Purchasing a washing machine is an important event for every family. As a rule, people try to choose equipment that is reliable and meets the necessary requirements. An excellent choice is the Zanussi washing machine. But its owners get very upset when any malfunctions occur. It is necessary to calmly analyze all the reasons. After reading this article and recommendations, you can find out why the Zanussi washing machine or one of its functions does not turn on, what spare parts should be changed yourself, and what types of work can only be done in a service center, or by calling a technician to your home.

Problems with filling and draining water

- E10 and E 11. These codes indicate that the water supply system to the drum is broken in the Zanussi washing machine. They appear if within 10 minutes the amount of water does not reach the required level.

- During the drying process, water enters the drum. Usually appears 10 minutes after the start of the process.

- E20 or E21. These error codes can be seen if, 10 minutes after the end of the wash, the process of draining the water has not begun. E20 also indicates problems that may have arisen during the draining process, such as a clogged hose or a faulty pump.

- During the drying process, condensate that appears is not removed.

- E23 - the element that controls the operation of the pump (triac) has failed.

- E24 – the triac track burned out.

- EC1 – for some reason the filling valve was blocked.

- EF1 – the filter or hose is clogged. This code also appears when water is drained for longer than expected.

Spin does not turn on

The wash has finished, but the spin process has not started. You should try restarting the wash cycle and manually turning on the spin function. Perhaps this was an isolated program glitch. It is necessary to check the voltage in the network.

If the problem persists, check the pump filter. There is no positive result, we check the pipe that connects the tank and the pump. It is also possible that the pump is clogged; the impeller is jammed with debris.

The pump is checked for serviceability. The drain hose may be clogged or kinked. The problem can occur if the motor is damaged or the motor brushes are worn out. A malfunction of the heating element may block the start of the washing program. The reason may also be a breakdown of the electronic module.

Engine malfunctions

These designations apply to washing machines controlled by both systems (EWM2000 and EWM1000). For example, these could be error codes for the Zanussi FE 1024n or FE 904 washing machine, as well as for devices of other modifications:

- The contact between the triac and the engine of the Zanussi car has broken.

- The washer that holds the tachometer has fallen off. As a result, this element does not transmit a signal to the engine.

- The circuit on the electronic board that controlled the triac was damaged.

- The relay contacts, which are responsible for the reverse motion of the motor, are stuck together.

- The integrity of the circuit controlling the engine has been compromised.

- The tachometer does not produce signals for a long time.

- The current in the system is more than 15A. The code indicates a motor or board failure.

- The motor current exceeds 4.5A. The reason is the same as in the previous case.

- For three seconds the tachometer did not give a single signal. Most likely, there was a breakdown in the electrical wiring or the inverter board failed.

Water connection

First of all, you need to make sure that the tap leading to the equipment is open. Pressure matters too. A water pressure of 0.3 to 0.4 bar is recommended. Reduced performance will negatively affect many stages of washing, and this will cause the Zanussi machine to stop working.

Pressure can be increased using pumps. There are several types of them, you can choose a silent one that reliably provides the required water pressure. You should also pay attention to the quality of the water. It is recommended to install the filter directly to the Zanussi washing machine. When a breakdown occurs, the latest models display a breakdown code. By reading the instructions and studying the codes, you can find out the causes of the problems.

Problems with sensors

- The water pressure switch does not work.

- There are fluctuations in the readings of the sensor, which is responsible for pressure.

- The water quantity sensors and the one that prevents dry running provide different information.

- The water level sensor and anti-boil sensor do not work in harmony.

- There is too much water in the drum of your Zanussi washing machine.

- The sensor that determines the degree of turbidity of the water has failed. It is worth noting that only the newest modifications of Zanussi washing machines have such a device.

Repair for faulty spin

First of all, the drainage system and the pump impeller are checked and the spin cycle is turned on. The water should drain and everything should work.

The electrical characteristics of the heating element are checked using a device. Visually you need to determine the degree of scale fouling. If the heating element malfunctions, the operation of the washing machine is blocked. In this situation, you need to replace the faulty heating element.

The tension and integrity of the belt should be checked periodically. If the engine is working properly, but loses power, then the brushes are worn out. They need to be replaced. To do this, you need to remove the engine and unscrew the brushes and replace them with new ones. It is also necessary to check the contact leakage on the motor with a device. Then assemble and check the operation of the system. If the electronic module is faulty, it must be replaced.

