Replacement of spare parts :: Error codes :: Malfunctions :: Diagnostics :: Module repair

bearing replacement :: hatch cuff replacement :: heating element replacement :: brush replacement

does not drain water :: does not spin :: does not turn on :: machine knocks out :: no water flows :: flows :: makes noise

| 8 (495) 772-76-52 8, 8, 8 daily from 8:00 to 22:00. Diagnostics + Departure - Free. * (see section “Prices”). If you refuse service - only 500 rubles . Our coordinates CALL FROM MOBILE CALL THE MASTER |

| Find out the cost of repairing your washing machine | |

| Find out the cost |

How to call a specialist

A technician will come out for diagnostics and repairs upon prior request. You can make a call by phone or through the form on the website. Provide the service manager with the following information:

- Make and model of the washing machine (see the instructions on the body).

- What happened, when, after what, the main symptoms of the breakdown (needed to select tools and components before leaving).

- Optimal time for repairs.

- Contact details.

SHOW MORE

Features of the Samsung modules design

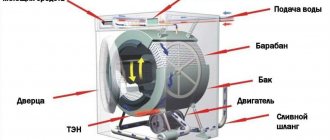

The washing machine control module is an “on-board computer” that monitors the state of the sensors during the execution of a specific program. The electronic module consists of several important elements, namely:

- controllers;

- microprocessor;

- electronic microcircuits.

You can see how the control module of a Samsung washing machine works in the photo below.

When loading the machine and selecting a specific washing program, the microprocessor begins controlling the executive elements of the equipment:

- pumps;

- electric motor;

- heating element (heating element);

- valves.

If for some reason the electronic board malfunctions, this will also affect the operation of the Samsung machine itself.

We repair:

Aeg, Ardo, Ariston, Asko, Atlant, Beko, Blomberg, Bosch, Brandt, Candy, Daewoo ), Electrolux, Elenberg, Euronova, Fagor, Gorenje, Hansa, Indesit, Kaiser, Kuppersbusch, Lg ), Miele (Miles), Samsung (Samsung), Siemens (Siemens), Smeg (Smeg), Thomson (Thomson), Whirlpool (Whirlpool), Zanussi (Zanussi), etc.

Repairing the washing machine module is necessary to restore functionality. This component of the equipment controls the basic processes of its operation, so its malfunction leads to the inability to operate the equipment partially or even completely.

Typical faults of electronic boards

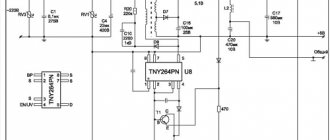

The control units of individual models of Samsung equipment may differ greatly, depending on the model. The photo shows diagrams of the most popular models from this manufacturer:

- WF7602S9;

- S821;

Each of them has its own weaknesses, which is due to the peculiarities of soldering microprocessors and technologies for the production of electronic components, such as Can Balance or Silver Nano. In this regard, the repair of controllers in the event of a breakdown will have some features. To choose the optimal model of equipment, we will consider typical types of breakdowns for machines, the circuit diagrams of which are shown in the photo below:

Repair of electronic units – guarantees

The electronic unit is responsible for controlling the washing processes and spin mode. The work occurs thanks to electronics, which can easily be damaged by incorrect use. Restoring the control units will return the functionality of the washing machine.

The following will work effectively:

- Drain pump;

- Fill valves;

- AC motor commutator;

- Programmer;

- Reception of signals from temperature sensors;

- Signal from water level switch;

- Signal from timer contact groups.

The functions of the module include ensuring the operation of two boards. One of them is responsible for the constant operation of all systems. The second board indexes modes, works with signals from control systems and analyzes them. A malfunction of electronic modules can be noticed by incorrect data of a certain node. Repairing or replacing the module will correct this problem and ensure understanding between the owner and her assistant.

Why does the control unit break down?

Samsung washing machines are highly reliable. The brand produces equipment that meets European quality standards, so the machines usually do not require repairs for many years of operation. However, there is still a small percentage of breakdowns.

The main electronic unit of a Samsung washing machine can break down due to various factors. Let's look at the main reasons for this problem.

- Manufacturing defects. Its percentage is minimal, but still this factor takes place. It can be determined visually - the board will have poorly soldered contacts, peeled tracks, areas of solder spreading, etc. Usually the problem manifests itself during the first month of using the washing machine. In this case, you should contact the service center; the breakdown is included in the warranty list, so it will be fixed free of charge.

- Electricity problems. The electronics of modern washing machines are very sensitive to voltage changes in the network. A strong “jump” can cause the control unit to fail.

