The washing machine is a high-risk electrical appliance. It operates on household voltage. Therefore, additional safety measures are required to prevent damage or electric shock to the user in a timely manner. It is for this reason that a fuse may be installed there. In the event of a breakdown, many specialists first check the network cable, and then begin to delve into the device control module. Essentially, this approach is wrong. First you need to determine whether this washing machine has such an element as a fuse. And if it is available, it is necessary to check its performance.

Determining the presence of a fuse

To understand whether the device has a fuse, you should find out in which country it was manufactured. If, for example, an automatic washing machine was produced in one of the European countries for the domestic market, then it must be installed there on a fusible basis.

This is explained by the fact that it is prohibited to sell such devices there without it. In the case of production of the unit in states that belong to the countries of the former Union, such confidence cannot be. In these countries there are no strict rules for equipping a washing machine with such components. On some models that are produced in the Middle Kingdom for the market of the former Soviet state, their installation is provided, but this is not a prerequisite. But a washing machine that was manufactured before the beginning of the 2000s inclusive will definitely be equipped with it.

Article on the topic: How to clean a washing machine from mold and odor

How does a fuse work?

There are situations when the electricity is often turned off or the supply is intermittent, and at this time a washing machine is running, for example.

The presence of a fuse prevents a short circuit in the network, which can burn the equipment. If the current increases, it opens the electrical circuit, and its conductive core melts.

Most often, a washing machine fuse looks like a tube with a glass bulb.

Where is

The next thing you need to know is where the electrical fuse is installed in the washing machine. It may be located:

- at the power cord input inside the device body;

- directly next to the control board;

- inside the power supply;

- at the end of the power cord inside the power plug.

If you carefully examined the “insides” of the unit, but did not find a similar element, it is possible that it is not there at all. To be completely sure, still strain and try to find the electrical circuit of the SM. Then you will finally be convinced whether you need to look for this part.

How to find an element

It should be noted that a number of craftsmen often confuse a fuse with a surge protector. This should never be done. It is also necessary to understand that even from the same manufacturer there may be a large number of models of washing machines. Moreover, in each of them it can be located in a different place. Therefore, to accurately find, you should follow these steps.

- You must carefully study the electrical diagram of the washing machine: it will definitely indicate the installation location.

Fuse on electrical diagram

- If there is no diagram, you need to pay attention to the base of the network type wire on the inside of the machine body. They are installed there very often.

- You can also find a part at the entrance to the board for controlling the machine. In this way, the manufacturer strives to ensure the safety of one of the most expensive elements of the device.

Washing machine electronic board

- There is also a need to look at the unit that powers the machine - manufacturers often put a fuse there.

- Another option for installation is at the end of the power cord in the inside of the plug.

Plug with fuse

If you do not find an element in all of the above places, it means that it is simply not installed.

It is worth noting that before you start looking for a fuse, you should carefully inspect the outlet and extension cord. There is an option that voltage is not supplied to the unit precisely because the circuit is broken in these areas.

Why does a fuse burn out?

The reasons for the burnout of this element may be different.

These include:

- Resetting the program while the washing machine is running.

- Increase in voltage indicator.

- Additional mechanical overloads.

- The fuse has reached the end of its service life.

- The part has failed.

- Malfunction of one of the parts.

If the electronic module is broken or the wiring inside the machine is damaged, it will not turn on immediately. Once connected to the network, the machine will not show any signs of life.

Article on the topic: Which narrow washing machine to choose 2018

The most expensive reason to repair why Ariston does not turn on is software problems. For example, the program does not respond to many user actions or washes for several hours, despite the quick wash mode being set. Unfortunately, it is impossible to repair the washing machine computer, and the only solution to this problem is to replace the board.

Replacing a part if it breaks

Experts note the following main reasons for fuse failure:

- incorrect operation of one of the unit parts;

- failure of the program prescribed for the machine control module;

- end of fuse service life;

- voltage drops in the household network;

- large mechanical loads on the device.

If you successfully find the fuse in the washing machine, you must perform the following steps.

