No equipment will work forever, which is why all Indesit washing machines break down over time. If the device is still under warranty, then you should not unscrew anything and look at it yourself, as this may invalidate the documents for free service.

When the warranty period has expired, in order to save on the services of a technician, you can try to fix the problem yourself. Do-it-yourself repair of an Indesit washing machine begins with diagnosing the device, localizing the problem area and step-by-step elimination of breakdowns that may occur in this unit. The article will be useful to everyone who has the necessary tools and skills to handle them, which will help save the family budget.

We understand the structure of Indesit washing machines

To repair an Indesit washing machine with your own hands, you need to understand its structure and the relationship of some parts to others. This will help more accurately determine the location of the problem and save time on disassembling components that are not involved in the problem. Indesit machines come with vertical and front loading. The latter are the most common. They include the following important components:

- top cover;

- front and rear detachable panels;

- drum (steel or plastic);

- a panel with control buttons, behind which the programmer or module is located;

- an electric motor that provides rotation during washing and spinning;

- a tank in which water accumulates and a drum with holes for collecting liquid rotates;

- inlet valve;

- drain filter;

- pump for pumping water;

- heating heating element;

- speed and liquid level sensors;

- shock absorbers and counterweight for stability;

- compartment for powder and conditioner;

- torque transmitting belt and pulley system.

There are machines without a belt drive, where the engine is made in the form of a huge tablet located on the same axis with the drum. Such devices have fewer mechanical components and lower vibration, so they break less often, but are more expensive.

Household appliances with mechanical controls are easier to operate, but if there is a malfunction in the program, the programmer itself needs to be replaced, which can only be done by a master. In machines with a display and electronic control, reconfiguration is available, but it requires an experienced specialist and computer equipment.

All other types of repairs to the Indesit washing machine can be done with your own hands, but to do this you need to correctly identify the breakdown.

Replacing shock absorbers and dampers

The main function of shock absorbers is to dampen sudden vibrations that occur during washing. Their work is especially important when spinning clothes when the drum reaches high speed. In each Indesit model, shock absorbers have a certain force, expressed in Newtons.

During operation, these devices gradually lose their qualities and cannot fully perform the functions assigned to them. As a result, extraneous noise, increased vibration, and knocking during spinning are observed. The main cause of failure is wear of the gasket located between the piston and cylinder. Gradually, the piston and cylinder may become deformed.

Since manufacturers do not produce separate spare parts, all repairs to shock absorbers consist of replacing them. Repairs require removal of the rear panel. In some models of Indesit washing machines, the side or front covers can be removed. After gaining access to the shock absorber, the nut is unscrewed from its lower part, and the shock absorber itself is disconnected from the body. In the same way, the part is unscrewed from above and disconnected from the tank. The new shock absorber is installed in place of the old one and screwed in the reverse order.

In modern designs of washing machines, dampers are used instead of shock absorbers. They do not contain a return spring and are used in conjunction with suspension springs. The overall shock absorption system consists of two return springs located at the top and two dampers located at the bottom and directed diagonally in relation to the body of the washing machine.

DIY diagnostics of the Indesit washing machine

To repair yourself, you need to determine the direction to look for the breakdown. If this is a mechanically controlled washing machine, then you need to pay attention to signs characteristic of certain malfunctions.

For example, if a leak appears from the outside, you should look for a violation in the connection of the solenoid valve, check the integrity of the hatch cuff, and monitor the tightness of the drain paths.

Complete “silence” of the machine indicates a breakdown in the electronics or a broken contact. If the lights come on, but the rotation does not start, then there is probably a problem with the engine. Stagnant water refers to a faulty pump or a clogged filter. If everything works, but washing occurs in cold water, then there is a problem with the heating element or the accompanying temperature sensor.

Repairing an Indesit washing machine with your own hands is easier if it has an electronic control that has a self-diagnostic module that can recognize the problem area. The equipment reports a fault found with a code on the display. It consists of the letter F and several numbers. Here are the codes for which it is possible to troubleshoot the problem yourself:

- 02 - elementary overload, which prevents the engine from rotating the drum, or bearing failure;

- 03 - failure of the heating element or the temperature sensor itself;

- 04 - no accurate data on the liquid level (clogged inlet);

- 05 - stagnation of water due to pump failure or blockage in communications;

- 07 - no liquid heating;

- 08 — heating element short circuit;

- 10 — level sensor is broken;

- 13 — drying mode is broken;

- 16 - bearing failure, drum overload or poorly closed door (in devices with vertical loading);

- 17 — UBL is broken or the front hatch is poorly closed.