- Liquid has gotten on the board. Under no circumstances should the module come into contact with water. Otherwise, this will lead to oxidation of contacts and tracks. Sometimes the user exceeds the dosage of detergent and the “soap cap” extends beyond the tank, seeping into the electronics. The microcontroller shorts out and stops functioning. Often in such a situation it is enough to dry the control unit well.

Water can get on the control board when transporting the automatic machine, so you need to transport the washing machine “standing”, securely fixing it in a vertical position.

Mice or rats, which like to gnaw contacts, can also disrupt the operation of the control unit of a Samsung washing machine. Cockroaches that get inside the machine can cause a malfunction. Let's figure out how you can check whether the electronic module is really functioning incorrectly.

Prices for services

| Services | Price from) | Application |

| Departure + Diagnosis of the problem (in case of repair work)* | 0 ₽* | |

| Departure + Diagnostics | 500 ₽. | |

| Replacing shock absorbers | 1150 ₽. | |

| Replacement of drum, tank | 2000 ₽. | |

| Replacing the motor (motor, drum drive, electric motor) | 1200 ₽. | |

| Replacing the wiring harness | 800 ₽. | |

| Replacing the fill/inlet valve (KEN, water supply valve) | 650 ₽. | |

| Replacing buttons and switches | 700 ₽. | |

| Replacing the cross (shaft) | 2200 ₽. | |

| Replacing the hatch (door, cover) | 1100 ₽. | |

| Replacing the hatch cuff (elastic band, rubber seal) | 850 ₽. | |

| Replacing the tank support | 2500 ₽. | |

| Replacing the pipe | 1200 ₽. | |

| Bearing replacement | 2500 ₽. | |

| Replacing the pressure switch (water level sensor, relay) | 1300 ₽. | |

| Replacing the drive belt | 700 ₽. | |

| Replacing the programmer (program selector, command device, timer) | 1500 ₽. | |

| Replacing the counterweight | 2200 ₽. | |

| Replacing springs | 1750 ₽. | |

| Replacing the hatch handle | 1000 ₽. | |

| Replacing the oil seal | 500 ₽. | |

| Replacing the mains filter (FPS, starting capacitor) | 1150 ₽. | |

| Replacing the drain/fill hose | 750 ₽. | |

| Replacing the drain pump (pump) | 1200 ₽. | |

| Replacing the drain filter | 1000 ₽. | |

| Sunroof glass replacement | 1000 ₽. | |

| Replacing the thermostat (water temperature sensor) | 1000 ₽. | |

| Replacing the heating element (heating element) | 1200 ₽. | |

| Replacement of UBL (hatch lock, lock) | 1000 ₽. | |

| Replacing the drum pulley | 1300 ₽. | |

| Replacing the drum curtain of a vertical machine | 2200 ₽. | |

| Replacing motor brushes | 1100 ₽. | |

| Repair of control module, board, block, triac | 2000 ₽. | |

| Cleaning the fill/drain system | 700 ₽. | |

| Clearing the blockage | 800 ₽. | |

| Removing a Foreign Object | 900 ₽. | |

| Installation / Connection of the machine | 2000 ₽. | |

| Telephone consultation | 0 ₽. | |

| Malfunctions | Price from) | Application |

| Gives an electric shock | 200 ₽. | |

| Vibration / Vibrates heavily / Jumps / Shakes / Jumps | 700 ₽. | |

| Stinks / Rotten smell | 600 ₽. | |

| Knocks out the machine (RCD, traffic jams) | 600 ₽. | |

| Gives off a fur coat | 500 ₽. | |

| Takes a long time to wash | 500 ₽. | |

| Freezes / Stopped during washing / Freezes during the spin cycle / Stopped with water | 500 ₽. | |

| Programs are frozen | 600 ₽. | |

| Smell of burning / Smoke | 700 ₽. | |

| Key flashing | 400 ₽. | |

| Indicators (buttons, lights) are flashing | 400 ₽. | |

| Won't turn on/Won't start/Won't start working/Stopped working | 500 ₽. | |

| Indicators do not light up | 400 ₽. | |

| Doesn't heat water / Doesn't heat water | 500 ₽. | |

| The door does not close / The hatch does not block | 600 ₽. | |

| The drum does not spin / The drum is jammed / The drum does not rotate | 700 ₽. | |

| Doesn’t take up water / Doesn’t get water / Doesn’t fill up with water | 500 ₽. | |

| Doesn't pick up speed / Drum doesn't spin well | 600 ₽. | |

| Doesn't stop/Won't turn off/Won't finish washing | 500 ₽. | |

| Doesn’t spin clothes / Stopped spinning / Spin doesn’t work | 600 ₽. | |

| The hatch (door, cover) does not open / Blocked / Jammed | 400 ₽. | |

| Doesn't rinse clothes | 550 ₽. | |

| Timer doesn't work | 700 ₽. | |

| Buttons don't work | 600 ₽. | |

| Doesn't respond / Doesn't switch modes | 400 ₽. | |

| Does not drain water / Drain does not work / Does not drain water / Drains poorly | 500 ₽. | |