As a result, it should be said that in order to reduce the risk of situations when the Zanussi washing machine does not turn on, care must be taken to install additional protection against voltage surges. Small appliances plug directly into sockets. They protect and disable equipment, and also prevent machine breakdown.

Other breakdowns

- There are two options for deciphering this code. The first is that the door is not closed. Second, the door lock was broken. This error code E40 is now very rare. Usually other codes are used.

- The door does not close tightly enough.

- For some reason the blocking did not work.

- The Zanussi washing machine is not set correctly. In this case, the right program will help correct the situation.

- Error in setting washing modes.

- There is too much foam in the drum or the drain hose is clogged.

- There is a leak inside the device.

- The spin process does not start due to the large amount of laundry in the drum.

All these codes indicate breakdowns that occur most often. They can be seen on the display. But what if your Zanussi washing machine does not have a display? Pay attention to how the indicators flash.

How to detect a breakdown using indicators?

To do this, you need to find out which module the device is running under:

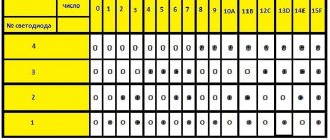

- If it is an EWM1000, then error codes for washing machines without a display are determined by the way the start/pause indicator and end of wash indicator flash. The end indicator shows the first digit of the code, and the start indicator shows the second. For example, the finish indicator blinked 4 times, and the start indicator blinked 3 times. This means that there is a problem with the code

- If the device is controlled by an EWM2000 module, such as the Zanussi FE 1024 n washing machine, you need to monitor the eight indicators located on the control panel. The top four are the first digit of the code, and the bottom four are the second. To translate the indicators into understandable notations, you will have to use a special table.

What to do if error codes on your Zanussi washing machine are flashing? First of all, find out what kind of breakdown occurred. Perhaps the door simply did not close (E40) or the water supply or drainage system (E10, E20) has failed. All error codes are the same for devices of any modification. The only difference is how they are presented: on the display or on the control panel (indicators), as, for example, in the FE904 or FE 1024n models.

No electricity

All washing machines operate from the electrical network. And if the Zanussi washing machine does not turn on, you need to check the serviceability of the socket. This can be done with an indicator or other electrical device.

If there is no voltage in the outlet, you need to check whether the machines are turned on. They turn off when there is a short circuit. Is there a smell of burnt plastic? You need to inspect the cord and plug connecting the machine.

Perhaps there was a bad contact and it got burnt. In this case, you should change the plug. If everything is in order here, the wire itself is inspected, since it may be broken in some place and the wire will have to be replaced. Such breakdowns can be avoided. Monitor the socket and check the plug for heating contacts. The wire must have a cross-section corresponding to the power of the consumer.

Assessing the condition of electric brushes

The first thing to check is the electric brushes. In most cases, they are the cause of engine braking. These are rectangular metal “cases”, inside of which graphite rods on a spring are placed. The “coals” smooth out the frictional force emanating from the device, while at the same time being erased. If the length of the tips becomes insufficient, the engine overheats and malfunctions.

Diagnosis of brushes consists of measuring their length. We proceed like this:

- Unscrew the screws holding the cases;

- clamp the spring and remove the rods;

- halve each case;

- take out the tip and measure it.

Electric brushes are replaced in pairs!

The minimum length is 1.5-2 cm. If the “coal” is smaller on at least one brush, then both need to be replaced at once. The rods are selected according to the engine serial number or Zanussi itself. The best option is to remove the old cases and select new ones based on the sample.

Dirt accumulation is to blame

Another reason for continuous filling and draining lies in a clogged drainage system. Accumulations of dirt in the pipes, on the impeller, on the filter and volute negatively affect the functioning of the pump - it begins to “freeze” and turn on randomly. The problem is resolved by cleaning clogged elements.

Cleaning begins with the debris filter. To get to the filter nozzle, you must:

- turn off the power to the machine, turn off the water;

- pry open the technical hatch in the lower part of the body with a knife, release the latches and remove the false panel;

- find the garbage filter - the black “washer” on the right;

- place a container under the plug (water will flow out of the hole!);

- grab the protrusion and unscrew the nozzle, working counterclockwise;

- clean the “spiral”, and if necessary, soak in a warm lemon solution;

- use a flashlight to illuminate the filter seat and inspect the drainage system;

- clean the drainage from debris, foreign objects and plaque.

When you unscrew the garbage filter, water will flow out of the machine - be prepared!

