Indesit brand machines are famous for their durable designs. Consumers choose this product due to its price-quality ratio and positive reviews. But any technology is prone to breakdowns. In this article we will look at one of the common problems, why the drum does not spin in washing machines and how this can be fixed at home.

Your device draws water, but then stops without moving due to the drum. The reasons for this uncharacteristic behavior may be the following factors:

- a foreign object has entered the tank and is interfering with the operation of the structure,

- wiring fault,

- failure in the control module,

- damaged drive repair,

- heating element malfunction,

- bearing jammed

- The electric motor brushes have become unusable.

These are the main failures associated with the dishwasher drum. But the list can be supplemented with other breakdowns - it all depends on the brand and components.

Preparing for fault diagnosis

If such a situation occurs with an Indesit machine, the first thing we do is disconnect it from the network, and do not open the hatch. First, use the button on the panel, then disconnect the cord from the outlet. Cover the floor around with towels and rags, place a container underneath the drain filter, like a scoop or container, and only then open it. The plug opens counterclockwise; if it is screwed tightly, use pliers. After all the water has drained, you can clean the drum from the laundry.

After all the operations, it is worth understanding at what point the drum stopped rotating. The chronology of work will help to establish the exact reason for its stop. If a failure occurs during the spin cycle, and the laundry is damp but not soapy, then you need to check the selected washing mode. If the delicate wash is turned on or the “no spin” function is active, then this small misunderstanding can be easily corrected. The water does not drain due to a blockage in the drain system, and therefore spinning does not occur. Also, stopping the drum’s operation may be due to an overload of things, due to which an imbalance has occurred. Problems with the pressure switch or control module lead to failures during the washing process. Expressed in burnt out wiring or errors in the control module.

How to find a breakdown of SMA Indesit

In search of answers to the question: how to repair an Indesit washing machine, you can refer to the operating instructions. If you have lost the manual, we will provide you with a detailed algorithm for finding the breakdown and its cause.

Proceed as follows:

- If your model has an electronic display, great! On it, the self-diagnosis system displays fault codes when it detects a breakdown. Indesit washing machines are characterized by the following error codes: H20, F02, F05, F10, F18 and others.

- If there is no display, the machine will still notify you of a breakdown - the indicators on it will light up in a certain combination or sequence. Also, some breakdowns can be detected by simply listening to the operation of the drum and electric motor - in the event of a malfunction, you will hear noise, hum, whistle, clanging and other uncharacteristic sounds.

- If there are no signs of breakdown, but the SM still does not work, you will need to disassemble the washing machine. The easiest way is with the parts located under the top cover - surge protector, water level sensor, and so on. But access to the motor, heater, bearings or pump is a little more difficult. You will learn more about disassembly in this video:

- Also take a tester with which you can test all sensors, contacts and wires. If there is no power in any of them, then it can be judged that there is a breakdown.

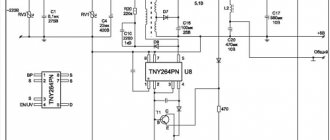

Attention! Before disassembling the SMA body, you need to study the structure of the washer. The electrical diagram of the Indesit washing machine will help you with this.

If you haven't found it, sketch, record, photograph or videotape all the stages of disassembly to put everything back together correctly.

The drum stopped working during washing

If you see soapy things inside, it means the drum has stopped during operation. Check whether it can be rotated; if not, it means one of the parts is stuck inside the system.

Possible cases are:

- an external object that is stuck inside the tank and drum,

- the drive belt has become unusable and wound around the pulley,

- weak rotation of the bearing caused by overload during operation or poor quality lubrication of the oil seal.

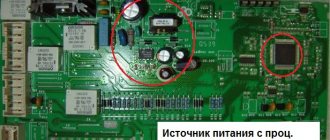

Control module

The control module controls the operation of all components of the washing machine and provides the necessary washing modes. To get to the board you need:

- Remove the top cover;

- Disconnect the power terminals (they are all different sizes, which makes it easier for later installation)

- Unscrew the fastening bolts.

It is necessary to pay attention to scorched contacts, tracks, and also to the operation of fuses and capacitors. Visually determine if there are any darkened areas.