| Doesn't wash / Takes up water but doesn't wash / Doesn't start washing | 400 ₽. | |

| Water remains in the drum | 400 ₽. | |

| Remains powder, conditioner | 300 ₽. | |

| Turns off during washing | 500 ₽. | |

| Stains laundry / Doesn’t wash things | 400 ₽. | |

| Water overflow/Collects a lot of water | 600 ₽. | |

| Squeaks | 400 ₽. | |

| Doesn't wring clothes well | 400 ₽. | |

| Constantly fills with water / Constantly fills with water | 300 ₽. | |

| Tears things | 600 ₽. | |

| Programs crash | 600 ₽. | |

| The hatch handle is broken | 700 ₽. | |

| Broken hatch (door, cover) | 700 ₽. | |

| Immediately drains water / Fills and drains water / Continuous drainage | 400 ₽. | |

| Leaking / Leaking / Leaking | 700 ₽. | |

| Noisy / Humming / Knocking / Rattles / Creaks / Crackles / Whistles | 800 ₽. | |

| Other fault | Call | |

| Full price list View » | ||

SHOW MORE

Let's make sure the block is broken

How to understand that the problem is really in the microcontroller? The “symptoms” of this problem may vary. You can think about the need to repair the control unit if the following symptoms are observed:

- the washing machine draws water into the tank and immediately drains it;

- the machine does not turn on, and a fault code appears on the display;

- all indicators on the dashboard are lit or flashing;

- washing programs are performed incorrectly, with significant violations (the cycle duration increases, the water does not heat up to the required degree, etc.);

- The drum rotates unpredictably - sometimes quickly, sometimes very slowly.

If the equipment simply freezes during program execution, then it is also likely that the problem is in the control module. of Samsung washing machines will help identify the cause of equipment failure. Information on how to activate test mode is provided in the instructions.

You can inspect the control board yourself, at home. To do this, the electronic unit will have to be removed. This is done as follows:

- de-energize the SMA;

- turn the shut-off valve to shut off the water supply to the washing machine;

- unscrew the two bolts holding the top cover of the case, remove it and put it aside;

- remove the powder receptacle from the machine;

- remove the screws around the perimeter of the control panel;

- remove the “tidy” by disconnecting the wire contacts;

- Unfasten the latch and open the module cover.

Be sure to take a photo of the terminal connection diagram - this will help you avoid making mistakes when reassembling the SMA.

Next, the block is inspected for carbon deposits, damage to contacts, tracks, and the presence of oxidized areas. Even one semiconductor can burn out - and this will already provoke equipment malfunctions. What to do if such defects are identified?

Repair or replacement of the control unit of a Samsung washing machine

Replacement is always more reliable than repair, but the first option is more expensive than the second. The need for replacement or repair will be determined by a private technician. This will become possible only after professional diagnostics, which allows us to accurately determine the nature of the failure.

If the scale of the damage is not large, then the technician carries out repairs. For example, a specialist repairs semiconductor devices, relays, tracks, fuses. However, more significant damage will not happen without replacement.

To repair a part, the technician does the following:

- dismantles the case and, if necessary, removes individual parts of the board;

- diagnoses the unit to determine the causes of failure;

- then comes the turn of the repair itself, during which the master uses original spare parts and modern equipment;

- then proceeds to flashing the software and resetting errors in the operation of the device;

- At the last stage, the washing machine is tested for performance. After which the client pays for the services provided.

WF6520N7W

Despite the fact that Samsung equipment is among the most reliable and durable, sooner or later any machine requires repairs. The control module diagram of a Samsung washing machine shown in the photo includes a fairly powerful processor, which itself rarely fails. Repairs are often carried out for the following reasons:

- Mechanical damage to terminals;

- Factory defect of the control unit;

- "Jumping" voltage in the electrical system. chains.

If you select the necessary components for this type of electronic boards, see the photo below, the machine after repair will work for at least another third of the time of its warranty period - 3-4 years.

Signs of failure of the Samsung washing machine control unit

There are typical signs that indicate a failure of the control unit. These include:

- random blinking of indicators;

- the device does not turn on;

- an attempt by the engine to increase the speed, which happens when the tachogenerator sensor falls out on the power unit;

- the triacister has broken, as a result of which more powerful voltage is supplied to the unit;

- cold water enters the machine, which is typical when the thermistor fails;

- a program that was not configured is running.