating element.

Be careful!

The listed signs only indirectly indicate a breakdown of the programmer.

To verify its malfunction, it is necessary to ring in detail all components of the washing machine control module

, units and components that have identical signs of failure and only then draw the appropriate conclusions.

If you need to repair the electronic module of your washing machine,

dial our company's phone number: 8 (499) 408-20-52 and we will provide you with high-quality service at the most reasonable prices.

Looking for firmware

So, one of the most important stages of the upcoming repair is selecting the software that is suitable for your SMA model. We recommend searching for firmware on the website bineep.ru, where an extensive free database of programs for all automatic washing machines is presented. The portal interface is quite simple. In the search bar, you must enter the model of the automatic washing machine without spaces, hyphens, etc. It is allowed to indicate the signs “/” and “.”, which are present in the designation of the models of some washing machines.

After you specify the model name, you should click the “Find” button. The system will display programs suitable for flashing

You should also pay attention to the product code of the machine. In some cases, there are several variants of this code for one SMA model

That is, the product code describes the model in more detail, so when choosing firmware, look at this parameter.

For example, the portal can provide information that such and such a program is used up to S/N 40829...., another - from S/N 40425... This means that if the serial number is greater than the specified value, it is better to select the firmware, for example, 30815480000, if less, then 30815480201.