- Carefully remove it from its installation location.

- Take a multimeter and determine the value of its resistance. If the device shows a breakdown, it must be replaced.

- Purchase a new item from the store.

- Install the purchased spare part in the same place - this will restore the working condition of the machine.

So, if there is a problem with the washing machine, there is a high probability of the fuse breaking. In this case, it is necessary to first determine the availability for a specific model, and then replace it with a working element.

Washing machine LG F1081TD 8 kg. The fuse has blown.

Solution

Comments (1)

Your comment +5

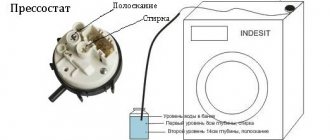

Please help me figure it out! Indesit washing machine (vertical load) The water did not fill (there was a faulty valve), replaced it with a new one, and in the end - in any mode.

After fixing the processor and flashing the firmware, the washing machine began to work incorrectly (at a washing temperature of 30 degrees, the washing machine heats the water to 90, setting mode.

SMA Atlant module (908092001583) after high voltage exploded PWM. Help me identify the part. Strange DIP-8 case and no 3rd leg. I even have it like that.

After the renovation, the Hotpoint Ariston WMSF 605 was reconnected to the apartment and the inlet valve began to intensively pass water. I took it apart, cleaned out the debris, and installed it.

sma indesit WIU 81 (CSI) 710221216*24345160905 Water got on the motor connector - the voltage intended for the motor windings came to the tachometer connector.

SIGNS The machine starts, draws water for 30 seconds, the drum rotates in one direction and stops rotating. then after 30 minutes it turns on.

Role in an electrical circuit

Numerous cases of burnout of the electronic component of entire systems and car fires confirm the fact that electricity must be treated, if not with caution, then with great caution

The fuse is designed to open the protected circuit by destroying a conductive part specially designed for this purpose. Destruction occurs when the rated current for which the fuse is designed is exceeded. The rated current strength of the fuse link is selected in accordance with the permissible load on the protected circuit, as well as taking into account the estimated current consumption of electrical appliances included in the circuit.

In the event of an emergency, the fuse link must burn out first, thereby opening the circuit and saving the car from fire. Excessive heating of circuit elements, which is a potentially dangerous situation, results from:

- short circuit (a connection of two points in a circuit not provided for by the design, causing a significant excess of current in the circuit). A short circuit can occur due to a violation of the insulation of current-carrying elements or improper connection of devices. Most likely, you yourself have more than once encountered chafing of the insulation of wires in a car;

- discrepancy between the consumer power and the rated current that can pass through the circuit without destroying its components. This often happens when additional electrical equipment (for example, lighting) is installed in cars without proper qualifications. Powerful consumers are powered from standard electrical wiring, which is designed for a much lower current. As a result, the wires in the circuit will overheat, causing the insulation to melt, which will lead to a short circuit and fire of the car.

Operation threshold

As you might have already guessed from the description of the purpose of automobile fuses, the essence of choosing the right fuse lies in selecting the resistance level of the fusible part. Destruction occurs due to the thermal effect of current. Exceeding the nominal value leads to excessive heating of the fusible part, which provokes its melting (burnout) and circuit breakage.

The rated current of the fuse is calculated using the formula: Inom=Pmax/U, where

- Inom – nominal current value, measured in Amperes (A)

- Pmax – maximum load power of the consumer, which must be indicated on the device; measured in Watts (W, W)

- U – network voltage, measured in Volts (V). Let us remind you that the power supply voltage of a passenger car is 12 V

It is much more convenient to use ready-made tables that indicate the power tolerances for each type of fuse.

Types

According to the classification according to the type of operation, fuses are used in cars. There are 3 sizes:

- micro;

- mini;

- norm;

- maxi.