If one of the above codes comes on, you can set yourself up for independent repairs. If other errors are displayed, you will have to call a technician. Next, we will consider ways to troubleshoot an Indesit washing machine with your own hands in two categories: mechanical breakdowns and failure of electronic equipment.

Control module malfunctions

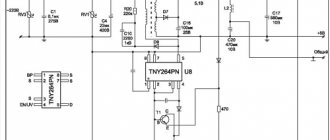

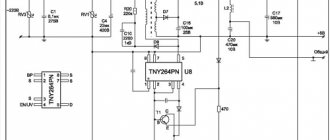

The operation of all components of the Indesit washing machine depends on the control panel. The performance of the module itself is closely related to operating conditions. It stops functioning normally under the influence of power surges and high humidity. Often the contact group of the surge protector burns out.

Violations manifest themselves in the form of various failures. The washing machine begins to switch inconsistently to different modes, freezes, and periodically refuses to spin, rinse, and drain. The wash time increases noticeably and the indicators blink erratically. When the control board circuitry fails completely, all programs stop running.

The causes of the problem may be related not only to the module itself, but also to mechanical factors. Therefore, accurate diagnostics in the “Autotest” mode is required. To repair the control unit of an Indesit washing machine, you need knowledge of radio engineering, practical skills in working with a soldering iron, printed circuit boards, microcircuits and semiconductor devices. Typically such work is performed by qualified specialists.

If the home mechanic nevertheless decides to carry out independent repairs, then you need to start by removing the cover from the control unit and removing the module. Next, damaged contacts and other faulty connections are inspected. Faulty parts are soldered off, and new elements are soldered in their place.

Do-it-yourself mechanical repair of the Indesit washing machine

Mechanical failures can be simple, which can be resolved in a couple of minutes, or complex, requiring disassembly of the case and replacement of components. Here are the most common malfunctions of Indesit machines and how to fix them yourself:

Increased vibration and jumping

If, during the spin cycle, Indesit begins to jump and move from place, then the reason may be in the directional distribution of the laundry or overload. To eliminate this phenomenon, it is necessary to stop the device when there is no water in it, wait until the hatch is unlocked and transfer things inside the drum. If the load is heavy, you can remove something and start the wash again.

Even increased vibration occurs due to an uneven floor, for which the machine is equipped with twist-out legs. The sagging corner is set on a level with the rest so that the body does not swing. You can finally check the evenness with a bubble level or a plate of water placed on the housing lid.

If the problem appeared immediately after purchase, then repairing the Indesit jumping washing machine with your own hands is done by unscrewing the transport bolts located on the rear wall of the case. When installing household appliances on tiles or laminate, you should place a rubber mat or small circles to prevent slipping.

If all of the above is done, but the machine continues to jump during the spin cycle, then the reason lies in loose shock absorbers. Over time, they stretch and no longer dampen vibrations properly. To solve the problem, turn the body on its side and remove the springs. They are attached with simple hooks, so DIY repairs are quite possible. To replace, it is worth choosing the correct length of the new shock absorbers. Parts from other machines will also work - the main thing is that the parameters match.

No water supply

Periodically, Indesit washing machines do not draw water, while all the buttons work, but when the program starts, the washing does not start. Here, the repair is performed at the inlet, where the supply filter in front of the tap or directly at the entrance to the housing is clogged.

To get to the first one, you will need to turn off the water in the house and unscrew the filter block in front of the tap that leads the water supply branch to the machine. Often rust and deposits from the system accumulate there.

Cleaning the filter of the Indesit washing machine with your own hands requires unscrewing the flexible hose connected to the back of the case. There is a fine steel mesh that traps residual debris. With prolonged use, the throughput drops and water stops flowing. Having removed foreign particles, the unit is assembled and the wash is started again.

Leaks on the front panel

Another common malfunction of this Italian brand of household appliances is water leakage on the front panel. This often occurs after carelessly removing laundry from the drum, when hard elements (large buttons, fasteners, metal decorations sewn to clothing) cling to the rubber cuff and tear it. Because of this, the tightness of the hatch cover is broken and water flows out.

When the leak is found, repairing the Indesit washing machine with your own hands is done by disconnecting the cuff clamps and twisting this place to the top, where the water pressure is less. The hole can be sealed with a rubber patch and “Moment”.