Another option is to check the drainage through the bottom. It is enough to turn off the washing machine, move it away from the wall, turn it over on its right side and look inside through the bottom. Most Zanussi machines do not have a pan and the Aquastop system, which will greatly facilitate the diagnostic and repair process.

Hatch lock

A common breakdown is the breakdown of the hatch locks. This is an obvious oversight by the manufacturer. The drum door stops locking and programs do not start.

Sometimes a blockage occurs while the machine is running and at the end of the wash cycle you cannot remove the laundry. Error code E40 – the hatch locking device needs to be replaced.

If you decide to fix the problem yourself, then unscrew the bottom panel and pull the cable - the hatch will open. The cause is broken latches or faulty electronics.

Drive belt

Experts recommend checking the belt tension every 3-4 months. If the belt has sagged, it needs to be tightened and sometimes replaced. To replace, you need to remove the back cover of the machine.

Simultaneous collection and drainage of water

There are several reasons for this problem. The simplest thing is that the hose is connected incorrectly. It is enough to raise the hose 30-50 cm, and the problem will be eliminated. If this does not help, then the problem is in a faulty control unit.

SMA Zanussi error codes

The Italian brand Zanussi is a trading sector of the Swiss concern Electrolux. For many consumers, this fact acts as a kind of double guarantee of product quality. This quite rightly applies to washing machines. But, like any other technology, they cannot be an everlasting and smoothly functioning gadget.

Therefore, sometimes there are individual problems, about which the equipment will inform the user immediately. This can be done depending on the modification of the CMA: as an alphanumeric combination on the display or by a certain light indication of individual buttons on machines without a display, for example, ZWY180 or Zanussi Aquacycle 1000. In any case, you can decipher the Zanussi CMA codes quite easily.

Extraneous noise

If the machine vibrates and makes a lot of noise when spinning, or the motor hums without turning the drum, the worn bearings often need to be replaced. They are closed with oil seals and located on the axis of the drum. When water gets under the seal, the bearing fails.

Craftsmen who change this part perform the following procedures:

- Disconnect the device from the network.

- Drain the water.

- Remove the outer panels.

- The drive belt, springs, pipes, temperature sensor and counterweight are disconnected from the tank.

- The tank is disconnected and the pulley is removed from the drum.

- The bearings are taken out along with the drum axle and disconnected from each other.

- Install new bearings and reassemble the car.

Extraneous noise can also be produced by one of three factors:

- An object is stuck between the drum and the tank (it should be removed).

- Weak pulley fastening (bolt needs to be tightened).

- Drive belt.

To correct the situation with the belt, the washing machine is disconnected from the network and the water is drained. Then do the following:

- Remove the back cover.

- If the belt placed on the pulley and motor is torn or worn out, pull it towards you while rotating the pulley.

- The new belt is first put on the motor shaft.

- The pulley is rotated, pulling the belt onto it.

- Adjust the edge of the belt so that it fits tightly in the grooves.

- Carry out a test run of the machine.