But the main division, of course, is based on the rated current. For the convenience of users, the color of the case is assigned to a certain rated current value. But you should not focus only on color, since no one forbids the manufacturer to change the color scheme of their products.

| 1A – black | 10A – red | 40A – orange |

| 2A – gray | 15A – blue | 60A – blue |

| 3A – purple | 20A – yellow | 70A – brown |

| 4A – pink | 25A – white | 80A – light yellow |

| 5A – yellow-orange | 30A – green | 100A – lilac |

| 7.5A - brown | 35A – light purple |

Replacement, circuit protection when installing additional equipment

It is necessary to replace standard fuses with products of exactly the same rating. All necessary information is presented in the repair and operation manual for your car. If the fuse blows 2-3 times in a row, look for a fault in the circuit. Do not install a fuse-link of a larger rating under any circumstances. Also, you should not change the electrical fuse on the Beetle. It is possible to repair a fuse-link on the road using a wire, but the length and cross-section of the conductor should be selected in such a way that the wire has the same rated current as the standard fuse. For this, the network has all the necessary formulas and tables with ready-made variables.

When installing additional consumers, first calculate whether the car's standard wiring can withstand the increased load, and only then calculate the current for installing a fuse of a larger rating. For powerful consumers, the wiring should be laid separately; the rated current of the fuse should be 1.5 times greater than the rated current in the circuit. To calculate the load on car wires, use Ohm's law; you can use special tables in which the cross-sectional area and permissible current are indicated for the main types of conductors.

Causes and signs of failure

If the washing machine stops working or is completely turned off, and no power is supplied, the reason may be a faulty fuse. It could burn out as a result of a sudden power surge. The principle of its operation is to protect the control board during network outages. And since this is not uncommon in our electrical networks, equipment suffers first of all.

Article on the topic: How to unlock an LG direct drive washing machine

Important rule

If the fuse is blown, the machine stops and does not respond to being plugged in.

When turning to specialists for help in repairing a washing machine, the fuse is not taken into account. People usually forget about him. This is the wrong approach.

The network cable should not be confused with this part, as is often the case.

Before delving into the device control module, you should check the equipment for the presence of a fuse and its functionality.

Checking the pump volute

If you hear an unusual noise in the area where the pump is located (the lower right side of the machine), then perhaps a small object has gotten into the pump volute after washing or a critical blockage has occurred. If this happens during the washing process, you will first have to empty the water from the drum. The check is as follows:

- Open the cover in the lower right part of the panel.

- We see a round hole with a plug - this is a filter.

- We open the filter by unscrewing it. Water leakage is possible, so we will place a small flat container in advance.

- We look inside the cochlea cavity (you can illuminate it with a flashlight), remove foreign objects if they are there. In normal condition, we will not see anything other than the pump impeller. Except in cases where two motors are installed on one snail - one for draining, the other for recirculation (watering).

Another traditional reason is a clogged inlet pipe. Purely mechanical cleaning will help.

Replacing the cigarette lighter fuse

It would seem that what’s wrong with replacing the fuse, I pulled it out and inserted a new one. But no. Here is the correct procedure for replacing a fuse:

- Turn off the car ignition.

- Disconnect the ground from the car battery.

- Carefully remove the blown fuse using special pliers. If they are not there, then use pliers (pliers).

- The new fuse must be installed so that it is designed for the same current strength that was on the old blown fuse. For example, on the PCB it says 20, which means that it can withstand up to 20 Amperes. If you install a more powerful one, then the fuse will be able to withstand load surges, but the cigarette lighter itself may burn out. The fuse can be inserted from either side.

- An old burnt-out fuse will have a burnt-out thread; you can look and find out whether it is the cause of the cigarette lighter failure. It also happens that the cause may not be a PP, but a broken wire. If the fuse is intact, you need to test the wiring with a multimeter.

- Close the block cover.

- We connect the disconnected negative wire back to the battery terminal.

- Turn on the ignition and check the functionality of the cigarette lighter.

The lights are on

This situation is also possible. The indicator lights up or blinks, but the machine does not start in any mode. On older models with a command device, the knob turns continuously.

Are you unplugging your washing machine?