Stagnation of water in the drum

Sometimes in household appliances of this Italian brand, water remains in the drum. The washing program cannot be completed because it is not possible to spin. A common cause is the accumulation of debris in the drain filter. Do-it-yourself repair of this part of the Indesit washing machine involves stopping the washing program and disconnecting the unit from the network. Next you need:

- Remove the plastic decorative cover from the bottom of the housing.

- Behind it there is a plug for emergency drainage of water. Due to the low height above the floor, you will need a basin with low walls and a rag. Substituting the container, the plug is unscrewed and the liquid is drained. This can be done in doses, periodically screwing it back to collect water from the floor.

- There is a filter on the back of the plug. It comes in the shape of a cone with catcher ribs or a cylinder with mesh walls. Garbage from clothes and items forgotten in pockets accumulate here. Due to the narrowing of permeability, water stagnates, which leads to breakdown.

- Having removed all the excess, the plug is returned to its place and rinsing is started to check the permeability of the system.

If after this water continues to accumulate in the drum, then the blockage may be located higher in the pipe. It is L-shaped and connects the tank to the filter. After prolonged use, large objects also collect there (underwires from bras, pen caps), on which smaller ones are placed, which leads to clogging. The plastic corrugated tube is secured with two clamps, but to get to it you will have to turn the machine on its side. Having removed and cleaned the channel, everything is returned to its place and tested by drawing and draining water.

Pump jamming

When water remains in the drum and the pipe and drain filter are cleaned, the cause of the breakdown may be jamming of the pump impeller. This is accompanied by an uncharacteristic hum of the pump during pumping, the inability to drain water, and even the smell of burnt wiring. Here you can repair the Indesit washing machine with your own hands by disassembling the drain filter and shining a flashlight into the channel further.

The pump impeller looks like four plastic blades on an axis, the rotation of which forces water into the drainage pipe. With the appliance unplugged, carefully check the rotation of the element with your finger. So, you can find the blocking object (often small coins or buttons), take it out and return everything to its place.

Bearing failure

The most serious mechanical failure is the failure of the bearing on which the drum rotates. When exposed to moisture or after a long service life, the lubricant in it dries out, which leads to the disintegration of the internal parts of the assembly. This is accompanied by a metallic grinding sound and poor rotation of the drum.

Repairing the bearing of an Indesit washing machine with your own hands complicates the hard-to-reach location of the part. To replace it you will need:

- Remove the top cover of the machine.

- Disconnect shock absorbers and springs.

- Pull the drum out.

- Treat its landing site with WD

- Try to knock out the bearing. Masters have special devices for this, so if it doesn’t work, it’s better to contact them.

- When the bearing has been knocked out, the new one is carefully lubricated and put in place by lightly tapping the side around it.

Do-it-yourself repair of the electronic part of the Indesit washing machine

Electronics include anything that operates using voltage or passes it through itself. The Indesit washing machine has many sensors and components that ensure the correct execution of programs. What can break here and how to fix it yourself is described below:

Doesn't heat water

If you find that the device does not heat the water, there may be two reasons. The first is related to the breakdown of the heating element. To determine this, you will need to turn the case on its side to get to the contacts of the equipment. The heating element has an M or U shape and is located at the bottom of the tank.

It has three terminals, where the tester contacts should be connected to the outer ones and the part should be “ringed”. If the internal cable breaks, the device needs to be replaced, which is very simple. To do this, unscrew the bar on which the heater is located and install a new one.

If the heating element is intact, but the water does not heat up, then repairing the Indesit washing machine yourself will require cleaning the deposits that cover the surface of the heater and interfere with heat transfer.

To do this, start the wash without items and add citric acid to the powder compartment (one packet per 1 kg of machine loading capacity). By removing the scale, you can restore the heater's functionality.

When the steps described above do not help, the problem lies in the temperature sensor, which incorrectly transmits data to the control module. This sensor is located at the bottom of the tank and has two contacts. By disconnecting the power wire and taking it out, you can clean the contacts and the surface of the device body. If this does not help, then the part is changed.

Eating problems

Indesit washing machines may also not respond at all when turned on. In this case, the indicator lights do not light up. The problem could be a broken start button wire. It is located at the top of the front panel.

By unscrewing two screws from the back, the top cover is removed and access to the insides is opened. The wires leading to the control panel are tugged with your fingers to check the integrity of the contact.

If a terminal is broken, repairing an Indesit washing machine involves soldering the contact with a soldering iron and tin. The area is first degreased with acid. When the lid is open, switching is tested.