The washing machine fills with water, but the drum does not spin

During the washing process, a humming sound is clearly heard; the drum can be set in motion by force, but it does not spin on its own. Such signs indicate engine failure, which is associated with wear of brushes, lamellas, or a jammed bearing.

Drum stopping is one of the typical breakdowns that occur in washing machines of the brands “Bosch”, “Indesit”, “Samsung”, “Ariston” and others. Technical faults associated with violations of operating conditions must be corrected at service centers. We will talk about problems that you can fix yourself at home below.

Foreign object inside the structure

Most often they find a bra bone in the drum, and if you're lucky, maybe a couple of coins. Regardless of your find, carefully remove it using the following guidelines.

- Move devices away from the wall for access from different directions.

- Open the top cover after unscrewing the bolts.

- Unscrew the back cover screws.

- To make it easier to find lost items, remove the heating element. To do this, disconnect the wires and unscrew the fastening nut.

- After the engine is removed, twist the wire and try to remove the stuck object.

- Next, assemble the machine parts in chronological order, checking the fit and don’t forget to tighten the nuts.

If an object is stuck between the drum and the tank, then it cannot be seen through the hole in the heating element. To do this, you need to remove the heating element, spin the drum, if things are stuck there, they will end up at the bottom.

The doors opened in a vertical machine

It will not be news to many owners of such machines that the tank flaps open during the spin cycle. The first thing users complain about is the latch, but that's not always the issue. The reason for the drum stopping may be due to overload of laundry or some clothing getting caught in the fastener. This part is protected from children's hands and careless movements by metal latches, but over time they become loose and the doors open automatically.

Outwardly, everything seems quite simple: do not overload with excess laundry, change the latches. But the severity of the damage depends on the time when the doors opened.

During the spin cycle, there is a risk that the blades may damage things and everything nearby. If this is a delicate wash, then exhale calmly: the trouble is over.

The threat is that at speed the doors “break” the protective barrier and damage the structure of the heating element; the tank and drum may also be damaged. Such serious breakdowns will lead you to purchase new equipment, because... repairs will be much more expensive. We will tell you how to return the drum to its place at home without the intervention of specialists.

Close the doors. To do this, you will need a wire with the diameter of the hole in the drum. Using pliers, bend the end of the wire half a centimeter to form a hook. Armed with a flashlight and wire, try to close the doors. If the unit’s warranty has expired, for convenience, you can slightly bend one of the flaps. If the result is positive, you will be able to spin the reel. Disassembly of the washing machine is inevitable if after all the described steps the drum does not start to rotate.

Important: disassemble the washing machine with a minimum tilt, because Residual water may damage some parts.

Briefly and clearly the sequence of actions when opening the doors:

- Unscrew the rear panel latches;

- Slide the side panel;

- Disconnect the wires, having previously recorded their location on the phone;

- Unscrew the screw that is responsible for the shaft;

- Remove the tank and close the loading hatch first;

- Separate the two parts of the tank and remove the drum;

- Clean the part from debris.

During repairs, inspect the integrity of the tank, valves, and any damage to the heating element. If there are deformations, then it is worth buying new parts.

Bearing jammed

Changes in the integrity of the bearing lead to problems with the drum. To make sure that this is the reason, knock the part out of the drum with a handy tool. Manufacturers recommend replacing a leaky bearing together with the seal. Treat the installation site with lithol and install a new part.

Owners of a horizontal machine should replace bearings in the following sequence:

- first unscrew the fasteners, disconnect the back and top covers;

- unfold the dispenser;

- take out the control unit, unscrew the fasteners;

- unscrew the rubber cuff, then insert it into the drum;

- remove the blocking;

- remove the front panel;

- remove the counterweight by loosening the clamp;

- take out the heating element;

- we remove the drive pipes and other things;

- we take out the engine and remove the tank along with the drum.

For comfortable operation, place the tank on a hard surface. Replacing the bearing is similar to that for a vertical washer: knock out the bearing, remove the seal, lubricate the hole and install new parts. Be careful when installing and treat the joints with sealant to avoid leaks.