Oh yes! No

Crash

First of all, try resetting the program. The machine may have frozen or there has been a power failure. Different brands and models have different reset mechanisms. You must read the instructions. Try unplugging for a few minutes.

On older Indesit models, to reset, do the following:

- put the switch on the point;

- launch;

- wait 3-5 seconds - the lights should blink several times;

- transfer to the washing program;

- turn it on.

Error code

On machines without a display, indicators indicate an error code that corresponds to a specific malfunction. It is deciphered using special correspondence tables. For Samsung SMA, the error values can be found here.

If any difficulties arise, it is better to contact a repair specialist.

A leak

Quite often, the reason for the strange behavior of the machine is an electrical leakage to the body. First of all, it occurs on the heating element or motor, but it is necessary to check all elements of the washing machine. To do this, you need a high-quality tester with a high “resistance” limit - 40 MOhm.

Control module

Repair Tips

When understanding the causes of the breakdown, you should not try to fix failures in the electronic board, change bearings, or disassemble the motor yourself.

Elementary faults can be eliminated without resorting to the help of a specialist. Do-it-yourself repair of an Indesit washing machine is possible if leaks, poor water and powder supply are detected.

If a puddle periodically forms under the device, it is necessary to check and, if necessary, replace the rubber parts: the pipe or the door cuff. A minor breakdown also includes replacing the belt on the drum if it stops spinning.

Features of repair of Indesit wisl models

Call and diagnosis

For beneficiaries Every breakdown is accompanied by symptoms. Some have a clear sign (visual) - mechanical, burning smell, destruction of components and devices.

And some hidden defects. These are the most insidious, since you have to check the entire chain of devices and time drags on. Especially from an inexperienced master.

Almost all Indesit models wisl 103, wisl 105, wisl 83, wisl 82, wisl 102 are built on an EVO II control module with a commutator motor.

Therefore, their design and repair will be largely similar.

- Deciphering the error code by flashing indicators:

By adding the numbers corresponding to the blinking LEDs, you will receive an error code. As an example of error F10, we add the sum 8+2=10 (F10).

- Faults by error code:

F01 - the signal between the control board and the engine is lost.

Using a tester, we measure the control voltages on the motor control block:

The motor control thyristor may have become unusable. In addition, ring the motor terminals.

F02 - lack of signal from the engine tachogenerator and electronic module.

We also check the engine block and connector.

We make sure that the tachogenerator is working properly:

The tachometer monitors the speed of rotation of the engine rotor.

When it rotates, an alternating voltage is generated at the terminals of the tachogenerator coil.

The frequency is compared by an electronic board and the rotation of the drum is controlled. It may be enough to tighten the sensor mounting screws or glue it to restore proper engine operation.

The resistance of the contact group in a quiet state should be about 70 Ohms. Without removing the probes from the coil terminals, rotate the motor shaft. The resistance must change. If this happens, then the tachogenerator is working.

F03 - break in the temperature sensor (thermistor), breakdown of the processor on the module.

The sensor itself rarely fails. Usually there is no signal from the board (connector contacts)

First, ring the temperature sensor, reflash the ROM, ring the kilo-ohm resistors. If that doesn’t help, the board needs to be replaced.

F05 - the drain pump or pressure switch (level sensor) does not work.

About 80 percent of the time, a clog (filter, drain hose) or pump is to blame.

We clean the filter by removing the front panel with a flat screwdriver and twisting it:

The pump impeller must be clean and free of debris:

Place the washing machine on its side and separate the pipe from the tank and pump:

If error F05 pops up again, the reason is electrical, namely, why doesn’t the sump pump work?

We take a multimeter in our hands and start the draining program and measure the voltage at the pump terminals. It should be equal to 220 volts.

Its presence tells us that the pump needs to be replaced.

F07, F08 - the heating element is not in the water, does not work (burnt out or broken).

Make sure there is water in the tank by looking into the drum. Next, remove the back wall and check the heating element with a tester:

F04, F08 - pressure switch (water level switch).

Presence of signal from the connector.