Recommendations for repairing Zanussi washing machines

_____________________________________________________________________________________

- Models FL, FCS, ZWN, FA, FLS

- Models ZWS, ZWO, FAE, FV, F, ZWP

- Models ZWY, ZWSE, ZWT, Aquacycle, TA

- Error codes

Narrow washing machine Zanussi ZWSG7101V. The washing program stops 1 minute before the end of the washing program. The water does not drain. The electronic control unit is not working correctly. First, check the drain. SMA ZWG 181. When you turn it on and press the “start” button, the pump turns on to drain the water, it works as expected, then it seems like the pumping of water should start, but nothing happens. Instead, the drain pump turns on again. After turning off and on various plugs, the unit seemed to work, but after washing and pumping out the water, the pump went into cycles of pumping out again. I disconnected the pressure switch tube, the result was the same. A chip with two black wires is connected to the heating element. Having turned it off, the pumping of water immediately begins without first draining, I didn’t bring it to washing, I decided to find out what this was connected with. The heating element is faulty (broken). I turned the car over and water got into the control unit. Model Zanussi zwd 586. All programs work and are selected, but when you select the “start” program, I press the button, it flashes green, but the unit does not react in any way and does not start in washing mode. Tell me what to do? If water gets into the control module, first check how many volts are reaching the board. Then remove the control board itself and check for burnt out and clearly visible transistors. If there are none (and this often happens), then check the entire control board sequentially with a multimeter. Model FJ 905 N (about 7 years in operation). When you turn on the main washing mode, it pours water, spins the drum several times and stops. When manually switching the relay to the next mode, the same picture occurs. In the gentle wash mode, sometimes it automatically runs some cycles, and sometimes it doesn’t. Spinning is possible only on gentle washing and “synthetics”. The “synthetic” cycle is sometimes completed completely if you turn the unit off and on when it is thinking about it. We recommend calling a specialist for diagnostics; a check of the command apparatus is necessary. I have a top-loading washing machine Zanussi zwq 5101 (5.5 kilograms). It washes, but does not drain the water, but when I manually lower the hose, the water drains. I try to continue setting it to rinse and that’s it - “stop”, nothing further, in short, it doesn’t drain the water itself and at the very beginning of the wash it doesn’t pump out the water. The drain pump has failed and needs to be replaced with a new one. When you lower the drain hose, the water simply drains from the tank by gravity. Model ZWQ 5104 (6 kilograms). With any given washing program, it starts to wash, pours water, heats, drains, washes, after some time it stops and the “Start/Pause” indicator lights up red. The rinsing, spinning and draining modes, separate from washing, occur in normal mode, without stopping. Before the red flashing, there are frequent clicking sounds, as if something is unable to turn on. The water supply system is clean and the drainage system, the filters are clean (unscrewed and checked). The reason why “Start/Pause” lights up in the unit in the middle of washing may be due to a malfunction of the following parts. Failure of the control module. Malfunction of the water level sensor (pressostat). Fault in the electric motor. Machine FE 1005 5 kilograms, does not turn on. In the evening I washed everything, wrung it out, without squeaking about the end of the wash, I passed out. We noticed that it didn’t beep for a long time, but it stood with the door closed, with a burning orange eye and not a single indicator or display was lit. Accordingly, it is also impossible to enter diagnostic mode. He removed the top cover, opened the hatch, and took out clean, wrung-out laundry. I measured the voltage - it comes to the button after the filter. But when turned on, only the orange eye lights up. Then one wire from the button goes to the control unit, there is voltage. The other wire along the circuit is somewhere to the UBL. Tell me, what could it be? If the door does not open, it means that something happened to the UBL itself (failure) or to the control unit (the command to open did not arrive at the UBL). Next, check all elements of the UBL circuit, including the control module. I have a Zanussi FE 1002 washing machine. Two breakdowns happened at the same time. When spinning and draining, it began to leak where the drain hose entered the sewer pipe. With these same functions, the unit makes strange sounds, as if sand were spilling out in the drum, and some metal part such as a coin was hitting the drum. And when spinning there is a strong hum. What could it be? The fact that the unit is leaking at the sewer connection point may be the reason for improper installation. The sounds you hear may be from the sound of objects caught between the tank and the drum. Hum, we need to look at what could be causing this. Zanussi ZWSG 7101 V (narrow). I collect water, it starts washing, after three or four rotations, the water begins to go into the sewer, the level drops, the unit stops and the water intake begins again. It feels like the exhaust valve is not holding, but when I turned it on for rinsing there were no problems. Self-draining into the sewer occurs (siphon effect), installing an anti-siphon valve or installing a drain hose on the edge of the bathtub will help. We use the ZWG 181 machine every day. Recently, an unpleasant putrid