In the same part of the case there is also a surge filter that protects equipment from power surges and impulses. The block looks like a coil and several transistors. Often replacing it eliminates the problem with the washing machine not turning on.

Wash does not start

If all contacts are in place and the light filter is working properly, the machine will respond with working light indicators. But when you click on the start of the program, the equipment may give an error of the hatch not being closed. Because of this, the wash does not start.

The problem here may be laundry caught in the vestibule. After checking that nothing is on this side of the cuff, close the door and press start again. If the problem persists, then the hatch locking device has deteriorated.

It mechanically closes the exit of the lock hook and informs the control module that it is ready for washing. If the lock breaks or the signal is transmitted incorrectly, the machine “thinks” that the door is open and does not start washing.

Do-it-yourself repair of an Indesit automatic washing machine involves dismantling the blocker and installing a new one. Its replacement is carried out from the front side, where:

- Two screws are removed where the lock enters.

- After this, the cuff is carefully pushed aside and the element is pulled out.

- The terminals are removed last.

- Installation of the new UBL is carried out in the reverse order.

Solenoid valve

If water spontaneously accumulates in the tank (when the device is turned off) or, on the contrary, does not accumulate during the start of the program, and there is no physical interference in the filter, then the problem is in the solenoid valve. This unit responds to commands from the control module and opens or closes the liquid supply.

The block consists of a wide inlet and two outlet pipes (for the compartment with powder and conditioner). Above each outlet tube there is a coil with a contact that controls the position of the valve. If something gets into the valve or it is stuck, then there will be such a problem.

Do-it-yourself repair of the Indesit washing machine valve requires removing the top cover and disconnecting the inlet hose. After this, the two fixing screws are unscrewed and the wires are disconnected. The assembly is taken out and blown through by alternately closing one of the holes. If this does not help, then it is replaced with a similar one.

Problems with sensors

If spinning occurs at low speeds or does not start at all, then the speed sensor has failed, which transmits incorrect information to the “brain”. The repair consists of replacing this unit, located on the axis with the drum. The coil is removed through the top cover.

When washing with an empty drum, the pressure switch responsible for the liquid level broke. It is attached to the bottom of the tank and has two terminals. Replacing the sensor will restore the functionality of the household appliance.

Thematic materials

4 Best Direct Drive Washing Machines

4 Best Front Load Washing Machines

4 best inexpensive washing machines

5 best Asko washing machines

6 best Hotpoint-Ariston washing machines

5 best Ardo washing machines

10 best semi-automatic washing machines

8 best Hansa washing machines

10 best washing machines

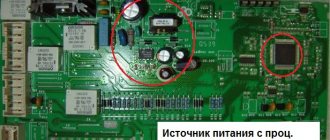

Repairing a faulty pump

The picture shows that the water pump is located at the bottom of the washing machine and is connected to the filter. Sometimes malfunctions occur in the operation of the pump, the first sign of which is a violation of water drainage. The main cause of the malfunction can be attributed to the significant loads that the water pump experiences for a long time. This is due to the purpose of the pump, which is to timely and completely pump out water from the working tank.

Before repairing the pump, it is recommended to clean the filter covered by the protective panel. First, the cap is unscrewed, and the filter itself is removed, cleaned and washed. It is imperative to check the hole from which it was removed. The water pump impeller will be visible inside. It is checked for the presence of foreign objects that could jam it. If any are found, they should be removed. As practice shows, the most common causes of difficult water drainage are a clogged filter, drain hoses and pump motor.

If cleaning the filter does not give the desired result, the pump will need to be repaired or completely replaced. For this purpose, the Indesit washing machine is laid on its side, after which the screws that secure the pump to the body are unscrewed. Next, the electrical wires are turned off and the two hoses are disconnected. These hoses also need to be inspected and cleaned. The check should begin with the motor winding for open circuits using a tester. In normal condition, the winding resistance is 150-300 Ohms.

To find other faults, the pump must be disassembled. You must first mark its position in relation to the engine. After this, the pump motor is disconnected from the housing, and the rotor is removed from the stator. Very often, everything inside the pump is clogged with dirt, preventing the rotor from rotating freely. In this case, all the insides are washed. The oil seal on the rotor axle needs to be corrected, and the axle bearing needs to be lubricated with lithol. Reassembly of the pump is carried out using sealant so that the connections and joints do not allow water to pass through. When assembling, you need to remember the marks applied.