Check the condition of the level sensor:

- contacts 2-4 are closed - level "EMPTY TANK" - contacts 2-3 are closed - level "FULL TANK" - contacts 2-1 are closed - level "OVERFLOW" (not less than half the level of the glass of the loading hatch.

Remove the top cover by unscrewing the two screws at the back. This sensor is located on top:

Why is it needed?

To adjust the water level in the tank: low, medium and high. Protection against overflow of the tank is also provided.

How to check? We just blow into it. You should hear clicks. There can be three of them. It depends on the water levels provided by the program: economical, delicate, half load.

F09 The memory card of the electronic board is faulty.

F10 - water intake time exceeded.

The filler pipe from the detergent cuvette to the tank may be clogged, or the water fill valve may not be working properly.

Also check the level sensor (see above).

F11 problem with the drain pump.

The pump winding resistance should be about 170 Ohms - measure with a tester. Follow the instructions for error F05

F12 - there is no signal between the control board and the program selector.

Carry out an external inspection of the board for damage to the elements.

If no burnt nodes are identified, 1. processor diagnostics is required:

Just check the reset pins (133DDB), quartz resonator, 50Hz signal, DATA and CLK.

2. Microcontroller failure: Usually the reason is that the lock (Q9) and valve control triacs (Q10-Q13) explode due to actuators or other reasons. In this case, SMD resistors always burn out between the U6 terminals and the control electrodes of the triac (560 Ohm), sometimes also between them and the common wire (1 kOhm).

Designations on the resistors: 561 and 102, respectively. 561 triacs must be replaced, even if they look intact!

In these cases, the corresponding pins of the U6 chip are always damaged.

It is best to remove a non-working microcircuit using a soldering station (heat gun).

If it is not available, you can use a very sharp knife and carefully cut off all the leads, while being careful not to damage the printed conductors, and then simply remove their remains from the board with a soldering iron and braid with flux. Another way: when heating the leads with a soldering iron, slip a safety razor blade under them, or, passing a loop of thin nichrome wire under them from the inside, carefully pull it out, also heating the leads one by one with a soldering iron.

After replacing U6, you can partially check the operation of the module: immediately after connecting to the network, a constant voltage of 5 volts should appear between pins 4 and 8 of the U3 memory chip, and after about 20 seconds relay K6 will click. This will happen even if there are no external devices connected and there is no memory chip.

After one of the triacs fails, before installing the restored board into the machine, you should check the device (lock or valve) connected to the corresponding output of the board to avoid repeated damage. For example, connect an incandescent lamp with a power of 75...100 W to the open circuit of a triac - device and install a program to launch this device. Or simply connect it to the network in series with the lamp. It shouldn't glow brightly.

Triacs are designed for a maximum current of 0.8...1 A, but in reality the lock's thermal relay and valves consume no more than 0.2 A through the triac circuit. In all cases, after repair, you should make sure that the data in the U3 memory chip (24C64) is intact. If necessary, replace (reprogram) it according to the model.

F17 - problem with the hatch lock.

There is no power to the door lock - ring the contacts.

F18 - board processor.

The module needs to be replaced.

- When turned on, all the lights on the panel begin to blink, like a garland.

Pay attention to the power supply of the control board - these are swollen capacitors C17, C16, C20.

We select new capacitors, maybe 1000 uF. We take a soldering iron and change them.

- A common defect is that the machine does not work, the lock lock works, the washing program starts and then there is silence.

Check the hatch lock, its contacts and wiring. Next we look at the motor brushes.

If the working reach of the embers is less than 7 mm, they must be replaced (both should be replaced). To do this, disconnect the wire and pull out the contact to remove it.

We remember in which direction the graphite contacts are ground. We clean the collector lamellas with sandpaper. We remove dust with a vacuum cleaner. We install new ones, making sure that they fit tightly to the collector.

If necessary, grind off the graphite with sandpaper. Attach the motor to the tank, connect the power wires, but do not put on the drive belt. We start the spin cycle and rub it in to reduce friction. Next, we assemble the remaining parts.