smell has appeared, although we try to regularly clean the rubber gaskets around the drum and leave the door open. What to do? Clean the filter. Connect the drain through a siphon. Washing machine Zanussi ZWG 281. When spinning, when the pump is running, the sound is very loud with some kind of grinding noise. Repeated a couple of times. What could be the problem? In this case, the problem may be that either the pump is clogged or something is wrong with the bearings. Washing machine Zanussi FJ905N in operation. In programs with pre-wash and at high temperatures, the water does not heat up well, and the drum is difficult to turn. On fast programs, at temperatures up to 60 degrees, everything is fine. What could it be? Is the belt loose, is there scale on the heating element? By the way, what is the best way to remove scale in this model? It can be assumed that the failures are coming from the control module. Zanussi zwq 5100. In the middle of the washing cycle, the wire heats up, the unit turns off, and the plugs in the apartment are knocked out? There is a short circuit somewhere, check the heating element. Zanussi ZWQ 61015 wa. When choosing a washing mode, after 20-30 minutes the drum stops rotating, and the display shows error E40 (the lid is not closed correctly). In this case, the lid is locked at the beginning of the wash, after a failure it opens easily, and the locking button is not at the top, but as it turns out. I paused it, closed the lid again correctly, removed it from pause - it doesn’t want to erase, it just restarts. And again error E40. It heats the water, everything else seems to work. It turns out not an automatic, but a semi-automatic. Probably an electronic failure. The problem is that the FE 802 washing machine stopped starting. During diagnostics, I discovered error E43 - a malfunction of the door lock control triac. I removed the control board (EWM 2182 01 05 1) and found that the ACS102-5T triac had broken and the 220 Ohm resistor had burned out. What analogues can replace a triac? How to check the door lock (type BP P/5-R, it has three wires)? What should the bimetal resistance be? Is it possible to apply 220 volts to the lock and check the contact closure? It's best for you to invite a specialist. The Zanussi FE 1024 N washing machine is in operation. It often happens, even before the water heats up (during the pre-wash), something inside clicks and all the indicators except the power go out, light up, go out again, light up again, etc. Then they go out for a long time, respectively. the wash stops. The clicking continues, everything may work in 10 minutes, or maybe in an hour. This also happens during the main wash with heated water. In principle, after such a “rest”, washing continues and ends normally. No other glitches were noticed. Previously, the plugs were knocked out, replaced them with new ones (25A) and everything went away. Tell me the cause of the problem, is it difficult to fix? In this case, you need to measure the voltage in the network, it should be 220-230V. If the voltage drops to 200V, the unit stops working. Zanussi FJ 905 n. Does the water flow into the washing machine in jerks and does the water level switch click? The filter may be clogged, the water supply tap or the solenoid valve and level switch may be faulty. Zanussi ZWD 7105. The drum began to rotate with force (tight) by hand. I would like to know the cause, consequences and cost of repairs. The force when rotating the drum can occur when a foreign object gets into it or the washing unit (bearings) malfunctions. Washing machine model ZWG 281. Error in EHO operation, what should I do? The error indicates a voltage problem. When you turn on the ZWSG7101VS machine for washing, water is drawn in as expected, and then the drum begins to turn at maximum speed. The unit begins to shake so much that foam begins to come out of all the cracks. Malfunction in the engine circuit (tacho, electronic components of the module in the electric motor circuit). Freestanding SMA Zanussi FE 802 5 kilograms, no water is added when starting the wash. It buzzes for about 5 minutes and comes out at the end of the wash. The defect does not always appear; yesterday I washed it, but today it doesn’t. It might start normally in a week. Replacing the intake valve did not change the operation of the unit; the fault remained. Before changing the water supply solenoid valve, it was necessary to check the resistance of the solenoids. For the working valve it is from 2 to 4 kOhm. If the valve is working properly, then you need to check whether 220 Volts are reaching the valve from the control board; if not, then the problem is either in the water level sensor or in the control module. Model FE 1024 N. Never had any problems, although it is already 5 years old. Now, when turned on, it draws water and when it starts to wash, the display goes out and the washing stops, then the shutdown indicator starts blinking and the buzzer rings. I tried to disable and restart the program to no avail. It was only possible to install the spin cycle, after which the machine completed the cycle itself and turned off. I tried without underwear at night, everything seemed fine. Tell me, maybe there is insufficient voltage, although I haven’t noticed this before? The model you specified allows deviations from the 220 volt network of no more than 15-20 volts. SMA ZWQ 5100. The loading hatch door of the machine (vertical loading) does not lock, it does not start, the relays do not work. The voltage in the network is 200 V. Can low voltage cause a failure? There might be something wrong with the lock. The vertical machine ZWQ 61015 wa does not turn on. If it's a fuse, how can I check? There are no fuses in the unit, there is only