Damaged drive belt

The appearance of the belt affects the performance of the drum. In order to check its condition, you need to remove the back panel of the machine. If the drive belt has come off, it's simple - put it back in place, turn on the device and check how it works. In case of serious damage, replacement is inevitable.

Drive belts are distinguished by the engines inside the machine: V-belts are found in asynchronous devices, V-belts are found in commutator engines. All parts have high strength and elasticity, because... Made from rubber, polyester and cotton materials.

Installing the V-belt is as follows:

- loosen the fastenings;

- we tighten the belts, gradually moving the engine;

- wind on a pulley;

- place the entire strip in the drum groove.

The tension on the entire belt should be tight enough not to slip. In the middle the permissible deflection is 5 mm.

The principle of replacing a poly-V belt is similar to a V-belt. Its main difference is the gear section and the tension for them should not be so strong. It is necessary to measure the middle of the mating side of the engine pulley and the drum; the belt must be installed strictly along this line.

Motor brushes are faulty

Worn brushes affect the rotation of the motor rotor. Over time, the part is shortened and does not reach the collector. The result is replacing the part with a new one.

Important: when purchasing a new part, buy two identical brushes suitable for your model, without defects.

We disassemble the car, remove the back wall, the belt, do not forget to disconnect the engine from the power supply, pull out the connector with the wires. Lower the device so that the brush body is on top, then unscrew the fasteners and remove the spare part from both sides. After you have disassembled the parts, measure the length of the brush; if it reaches 1.5 cm, then it is not the reason for the poor rotation of the drum. Even if it’s not the brushes, it’s a good idea to clean the commutator of black deposits.

The service life of the brushes reaches 8 years, but non-compliance with the rules for using the equipment and frequent loads lead to early wear.

Control module malfunction

The absence of a “top” command prevents the machine from starting to wash. Wear of the control device or voltage fluctuations can cause serious malfunction.

Modern models are equipped with a self-test function that checks the source of the problem. Verification methods depend on the company and device models. For example, it performs an auto-check like this: you need to hold down the power, spin and temperature keys, then press the start key three times in a row to test the operation of the drum.

Manufacturers identify four serious signs, after which the consumer needs to think about repairs: the appearance of a bulge on the capacitor, darkening of the processor where the tracks are installed, the formation of scorch marks, cracks in the varnish coating on the damping coils.

Advice: if you find the above problems in your device and do not have the knowledge and experience in repairing washing machines, it is better to contact a service center.

There are several options for eliminating it yourself:

- program reset

- flashing

- module replacement.

To remove the board, remove the top panel, disassemble this part of the machine, remove the retaining bars and find the module. To repair the unit, you must have knowledge in the field of electrical engineering, because... it is necessary to check the parameters of all board elements. Failures in the operation of sensors can be resolved on your own. Clean the wire contacts and the regulator, which quickly become greasy and clogged.

Engine burned out

This type of problem is a rare breakdown, but it also happens. The reason is the short circuit of the winding, its break at the rotor. If a short circuit occurs, the drum does not rotate during washing, but without laundry it can move. If the winding of the rotor or stator breaks, the drum does not function at all.

A total replacement of the engine cannot be avoided if the device smells of burning, does not start, and sparks are visible. If the drum has stopped, but the unit is humming, repair is possible.

Removing the motor is easy: lift the tank and release the motor. There are three main problems known: winding, lamellas, brushes. We already know the principle of replacing brushes. The operating functions of the winding can be checked with a multimeter by touching the lamellas one by one. The discrepancy should not exceed 5 ohms. If you place one probe on the body and the other on the lamellas, you will find out the level of short circuit of all windings. The resistance must be high enough. The malfunction of the lamellas is easy to determine. To do this, you need to remove the rotor and visually inspect the commutator for possible broken contacts and burrs. Minor peeling can be corrected using a lathe. If the winding is damaged, it should be replaced. However, engine damage is a serious problem that can only be solved by replacing parts or the entire structure with a new one.

Damage to the surge protector, motor sensor or heating element

A faulty surge protector should be replaced.