What can break in your washing machine:

Is it worth repairing?

Before making repairs, you need to think about how to check the fuse. You can check it with a multimeter tester. These parts may be different in appearance, but they are checked the same way.

Do the work in the following sequence:

- Set your tester to resistance measurement mode.

- Disconnect the fuse from the element on which it is located.

- Press the tester probes onto the element contacts.

- Look at the readings on the screen.

- A working element will show 0 ohm. If the tester does not show anything, then a malfunction has occurred.

The problem may indicate a short circuit in the electronic circuit of the washing machine: for example, the heating element has shorted. We need to check everything properly. Should I replace the fuse myself? It cannot be repaired, and manipulations with the electronic board can lead to an undesirable effect. Therefore, in this case it is better to contact a specialist. A video on the topic will help you check it yourself:

Major breakdowns

Rinse or spin mode does not turn on

Before rinsing, the machine stops, starts draining water and displays an error. There are 2 LEDs blinking on the panel: above the button with the image of a clock and with the “lock” icon.

Error code F08 means the relay for turning on the heating element is stuck, a signal if there is emptying. Or the pressure switch is stuck in the “filling” position.

To resolve this error, you should check:

- pins of connector J3 on the board

- state of the reset switch by ringing it on the connectors

- wires connecting the transfer switch to J3 connectors

- the need to replace the pressure switch, control board or heating element

Most often, such an error code signals a damaged heating element, the main heating element. This part is easy to replace yourself and is accessible through the rear panel.

Water leakage

The presence of a leak indicates a hole in the rubber cuff sealing the hatch. If the cuff is not damaged, but water is leaking, you should clean the lower part of the door glass from the inside.

During operation, dirt accumulates in this place, worsening the contact between the glass and the rubber seal. To eliminate this problem, simply wipe the glass with a cotton swab dipped in nail polish remover.

Washing machines of the Wisl series provide additional protection for the housing against leaks.

The washing machine does not turn on

If the washing machine does not respond when you press the power button, you need to check the serviceability of the socket.

Disconnect the cord plug from the outlet and plug in any other electrical device, for example, a table lamp. If the outlet is working properly, you need to visually inspect the power cord for damage.

A complete failure of the machine to operate may indicate a malfunction of the electronic control module and requires specialist intervention.

If the machine turns on but does not start the washing program, you need to check that the door is closed tightly.

Various blockages

Blockages in the drain system are considered one of the main problems with Indesit washing machines. If the drain hose and filter are clogged, the machine stops draining water. If the model is equipped with a display, error code F05 is displayed on it.

Cleaning the filters yourself is not difficult even for those who do not have the skills to handle equipment. To clear the blockage, you need to open the bottom door on the front panel, lay rags on the floor or place a flat tray and pull out the catch filter, rotating it counterclockwise.

Garbage and small objects (coins, buttons, pins) accumulate here. After cleaning the filter, the unit is ready for use. This procedure is recommended to be done once every few months as a preventative measure.

Failure of parts

The Italian brand Indesit complies with European technical standards. Washing machines of this brand have vulnerabilities that you should pay attention to when operating and repairing the devices.

The following parts are subject to frequent breakdowns:

- Surge filter - can withstand operation for up to 4 years, often defective

- Heating element (tubular heating element) - made of stainless steel without coating, which leads to rapid scale fouling

- Electric motor parts - capacitors, trim and tachogenerator sensor

- Depressurization of the door seal

Experts consider replacing bearings to be difficult to repair due to the tank being welded tightly. Often, owners of the Indesit Wisl automatic machine contact the service due to blockages in the drain system.

Breakdowns occur due to improper connection of equipment, careless handling of the machine, or as a result of natural wear and tear.

Bearings

A special feature of the Indesit washing machine is its lightweight, sealed tank. This is the weak point of the unit, due to which bearings often break. The design of the tank does not allow you to disassemble it yourself; it is better to contact a workshop where the tank will be completely replaced. This is an expensive operation, so sometimes it is cheaper to purchase a new device.