a noise filter, which is located at the power cord entry point inside it. Zanussi zwq 61216 wa vertical. The master changed the bearing, but I can’t say anything about the seal, I haven’t seen it. I called the technician again and he offered to change the pump. For some reason I think this is unnecessary. The machine spins, but during the last spin at high speed at the end of the program, a strong grinding noise appears again. And further. I washed it with citric acid. The master said that by doing this I had destroyed the bearing and advised me to use soda. What to do? As for the slight rattling sound at the end of the spin cycle, this is normal. The bearing is rubbing in. Citric acid can only destroy an already worn bearing. We also need to see if the drum touches the heating element. I don’t remember the year of manufacture of the FJ905N washing machine. Water does not flow into the powder washing compartment; water flows into the drum. The inlet hose filter is clean. The washing process is underway. The fill valve may be faulty. SMA ZWSG7101V. I stopped turning the motor, changed the brushes - it turns, but does not heat the water, I measured the heating element - 24.7 ohms. What to do, what is the reason? If now the unit does not heat up, the first thing that comes to mind is that the heating element is faulty. But you say that the resistance of the heating element is 25 ohms - this is the norm. We recommend checking whether the programmer (triac) is sending a heating signal. Washing machine ZWD 5106. Water remains in the air conditioner compartment, and fungus has appeared in all three sections. What to do? Check the water pressure and flush the hopper. SMA FE 1024, when filling water flows from under the control panel. May leak at the beginning of the wash. Maybe when rinsing. It may leak only on the second wash. Water also varies in different ways - from a puddle to half a bucket. I looked into the tray, it felt like it wasn’t having time to drain away. They called a technician, the hoses were not clogged. The master did not help in any way. It is necessary to remove the cuvette (powder dispenser) and check for blockages in the water supply pipe. If there is no blockage, then it is necessary to remove the top and front panels in order to check the fastening of all pipes and their wear. Washing machine FE 925 N. The question is: When running the program, it stops after rinsing, does not start draining the water and stops. Attempts to restart, as well as attempts to start any stage of the program, lead to nothing. After the emergency drain of the water, you put it on spin - everything works. Sometimes it performs all stages of the program without failures, sometimes it doesn’t. The filter is clean and so are the drain hoses. How to find a fault? Apparently the pump needs to be replaced. Listen to see if the pump is making a hum when it should be draining. The pump, apparently due to use, simply stops. It’s even easier to check if the pump is working, if there is no drain, you can blow into the drain hose - the pump will turn on and water will flow. The washing machine zwq 61216 wa does not heat the water in the cotton program, there is no voltage supplied to the heating element. In other programs, heating occurs normally. What could be the reason? The cause of the problem may be a faulty heating element (water heater) or a failure in the control module. To begin with, we recommend disconnecting the unit from the power supply for 30 minutes, unplugging the plug from the socket, to reboot the processor. We bought a zwq 61215 wa machine. We connected it, set the program, pressed “start”, the water pumped, the drum stood still (the transport bolts were unscrewed), the program reads the time. Most likely, your water tank is draining itself. Check the drain connection to the sewer. The drain hose must make a top loop before entering the sewer. If the connection point and the entire hose are below the level of the tank, then the water will flow out of the drum by gravity. Washing machine Zanussi FJ 905 N, the drum does not spin, it heats the water, the drain works. If you can hear the engine running, most likely the drive belt that drives the drum has fallen off and broken. It will need to be replaced. Narrow Zanussi ZWSG7101VS. How to clean the drain pump, otherwise it’s humming? The pump cannot be cleaned, but the filter can be cleaned by first unscrewing it. The ZWSG 6101 washing machine is in operation. During the last rinse, I noticed a small stream of water flowing out from under it. I checked everything, the hoses are dry. Tell me, what could this mean? The unit needs to be inspected. There may be depressurization of one of the pipes, or a crack in the hatch cuff. Model FE 925 N. After starting the wash, it fills in water and immediately after filling it begins to drain it. The position of the hoses was changed and tried in different ways. I managed to enter the service menu, after draining the water it gives three sound signals with 2 lights flashing simultaneously. If there is no self-draining, the level relay or control module may be faulty. The washing machine fe 904 nn periodically did not heat the water, once it heated up to 90 degrees, although it was 60. Within a month, it stopped even heating the water sometimes, it washes in cold. After disassembling and cleaning the heating element (its resistance is 37.5 Ohms), nothing has changed. The temperature sensor reading is 4.2 KOM at 20 degrees; as the temperature rises, the readings decrease, and when cooled, they rise. What could be the reason for the breakdown? The malfunction may involve both the heating element, the thermostat, and the control unit. Model zwq 61215. While washing, I started thinking and the drum