Note that even with good quality power supply (no power surges), the new part may not last long. The reason is the formation of condensation on the contacts, resulting in a short circuit.

To extend the service life of the surge protector, its contacts need to be cleaned and wiped with a clean rag, and then filled with silicone sealant. Similarly, you can insulate other contacts that may be damaged by moisture.

Capacitor breakdown in the motor circuit is a more significant problem. Trying to deal with it on your own can make the situation worse. Difficulties can await an inexperienced repairman even at the diagnostic stage: the observed “symptoms” are often similar to those that occur when the electric motor itself breaks down. In order not to completely ruin the machine, it is better to contact a service center.

Another characteristic problem is caused by the use of commutator electric motors. They are low cost, highly reliable and, with minor improvements, can smoothly change the shaft speed. But these motors have brushes that have to be changed periodically. If you lack experience, it is also better to entrust this task to a master.

Surge filter and cable for Indesit washing machine

But replacing the heating element will be quite within the capabilities of an amateur. Here's what you need to do to do this:

- After unscrewing the fasteners, remove the back wall of the device.

- The heating element is detected by two contacts protruding from the wall of the tank in its lower part.

- Using a tester, check the presence of power at the contacts. If everything is in order with this, it means that the heating element has burned out and needs to be replaced.

To dismantle the heater, you need to unscrew the centrally located fastening element. Then the rubber seal is removed, after which the part itself can be removed. An unusable heating element usually has a characteristic appearance - a “fur coat” of scale, burnt marks and other defects. The new heating element is installed in the reverse order.

Before installing the washing machine, you need to decide on the installation location. This could be a bathroom, a combined toilet; in some cases, the equipment is installed in the hallway or in the kitchen. Connecting a washing machine - let's look at the main problems and solutions.

How to choose the right faucet for the kitchen, see this review. The main selection criteria are material, type, manufacturer.

In small apartments there is not always room for a washing machine in the bathroom, so you have to install it in the kitchen. Follow this link https://aquacomm.ru/cancliz/mnogokvartirnyie-doma/santehnika/kak-podklyuchit-stiralnuyu-mashinku-na-kuhne.html you will find tips on installing the device from the experts.

Recommendations for the future

The first and most obvious thing that many people forget is compliance with the rules for using household appliances, which are written in the instructions for them.

Do not overload the drum with laundry, follow the weight recommendations. Wash small items, socks, bras, handkerchiefs in special mesh bags.

It is important to pay attention to connecting the unit to the network. If you have a modern design with built-in “brains,” then think about properly grounding the washing machine and connecting it to electricity through an uninterruptible power supply or through an extension cord with surge blocking. Power surges can be costly when repairing an engine, so it is better to secure the device in advance.

Question details

Electrical problem

If your Indesit washing machine turns off and shows no signs of life, then do not panic. The problem is not necessarily with the machine. Perhaps something happened to the power grid. If there is light in the entire apartment and other sockets are working, then you need to check the power of the socket. Just turn off the machine and plug another electrical appliance into this outlet that is in good working order. If the device does not turn on, then you need to repair the socket. Do it yourself if you have the required skills, or invite a specialist.

Important! Disconnect the power supply before carrying out any manipulations with the outlet.

Problem with FPS or network drive

Common failures and their manifestations

Since the washing machine has a complex structure, the washing program may go wrong due to the failure of a variety of parts and mechanisms. In this case, the cause of the problem may be damage to both electronic components and performing parts. Most often failures occur in the following cases:

- surge or sudden drop in voltage;

- failure of the control module;

- incorrect operation of one or more sensors;

- breakdown or blockage of drain parts;

- wear of electric motor brushes;

- problems with the heating element.

Failure can manifest itself in different ways. The washing machine may freeze and not respond to user actions. Sometimes it seems that the washing is proceeding normally, but the program takes longer to complete, and occasionally it suddenly stops at one of the stages.

No matter how the wash program failure appears, immediate action must be taken to correct the problem. What to do in such a situation is up to the owners of the washing machine to decide. Many people prefer to call a specialist, which seems logical, but there are some things you can do with your own hands, first to identify the problem node.