A number of Indesit models produced in Italy, Turkey and some other countries provide the ability to replace bearings. Only a qualified technician can determine whether the device can be repaired.

Control module

The electronic control module in Wisl series machines is highly reliable. It is equipped with an automatic protection system that is triggered if the operating requirements of the machine are not met.

The control module of the Indesit washing machine is sensitive to air humidity, drops of water entering the system or voltage drops.

In order to “please” the electronics, you should strictly follow the instructions included with the device.

If a module error code is displayed on the panel, you need to check:

- condensation on current-carrying circuits

- reliability of contact fastening

- presence of oxidations

- no blockages in the drain hose and filter

- accumulation of dirt on components and parts.

After eliminating inconsistencies with the program requirements, the machine can be restarted - many models support starting the cycle from the middle.

Electric motor

A commutator type electric motor is installed here.

The most common problems:

- Brushing of brushes. Occurs if you use the device too often. When starting the program, it does not start working, which indicates a breakdown of the main motor brushes. The parts are paired and must be replaced at the same time for correct operation of the motor.

- Peeling of lamellas on the collector. The lamellas peel off most often in old devices when the brushes rub them into holes.

- Break or interturn short circuit in the rotor and stator windings. If there are any signs of winding burning, the motor must be completely replaced.

Electric motor failure is also determined by the lack of rinsing and spinning. If the washing machine heats the water and washes, but when moving to the final modes the engine starts to turn idle, this means that the engine is broken and must be replaced.

Shock absorber and dampers

The shock absorber is an elongated device, inside of which there is a piston with a return spring. They serve to reduce drum vibrations.

Dampers are devices similar to shock absorbers, they differ in the absence of a return spring. Dampers are installed in new models of washing machines.

If the tank knocks during washing and vibrates with a hum, it is worth checking the condition of the shock absorbers. The lack of lubrication in them is indicated by the characteristic creaking and tight rotation of the drum.

Some washing machine owners save on parts by replacing the rubber insert in the old shock absorber. This method does not guarantee correct operation of the device; it is better to purchase a new working shock absorber.

water pump

The pump is part of the drainage system of the washing machine and performs the important function of pumping water out of the tank. This part experiences the greatest loads and can quickly fail. You can determine if the pump is faulty by hearing.

Signs of pump failure:

- When draining water, the pump makes a loud noise, but no water flows into the tank.

- Pump doesn't work

Before changing the pump, you should make sure the drainage system is clean. Inspect and, if necessary, clean the drain filter, hose and drain pump impeller. Find out if there are any foreign objects in the system.

If the above measures do not help, the pump must be replaced.

Water supply problem

If problems arise with the water supply, you need to check the presence of pressure in the tap, and then inspect the inlet hose and its filter.

The washing machine does not fill with water well

If the pump does not fill the tank with water, this may indicate a clogged filter in the fill valve. You should turn the unit away from the wall and unscrew the drain hose from the rear panel. Using pliers, pull out the fill valve filter and then rinse it well under running hot water. If necessary, clean with a brush.

The washing machine does not fill with water

If the washing machine does not fill with water, you need to check:

- connecting the inlet hose to the tap

- hose for kinks and kinks

- tap water pressure

- water supply tap open/closed

- pressing the "Start" button

If you suspect a blockage, you need to turn off the water supply to the washing machine, unscrew the inlet hose, direct it into the basin and resume the water supply. This will allow you to rinse it free of debris.

It is recommended to check the inlet hose at least once a year and replace it immediately if there is any suspicion of a leak. Do not install used hoses.

The supply of washing powder is interrupted

If the powder does not pass through the washing machine, and water flows out of the tray where it is poured, this indicates a blockage.

To solve the problem, carefully pour a small amount of boiling water into the tray. A similar problem occurs when using poor quality washing powder or too low pressure in the pipe that connects the tray and the tank of the machine.

As a result, a dense powder plug is formed, which prevents water from entering the tank. Periodically it is worth rinsing the cuvette itself under running water.