stopped spinning. In various operating modes, the drum does not rotate stably, it does not want to drain water, but it fills. Does this sound like a hardware failure? The unit appears to have a problem with the drainage system (clogged) or with the drain pump. The SMA zwq 61216, year of manufacture 2008, does not press. Tell me, what is the problem? The pump is faulty or the drain pump is clogged. The control board may be faulty. Machine FJ905N. The term of work is 7 years. It stopped working at the beginning of the cycle after a click, and then the machine was knocked out. After turning on the electricity, I turned on the washer again and it washed. But the door did not open, I still managed to open it. Now I decided to wash it, but it won’t turn on. What can be done? There may be a problem with the UBL. Model ZWSG 7101. When rinsing, fabric softener remains in the softener compartment and does not enter the drum. Tell me why this problem could arise. Low water pressure, malfunction of one of the water valves or the water supply switch to the dispenser. Water got on the pump winding, the display on the panel of the FE925N machine went out, the pump was previously replaced. Unfortunately, the pump will have to be changed again and it will be necessary to check whether the control module has burned out. Car Zanussi FE1014N 2001 release. After 1 wash with boiling (we had not used this mode before), the smell of rotten rags began to emanate from it. What could this be and is it possible to get rid of this defect on my own? It is possible that the heating element, which has grown overgrown over 10 years of operation, will burn out. SMA FE 1026 N starts washing when the program is turned on. After 5-7 minutes, all indicators and time displays begin to flash at intervals of 1 second. The power indicator does not turn off. The program is not reset, but the washing does not proceed. The intervals between turning on and off are from a fraction of a second to 2 seconds. When turned off, it does not respond to buttons; when turned on, you can pause and reset the program. What could have happened? Presumably, from your description of the malfunction, the breakdown lies in the control module. The washing machine zwq 61215 wa with vertical loading is in operation. I set any wash, it washes, then reaches the rinse mode and stops. I tried to set the regimen and the drain and does the drain, but does not fulfill the mode, does not even fill the water into the air conditioner compartment and does not use it, recently changed the bearings. About rinsing - if the mode does not work, then the reason may be a malfunction of the filling electromagnetic valve or control module. We recommend checking these modules. SMA ZWSG7101V. At its first launch, the indicator began to blink, and EH0 error shines on the display. I did everything according to the instructions, poured water 2 liters and so on. It seems that you have problems with the network voltage, try to turn on through the stabilizer. Submary fj905n, instead of usual 1.5 hours, erases 4 hours. Moreover, it works, then no, and does not perfectly squeeze it out. Tell me, what could it be? You can assume a malfunction of the heater, blockage or breakdown of the pump. Zanussi Fe 904 NN. When the start button is turned on, instead of a water set, drain begins. When resetting the program, it itself switches to the drain mode and the drain light lights up, and the cold water mode all the lights go out. It does not come out of this mode until you turn off the power. Apparently, an emergency drain is turned on. We recommend calling the master if the unit does not show the breakdown code. Submers Fe925n erases and caresses, but does not merge. The filter is clean, the hose is not twisted. Most likely, you need to change the pump. We can’t find how to clean the machine from garbage, it is 10 years old, and never disappeared. You can extract through the technological hole - the heater in the tank or disconnecting the "tank - drain pump" pipe. There is no filter in the unit, so disconnect the pipe going to the pump and clean there. Model 726 CN. The drum during washing remains motionless. At the same time, the command -apparatus seems to be working - all other washing procedures go according to the program - pouring, heating, draining and so on. Subjectively the sound has changed when the drum is scrolling with the hand. What can be the cause and procedure for the cost of repair? Is it possible to diagnose and repair on the spot? The described situation can be for three main reasons: the belt broke (or just flew, which is also rare for no reason); Electronic module failed; The engine failed. On the washing machine with the upper load, the bearing thundered. The tank is plastic, glued. Can I dismantle the drum supports without disassembling the tank? The supports are twisted and completely change. The FJS 904 CV washing - floods and drains water continuously by 40 degrees. Suba old, before that she worked normally. Four months were not used, she was moved to the corridor. Then they began to operate again, and in the laundry mode at 40 degrees for light fabrics, it floods and drains water all the time, continuously. When washing cotton 60 degrees, it seems, the valve works fine. Pour, washed, leaked. Try to raise the siphon. In use, the Easy Iron model, vertical loading. He folded his linen and did not close the drum. He closed the lid and launched the unit, naturally falling asleep for the powder. A couple of seconds later something hit. After this story, a couple of minutes could not raise the lid. The drum itself cannot be twisted and it is natural to not get linen. What exactly happened, how to repair and how to get linen? You need to disassemble the tank.

_________________________________________________________________________________

_________________________________________________________________________________

_____________________________________________________________________________________

Operation of the LG SMA I bought an LG E10B8ND DD washing machine and have only washed it 3 times so far. The problem is this. It washes very quietly, since the all-wheel drive goes directly to the drum. Even spinning at 1000 rpm is quiet, but when it drains...

Samsung WF 8590,6450,6520 We repair the Samsung WF8590NMW8 diamond washing machine (5 kg load). The DE error appears on the display, although 220 is supplied to the lock itself (checked). The most interesting thing is that I decided to test the lock on another SMA, and it worked. Has anyone encountered...

Ariston RSM, WMSF, AVTL Washing machine Ariston avtl 104, with vertical loading 5 kg. The situation is very unclear. SMA can wash off normally, but recently it has started to behave strangely. When rinsing, it stops and the indicator on the power button goes out...

Indesit IWSB, WS, WIU, WIN Machine iwsb 5085, description of the problem. She pours water, the drum rotates for a couple of seconds in one direction, stops, then 2 more times, a couple of seconds each, in the opposite direction and silence. The indicators light up as expected, programs switch, but...

______________________________________________________________________________________

FAULTS AND REPAIRS OPERATION AND SERVICE ERROR CODES

______________________________________________________________________________________

Repair of Bosch Maxx 5 automatic washing machine. Bosch maxx 5 speed edition WLX 20463 OE washing machine in operation. I began to perform the washing program incorrectly. We set the hand wash program, the spin was completely turned off. After washing, SMA switched to rinsing...

Candy Aqua, GVS4, GS3, CS2 There is a smell in the gvs4 126dw3 washing machine. I wash with the addition of liquid Calgon, but there is no effect. Sometimes I rinse my laundry with vinegar. If the linen is thin, like bed linen, then it does not smell. But the towels started to smell. What to do?

Electrolux EWW, EW, EWX The Electrolux EWW 1686 washing machine is in operation. It started tapping when washing, regardless of whether it was spinning, stopping before changing modes, or washing. It knocks periodically, not all the time. The sound comes approximately from the control module...

Zanussi ZWY, ZWSE, ZWT Washing machine zwy 51004 wa, bought about a month ago. I set the washing program, the final spin occurs, and the machine starts washing again, and so on ad infinitum, until you just turn on the water draining program. What could be the problem?

Repair of Ardo SED, TLN, FL Ardo TLN 126. It has a display, and when you turn on the washing program, the washing time is displayed. Gradually it should decrease, but here it is. I turn on the 20-minute wash, but in the end it takes 40 minutes or even more to wash, and the time is constant...

Beko WKB, WN, WKE, WM Model WM 3350 E. We started working in the “short wash” mode, the program worked completely (the door unlock button lit up), but water remained inside. In fact, rinsing and spinning did not work. When I tried to reboot, nothing changed, the sensors...

Repair of ACS Gorenje WS,WT Model WS 43100. The fill valve does not open. Writes "Error 9". This is an error related to aquastop. There is no aquastop. I bought a new non-original valve, took the coils from the old one, put it on with difficulty, one might say, hammered it in. I installed it, did a couple of washes...

Whirlpool AWE, WTLS, AWOC We bought a Whirlpool AWE 6516 washing machine with top loading and electronic control. Container for detergents under the lid. I pour the conditioner into the container, and it immediately pours out of the small...

The owner of the car mixed up something

First of all, you need to check whether a user error was made when starting the wash. It is likely that a program that does not involve spinning was initially selected. A number of modes on Zanussi, for example “Delicate”, “Hand”, “Shoes”, “Wool” and “Outerwear” always end after rinsing - this is included in the factory settings. It is worth looking at the display with the selector or remembering which cycle was turned on. If there is any confusion, then you can restart the machine with the required parameters.

Another possible problem due to which the spin on the machine does not work is the forced refusal of this option. Some Zanussi models provide a special button that operates on the “old” spring mechanism. If the key was previously pressed, then the spring does not always return to its previous position after the cycle ends and even the system is turned off. Most likely, it remains activated and automatically turns off the “centrifuge” stage with each subsequent program.

The spin stop button on your Zanussi may remain activated after the previous wash - check that it is pressed!

If the mode is selected correctly and the spin does not turn off, then you need to check the drum. Modern washing machines have a built-in imbalance control function. When the user loads too much or, on the contrary, not enough laundry into the machine, the system, when unwinding the shaft, detects the imbalance of the unit and, for safety reasons, stops the cycle. Equipment also arrives with clothes that become wrinkled during washing and pose a threat to equipment. The instructions on what to do to “rescue” are simple: open the hatch, straighten things, take out the excess or add the missing kilograms.